Borosilicate Glass Microstructural Analysis

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Evolution and Research Objectives

Borosilicate glass has a rich history dating back to its invention in the late 19th century by German glassmaker Otto Schott. This specialized glass composition, primarily consisting of silica and boron trioxide, has since evolved to become a crucial material in various scientific and industrial applications. The development of borosilicate glass marked a significant advancement in glass technology, offering superior thermal shock resistance and chemical durability compared to conventional soda-lime glass.

Over the years, the microstructure of borosilicate glass has been a subject of intense research and development. The unique properties of this material stem from its complex atomic arrangement and the interactions between its constituent elements. Understanding and manipulating these microstructural features have been key drivers in enhancing the performance and expanding the applications of borosilicate glass.

The evolution of borosilicate glass has been characterized by continuous improvements in composition and manufacturing processes. Early formulations focused on achieving a balance between thermal expansion coefficient and chemical resistance. As analytical techniques advanced, researchers gained deeper insights into the glass network structure, leading to more refined compositions tailored for specific applications.

Current research objectives in borosilicate glass microstructural analysis are multifaceted and ambitious. One primary goal is to develop advanced imaging and characterization techniques that can provide high-resolution, three-dimensional information about the glass structure at the nanoscale. This includes the use of advanced electron microscopy, X-ray tomography, and spectroscopic methods to probe the distribution of elements, the presence of nano-inhomogeneities, and the nature of interatomic bonds.

Another critical research objective is to understand the relationship between the glass microstructure and its macroscopic properties. This involves investigating how subtle changes in composition or processing conditions affect the formation of micro-phase separations, the distribution of network-forming and modifying ions, and the overall network connectivity. Such knowledge is essential for designing borosilicate glasses with enhanced mechanical strength, improved chemical durability, or tailored optical properties.

Researchers are also focusing on developing predictive models that can simulate the formation and evolution of borosilicate glass microstructures under various conditions. These computational approaches aim to accelerate the development of new glass compositions and optimize manufacturing processes. By combining experimental data with theoretical models, scientists seek to establish a comprehensive framework for understanding and controlling the microstructural features of borosilicate glass.

Over the years, the microstructure of borosilicate glass has been a subject of intense research and development. The unique properties of this material stem from its complex atomic arrangement and the interactions between its constituent elements. Understanding and manipulating these microstructural features have been key drivers in enhancing the performance and expanding the applications of borosilicate glass.

The evolution of borosilicate glass has been characterized by continuous improvements in composition and manufacturing processes. Early formulations focused on achieving a balance between thermal expansion coefficient and chemical resistance. As analytical techniques advanced, researchers gained deeper insights into the glass network structure, leading to more refined compositions tailored for specific applications.

Current research objectives in borosilicate glass microstructural analysis are multifaceted and ambitious. One primary goal is to develop advanced imaging and characterization techniques that can provide high-resolution, three-dimensional information about the glass structure at the nanoscale. This includes the use of advanced electron microscopy, X-ray tomography, and spectroscopic methods to probe the distribution of elements, the presence of nano-inhomogeneities, and the nature of interatomic bonds.

Another critical research objective is to understand the relationship between the glass microstructure and its macroscopic properties. This involves investigating how subtle changes in composition or processing conditions affect the formation of micro-phase separations, the distribution of network-forming and modifying ions, and the overall network connectivity. Such knowledge is essential for designing borosilicate glasses with enhanced mechanical strength, improved chemical durability, or tailored optical properties.

Researchers are also focusing on developing predictive models that can simulate the formation and evolution of borosilicate glass microstructures under various conditions. These computational approaches aim to accelerate the development of new glass compositions and optimize manufacturing processes. By combining experimental data with theoretical models, scientists seek to establish a comprehensive framework for understanding and controlling the microstructural features of borosilicate glass.

Market Demand for Advanced Borosilicate Glass Products

The market demand for advanced borosilicate glass products has been experiencing significant growth in recent years, driven by the increasing need for high-performance materials in various industries. Borosilicate glass, known for its exceptional thermal and chemical resistance, has found widespread applications in laboratory equipment, pharmaceutical packaging, and high-tech industries.

In the laboratory and scientific research sector, there is a growing demand for borosilicate glass products due to their ability to withstand extreme temperatures and resist chemical corrosion. This has led to an increased use of borosilicate glass in the production of beakers, test tubes, and other laboratory glassware. The pharmaceutical industry has also shown a rising interest in borosilicate glass for packaging and storage solutions, particularly for sensitive drugs and vaccines that require stable and inert containers.

The electronics and semiconductor industries have emerged as significant consumers of advanced borosilicate glass products. The material's low coefficient of thermal expansion and excellent electrical insulation properties make it ideal for use in the production of display panels, optical fibers, and semiconductor components. As these industries continue to evolve and demand higher-performance materials, the market for specialized borosilicate glass is expected to expand further.

In the renewable energy sector, borosilicate glass has gained traction in solar energy applications. Its durability and heat resistance make it suitable for use in solar collectors and concentrated solar power systems. As the global push for sustainable energy solutions intensifies, the demand for borosilicate glass in this sector is projected to grow substantially.

The automotive industry has also shown increasing interest in advanced borosilicate glass products. The material's strength and thermal properties make it suitable for use in high-performance headlights, sensors, and display systems. As vehicles become more technologically advanced and incorporate more electronic components, the demand for specialized glass solutions is expected to rise.

The global market for advanced borosilicate glass products is influenced by regional factors as well. Developed economies in North America and Europe have traditionally been strong markets due to their established pharmaceutical and research sectors. However, emerging economies in Asia-Pacific, particularly China and India, are showing rapid growth in demand, driven by expanding industrial bases and increasing investments in research and development.

In the laboratory and scientific research sector, there is a growing demand for borosilicate glass products due to their ability to withstand extreme temperatures and resist chemical corrosion. This has led to an increased use of borosilicate glass in the production of beakers, test tubes, and other laboratory glassware. The pharmaceutical industry has also shown a rising interest in borosilicate glass for packaging and storage solutions, particularly for sensitive drugs and vaccines that require stable and inert containers.

The electronics and semiconductor industries have emerged as significant consumers of advanced borosilicate glass products. The material's low coefficient of thermal expansion and excellent electrical insulation properties make it ideal for use in the production of display panels, optical fibers, and semiconductor components. As these industries continue to evolve and demand higher-performance materials, the market for specialized borosilicate glass is expected to expand further.

In the renewable energy sector, borosilicate glass has gained traction in solar energy applications. Its durability and heat resistance make it suitable for use in solar collectors and concentrated solar power systems. As the global push for sustainable energy solutions intensifies, the demand for borosilicate glass in this sector is projected to grow substantially.

The automotive industry has also shown increasing interest in advanced borosilicate glass products. The material's strength and thermal properties make it suitable for use in high-performance headlights, sensors, and display systems. As vehicles become more technologically advanced and incorporate more electronic components, the demand for specialized glass solutions is expected to rise.

The global market for advanced borosilicate glass products is influenced by regional factors as well. Developed economies in North America and Europe have traditionally been strong markets due to their established pharmaceutical and research sectors. However, emerging economies in Asia-Pacific, particularly China and India, are showing rapid growth in demand, driven by expanding industrial bases and increasing investments in research and development.

Current Microstructural Analysis Techniques and Challenges

The microstructural analysis of borosilicate glass presents unique challenges due to its complex composition and varied applications. Current techniques for analyzing the microstructure of this material include a range of advanced microscopy and spectroscopy methods, each with its own strengths and limitations.

Scanning Electron Microscopy (SEM) is widely used for surface analysis, providing high-resolution images of the glass microstructure. When coupled with Energy Dispersive X-ray Spectroscopy (EDS), it offers valuable insights into elemental composition and distribution. However, SEM is limited to surface analysis and may require sample preparation that could alter the glass structure.

Transmission Electron Microscopy (TEM) allows for even higher resolution imaging and can reveal nanoscale features within the glass matrix. TEM is particularly useful for studying phase separation and crystallization phenomena in borosilicate glasses. The main challenge with TEM is the complex sample preparation process, which requires extremely thin specimens and can potentially introduce artifacts.

X-ray diffraction (XRD) techniques are essential for identifying crystalline phases within the glass structure. While borosilicate glasses are predominantly amorphous, XRD can detect and quantify any crystalline regions that may form during manufacturing or subsequent heat treatments. The challenge lies in detecting very small crystalline fractions and distinguishing them from the amorphous background.

Atomic Force Microscopy (AFM) provides three-dimensional surface topography at the nanoscale, which is valuable for studying surface roughness and nanoscale phase separation. However, AFM is limited to surface analysis and may not capture the full complexity of the bulk glass structure.

Raman spectroscopy and Fourier Transform Infrared Spectroscopy (FTIR) offer insights into the molecular structure and bonding within the glass. These techniques are non-destructive and can provide information about both the surface and bulk properties. The challenge lies in interpreting the complex spectra produced by the various components in borosilicate glass.

Nuclear Magnetic Resonance (NMR) spectroscopy, particularly solid-state NMR, is powerful for studying the local atomic environment and network structure of borosilicate glasses. It can provide detailed information about the coordination of boron and silicon atoms. However, NMR requires specialized equipment and expertise for data interpretation.

A significant challenge across all these techniques is the need for complementary methods to build a comprehensive understanding of the glass microstructure. No single technique can provide a complete picture, necessitating the integration of data from multiple analytical methods.

Another overarching challenge is the dynamic nature of glass microstructure, which can change with thermal history, stress, and environmental factors. Capturing these changes in real-time or under in-situ conditions remains a frontier in borosilicate glass analysis.

Scanning Electron Microscopy (SEM) is widely used for surface analysis, providing high-resolution images of the glass microstructure. When coupled with Energy Dispersive X-ray Spectroscopy (EDS), it offers valuable insights into elemental composition and distribution. However, SEM is limited to surface analysis and may require sample preparation that could alter the glass structure.

Transmission Electron Microscopy (TEM) allows for even higher resolution imaging and can reveal nanoscale features within the glass matrix. TEM is particularly useful for studying phase separation and crystallization phenomena in borosilicate glasses. The main challenge with TEM is the complex sample preparation process, which requires extremely thin specimens and can potentially introduce artifacts.

X-ray diffraction (XRD) techniques are essential for identifying crystalline phases within the glass structure. While borosilicate glasses are predominantly amorphous, XRD can detect and quantify any crystalline regions that may form during manufacturing or subsequent heat treatments. The challenge lies in detecting very small crystalline fractions and distinguishing them from the amorphous background.

Atomic Force Microscopy (AFM) provides three-dimensional surface topography at the nanoscale, which is valuable for studying surface roughness and nanoscale phase separation. However, AFM is limited to surface analysis and may not capture the full complexity of the bulk glass structure.

Raman spectroscopy and Fourier Transform Infrared Spectroscopy (FTIR) offer insights into the molecular structure and bonding within the glass. These techniques are non-destructive and can provide information about both the surface and bulk properties. The challenge lies in interpreting the complex spectra produced by the various components in borosilicate glass.

Nuclear Magnetic Resonance (NMR) spectroscopy, particularly solid-state NMR, is powerful for studying the local atomic environment and network structure of borosilicate glasses. It can provide detailed information about the coordination of boron and silicon atoms. However, NMR requires specialized equipment and expertise for data interpretation.

A significant challenge across all these techniques is the need for complementary methods to build a comprehensive understanding of the glass microstructure. No single technique can provide a complete picture, necessitating the integration of data from multiple analytical methods.

Another overarching challenge is the dynamic nature of glass microstructure, which can change with thermal history, stress, and environmental factors. Capturing these changes in real-time or under in-situ conditions remains a frontier in borosilicate glass analysis.

Existing Microstructural Characterization Methods

01 Composition and structure of borosilicate glass

Borosilicate glass is characterized by its unique composition, typically containing silica and boron oxide as major components. The microstructure of this glass type is influenced by the ratio of these components and the presence of other additives. The arrangement of silica tetrahedra and boron oxide units forms a network structure that contributes to the glass's properties, such as thermal resistance and chemical durability.- Composition and structure of borosilicate glass: Borosilicate glass is characterized by its unique composition, typically containing silica and boron oxide as major components. The microstructure of this glass type is influenced by the ratio of these components and the presence of other additives. The arrangement of silica tetrahedra and boron oxide units forms a network structure that contributes to the glass's properties, such as thermal resistance and chemical durability.

- Porous borosilicate glass microstructure: Porous borosilicate glass exhibits a microstructure with interconnected voids or channels. This porosity can be controlled during the manufacturing process to achieve specific pore sizes and distributions. The porous nature of the glass enhances its surface area and allows for applications in filtration, catalysis, and as a substrate for various materials.

- Surface modification of borosilicate glass: The surface of borosilicate glass can be modified to alter its microstructure and properties. Techniques such as etching, coating, or functionalization can create specific surface textures or introduce functional groups. These modifications can enhance the glass's performance in applications such as biomedical devices, optical components, or microfluidic systems.

- Nanostructured borosilicate glass: Nanostructured borosilicate glass involves the incorporation or formation of nanoscale features within the glass matrix. This can include nanoparticles, nanofibers, or nanoporous structures. The presence of these nanostructures can significantly alter the glass's properties, such as optical characteristics, mechanical strength, or thermal behavior, opening up new applications in advanced materials and technologies.

- Crystallization in borosilicate glass: Under certain conditions, borosilicate glass can undergo partial crystallization, leading to the formation of glass-ceramic materials. This process, known as devitrification, results in the growth of crystalline phases within the amorphous glass matrix. The size, distribution, and nature of these crystalline regions can be controlled to tailor the material's properties for specific applications, such as cookware or precision optical components.

02 Porous borosilicate glass microstructure

Porous borosilicate glass can be created through various methods, resulting in a microstructure with interconnected pores. This porous structure enhances specific surface area and can be tailored for applications such as filtration, catalysis, or as a substrate for other materials. The pore size, distribution, and connectivity can be controlled through processing parameters.Expand Specific Solutions03 Surface modification of borosilicate glass

The surface of borosilicate glass can be modified to alter its properties or functionality. Techniques such as etching, coating, or chemical treatments can create specific surface textures or introduce functional groups. These modifications can affect the glass's wettability, optical properties, or its ability to bond with other materials, expanding its range of applications.Expand Specific Solutions04 Nanostructured borosilicate glass

Nanostructured borosilicate glass involves the incorporation or formation of nanoscale features within the glass matrix. This can include nanoparticles, nanofibers, or nanoporous structures. These nanostructures can significantly alter the glass's properties, such as its optical characteristics, mechanical strength, or thermal behavior, opening up new possibilities for advanced applications.Expand Specific Solutions05 Borosilicate glass microstructure for optical applications

The microstructure of borosilicate glass can be engineered for specific optical applications. This includes creating waveguides, photonic crystals, or other optical elements directly within the glass. By controlling the refractive index distribution or introducing specific structural features, the glass can be tailored for use in optical devices, sensors, or communication systems.Expand Specific Solutions

Key Players in Borosilicate Glass Manufacturing and Analysis

The competitive landscape for Borosilicate Glass Microstructural Analysis is characterized by a mature market with established players and growing demand across various industries. Key companies like SCHOTT AG, Corning, Inc., and AGC, Inc. dominate the field, leveraging decades of expertise in specialty glass manufacturing. The market is experiencing steady growth due to increasing applications in pharmaceuticals, electronics, and laboratory equipment. Technological advancements by major players and research institutions are driving innovation in microstructural analysis techniques, enhancing the understanding of borosilicate glass properties and performance. Emerging companies from China, such as Hunan Kibing and Zhangzhou Kibing Glass, are also entering the market, potentially disrupting the existing competitive dynamics.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced techniques for borosilicate glass microstructural analysis, including high-resolution electron microscopy and X-ray tomography. Their approach combines in-situ characterization methods with computational modeling to understand glass structure at the atomic scale[1]. They utilize Raman spectroscopy and nuclear magnetic resonance (NMR) to study the local structure and chemical bonding in borosilicate glasses[3]. SCHOTT has also pioneered the use of atom probe tomography for 3D elemental mapping of glass compositions with near-atomic resolution[5]. These methods allow them to optimize glass formulations for specific applications, such as pharmaceutical packaging and optical components.

Strengths: Comprehensive suite of analytical techniques, industry-leading expertise in glass science. Weaknesses: High-end equipment requirements may limit accessibility for some applications.

Corning, Inc.

Technical Solution: Corning's approach to borosilicate glass microstructural analysis involves a multi-scale characterization strategy. They employ synchrotron-based X-ray techniques, including small-angle X-ray scattering (SAXS) and X-ray absorption fine structure (XAFS), to probe the glass structure at different length scales[2]. Corning has developed proprietary software for interpreting spectroscopic data and linking it to macroscopic properties. Their researchers use advanced electron microscopy techniques, such as scanning transmission electron microscopy (STEM) with energy-dispersive X-ray spectroscopy (EDS), to map elemental distributions at nanometer scales[4]. Corning also utilizes machine learning algorithms to predict glass properties based on composition and processing parameters.

Strengths: Integration of experimental techniques with computational modeling, strong focus on structure-property relationships. Weaknesses: Reliance on expensive, specialized equipment may limit broader application.

Innovative Approaches in Borosilicate Glass Microanalysis

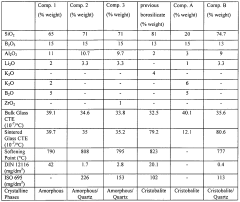

Borosilicate glass compositions and uses thereof

PatentWO2004050575A1

Innovation

- A borosilicate glass composition with silicon dioxide, boric oxide, aluminum oxide, and at least one alkali oxide, which resists devitrification without the addition of inhibitor oxides, maintaining a suitable coefficient of thermal expansion and mechanical strength.

Borosilicate glass compositions and uses thereof

PatentInactiveEP1567459A1

Innovation

- A borosilicate glass composition with silicon dioxide, boric oxide, aluminum oxide, and at least one alkali oxide, which resists devitrification without the addition of inhibitor oxides, maintaining a coefficient of thermal expansion between 30 x 10^-7/°C and 55 x 10^-7/°C, thereby preventing mechanical strength loss and crack formation.

Environmental Impact of Borosilicate Glass Production

The production of borosilicate glass, while offering numerous advantages in terms of durability and heat resistance, carries significant environmental implications. The manufacturing process involves high-temperature fusion of silica sand, boric oxide, and other additives, which requires substantial energy input. This energy-intensive production contributes to increased greenhouse gas emissions, particularly when fossil fuels are the primary energy source.

Raw material extraction for borosilicate glass production also poses environmental challenges. Mining operations for silica sand and boron compounds can lead to habitat disruption, soil erosion, and water pollution if not managed responsibly. The transportation of these raw materials to production facilities further adds to the carbon footprint of the industry.

Water usage in the production process is another environmental concern. Cooling and cleaning operations consume significant amounts of water, potentially straining local water resources in areas where glass manufacturing is concentrated. Proper water management and recycling systems are crucial to mitigate this impact.

The production of borosilicate glass generates various waste products, including off-spec glass, dust, and chemical residues. While much of the glass waste can be recycled back into the production process, other waste materials require careful disposal to prevent environmental contamination. Implementing efficient waste management strategies is essential for minimizing the environmental footprint of borosilicate glass production.

Air emissions from borosilicate glass manufacturing facilities can include particulate matter, nitrogen oxides, and sulfur dioxide. These pollutants contribute to air quality degradation and can have adverse effects on human health and ecosystems in surrounding areas. Advanced emission control technologies and stringent regulatory compliance are necessary to address these air quality concerns.

On the positive side, the durability and recyclability of borosilicate glass offer environmental benefits in the long term. Its resistance to chemical corrosion and thermal shock reduces the need for frequent replacement, potentially lowering overall resource consumption. Additionally, the ability to recycle borosilicate glass helps to conserve raw materials and reduce energy consumption in future production cycles.

Raw material extraction for borosilicate glass production also poses environmental challenges. Mining operations for silica sand and boron compounds can lead to habitat disruption, soil erosion, and water pollution if not managed responsibly. The transportation of these raw materials to production facilities further adds to the carbon footprint of the industry.

Water usage in the production process is another environmental concern. Cooling and cleaning operations consume significant amounts of water, potentially straining local water resources in areas where glass manufacturing is concentrated. Proper water management and recycling systems are crucial to mitigate this impact.

The production of borosilicate glass generates various waste products, including off-spec glass, dust, and chemical residues. While much of the glass waste can be recycled back into the production process, other waste materials require careful disposal to prevent environmental contamination. Implementing efficient waste management strategies is essential for minimizing the environmental footprint of borosilicate glass production.

Air emissions from borosilicate glass manufacturing facilities can include particulate matter, nitrogen oxides, and sulfur dioxide. These pollutants contribute to air quality degradation and can have adverse effects on human health and ecosystems in surrounding areas. Advanced emission control technologies and stringent regulatory compliance are necessary to address these air quality concerns.

On the positive side, the durability and recyclability of borosilicate glass offer environmental benefits in the long term. Its resistance to chemical corrosion and thermal shock reduces the need for frequent replacement, potentially lowering overall resource consumption. Additionally, the ability to recycle borosilicate glass helps to conserve raw materials and reduce energy consumption in future production cycles.

Standardization of Microstructural Analysis Protocols

The standardization of microstructural analysis protocols for borosilicate glass is crucial for ensuring consistent and reliable results across different laboratories and research institutions. This process involves establishing uniform procedures for sample preparation, imaging techniques, and data analysis.

Sample preparation is a critical first step in the standardization process. Protocols should specify methods for cutting, grinding, and polishing borosilicate glass samples to achieve consistent surface quality. Standardized etching procedures, including etchant composition and etching time, are essential for revealing the microstructure effectively.

Imaging techniques play a vital role in microstructural analysis. Standardized protocols should define the optimal microscopy methods for borosilicate glass, such as scanning electron microscopy (SEM) or transmission electron microscopy (TEM). These protocols must include guidelines for instrument settings, magnification ranges, and image acquisition parameters to ensure reproducibility.

Data analysis is another key area requiring standardization. Protocols should establish uniform methods for quantifying microstructural features, such as grain size, porosity, and phase distribution. This may involve the use of specific image analysis software and statistical methods to ensure consistent interpretation of results across different studies.

Interlaboratory comparisons are essential for validating and refining standardized protocols. These comparisons involve multiple laboratories analyzing identical borosilicate glass samples using the same protocols, allowing for the identification and resolution of any discrepancies in results or methodologies.

The development of reference materials is crucial for calibrating instruments and validating analysis methods. Standardized borosilicate glass samples with well-characterized microstructures can serve as benchmarks for comparing results across different laboratories and ensuring the accuracy of analytical techniques.

Documentation and reporting standards are integral to the standardization process. Detailed guidelines should be established for recording experimental conditions, data processing steps, and presenting results. This ensures that studies can be replicated and compared effectively across the scientific community.

Continuous review and updating of standardized protocols are necessary to incorporate advancements in technology and analytical methods. Regular workshops and collaborative efforts among experts in the field can facilitate the evolution of these standards, ensuring they remain relevant and effective for borosilicate glass microstructural analysis.

Sample preparation is a critical first step in the standardization process. Protocols should specify methods for cutting, grinding, and polishing borosilicate glass samples to achieve consistent surface quality. Standardized etching procedures, including etchant composition and etching time, are essential for revealing the microstructure effectively.

Imaging techniques play a vital role in microstructural analysis. Standardized protocols should define the optimal microscopy methods for borosilicate glass, such as scanning electron microscopy (SEM) or transmission electron microscopy (TEM). These protocols must include guidelines for instrument settings, magnification ranges, and image acquisition parameters to ensure reproducibility.

Data analysis is another key area requiring standardization. Protocols should establish uniform methods for quantifying microstructural features, such as grain size, porosity, and phase distribution. This may involve the use of specific image analysis software and statistical methods to ensure consistent interpretation of results across different studies.

Interlaboratory comparisons are essential for validating and refining standardized protocols. These comparisons involve multiple laboratories analyzing identical borosilicate glass samples using the same protocols, allowing for the identification and resolution of any discrepancies in results or methodologies.

The development of reference materials is crucial for calibrating instruments and validating analysis methods. Standardized borosilicate glass samples with well-characterized microstructures can serve as benchmarks for comparing results across different laboratories and ensuring the accuracy of analytical techniques.

Documentation and reporting standards are integral to the standardization process. Detailed guidelines should be established for recording experimental conditions, data processing steps, and presenting results. This ensures that studies can be replicated and compared effectively across the scientific community.

Continuous review and updating of standardized protocols are necessary to incorporate advancements in technology and analytical methods. Regular workshops and collaborative efforts among experts in the field can facilitate the evolution of these standards, ensuring they remain relevant and effective for borosilicate glass microstructural analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!