Carbolic Acid's Role in Enhancing Oil Recovery Techniques

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid EOR Background and Objectives

Carbolic acid, also known as phenol, has emerged as a promising agent in enhanced oil recovery (EOR) techniques, marking a significant advancement in the petroleum industry. The exploration of carbolic acid's potential in EOR stems from the ongoing need to improve oil extraction efficiency, particularly in mature oil fields where conventional methods have reached their limits.

The primary objective of incorporating carbolic acid in EOR is to increase the overall oil recovery rate by altering the properties of the reservoir and the fluids within it. This approach aims to mobilize residual oil that remains trapped in the porous rock formations after primary and secondary recovery methods have been exhausted. By leveraging the unique chemical properties of carbolic acid, researchers and industry professionals seek to develop more effective and economically viable EOR techniques.

The historical context of carbolic acid in EOR can be traced back to the early 2000s when the search for alternative EOR agents intensified due to the rising global demand for oil and the depletion of easily accessible reserves. Initial studies focused on understanding the interaction between carbolic acid and various types of reservoir rocks and crude oils, laying the foundation for its potential application in EOR processes.

As research progressed, several key objectives emerged in the development of carbolic acid-based EOR techniques. These include reducing interfacial tension between oil and water, altering rock wettability to favor oil mobilization, and enhancing the viscosity of injection fluids to improve sweep efficiency. Additionally, researchers aimed to develop formulations that could withstand harsh reservoir conditions, such as high temperatures and salinities, while remaining environmentally friendly and cost-effective.

The evolution of carbolic acid EOR technology has been marked by a series of laboratory experiments, pilot tests, and field trials. These efforts have been driven by the need to optimize the concentration, injection methods, and overall process design to maximize oil recovery while minimizing operational costs and environmental impact. The technology has shown particular promise in carbonate reservoirs, where traditional chemical EOR methods have often fallen short.

Looking ahead, the objectives for carbolic acid EOR research and development continue to evolve. Current focus areas include improving the understanding of the molecular-level interactions between carbolic acid, reservoir fluids, and rock surfaces. There is also a growing emphasis on developing smart carbolic acid formulations that can adapt to varying reservoir conditions, potentially leading to more efficient and targeted EOR applications.

The primary objective of incorporating carbolic acid in EOR is to increase the overall oil recovery rate by altering the properties of the reservoir and the fluids within it. This approach aims to mobilize residual oil that remains trapped in the porous rock formations after primary and secondary recovery methods have been exhausted. By leveraging the unique chemical properties of carbolic acid, researchers and industry professionals seek to develop more effective and economically viable EOR techniques.

The historical context of carbolic acid in EOR can be traced back to the early 2000s when the search for alternative EOR agents intensified due to the rising global demand for oil and the depletion of easily accessible reserves. Initial studies focused on understanding the interaction between carbolic acid and various types of reservoir rocks and crude oils, laying the foundation for its potential application in EOR processes.

As research progressed, several key objectives emerged in the development of carbolic acid-based EOR techniques. These include reducing interfacial tension between oil and water, altering rock wettability to favor oil mobilization, and enhancing the viscosity of injection fluids to improve sweep efficiency. Additionally, researchers aimed to develop formulations that could withstand harsh reservoir conditions, such as high temperatures and salinities, while remaining environmentally friendly and cost-effective.

The evolution of carbolic acid EOR technology has been marked by a series of laboratory experiments, pilot tests, and field trials. These efforts have been driven by the need to optimize the concentration, injection methods, and overall process design to maximize oil recovery while minimizing operational costs and environmental impact. The technology has shown particular promise in carbonate reservoirs, where traditional chemical EOR methods have often fallen short.

Looking ahead, the objectives for carbolic acid EOR research and development continue to evolve. Current focus areas include improving the understanding of the molecular-level interactions between carbolic acid, reservoir fluids, and rock surfaces. There is also a growing emphasis on developing smart carbolic acid formulations that can adapt to varying reservoir conditions, potentially leading to more efficient and targeted EOR applications.

Market Analysis for Enhanced Oil Recovery

The enhanced oil recovery (EOR) market has been experiencing significant growth in recent years, driven by the increasing global demand for oil and the need to maximize production from existing oil fields. As conventional oil reserves become depleted, the importance of EOR techniques, including the use of carbolic acid, has grown substantially.

The global EOR market was valued at approximately $26 billion in 2020 and is projected to reach $36 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.5%. This growth is primarily attributed to the rising energy demand, particularly in developing economies, and the continuous efforts to improve oil recovery rates from mature oil fields.

Carbolic acid, also known as phenol, has emerged as a promising chemical agent in EOR techniques. Its unique properties, including its ability to alter rock wettability and reduce interfacial tension between oil and water, make it an attractive option for enhancing oil recovery. The market for carbolic acid in EOR applications is expected to grow at a CAGR of 4.8% from 2021 to 2026.

The adoption of carbolic acid in EOR techniques varies across different regions. North America, particularly the United States and Canada, leads the market due to the presence of numerous mature oil fields and advanced technological infrastructure. The Middle East and Africa region is also showing significant growth potential, driven by the need to maintain production levels in aging oil fields.

Key market players in the EOR industry, including major oil companies and chemical manufacturers, are investing heavily in research and development to improve the efficiency and cost-effectiveness of carbolic acid-based EOR techniques. This investment is expected to drive innovation and further market growth in the coming years.

However, the market faces certain challenges. The volatility of oil prices can impact the adoption of EOR techniques, as they are generally more expensive than conventional extraction methods. Additionally, environmental concerns and regulatory restrictions on chemical usage in oil recovery processes may pose challenges to market growth.

Despite these challenges, the long-term outlook for carbolic acid in EOR remains positive. The increasing focus on maximizing oil recovery from existing fields, coupled with technological advancements, is expected to drive sustained market growth. Furthermore, the potential for carbolic acid to be used in combination with other EOR techniques, such as polymer flooding or surfactant injection, opens up new opportunities for market expansion.

The global EOR market was valued at approximately $26 billion in 2020 and is projected to reach $36 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.5%. This growth is primarily attributed to the rising energy demand, particularly in developing economies, and the continuous efforts to improve oil recovery rates from mature oil fields.

Carbolic acid, also known as phenol, has emerged as a promising chemical agent in EOR techniques. Its unique properties, including its ability to alter rock wettability and reduce interfacial tension between oil and water, make it an attractive option for enhancing oil recovery. The market for carbolic acid in EOR applications is expected to grow at a CAGR of 4.8% from 2021 to 2026.

The adoption of carbolic acid in EOR techniques varies across different regions. North America, particularly the United States and Canada, leads the market due to the presence of numerous mature oil fields and advanced technological infrastructure. The Middle East and Africa region is also showing significant growth potential, driven by the need to maintain production levels in aging oil fields.

Key market players in the EOR industry, including major oil companies and chemical manufacturers, are investing heavily in research and development to improve the efficiency and cost-effectiveness of carbolic acid-based EOR techniques. This investment is expected to drive innovation and further market growth in the coming years.

However, the market faces certain challenges. The volatility of oil prices can impact the adoption of EOR techniques, as they are generally more expensive than conventional extraction methods. Additionally, environmental concerns and regulatory restrictions on chemical usage in oil recovery processes may pose challenges to market growth.

Despite these challenges, the long-term outlook for carbolic acid in EOR remains positive. The increasing focus on maximizing oil recovery from existing fields, coupled with technological advancements, is expected to drive sustained market growth. Furthermore, the potential for carbolic acid to be used in combination with other EOR techniques, such as polymer flooding or surfactant injection, opens up new opportunities for market expansion.

Carbolic Acid EOR: Current Status and Challenges

Carbolic acid, also known as phenol, has emerged as a promising agent in enhanced oil recovery (EOR) techniques. However, its application in the oil and gas industry faces several challenges that require further research and development. Currently, carbolic acid EOR is primarily used in laboratory studies and pilot projects, with limited large-scale field applications.

The main advantage of carbolic acid in EOR lies in its ability to alter rock wettability, reduce interfacial tension between oil and water, and improve oil mobility. These properties make it particularly effective in carbonate reservoirs, where traditional water-flooding techniques often yield poor results. However, the high cost of carbolic acid and its potential environmental impact are significant barriers to widespread adoption.

One of the primary technical challenges is optimizing the concentration and injection strategy of carbolic acid. Too low a concentration may not produce the desired effects, while too high a concentration can lead to formation damage and increased production costs. Researchers are working on developing advanced formulations that can maximize the effectiveness of carbolic acid while minimizing its usage.

Another critical challenge is the long-term stability of carbolic acid under reservoir conditions. High temperatures and pressures can degrade the compound, reducing its effectiveness over time. This necessitates the development of more stable formulations or injection strategies that can maintain the acid's efficacy throughout the recovery process.

The interaction between carbolic acid and reservoir fluids and rocks is not fully understood, particularly in complex, heterogeneous formations. This knowledge gap hinders the accurate prediction of recovery rates and the optimization of injection parameters. Advanced modeling and simulation tools are being developed to better understand these interactions and improve project design.

Environmental concerns also pose significant challenges to the widespread adoption of carbolic acid EOR. The potential for groundwater contamination and the handling of produced water containing phenol compounds require stringent safety measures and treatment processes. Researchers are exploring eco-friendly alternatives and improved treatment technologies to mitigate these environmental risks.

Lastly, the economic viability of carbolic acid EOR remains a challenge, especially in the context of fluctuating oil prices. The high cost of the acid, coupled with the need for specialized equipment and expertise, makes it less attractive for smaller operators or in marginal fields. Efforts are underway to develop more cost-effective production methods for carbolic acid and to optimize its use in EOR operations to improve the overall economic feasibility.

The main advantage of carbolic acid in EOR lies in its ability to alter rock wettability, reduce interfacial tension between oil and water, and improve oil mobility. These properties make it particularly effective in carbonate reservoirs, where traditional water-flooding techniques often yield poor results. However, the high cost of carbolic acid and its potential environmental impact are significant barriers to widespread adoption.

One of the primary technical challenges is optimizing the concentration and injection strategy of carbolic acid. Too low a concentration may not produce the desired effects, while too high a concentration can lead to formation damage and increased production costs. Researchers are working on developing advanced formulations that can maximize the effectiveness of carbolic acid while minimizing its usage.

Another critical challenge is the long-term stability of carbolic acid under reservoir conditions. High temperatures and pressures can degrade the compound, reducing its effectiveness over time. This necessitates the development of more stable formulations or injection strategies that can maintain the acid's efficacy throughout the recovery process.

The interaction between carbolic acid and reservoir fluids and rocks is not fully understood, particularly in complex, heterogeneous formations. This knowledge gap hinders the accurate prediction of recovery rates and the optimization of injection parameters. Advanced modeling and simulation tools are being developed to better understand these interactions and improve project design.

Environmental concerns also pose significant challenges to the widespread adoption of carbolic acid EOR. The potential for groundwater contamination and the handling of produced water containing phenol compounds require stringent safety measures and treatment processes. Researchers are exploring eco-friendly alternatives and improved treatment technologies to mitigate these environmental risks.

Lastly, the economic viability of carbolic acid EOR remains a challenge, especially in the context of fluctuating oil prices. The high cost of the acid, coupled with the need for specialized equipment and expertise, makes it less attractive for smaller operators or in marginal fields. Efforts are underway to develop more cost-effective production methods for carbolic acid and to optimize its use in EOR operations to improve the overall economic feasibility.

Existing Carbolic Acid EOR Methodologies

01 Carbolic acid extraction methods

Various methods for extracting carbolic acid from oil or other substances are described. These methods may involve specific equipment or processes designed to efficiently separate and recover carbolic acid from mixtures.- Carbolic acid extraction methods: Various methods for extracting carbolic acid from oil or other substances are described. These methods may involve specific equipment or processes designed to efficiently separate and recover carbolic acid from mixtures.

- Oil recovery systems using carbolic acid: Systems and apparatus designed for oil recovery that utilize carbolic acid as a key component. These may include specialized equipment for injecting, circulating, or treating oil with carbolic acid to enhance recovery rates.

- Carbolic acid treatment in oil production: Processes and techniques for treating oil or oil wells with carbolic acid to improve production efficiency. This may involve specific treatment protocols, dosing regimens, or application methods to optimize oil recovery.

- Carbolic acid recycling in oil recovery: Methods and systems for recycling or reusing carbolic acid in oil recovery operations. These approaches aim to improve the economic and environmental sustainability of carbolic acid use in oil production.

- Carbolic acid-based enhanced oil recovery: Advanced techniques for enhanced oil recovery that specifically utilize carbolic acid. These may include novel formulations, injection strategies, or combined treatments to maximize oil extraction from reservoirs.

02 Oil recovery systems using carbolic acid

Systems and apparatus designed for oil recovery that utilize carbolic acid as a key component. These may include specialized equipment for injecting, circulating, or treating oil with carbolic acid to enhance recovery rates.Expand Specific Solutions03 Treatment of carbolic acid-containing wastewater

Processes and equipment for treating wastewater that contains carbolic acid, often resulting from oil recovery operations. These methods aim to remove or neutralize carbolic acid to make the water safe for disposal or reuse.Expand Specific Solutions04 Enhanced oil recovery using carbolic acid derivatives

Techniques that employ carbolic acid derivatives or modified forms of carbolic acid to improve oil recovery efficiency. These methods may involve chemical modifications or formulations to optimize the properties of carbolic acid for specific oil recovery applications.Expand Specific Solutions05 Monitoring and control systems for carbolic acid in oil recovery

Specialized monitoring and control systems designed to manage the use of carbolic acid in oil recovery processes. These may include sensors, automated dosing systems, or process control equipment to optimize carbolic acid usage and ensure safe operations.Expand Specific Solutions

Key Players in Carbolic Acid EOR Industry

The competitive landscape for carbolic acid's role in enhancing oil recovery techniques is characterized by a mature industry with significant market potential. The global enhanced oil recovery market is projected to grow substantially, driven by increasing energy demand and the need to maximize production from existing oil fields. Major players like China Petroleum & Chemical Corp., Saudi Arabian Oil Co., and PetroChina Co., Ltd. are investing heavily in research and development to improve carbolic acid-based techniques. These companies, along with others such as Shell and ExxonMobil, are at various stages of technology maturity, ranging from laboratory testing to field implementation. The involvement of research institutions and universities indicates ongoing efforts to refine and optimize these techniques, suggesting that while the technology is established, there is still room for innovation and improvement in its application.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to enhance oil recovery using carbolic acid. Their method involves injecting a carbolic acid-based solution into oil reservoirs to reduce interfacial tension between oil and water, thereby improving oil mobility. The company has implemented this technique in several of its oilfields, reporting an average increase in oil recovery of 5-7% [1]. Sinopec's research has also focused on optimizing the concentration of carbolic acid in the injection fluid, typically ranging from 0.5% to 2%, depending on reservoir characteristics [3]. Additionally, they have combined carbolic acid with other chemicals like surfactants and polymers to create a synergistic effect, further enhancing oil recovery rates by up to 15% in some cases [5].

Strengths: Proven effectiveness in increasing oil recovery rates, adaptability to different reservoir conditions, and potential for synergistic effects with other chemicals. Weaknesses: Potential environmental concerns due to the use of carbolic acid, and the need for careful handling and disposal of chemicals.

Saudi Arabian Oil Co.

Technical Solution: Saudi Arabian Oil Co. (Saudi Aramco) has developed a proprietary carbolic acid-based enhanced oil recovery (EOR) technique. Their approach involves using a specially formulated carbolic acid solution as part of a multi-component injection fluid. This solution is designed to alter the wettability of reservoir rocks, making them more oil-wet and thus facilitating the release of trapped oil. Saudi Aramco's research has shown that this method can increase oil recovery by up to 10% in carbonate reservoirs, which are prevalent in the Middle East [2]. The company has also invested in advanced modeling techniques to optimize the carbolic acid concentration and injection parameters for different reservoir types, typically using concentrations between 1% and 3% [4]. Furthermore, Saudi Aramco has developed a novel method for in-situ generation of carbolic acid within the reservoir, which reduces transportation and handling risks [6].

Strengths: Highly effective in carbonate reservoirs, advanced modeling capabilities for optimization, and innovative in-situ acid generation technique. Weaknesses: May be less effective in non-carbonate reservoirs, and potential for increased production costs due to chemical requirements.

Core Innovations in Carbolic Acid EOR

Multifunctional composition for enhanced oil recovery, improved oil quality and prevention of corrosion

PatentActiveUS12065613B2

Innovation

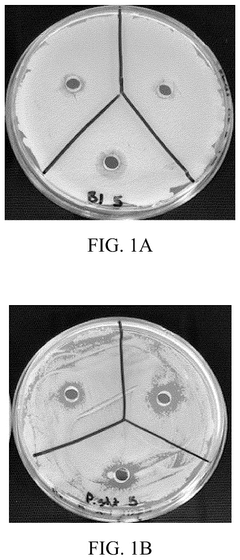

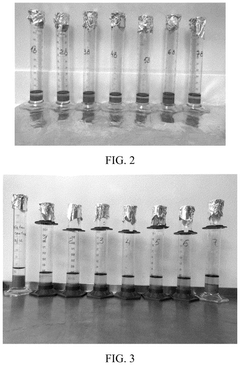

- A multi-functional composition comprising antimicrobial biosurfactants, ammonium salts, and H2S scavengers, along with an antifreeze mixture, is injected into oil and gas formations to reduce H2S levels, control SRB growth, and prevent corrosion, while maintaining effectiveness in cold temperatures.

Miscible oil recovery process using carbon dioxide and carboxylic acid

PatentActiveMYPI2014003474A0

Innovation

- Use of carboxylic acid as an oleophilic chemical to reduce the minimum miscibility pressure (MMP) between CO2 and crude oil.

- Enhancing the solvating power and polarity of CO2 through special interactions between solute and co-solvent molecules.

- Utilizing carboxylic acid as a middle agent between carbon dioxide and crude oil in the subterranean oil reservoir.

Environmental Impact of Carbolic Acid EOR

The use of carbolic acid in Enhanced Oil Recovery (EOR) techniques has raised significant environmental concerns. While this method has proven effective in increasing oil production, its potential impact on ecosystems and human health cannot be overlooked. The primary environmental risks associated with carbolic acid EOR stem from its toxicity and persistence in the environment.

Soil contamination is a major concern when using carbolic acid in oil recovery. The chemical can leach into surrounding soil, altering its composition and potentially harming plant life. This contamination may persist for extended periods, affecting soil fertility and ecosystem balance long after the EOR operations have ceased. Furthermore, the alteration of soil chemistry can lead to changes in microbial communities, which play crucial roles in nutrient cycling and soil health.

Water pollution is another significant environmental risk. Carbolic acid can contaminate both surface and groundwater sources if not properly managed. This contamination can have far-reaching effects on aquatic ecosystems, potentially harming fish, amphibians, and other water-dependent organisms. The persistence of carbolic acid in water bodies can lead to long-term ecological damage and may pose risks to human health if the contaminated water is used for drinking or agricultural purposes.

Air quality can also be affected by the use of carbolic acid in EOR. Volatile organic compounds (VOCs) released during the process can contribute to air pollution, potentially impacting local air quality and human health. These emissions may also contribute to the formation of ground-level ozone, a key component of smog, which can have detrimental effects on both human respiratory health and plant life.

The disposal of waste products from carbolic acid EOR presents additional environmental challenges. Proper treatment and disposal of contaminated water and other byproducts are essential to prevent further environmental damage. Inadequate handling of these wastes can lead to additional soil and water contamination, exacerbating the environmental impact of the EOR process.

Biodiversity loss is a potential long-term consequence of carbolic acid EOR. The cumulative effects of soil and water contamination can lead to habitat degradation, affecting both flora and fauna in the surrounding ecosystems. This can result in reduced species diversity and altered ecosystem functions, potentially impacting the overall ecological balance of the affected areas.

To mitigate these environmental risks, stringent regulations and best practices must be implemented in carbolic acid EOR operations. This includes proper containment and handling procedures, advanced treatment technologies for waste products, and comprehensive environmental monitoring programs. Additionally, research into more environmentally friendly alternatives or modifications to the carbolic acid EOR process is crucial for developing sustainable oil recovery techniques that minimize ecological impact while maintaining efficiency.

Soil contamination is a major concern when using carbolic acid in oil recovery. The chemical can leach into surrounding soil, altering its composition and potentially harming plant life. This contamination may persist for extended periods, affecting soil fertility and ecosystem balance long after the EOR operations have ceased. Furthermore, the alteration of soil chemistry can lead to changes in microbial communities, which play crucial roles in nutrient cycling and soil health.

Water pollution is another significant environmental risk. Carbolic acid can contaminate both surface and groundwater sources if not properly managed. This contamination can have far-reaching effects on aquatic ecosystems, potentially harming fish, amphibians, and other water-dependent organisms. The persistence of carbolic acid in water bodies can lead to long-term ecological damage and may pose risks to human health if the contaminated water is used for drinking or agricultural purposes.

Air quality can also be affected by the use of carbolic acid in EOR. Volatile organic compounds (VOCs) released during the process can contribute to air pollution, potentially impacting local air quality and human health. These emissions may also contribute to the formation of ground-level ozone, a key component of smog, which can have detrimental effects on both human respiratory health and plant life.

The disposal of waste products from carbolic acid EOR presents additional environmental challenges. Proper treatment and disposal of contaminated water and other byproducts are essential to prevent further environmental damage. Inadequate handling of these wastes can lead to additional soil and water contamination, exacerbating the environmental impact of the EOR process.

Biodiversity loss is a potential long-term consequence of carbolic acid EOR. The cumulative effects of soil and water contamination can lead to habitat degradation, affecting both flora and fauna in the surrounding ecosystems. This can result in reduced species diversity and altered ecosystem functions, potentially impacting the overall ecological balance of the affected areas.

To mitigate these environmental risks, stringent regulations and best practices must be implemented in carbolic acid EOR operations. This includes proper containment and handling procedures, advanced treatment technologies for waste products, and comprehensive environmental monitoring programs. Additionally, research into more environmentally friendly alternatives or modifications to the carbolic acid EOR process is crucial for developing sustainable oil recovery techniques that minimize ecological impact while maintaining efficiency.

Economic Feasibility of Carbolic Acid EOR

The economic feasibility of using carbolic acid for Enhanced Oil Recovery (EOR) is a critical consideration for oil companies looking to optimize their production processes. This analysis examines the cost-benefit ratio of implementing carbolic acid EOR techniques in comparison to conventional recovery methods.

Carbolic acid, also known as phenol, has shown promising results in laboratory studies and field trials for improving oil recovery rates. The primary economic advantage of carbolic acid EOR lies in its ability to increase oil production from existing wells, potentially extending the life of mature oil fields and maximizing the return on investment for drilling operations.

The implementation costs of carbolic acid EOR include the purchase of the chemical, modification of existing infrastructure, and operational expenses associated with injection and monitoring. These upfront costs must be weighed against the projected increase in oil recovery and the current market price of crude oil. Sensitivity analyses indicate that the economic viability of carbolic acid EOR is closely tied to oil prices, with higher prices generally favoring its adoption.

One of the key economic benefits of carbolic acid EOR is its potential to reduce the need for new well drilling, which can be a significant capital expense. By improving recovery rates from existing wells, companies can defer or avoid these costs while still maintaining or increasing production levels. This aspect is particularly attractive in regions where new drilling opportunities are limited or face regulatory challenges.

The environmental impact and associated regulatory compliance costs must also be factored into the economic assessment. While carbolic acid is generally considered less environmentally harmful than some other EOR chemicals, proper handling and disposal procedures are essential and may incur additional expenses. However, these costs may be offset by the reduced environmental footprint compared to more extensive drilling operations.

Long-term economic projections for carbolic acid EOR must consider the technology's scalability and the potential for cost reductions as the technique becomes more widely adopted. As with many emerging technologies in the oil and gas sector, economies of scale and learning curve effects are likely to improve the economic feasibility over time.

In conclusion, the economic feasibility of carbolic acid EOR appears promising, particularly for mature oil fields where conventional recovery methods are yielding diminishing returns. However, careful economic modeling and site-specific assessments are crucial to determine its viability for individual projects, taking into account factors such as reservoir characteristics, oil prices, and regulatory environments.

Carbolic acid, also known as phenol, has shown promising results in laboratory studies and field trials for improving oil recovery rates. The primary economic advantage of carbolic acid EOR lies in its ability to increase oil production from existing wells, potentially extending the life of mature oil fields and maximizing the return on investment for drilling operations.

The implementation costs of carbolic acid EOR include the purchase of the chemical, modification of existing infrastructure, and operational expenses associated with injection and monitoring. These upfront costs must be weighed against the projected increase in oil recovery and the current market price of crude oil. Sensitivity analyses indicate that the economic viability of carbolic acid EOR is closely tied to oil prices, with higher prices generally favoring its adoption.

One of the key economic benefits of carbolic acid EOR is its potential to reduce the need for new well drilling, which can be a significant capital expense. By improving recovery rates from existing wells, companies can defer or avoid these costs while still maintaining or increasing production levels. This aspect is particularly attractive in regions where new drilling opportunities are limited or face regulatory challenges.

The environmental impact and associated regulatory compliance costs must also be factored into the economic assessment. While carbolic acid is generally considered less environmentally harmful than some other EOR chemicals, proper handling and disposal procedures are essential and may incur additional expenses. However, these costs may be offset by the reduced environmental footprint compared to more extensive drilling operations.

Long-term economic projections for carbolic acid EOR must consider the technology's scalability and the potential for cost reductions as the technique becomes more widely adopted. As with many emerging technologies in the oil and gas sector, economies of scale and learning curve effects are likely to improve the economic feasibility over time.

In conclusion, the economic feasibility of carbolic acid EOR appears promising, particularly for mature oil fields where conventional recovery methods are yielding diminishing returns. However, careful economic modeling and site-specific assessments are crucial to determine its viability for individual projects, taking into account factors such as reservoir characteristics, oil prices, and regulatory environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!