Challenges in Miniaturizing V12 Engines for Compact Vehicles

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution

The V12 engine has a rich history dating back to the early 20th century. Initially developed for luxury automobiles and high-performance racing cars, V12 engines have long been synonymous with power, smoothness, and prestige. The evolution of V12 engines can be traced through several key phases, each marked by significant technological advancements and changing market demands.

In the 1920s and 1930s, V12 engines gained prominence in luxury vehicles and motorsports. Manufacturers like Packard, Cadillac, and Lincoln introduced V12 engines to their top-tier models, offering unparalleled smoothness and power for the era. During this period, V12 engines were large, heavy, and primarily focused on delivering maximum power output.

The post-World War II era saw a shift in V12 engine development. As fuel efficiency became more important, many manufacturers moved away from V12 engines in favor of smaller, more economical options. However, high-end luxury brands like Ferrari and Lamborghini continued to refine V12 designs, focusing on performance and exclusivity.

The 1960s and 1970s marked a renaissance for V12 engines in motorsports. Formula 1 racing saw the widespread adoption of V12 engines, pushing the boundaries of power-to-weight ratios and engine speeds. This era of competition drove significant advancements in materials science and engine design, many of which would later trickle down to production vehicles.

In the 1980s and 1990s, electronic fuel injection and engine management systems revolutionized V12 engine performance and efficiency. These technologies allowed for more precise control over fuel delivery and ignition timing, resulting in increased power output and improved fuel economy. During this period, V12 engines began to appear in a wider range of high-performance vehicles, including some more accessible sports cars.

The turn of the 21st century brought new challenges and opportunities for V12 engine development. Stricter emissions regulations and a growing focus on fuel efficiency led to the integration of technologies like variable valve timing, direct fuel injection, and cylinder deactivation. These advancements allowed V12 engines to maintain their performance characteristics while meeting increasingly stringent environmental standards.

Recent years have seen a renewed interest in V12 engines for ultra-luxury and hypercar applications. Manufacturers are exploring ways to combine V12 power with hybrid electric systems, aiming to balance performance with efficiency. This trend represents the latest evolution in V12 technology, as engineers work to adapt these iconic engines to the demands of a changing automotive landscape.

In the 1920s and 1930s, V12 engines gained prominence in luxury vehicles and motorsports. Manufacturers like Packard, Cadillac, and Lincoln introduced V12 engines to their top-tier models, offering unparalleled smoothness and power for the era. During this period, V12 engines were large, heavy, and primarily focused on delivering maximum power output.

The post-World War II era saw a shift in V12 engine development. As fuel efficiency became more important, many manufacturers moved away from V12 engines in favor of smaller, more economical options. However, high-end luxury brands like Ferrari and Lamborghini continued to refine V12 designs, focusing on performance and exclusivity.

The 1960s and 1970s marked a renaissance for V12 engines in motorsports. Formula 1 racing saw the widespread adoption of V12 engines, pushing the boundaries of power-to-weight ratios and engine speeds. This era of competition drove significant advancements in materials science and engine design, many of which would later trickle down to production vehicles.

In the 1980s and 1990s, electronic fuel injection and engine management systems revolutionized V12 engine performance and efficiency. These technologies allowed for more precise control over fuel delivery and ignition timing, resulting in increased power output and improved fuel economy. During this period, V12 engines began to appear in a wider range of high-performance vehicles, including some more accessible sports cars.

The turn of the 21st century brought new challenges and opportunities for V12 engine development. Stricter emissions regulations and a growing focus on fuel efficiency led to the integration of technologies like variable valve timing, direct fuel injection, and cylinder deactivation. These advancements allowed V12 engines to maintain their performance characteristics while meeting increasingly stringent environmental standards.

Recent years have seen a renewed interest in V12 engines for ultra-luxury and hypercar applications. Manufacturers are exploring ways to combine V12 power with hybrid electric systems, aiming to balance performance with efficiency. This trend represents the latest evolution in V12 technology, as engineers work to adapt these iconic engines to the demands of a changing automotive landscape.

Compact Vehicle Market

The compact vehicle market has experienced significant growth and transformation in recent years, driven by changing consumer preferences, urbanization trends, and environmental concerns. This segment primarily consists of small cars designed for efficient urban mobility, typically measuring between 3.5 to 4.2 meters in length. These vehicles offer advantages such as improved fuel efficiency, easier parking, and lower overall costs, making them particularly attractive to urban dwellers and budget-conscious consumers.

In developed markets like Europe and Japan, compact vehicles have long been popular due to space constraints and high fuel prices. However, emerging markets such as India, China, and Southeast Asian countries are now witnessing a surge in demand for these vehicles. This shift is attributed to rising disposable incomes, growing middle-class populations, and increasing traffic congestion in urban areas.

The global compact vehicle market size was valued at approximately $500 billion in 2020, with projections indicating steady growth over the next decade. Factors contributing to this growth include stricter emission regulations, advancements in electric and hybrid powertrains, and the integration of smart technologies in smaller vehicles.

Key players in the compact vehicle market include established automakers like Toyota, Volkswagen, Honda, and Renault-Nissan, as well as emerging brands from China and India. These companies are investing heavily in research and development to improve the performance, safety, and features of compact vehicles while maintaining their affordability.

One of the most significant trends in the compact vehicle market is the rapid electrification of this segment. Electric compact cars are gaining traction due to their lower operating costs, zero emissions, and improving range capabilities. Many governments are offering incentives for electric vehicle adoption, further driving demand in this sector.

Another notable trend is the increasing focus on advanced driver assistance systems (ADAS) and connectivity features in compact vehicles. Consumers now expect these smaller cars to offer similar technology and safety features as their larger counterparts, pushing manufacturers to innovate within the constraints of compact designs.

The compact vehicle market also faces challenges, including the need to balance affordability with advanced features, meeting stringent safety standards in smaller form factors, and addressing consumer perceptions about the comfort and performance of compact cars. Additionally, the growing popularity of compact SUVs and crossovers is creating competition within the broader small vehicle segment.

In developed markets like Europe and Japan, compact vehicles have long been popular due to space constraints and high fuel prices. However, emerging markets such as India, China, and Southeast Asian countries are now witnessing a surge in demand for these vehicles. This shift is attributed to rising disposable incomes, growing middle-class populations, and increasing traffic congestion in urban areas.

The global compact vehicle market size was valued at approximately $500 billion in 2020, with projections indicating steady growth over the next decade. Factors contributing to this growth include stricter emission regulations, advancements in electric and hybrid powertrains, and the integration of smart technologies in smaller vehicles.

Key players in the compact vehicle market include established automakers like Toyota, Volkswagen, Honda, and Renault-Nissan, as well as emerging brands from China and India. These companies are investing heavily in research and development to improve the performance, safety, and features of compact vehicles while maintaining their affordability.

One of the most significant trends in the compact vehicle market is the rapid electrification of this segment. Electric compact cars are gaining traction due to their lower operating costs, zero emissions, and improving range capabilities. Many governments are offering incentives for electric vehicle adoption, further driving demand in this sector.

Another notable trend is the increasing focus on advanced driver assistance systems (ADAS) and connectivity features in compact vehicles. Consumers now expect these smaller cars to offer similar technology and safety features as their larger counterparts, pushing manufacturers to innovate within the constraints of compact designs.

The compact vehicle market also faces challenges, including the need to balance affordability with advanced features, meeting stringent safety standards in smaller form factors, and addressing consumer perceptions about the comfort and performance of compact cars. Additionally, the growing popularity of compact SUVs and crossovers is creating competition within the broader small vehicle segment.

Miniaturization Hurdles

Miniaturizing V12 engines for compact vehicles presents significant technical challenges due to the inherent size and complexity of these powerplants. The primary hurdle lies in maintaining the performance characteristics and prestige associated with V12 engines while drastically reducing their physical dimensions.

One of the most pressing issues is thermal management. As engine components are packed more tightly together, heat dissipation becomes increasingly difficult. This can lead to overheating, reduced efficiency, and potential damage to critical engine parts. Engineers must develop innovative cooling systems and materials that can withstand higher temperatures in confined spaces.

Weight reduction is another crucial factor in the miniaturization process. V12 engines are traditionally heavy, which is at odds with the goal of creating compact, fuel-efficient vehicles. Lightweight materials such as advanced alloys and composites must be employed without compromising structural integrity or durability.

The complexity of the V12 configuration itself poses a significant challenge. With twelve cylinders, the engine requires intricate timing and balancing mechanisms. Miniaturizing these components while ensuring precise operation and minimal vibration is a formidable task that demands cutting-edge engineering solutions.

Fuel efficiency and emissions control become more challenging as engine size decreases. Smaller combustion chambers can lead to incomplete fuel burning, potentially increasing emissions. Advanced fuel injection systems, turbocharging, and hybrid technologies may need to be integrated to maintain performance while meeting stringent environmental regulations.

Packaging constraints present another obstacle. Fitting a V12 engine, even a miniaturized one, into a compact vehicle requires careful consideration of the entire drivetrain layout. This may necessitate redesigning transmission systems, exhaust configurations, and other auxiliary components to accommodate the engine within the limited space available.

Maintaining the characteristic sound and feel of a V12 engine in a smaller package is also crucial for preserving brand identity and customer satisfaction. Acoustic engineering and vibration control become critical aspects of the miniaturization process, requiring innovative solutions to replicate the signature V12 experience in a compact form factor.

Lastly, the cost implications of miniaturizing V12 engines cannot be overlooked. The research, development, and specialized manufacturing processes required for such engines can significantly increase production costs, potentially limiting their market viability in compact vehicles.

One of the most pressing issues is thermal management. As engine components are packed more tightly together, heat dissipation becomes increasingly difficult. This can lead to overheating, reduced efficiency, and potential damage to critical engine parts. Engineers must develop innovative cooling systems and materials that can withstand higher temperatures in confined spaces.

Weight reduction is another crucial factor in the miniaturization process. V12 engines are traditionally heavy, which is at odds with the goal of creating compact, fuel-efficient vehicles. Lightweight materials such as advanced alloys and composites must be employed without compromising structural integrity or durability.

The complexity of the V12 configuration itself poses a significant challenge. With twelve cylinders, the engine requires intricate timing and balancing mechanisms. Miniaturizing these components while ensuring precise operation and minimal vibration is a formidable task that demands cutting-edge engineering solutions.

Fuel efficiency and emissions control become more challenging as engine size decreases. Smaller combustion chambers can lead to incomplete fuel burning, potentially increasing emissions. Advanced fuel injection systems, turbocharging, and hybrid technologies may need to be integrated to maintain performance while meeting stringent environmental regulations.

Packaging constraints present another obstacle. Fitting a V12 engine, even a miniaturized one, into a compact vehicle requires careful consideration of the entire drivetrain layout. This may necessitate redesigning transmission systems, exhaust configurations, and other auxiliary components to accommodate the engine within the limited space available.

Maintaining the characteristic sound and feel of a V12 engine in a smaller package is also crucial for preserving brand identity and customer satisfaction. Acoustic engineering and vibration control become critical aspects of the miniaturization process, requiring innovative solutions to replicate the signature V12 experience in a compact form factor.

Lastly, the cost implications of miniaturizing V12 engines cannot be overlooked. The research, development, and specialized manufacturing processes required for such engines can significantly increase production costs, potentially limiting their market viability in compact vehicles.

Current Downsizing Tech

01 V12 Engine Displacement

V12 engines typically have large displacements, often ranging from 5.0 to 7.0 liters or more. The size of these engines contributes to their power output and smooth operation, making them suitable for high-performance and luxury vehicles.- V12 engine displacement and configuration: V12 engines typically have large displacements, often ranging from 5.0 to 7.0 liters or more. The V-configuration allows for a compact design while accommodating 12 cylinders, resulting in a powerful and smooth-running engine. These engines are commonly used in high-performance luxury vehicles and sports cars.

- Cylinder arrangement and dimensions: V12 engines feature two banks of six cylinders arranged in a V-shape. The angle between the cylinder banks can vary, with common configurations including 60-degree and 180-degree layouts. The cylinder dimensions, including bore and stroke, are carefully designed to optimize performance and efficiency while considering the overall engine size constraints.

- Engine block and crankcase design: The engine block and crankcase of V12 engines are designed to accommodate the large number of cylinders while maintaining structural integrity. Advanced materials and manufacturing techniques are employed to reduce weight and improve heat dissipation. The overall dimensions of the engine block are influenced by factors such as cylinder spacing and cooling system requirements.

- Cooling and lubrication systems: V12 engines require sophisticated cooling and lubrication systems due to their size and power output. The cooling system design must efficiently manage heat across all 12 cylinders, while the lubrication system ensures proper oil distribution throughout the engine. These systems contribute to the overall size and complexity of V12 engines.

- Performance characteristics and applications: V12 engines are known for their high power output, smooth operation, and distinctive sound. Their size and performance characteristics make them suitable for various applications, including luxury automobiles, high-performance sports cars, marine vessels, and even some aircraft. The engine's dimensions and weight are carefully considered in vehicle design to optimize performance and handling.

02 Compact V12 Engine Design

Some manufacturers have developed compact V12 engine designs to fit into smaller engine bays. These engines may have a reduced overall size while maintaining the characteristic V12 configuration and performance benefits.Expand Specific Solutions03 V12 Engine Block Dimensions

The physical dimensions of V12 engine blocks can vary depending on the specific design and application. Factors such as bore spacing, cylinder arrangement, and cooling system design influence the overall size of the engine block.Expand Specific Solutions04 V12 Engine Weight Considerations

The size of V12 engines often correlates with their weight. Manufacturers may employ lightweight materials and advanced design techniques to reduce the overall mass of these large engines, balancing performance with weight considerations.Expand Specific Solutions05 V12 Engine Cooling System Size

The size of V12 engines necessitates appropriately sized cooling systems. These may include larger radiators, oil coolers, and complex coolant passages within the engine block to manage the heat generated by the large displacement and high power output.Expand Specific Solutions

Key Engine Manufacturers

The miniaturization of V12 engines for compact vehicles presents a complex competitive landscape. The industry is in a transitional phase, with established automotive giants like Honda, Toyota, and Hyundai competing against specialized powertrain manufacturers such as BRP-Rotax and Aisin AW. The market size remains niche due to the challenges of fitting large engines into small spaces, but there's growing interest in high-performance compact vehicles. Technologically, companies like DENSO and Schaeffler are pushing boundaries in engine efficiency and miniaturization, while others like Panasonic and Hitachi contribute advanced electronic systems. The maturity of this technology varies, with some firms still in research stages while others have prototype systems, indicating a dynamic and evolving field.

Honda Motor Co., Ltd.

Technical Solution: Honda's approach to miniaturizing V12 engines for compact vehicles centers on their Earth Dreams Technology philosophy. Their compact V12 concept features a die-cast aluminum block with fiber-reinforced metal (FRM) cylinder liners for reduced weight and improved heat dissipation[7]. The engine utilizes a compact 60-degree V-angle and incorporates Honda's VTEC (Variable Valve Timing and Lift Electronic Control) system for optimized performance across the rev range. To address packaging concerns, Honda employs a dry-sump lubrication system, allowing for a lower engine placement and reduced overall height. The company also integrates a compact twin-scroll turbocharging system and direct injection for increased power density[8].

Strengths: Lightweight construction with advanced materials (FRM liners). Proven VTEC technology provides flexibility in engine operation. Weaknesses: Dry-sump system adds complexity and cost, potentially limiting application in more affordable compact vehicles.

Toyota Motor Corp.

Technical Solution: Toyota's approach to miniaturizing V12 engines focuses on a combination of innovative design and cutting-edge technology. Their compact V12 concept utilizes a high-strength, thin-wall cast iron block with aluminum heads to balance weight reduction and durability[3]. The engine features a narrow 60-degree V-angle to reduce width, along with a short-stroke design for decreased length. Toyota implements advanced thermal management systems, including precision cooling and integrated exhaust manifolds, to optimize packaging. The company also employs electrification in the form of a 48V mild hybrid system to supplement power and improve efficiency, allowing for further engine downsizing[4].

Strengths: Balanced approach to weight reduction and durability. Integration of hybrid technology allows for further miniaturization. Weaknesses: Cast iron block may still be heavier than all-aluminum designs, potentially limiting application in the smallest vehicle segments.

Innovative V12 Patents

Electric motor

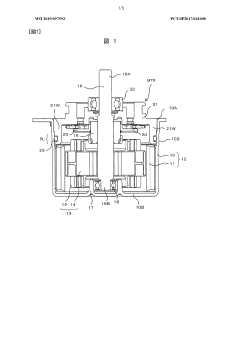

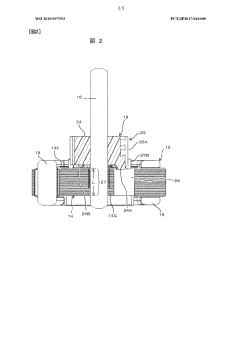

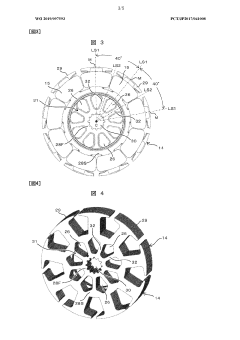

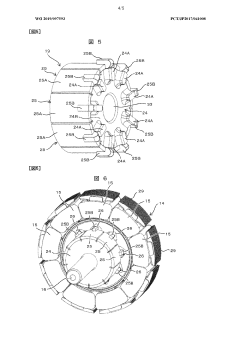

PatentWO2019097593A1

Innovation

- The formation of unit storage recesses at predetermined angle intervals on the rotor core's end face allows the hook portions of the commutator's conductive segments to be housed, ensuring a secure connection and sufficient axial length for reliable fastening between the rotor core and rotating shaft, while minimizing the motor's axial length.

Emissions Regulations

Emissions regulations have become a critical factor in the development and miniaturization of V12 engines for compact vehicles. As governments worldwide implement increasingly stringent emission standards, automakers face significant challenges in adapting high-performance engines to meet these requirements while maintaining their power and prestige.

The European Union's Euro 6d standards and the United States' Tier 3 regulations have set ambitious targets for reducing nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions. These standards have forced manufacturers to implement advanced emission control technologies, such as selective catalytic reduction (SCR) systems and gasoline particulate filters (GPF), which add complexity and weight to the engine package.

For V12 engines, which are inherently less fuel-efficient due to their large displacement and high cylinder count, meeting these standards becomes even more challenging when attempting to fit them into compact vehicles. The need for additional emission control equipment further complicates the space constraints and weight distribution issues already present in miniaturization efforts.

To address these challenges, manufacturers are exploring various strategies. One approach involves the integration of mild hybrid systems, which can assist in reducing emissions during low-load conditions and improve overall fuel efficiency. However, incorporating these systems adds further complexity to the already intricate packaging of a miniaturized V12 engine.

Another strategy focuses on advanced combustion technologies, such as lean-burn engines and homogeneous charge compression ignition (HCCI), which promise lower emissions and improved fuel economy. However, these technologies are still in development stages and face their own set of challenges in terms of control and stability, particularly in high-performance applications like V12 engines.

The use of lightweight materials and advanced manufacturing techniques, such as 3D printing for complex components, is also being explored to reduce the overall weight of the engine and its associated systems. This approach can help offset the additional weight of emission control equipment and improve the power-to-weight ratio of the vehicle.

As emission regulations continue to evolve, the future of V12 engines in compact vehicles remains uncertain. Some manufacturers may opt to downsize to smaller engine configurations or shift towards electrification to meet stringent emission targets. However, for those committed to preserving the V12 legacy, ongoing research and development in areas such as advanced materials, combustion technologies, and hybrid systems will be crucial in overcoming the emissions-related challenges of miniaturization.

The European Union's Euro 6d standards and the United States' Tier 3 regulations have set ambitious targets for reducing nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions. These standards have forced manufacturers to implement advanced emission control technologies, such as selective catalytic reduction (SCR) systems and gasoline particulate filters (GPF), which add complexity and weight to the engine package.

For V12 engines, which are inherently less fuel-efficient due to their large displacement and high cylinder count, meeting these standards becomes even more challenging when attempting to fit them into compact vehicles. The need for additional emission control equipment further complicates the space constraints and weight distribution issues already present in miniaturization efforts.

To address these challenges, manufacturers are exploring various strategies. One approach involves the integration of mild hybrid systems, which can assist in reducing emissions during low-load conditions and improve overall fuel efficiency. However, incorporating these systems adds further complexity to the already intricate packaging of a miniaturized V12 engine.

Another strategy focuses on advanced combustion technologies, such as lean-burn engines and homogeneous charge compression ignition (HCCI), which promise lower emissions and improved fuel economy. However, these technologies are still in development stages and face their own set of challenges in terms of control and stability, particularly in high-performance applications like V12 engines.

The use of lightweight materials and advanced manufacturing techniques, such as 3D printing for complex components, is also being explored to reduce the overall weight of the engine and its associated systems. This approach can help offset the additional weight of emission control equipment and improve the power-to-weight ratio of the vehicle.

As emission regulations continue to evolve, the future of V12 engines in compact vehicles remains uncertain. Some manufacturers may opt to downsize to smaller engine configurations or shift towards electrification to meet stringent emission targets. However, for those committed to preserving the V12 legacy, ongoing research and development in areas such as advanced materials, combustion technologies, and hybrid systems will be crucial in overcoming the emissions-related challenges of miniaturization.

Powertrain Integration

The integration of a miniaturized V12 engine into compact vehicles presents significant challenges in terms of powertrain design and packaging. The primary obstacle lies in accommodating the larger engine within the limited space of a compact vehicle's engine bay while maintaining optimal performance and efficiency.

One of the key considerations in powertrain integration is the arrangement of the engine and transmission. Traditional longitudinal engine placement may not be feasible due to space constraints, necessitating a transverse configuration. This shift requires a complete redesign of the engine mounting system, as well as modifications to the transmission and drivetrain components to ensure proper power transfer and weight distribution.

The cooling system for a miniaturized V12 engine in a compact vehicle demands innovative solutions. The increased heat generation from the powerful engine, coupled with the reduced space for radiators and cooling channels, requires advanced thermal management techniques. This may involve the use of high-efficiency heat exchangers, precision-engineered coolant flow paths, and potentially the integration of electric cooling fans to maintain optimal operating temperatures.

Exhaust system design becomes particularly challenging in this context. The complex manifold structure of a V12 engine must be carefully engineered to fit within the confined space while still providing efficient exhaust gas flow. This may necessitate the use of compact catalytic converters and innovative muffler designs to meet both space and emissions requirements.

The integration of auxiliary systems such as power steering, air conditioning, and electrical components also requires careful consideration. These systems must be redesigned or repositioned to accommodate the larger engine while maintaining accessibility for maintenance and repairs. In some cases, electrification of certain auxiliary systems may be necessary to reduce the overall package size and improve efficiency.

Weight distribution is another critical factor in powertrain integration for compact vehicles with miniaturized V12 engines. The heavier engine must be positioned to maintain proper front-to-rear and side-to-side balance, which may require adjustments to the vehicle's chassis and suspension systems. This could involve the use of lightweight materials in other areas of the vehicle to offset the increased engine weight.

Lastly, the integration process must address NVH (Noise, Vibration, and Harshness) concerns. The powerful V12 engine in a smaller vehicle body may lead to increased vibrations and noise levels. Advanced isolation techniques, such as active engine mounts and sound-dampening materials, may be necessary to ensure a comfortable driving experience that meets consumer expectations for a compact vehicle.

One of the key considerations in powertrain integration is the arrangement of the engine and transmission. Traditional longitudinal engine placement may not be feasible due to space constraints, necessitating a transverse configuration. This shift requires a complete redesign of the engine mounting system, as well as modifications to the transmission and drivetrain components to ensure proper power transfer and weight distribution.

The cooling system for a miniaturized V12 engine in a compact vehicle demands innovative solutions. The increased heat generation from the powerful engine, coupled with the reduced space for radiators and cooling channels, requires advanced thermal management techniques. This may involve the use of high-efficiency heat exchangers, precision-engineered coolant flow paths, and potentially the integration of electric cooling fans to maintain optimal operating temperatures.

Exhaust system design becomes particularly challenging in this context. The complex manifold structure of a V12 engine must be carefully engineered to fit within the confined space while still providing efficient exhaust gas flow. This may necessitate the use of compact catalytic converters and innovative muffler designs to meet both space and emissions requirements.

The integration of auxiliary systems such as power steering, air conditioning, and electrical components also requires careful consideration. These systems must be redesigned or repositioned to accommodate the larger engine while maintaining accessibility for maintenance and repairs. In some cases, electrification of certain auxiliary systems may be necessary to reduce the overall package size and improve efficiency.

Weight distribution is another critical factor in powertrain integration for compact vehicles with miniaturized V12 engines. The heavier engine must be positioned to maintain proper front-to-rear and side-to-side balance, which may require adjustments to the vehicle's chassis and suspension systems. This could involve the use of lightweight materials in other areas of the vehicle to offset the increased engine weight.

Lastly, the integration process must address NVH (Noise, Vibration, and Harshness) concerns. The powerful V12 engine in a smaller vehicle body may lead to increased vibrations and noise levels. Advanced isolation techniques, such as active engine mounts and sound-dampening materials, may be necessary to ensure a comfortable driving experience that meets consumer expectations for a compact vehicle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!