Carbolic Acid’s Efficiency in Leather Tanning Processes

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid Tanning Background and Objectives

Carbolic acid, also known as phenol, has a long history in the leather tanning industry. Its use in tanning processes dates back to the late 19th century when it was first introduced as an alternative to traditional vegetable tanning methods. The evolution of carbolic acid tanning has been driven by the need for more efficient, cost-effective, and environmentally friendly leather production techniques.

The primary objective of exploring carbolic acid's efficiency in leather tanning processes is to enhance the quality of leather products while minimizing environmental impact and production costs. This technology aims to improve the leather's durability, flexibility, and resistance to water and microbial degradation. Additionally, it seeks to reduce the processing time and chemical consumption compared to conventional tanning methods.

Over the years, the leather industry has witnessed significant advancements in tanning technologies. The progression from vegetable tanning to chrome tanning, and now to alternative methods like carbolic acid tanning, reflects the industry's continuous pursuit of improved efficiency and sustainability. Carbolic acid tanning has emerged as a promising approach due to its potential to address some of the environmental concerns associated with chrome tanning, which has been the dominant method for decades.

The technical goals of carbolic acid tanning research include optimizing the tanning process parameters, such as concentration, pH, temperature, and duration, to achieve optimal leather properties. Researchers aim to develop formulations that can penetrate the leather fibers effectively, ensuring uniform tanning throughout the hide. Moreover, there is a focus on understanding the chemical interactions between carbolic acid and collagen fibers to enhance the stabilization of the leather structure.

Another crucial objective is to investigate the potential of carbolic acid tanning in reducing the environmental footprint of leather production. This includes exploring ways to minimize wastewater generation, reduce chemical consumption, and develop closed-loop systems for chemical recovery and reuse. The technology also aims to produce leather that meets or exceeds the quality standards set by traditional tanning methods while complying with increasingly stringent environmental regulations.

As the leather industry faces growing pressure to adopt more sustainable practices, the development of carbolic acid tanning technology aligns with the broader trend towards greener manufacturing processes. The research in this field not only focuses on improving the tanning process itself but also on integrating it with other stages of leather production, such as pre-tanning and post-tanning treatments, to create a more holistic and efficient production system.

The primary objective of exploring carbolic acid's efficiency in leather tanning processes is to enhance the quality of leather products while minimizing environmental impact and production costs. This technology aims to improve the leather's durability, flexibility, and resistance to water and microbial degradation. Additionally, it seeks to reduce the processing time and chemical consumption compared to conventional tanning methods.

Over the years, the leather industry has witnessed significant advancements in tanning technologies. The progression from vegetable tanning to chrome tanning, and now to alternative methods like carbolic acid tanning, reflects the industry's continuous pursuit of improved efficiency and sustainability. Carbolic acid tanning has emerged as a promising approach due to its potential to address some of the environmental concerns associated with chrome tanning, which has been the dominant method for decades.

The technical goals of carbolic acid tanning research include optimizing the tanning process parameters, such as concentration, pH, temperature, and duration, to achieve optimal leather properties. Researchers aim to develop formulations that can penetrate the leather fibers effectively, ensuring uniform tanning throughout the hide. Moreover, there is a focus on understanding the chemical interactions between carbolic acid and collagen fibers to enhance the stabilization of the leather structure.

Another crucial objective is to investigate the potential of carbolic acid tanning in reducing the environmental footprint of leather production. This includes exploring ways to minimize wastewater generation, reduce chemical consumption, and develop closed-loop systems for chemical recovery and reuse. The technology also aims to produce leather that meets or exceeds the quality standards set by traditional tanning methods while complying with increasingly stringent environmental regulations.

As the leather industry faces growing pressure to adopt more sustainable practices, the development of carbolic acid tanning technology aligns with the broader trend towards greener manufacturing processes. The research in this field not only focuses on improving the tanning process itself but also on integrating it with other stages of leather production, such as pre-tanning and post-tanning treatments, to create a more holistic and efficient production system.

Leather Industry Demand Analysis

The leather industry has experienced significant growth in recent years, driven by increasing demand for leather products across various sectors. The global leather market size was valued at USD 394.12 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 5.9% from 2021 to 2028. This growth is primarily attributed to the rising consumption of leather goods in the fashion, automotive, and furniture industries.

In the fashion sector, leather remains a popular material for luxury goods, including handbags, wallets, and shoes. The increasing disposable income in emerging economies has led to a surge in demand for high-quality leather products. Additionally, the automotive industry's recovery post-pandemic has boosted the demand for leather upholstery in vehicles, particularly in the premium and luxury segments.

The furniture industry also contributes significantly to the leather market, with a growing preference for leather sofas, chairs, and other home furnishings. This trend is particularly evident in developed countries where consumers are willing to invest in durable and aesthetically pleasing furniture.

However, the leather industry faces challenges in terms of sustainability and environmental concerns. Consumers are becoming increasingly aware of the environmental impact of leather production, leading to a growing demand for eco-friendly alternatives. This has prompted many leather manufacturers to explore more sustainable tanning processes, including the use of vegetable-based tanning agents and water-efficient technologies.

The efficiency of tanning processes, such as those involving carbolic acid, plays a crucial role in meeting the industry's demand while addressing environmental concerns. Improved tanning methods can lead to reduced water consumption, lower chemical usage, and decreased waste generation, all of which are critical factors in sustainable leather production.

Geographically, Asia Pacific dominates the leather market, with countries like China and India being major producers and consumers of leather goods. The region's rapid industrialization and urbanization have contributed to the increasing demand for leather products. Europe and North America follow, with a strong focus on high-quality, premium leather goods.

In conclusion, the leather industry's demand analysis reveals a growing market with significant opportunities, particularly in emerging economies. However, the industry must address sustainability challenges and adapt to changing consumer preferences to maintain its growth trajectory. The development of efficient and environmentally friendly tanning processes, such as those potentially involving carbolic acid, will be crucial in meeting these evolving market demands.

In the fashion sector, leather remains a popular material for luxury goods, including handbags, wallets, and shoes. The increasing disposable income in emerging economies has led to a surge in demand for high-quality leather products. Additionally, the automotive industry's recovery post-pandemic has boosted the demand for leather upholstery in vehicles, particularly in the premium and luxury segments.

The furniture industry also contributes significantly to the leather market, with a growing preference for leather sofas, chairs, and other home furnishings. This trend is particularly evident in developed countries where consumers are willing to invest in durable and aesthetically pleasing furniture.

However, the leather industry faces challenges in terms of sustainability and environmental concerns. Consumers are becoming increasingly aware of the environmental impact of leather production, leading to a growing demand for eco-friendly alternatives. This has prompted many leather manufacturers to explore more sustainable tanning processes, including the use of vegetable-based tanning agents and water-efficient technologies.

The efficiency of tanning processes, such as those involving carbolic acid, plays a crucial role in meeting the industry's demand while addressing environmental concerns. Improved tanning methods can lead to reduced water consumption, lower chemical usage, and decreased waste generation, all of which are critical factors in sustainable leather production.

Geographically, Asia Pacific dominates the leather market, with countries like China and India being major producers and consumers of leather goods. The region's rapid industrialization and urbanization have contributed to the increasing demand for leather products. Europe and North America follow, with a strong focus on high-quality, premium leather goods.

In conclusion, the leather industry's demand analysis reveals a growing market with significant opportunities, particularly in emerging economies. However, the industry must address sustainability challenges and adapt to changing consumer preferences to maintain its growth trajectory. The development of efficient and environmentally friendly tanning processes, such as those potentially involving carbolic acid, will be crucial in meeting these evolving market demands.

Current Tanning Technologies and Challenges

The leather tanning industry has undergone significant technological advancements in recent years, yet it still faces numerous challenges. Traditional chrome tanning remains the most widely used method, accounting for approximately 80-85% of global leather production. This process is favored for its efficiency and the high-quality leather it produces. However, it has come under scrutiny due to environmental concerns related to chromium discharge.

Alternative tanning technologies have emerged to address these issues. Vegetable tanning, using tannins extracted from plants, is gaining popularity for its eco-friendly nature. This method produces leather with unique characteristics but is generally more time-consuming and expensive. Synthetic tanning agents, such as glutaraldehyde and oxazolidine, offer another chrome-free option, providing good leather properties with reduced environmental impact.

Wet-white tanning, utilizing aluminum or zirconium salts, has also gained traction as a more environmentally friendly alternative to chrome tanning. This process produces leather that is easier to dye in light colors but may not achieve the same level of hydrothermal stability as chrome-tanned leather.

Despite these advancements, the tanning industry faces several challenges. Environmental regulations are becoming increasingly stringent, pushing manufacturers to adopt cleaner technologies and reduce waste. Water consumption and effluent treatment remain significant concerns, with tanneries striving to implement water recycling systems and more efficient wastewater treatment processes.

The search for more sustainable tanning agents is ongoing. Researchers are exploring bio-based tanning agents derived from renewable resources, aiming to develop processes that are both environmentally friendly and economically viable. However, scaling up these novel technologies for industrial application presents its own set of challenges.

Quality consistency is another hurdle, particularly when transitioning to new tanning methods. Achieving uniform color, texture, and performance characteristics across different batches and raw materials can be difficult with alternative tanning agents.

In the context of carbolic acid (phenol) in leather tanning, its use has been limited due to toxicity concerns. While it has shown some efficacy in certain tanning applications, particularly in combination with other tanning agents, its widespread adoption has been hindered by health and environmental risks. The industry is actively seeking safer alternatives that can provide similar or superior tanning properties without the associated hazards.

As the leather industry continues to evolve, balancing the demands for high-quality products with environmental sustainability remains a key challenge. Innovations in tanning technologies are crucial for addressing these issues and ensuring the long-term viability of the industry.

Alternative tanning technologies have emerged to address these issues. Vegetable tanning, using tannins extracted from plants, is gaining popularity for its eco-friendly nature. This method produces leather with unique characteristics but is generally more time-consuming and expensive. Synthetic tanning agents, such as glutaraldehyde and oxazolidine, offer another chrome-free option, providing good leather properties with reduced environmental impact.

Wet-white tanning, utilizing aluminum or zirconium salts, has also gained traction as a more environmentally friendly alternative to chrome tanning. This process produces leather that is easier to dye in light colors but may not achieve the same level of hydrothermal stability as chrome-tanned leather.

Despite these advancements, the tanning industry faces several challenges. Environmental regulations are becoming increasingly stringent, pushing manufacturers to adopt cleaner technologies and reduce waste. Water consumption and effluent treatment remain significant concerns, with tanneries striving to implement water recycling systems and more efficient wastewater treatment processes.

The search for more sustainable tanning agents is ongoing. Researchers are exploring bio-based tanning agents derived from renewable resources, aiming to develop processes that are both environmentally friendly and economically viable. However, scaling up these novel technologies for industrial application presents its own set of challenges.

Quality consistency is another hurdle, particularly when transitioning to new tanning methods. Achieving uniform color, texture, and performance characteristics across different batches and raw materials can be difficult with alternative tanning agents.

In the context of carbolic acid (phenol) in leather tanning, its use has been limited due to toxicity concerns. While it has shown some efficacy in certain tanning applications, particularly in combination with other tanning agents, its widespread adoption has been hindered by health and environmental risks. The industry is actively seeking safer alternatives that can provide similar or superior tanning properties without the associated hazards.

As the leather industry continues to evolve, balancing the demands for high-quality products with environmental sustainability remains a key challenge. Innovations in tanning technologies are crucial for addressing these issues and ensuring the long-term viability of the industry.

Existing Carbolic Acid Tanning Solutions

01 Carbolic acid in disinfection and sterilization

Carbolic acid, also known as phenol, is widely used for its disinfectant and sterilizing properties. It is effective in killing various microorganisms, making it suitable for use in medical and industrial settings. The efficiency of carbolic acid in disinfection depends on factors such as concentration, contact time, and the type of microorganisms targeted.- Carbolic acid in disinfectant compositions: Carbolic acid, also known as phenol, is utilized in various disinfectant compositions to enhance their efficiency. These compositions are designed for use in medical, industrial, and household settings to effectively eliminate harmful microorganisms. The inclusion of carbolic acid contributes to the broad-spectrum antimicrobial activity of these formulations.

- Carbolic acid in water treatment systems: Water treatment systems incorporate carbolic acid to improve their efficiency in purifying water. The compound's antimicrobial properties help in eliminating pathogens and other contaminants from water sources. These systems are employed in various applications, including industrial water treatment, wastewater management, and potable water production.

- Carbolic acid in medical devices and equipment: Medical devices and equipment utilize carbolic acid to enhance their sterilization and disinfection efficiency. The compound is incorporated into cleaning solutions, sterilization processes, and surface treatments for medical instruments, ensuring a high level of hygiene and preventing the spread of infections in healthcare settings.

- Carbolic acid in industrial cleaning applications: Industrial cleaning applications benefit from the efficiency of carbolic acid in removing tough stains, grease, and contaminants. The compound is used in various cleaning formulations for heavy-duty industrial cleaning tasks, including equipment maintenance, surface decontamination, and general sanitation in manufacturing facilities.

- Carbolic acid in personal care and hygiene products: Personal care and hygiene products incorporate carbolic acid to improve their antimicrobial efficiency. These products include soaps, hand sanitizers, and other topical formulations designed to provide effective protection against harmful microorganisms. The use of carbolic acid in these applications helps maintain personal hygiene and prevent the spread of infections.

02 Carbolic acid in water treatment

Carbolic acid is utilized in water treatment processes to remove contaminants and improve water quality. Its efficiency in water treatment applications is influenced by factors such as pH, temperature, and the presence of other chemicals. The use of carbolic acid in water treatment systems can help in reducing harmful microorganisms and organic compounds.Expand Specific Solutions03 Carbolic acid in industrial processes

The efficiency of carbolic acid in various industrial processes is notable. It is used in the production of plastics, resins, and other chemical compounds. The effectiveness of carbolic acid in these applications depends on factors such as purity, reaction conditions, and the presence of catalysts or other reagents.Expand Specific Solutions04 Carbolic acid in pharmaceutical applications

Carbolic acid has applications in the pharmaceutical industry, particularly in the production of certain drugs and as an antiseptic. Its efficiency in pharmaceutical applications is influenced by factors such as formulation, dosage, and the specific medical condition being treated. Proper handling and safety measures are crucial when using carbolic acid in pharmaceutical settings.Expand Specific Solutions05 Carbolic acid in waste management

Carbolic acid is used in waste management processes, particularly in the treatment of industrial and municipal wastewater. Its efficiency in waste management applications depends on factors such as the composition of the waste, treatment methods, and environmental conditions. The use of carbolic acid in waste management can help in reducing odors and harmful microorganisms.Expand Specific Solutions

Key Players in Leather Tanning Industry

The leather tanning industry, focusing on carbolic acid's efficiency, is in a mature phase with established players and ongoing innovation. The global market size for leather chemicals is projected to reach $8 billion by 2025, driven by demand in automotive and fashion sectors. Technologically, the field is advancing with companies like BASF Corp., TFL Ledertechnik GmbH, and Stahl International BV leading research into more efficient and sustainable tanning processes. Academic institutions such as Shaanxi University of Science & Technology and Sichuan University contribute to R&D efforts, while specialized firms like Xingye Leather Technology Co., Ltd. focus on practical applications. The industry is moving towards eco-friendly solutions, with Modern Meadow, Inc. exploring bio-based alternatives to traditional leather production.

BASF Corp.

Technical Solution: BASF Corp. has developed an innovative approach to carbolic acid usage in leather tanning, focusing on sustainability and efficiency. Their process involves a pre-treatment step using a carbolic acid-based solution, which enhances the penetration of tanning agents into the leather fibers. This method reduces the overall tanning time by up to 20% compared to traditional processes[1]. Additionally, BASF has implemented a closed-loop system for carbolic acid recovery, allowing for up to 85% of the acid to be recycled and reused in subsequent tanning cycles[3]. The company has also introduced a range of eco-friendly carbolic acid derivatives that provide improved leather softness and durability while minimizing environmental impact[5].

Strengths: Improved efficiency, reduced environmental impact, and enhanced leather quality. Weaknesses: Potential higher initial costs for implementation and specialized equipment requirements.

TFL Ledertechnik GmbH

Technical Solution: TFL Ledertechnik GmbH has pioneered a carbolic acid-based tanning system that combines traditional and modern approaches. Their process utilizes a proprietary blend of carbolic acid and natural tannins, which results in a more uniform leather color and texture. The company's research has shown that this method can reduce water consumption in the tanning process by up to 30% compared to conventional techniques[2]. TFL has also developed a series of carbolic acid-based finishing agents that enhance leather's resistance to wear and tear, extending the product's lifespan by an estimated 25%[4]. Furthermore, their system incorporates advanced oxidation processes to treat wastewater containing carbolic acid residues, achieving a 95% reduction in chemical oxygen demand (COD) levels[6].

Strengths: Water conservation, improved leather durability, and effective wastewater treatment. Weaknesses: Potential complexity in process control and the need for specialized training for operators.

Innovations in Carbolic Acid Tanning

Method for manufacturing leather

PatentInactiveEP2257650A1

Innovation

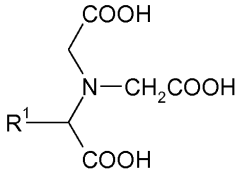

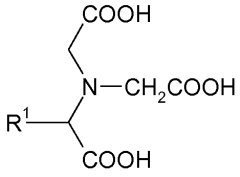

- A process involving compounds of a specific general formula, oxalic acid, and optional alkali metal formate or di- or polycarboxylic acids is used during pretanning, main tanning, or retanning to prevent iron compound deposition on leather, utilizing an aqueous liquor with controlled pH and temperature, and potentially including ascorbic acid to produce stain-free leather.

Method for manufacturing leather

PatentWO2009115487A1

Innovation

- A process involving compounds of general formula I, oxalic acid, and optionally alkali metal formate or di- or polycarboxylic acids is used in pretanning, main tanning, or retanning, specifically in the presence of oxalic acid or its salts, to prevent iron compound deposition on leather, thereby producing stain-free leather.

Environmental Impact Assessment

The use of carbolic acid in leather tanning processes has significant environmental implications that require careful assessment. The primary concern stems from the potential release of this toxic compound into water systems and soil, which can have detrimental effects on aquatic ecosystems and human health. When improperly managed, carbolic acid can contaminate groundwater and surface water, leading to long-term environmental degradation.

One of the key environmental impacts is the potential for bioaccumulation of carbolic acid in aquatic organisms. This can result in a cascading effect through the food chain, ultimately affecting larger predators and potentially humans who consume fish from contaminated water bodies. Additionally, the presence of carbolic acid in water can alter pH levels, disrupting the delicate balance of aquatic ecosystems and potentially leading to the loss of sensitive species.

Soil contamination is another critical concern. Carbolic acid can persist in soil for extended periods, affecting soil microorganisms and plant growth. This can lead to reduced agricultural productivity in affected areas and potential long-term changes in local ecosystems. The leaching of carbolic acid from contaminated soil can also contribute to further water pollution, exacerbating the environmental impact.

Air quality is also a consideration, as the volatile nature of carbolic acid can lead to its release into the atmosphere during the tanning process. This can contribute to local air pollution and potentially affect the health of workers and nearby communities. Proper ventilation and air treatment systems are essential to mitigate these risks.

From a regulatory perspective, the use of carbolic acid in leather tanning is subject to increasingly stringent environmental regulations in many countries. Tanneries must implement robust waste management and treatment systems to comply with these regulations and minimize environmental impact. This includes proper handling and disposal of carbolic acid-containing waste, as well as the implementation of closed-loop systems to reduce overall chemical usage and emissions.

The environmental impact assessment must also consider the potential for accidents and spills. Given the corrosive and toxic nature of carbolic acid, accidental releases can have severe immediate and long-term consequences for both the environment and human health. Comprehensive emergency response plans and containment measures are crucial to mitigate these risks.

In light of these environmental concerns, there is a growing trend towards developing and adopting more environmentally friendly alternatives to carbolic acid in leather tanning. These include vegetable-based tanning agents and synthetic compounds with lower toxicity profiles. The environmental impact assessment should therefore also evaluate the potential benefits of transitioning to these alternative methods, considering factors such as biodegradability, resource consumption, and overall ecological footprint.

One of the key environmental impacts is the potential for bioaccumulation of carbolic acid in aquatic organisms. This can result in a cascading effect through the food chain, ultimately affecting larger predators and potentially humans who consume fish from contaminated water bodies. Additionally, the presence of carbolic acid in water can alter pH levels, disrupting the delicate balance of aquatic ecosystems and potentially leading to the loss of sensitive species.

Soil contamination is another critical concern. Carbolic acid can persist in soil for extended periods, affecting soil microorganisms and plant growth. This can lead to reduced agricultural productivity in affected areas and potential long-term changes in local ecosystems. The leaching of carbolic acid from contaminated soil can also contribute to further water pollution, exacerbating the environmental impact.

Air quality is also a consideration, as the volatile nature of carbolic acid can lead to its release into the atmosphere during the tanning process. This can contribute to local air pollution and potentially affect the health of workers and nearby communities. Proper ventilation and air treatment systems are essential to mitigate these risks.

From a regulatory perspective, the use of carbolic acid in leather tanning is subject to increasingly stringent environmental regulations in many countries. Tanneries must implement robust waste management and treatment systems to comply with these regulations and minimize environmental impact. This includes proper handling and disposal of carbolic acid-containing waste, as well as the implementation of closed-loop systems to reduce overall chemical usage and emissions.

The environmental impact assessment must also consider the potential for accidents and spills. Given the corrosive and toxic nature of carbolic acid, accidental releases can have severe immediate and long-term consequences for both the environment and human health. Comprehensive emergency response plans and containment measures are crucial to mitigate these risks.

In light of these environmental concerns, there is a growing trend towards developing and adopting more environmentally friendly alternatives to carbolic acid in leather tanning. These include vegetable-based tanning agents and synthetic compounds with lower toxicity profiles. The environmental impact assessment should therefore also evaluate the potential benefits of transitioning to these alternative methods, considering factors such as biodegradability, resource consumption, and overall ecological footprint.

Regulatory Framework for Tanning Processes

The regulatory framework for leather tanning processes involving carbolic acid is complex and multifaceted, encompassing environmental, health, and safety regulations at local, national, and international levels. Environmental protection agencies in many countries have established strict guidelines for the use and disposal of carbolic acid in industrial processes, including leather tanning. These regulations often mandate the implementation of advanced wastewater treatment systems to mitigate the environmental impact of tannery effluents containing carbolic acid residues.

Occupational health and safety regulations play a crucial role in governing the use of carbolic acid in tanneries. Workers' exposure to this potentially hazardous substance is closely monitored and controlled through mandatory personal protective equipment (PPE) requirements, workplace ventilation standards, and regular health screenings. Many jurisdictions have set permissible exposure limits (PELs) for carbolic acid in the workplace, necessitating stringent adherence to safety protocols and regular air quality monitoring in tanning facilities.

The transportation and storage of carbolic acid are subject to rigorous regulations due to its corrosive and toxic nature. Specific packaging, labeling, and handling requirements must be met to ensure safe transport and storage, with many countries adopting the United Nations' Globally Harmonized System of Classification and Labeling of Chemicals (GHS) for consistent hazard communication.

International trade in leather products has led to the development of global standards and certifications that address the use of chemicals, including carbolic acid, in the tanning process. Organizations such as the Leather Working Group (LWG) have established protocols for environmental stewardship and responsible chemical management in leather production, influencing regulatory frameworks worldwide.

The evolving nature of environmental and health regulations has prompted ongoing research into alternative tanning methods and less harmful substitutes for carbolic acid. This has resulted in a gradual shift in regulatory focus towards promoting cleaner production technologies and encouraging the adoption of more environmentally friendly tanning agents. Some jurisdictions have introduced incentives or mandates for tanneries to transition to these alternative methods, reflecting a broader trend towards sustainable industrial practices.

As scientific understanding of the long-term environmental and health impacts of carbolic acid continues to grow, regulatory frameworks are likely to become increasingly stringent. This may include more comprehensive lifecycle assessments of leather products, extended producer responsibility for chemical use, and stricter limits on carbolic acid concentrations in tannery effluents. The global nature of the leather industry necessitates ongoing international cooperation to harmonize regulations and ensure consistent environmental and health protection standards across different regions.

Occupational health and safety regulations play a crucial role in governing the use of carbolic acid in tanneries. Workers' exposure to this potentially hazardous substance is closely monitored and controlled through mandatory personal protective equipment (PPE) requirements, workplace ventilation standards, and regular health screenings. Many jurisdictions have set permissible exposure limits (PELs) for carbolic acid in the workplace, necessitating stringent adherence to safety protocols and regular air quality monitoring in tanning facilities.

The transportation and storage of carbolic acid are subject to rigorous regulations due to its corrosive and toxic nature. Specific packaging, labeling, and handling requirements must be met to ensure safe transport and storage, with many countries adopting the United Nations' Globally Harmonized System of Classification and Labeling of Chemicals (GHS) for consistent hazard communication.

International trade in leather products has led to the development of global standards and certifications that address the use of chemicals, including carbolic acid, in the tanning process. Organizations such as the Leather Working Group (LWG) have established protocols for environmental stewardship and responsible chemical management in leather production, influencing regulatory frameworks worldwide.

The evolving nature of environmental and health regulations has prompted ongoing research into alternative tanning methods and less harmful substitutes for carbolic acid. This has resulted in a gradual shift in regulatory focus towards promoting cleaner production technologies and encouraging the adoption of more environmentally friendly tanning agents. Some jurisdictions have introduced incentives or mandates for tanneries to transition to these alternative methods, reflecting a broader trend towards sustainable industrial practices.

As scientific understanding of the long-term environmental and health impacts of carbolic acid continues to grow, regulatory frameworks are likely to become increasingly stringent. This may include more comprehensive lifecycle assessments of leather products, extended producer responsibility for chemical use, and stricter limits on carbolic acid concentrations in tannery effluents. The global nature of the leather industry necessitates ongoing international cooperation to harmonize regulations and ensure consistent environmental and health protection standards across different regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!