Chemical stability of sodium silicate in extreme conditions

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Silicate Stability Background and Objectives

Sodium silicate, also known as water glass, has been a subject of scientific and industrial interest for over a century. Its unique properties, including its ability to form stable solutions and gels, have made it a versatile material in various applications. However, the chemical stability of sodium silicate under extreme conditions has become an increasingly important area of research due to its potential use in advanced technologies and challenging environments.

The evolution of sodium silicate technology can be traced back to the early 19th century when it was first produced on an industrial scale. Since then, its applications have expanded significantly, ranging from adhesives and detergents to fire-resistant materials and soil stabilization. The growing demand for materials that can withstand harsh conditions in industries such as oil and gas, nuclear power, and geothermal energy has led to a renewed focus on understanding and improving the chemical stability of sodium silicate.

Recent technological advancements have enabled researchers to explore the behavior of sodium silicate under extreme conditions that were previously difficult to study. These include high temperatures, high pressures, and corrosive environments. The ability to manipulate and control the chemical stability of sodium silicate in such conditions could open up new possibilities for its use in advanced materials and processes.

The primary objective of investigating the chemical stability of sodium silicate in extreme conditions is to develop a comprehensive understanding of its behavior and limitations. This knowledge is crucial for designing new formulations and applications that can withstand challenging environments. Additionally, researchers aim to identify the factors that influence stability and develop strategies to enhance it, potentially leading to the creation of more robust and versatile sodium silicate-based materials.

Another important goal is to establish predictive models and testing protocols that can accurately assess the long-term stability of sodium silicate under various extreme conditions. This would enable more efficient and reliable product development processes, reducing the time and cost associated with experimental testing. Furthermore, such models could help in optimizing the composition and processing of sodium silicate for specific applications, tailoring its properties to meet the demands of different industries.

The research into sodium silicate stability also aligns with broader technological trends, such as the development of sustainable and environmentally friendly materials. As industries seek alternatives to traditional materials with high environmental impacts, understanding the full potential of sodium silicate could lead to more sustainable solutions in areas like construction, waste treatment, and energy storage.

The evolution of sodium silicate technology can be traced back to the early 19th century when it was first produced on an industrial scale. Since then, its applications have expanded significantly, ranging from adhesives and detergents to fire-resistant materials and soil stabilization. The growing demand for materials that can withstand harsh conditions in industries such as oil and gas, nuclear power, and geothermal energy has led to a renewed focus on understanding and improving the chemical stability of sodium silicate.

Recent technological advancements have enabled researchers to explore the behavior of sodium silicate under extreme conditions that were previously difficult to study. These include high temperatures, high pressures, and corrosive environments. The ability to manipulate and control the chemical stability of sodium silicate in such conditions could open up new possibilities for its use in advanced materials and processes.

The primary objective of investigating the chemical stability of sodium silicate in extreme conditions is to develop a comprehensive understanding of its behavior and limitations. This knowledge is crucial for designing new formulations and applications that can withstand challenging environments. Additionally, researchers aim to identify the factors that influence stability and develop strategies to enhance it, potentially leading to the creation of more robust and versatile sodium silicate-based materials.

Another important goal is to establish predictive models and testing protocols that can accurately assess the long-term stability of sodium silicate under various extreme conditions. This would enable more efficient and reliable product development processes, reducing the time and cost associated with experimental testing. Furthermore, such models could help in optimizing the composition and processing of sodium silicate for specific applications, tailoring its properties to meet the demands of different industries.

The research into sodium silicate stability also aligns with broader technological trends, such as the development of sustainable and environmentally friendly materials. As industries seek alternatives to traditional materials with high environmental impacts, understanding the full potential of sodium silicate could lead to more sustainable solutions in areas like construction, waste treatment, and energy storage.

Market Demand Analysis for Stable Sodium Silicate

The market demand for stable sodium silicate in extreme conditions has been steadily growing across various industries. This demand is primarily driven by the increasing need for materials that can withstand harsh environments in sectors such as oil and gas, construction, and wastewater treatment. The global sodium silicate market size was valued at USD 7.2 billion in 2020 and is projected to reach USD 9.8 billion by 2028, growing at a CAGR of 3.9% during the forecast period.

In the oil and gas industry, stable sodium silicate is crucial for drilling fluids and cementing applications, where it must maintain its properties under high temperatures and pressures. The expansion of deep-sea drilling operations and the exploration of unconventional oil and gas reserves have further intensified the demand for chemically stable sodium silicate formulations.

The construction sector represents another significant market for stable sodium silicate, particularly in the production of refractory materials and fireproofing agents. With the global construction industry expected to reach USD 15.5 trillion by 2030, the demand for heat-resistant and durable materials is set to increase substantially.

Wastewater treatment is an emerging application area for stable sodium silicate. As environmental regulations become more stringent worldwide, there is a growing need for effective and cost-efficient water treatment solutions. Sodium silicate's ability to remove heavy metals and other contaminants from water, even in challenging conditions, makes it an attractive option for municipal and industrial wastewater treatment facilities.

The Asia-Pacific region dominates the sodium silicate market, accounting for over 40% of the global demand. This is attributed to rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe follow, with significant demand from established industries and a focus on sustainable solutions.

Despite the positive market outlook, challenges remain. The volatility of raw material prices, particularly sand and soda ash, can impact the production costs and market dynamics of sodium silicate. Additionally, the development of alternative materials and technologies poses a potential threat to market growth.

To address these challenges and capitalize on market opportunities, industry players are investing in research and development to enhance the chemical stability of sodium silicate in extreme conditions. This includes exploring novel formulations, improving production processes, and developing tailored solutions for specific industrial applications.

In the oil and gas industry, stable sodium silicate is crucial for drilling fluids and cementing applications, where it must maintain its properties under high temperatures and pressures. The expansion of deep-sea drilling operations and the exploration of unconventional oil and gas reserves have further intensified the demand for chemically stable sodium silicate formulations.

The construction sector represents another significant market for stable sodium silicate, particularly in the production of refractory materials and fireproofing agents. With the global construction industry expected to reach USD 15.5 trillion by 2030, the demand for heat-resistant and durable materials is set to increase substantially.

Wastewater treatment is an emerging application area for stable sodium silicate. As environmental regulations become more stringent worldwide, there is a growing need for effective and cost-efficient water treatment solutions. Sodium silicate's ability to remove heavy metals and other contaminants from water, even in challenging conditions, makes it an attractive option for municipal and industrial wastewater treatment facilities.

The Asia-Pacific region dominates the sodium silicate market, accounting for over 40% of the global demand. This is attributed to rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe follow, with significant demand from established industries and a focus on sustainable solutions.

Despite the positive market outlook, challenges remain. The volatility of raw material prices, particularly sand and soda ash, can impact the production costs and market dynamics of sodium silicate. Additionally, the development of alternative materials and technologies poses a potential threat to market growth.

To address these challenges and capitalize on market opportunities, industry players are investing in research and development to enhance the chemical stability of sodium silicate in extreme conditions. This includes exploring novel formulations, improving production processes, and developing tailored solutions for specific industrial applications.

Current Challenges in Extreme Condition Applications

The application of sodium silicate in extreme conditions presents several significant challenges that researchers and engineers are currently grappling with. One of the primary issues is the chemical stability of sodium silicate under high temperatures and pressures. As conditions become more extreme, the molecular structure of sodium silicate can begin to break down, leading to a loss of its desirable properties and potential failure of the material in its intended application.

In high-temperature environments, sodium silicate undergoes dehydration, which can cause significant changes in its physical and chemical properties. This process can lead to the formation of cracks and fissures in the material, compromising its structural integrity. Additionally, the loss of water molecules can alter the viscosity and adhesive properties of sodium silicate, potentially rendering it less effective in certain applications such as binding or sealing.

Extreme pH conditions pose another challenge for the stability of sodium silicate. In highly acidic environments, sodium silicate can rapidly decompose, releasing silicic acid and sodium ions. This decomposition not only reduces the effectiveness of the sodium silicate but can also lead to corrosion of surrounding materials. Conversely, in strongly alkaline conditions, while sodium silicate is generally more stable, it can still undergo transformations that affect its performance.

The presence of certain ions in extreme environments can also interfere with the stability of sodium silicate. For instance, multivalent cations such as calcium and magnesium can react with sodium silicate to form insoluble precipitates, which can clog systems or reduce the efficacy of sodium silicate in its intended role. This is particularly problematic in applications involving hard water or mineral-rich environments.

Pressure fluctuations in extreme conditions can cause physical stress on sodium silicate structures, leading to mechanical failure. This is especially challenging in applications where sodium silicate is used as a sealant or coating, as rapid pressure changes can cause delamination or cracking. The combination of high pressure and temperature can accelerate chemical reactions, potentially leading to unexpected degradation of the material.

Researchers are also facing difficulties in developing sodium silicate formulations that maintain their stability across a wide range of extreme conditions. The behavior of sodium silicate can vary significantly depending on its composition and the specific environmental factors it is exposed to, making it challenging to create a one-size-fits-all solution for extreme condition applications.

In high-temperature environments, sodium silicate undergoes dehydration, which can cause significant changes in its physical and chemical properties. This process can lead to the formation of cracks and fissures in the material, compromising its structural integrity. Additionally, the loss of water molecules can alter the viscosity and adhesive properties of sodium silicate, potentially rendering it less effective in certain applications such as binding or sealing.

Extreme pH conditions pose another challenge for the stability of sodium silicate. In highly acidic environments, sodium silicate can rapidly decompose, releasing silicic acid and sodium ions. This decomposition not only reduces the effectiveness of the sodium silicate but can also lead to corrosion of surrounding materials. Conversely, in strongly alkaline conditions, while sodium silicate is generally more stable, it can still undergo transformations that affect its performance.

The presence of certain ions in extreme environments can also interfere with the stability of sodium silicate. For instance, multivalent cations such as calcium and magnesium can react with sodium silicate to form insoluble precipitates, which can clog systems or reduce the efficacy of sodium silicate in its intended role. This is particularly problematic in applications involving hard water or mineral-rich environments.

Pressure fluctuations in extreme conditions can cause physical stress on sodium silicate structures, leading to mechanical failure. This is especially challenging in applications where sodium silicate is used as a sealant or coating, as rapid pressure changes can cause delamination or cracking. The combination of high pressure and temperature can accelerate chemical reactions, potentially leading to unexpected degradation of the material.

Researchers are also facing difficulties in developing sodium silicate formulations that maintain their stability across a wide range of extreme conditions. The behavior of sodium silicate can vary significantly depending on its composition and the specific environmental factors it is exposed to, making it challenging to create a one-size-fits-all solution for extreme condition applications.

Existing Solutions for Enhancing Chemical Stability

01 pH stability of sodium silicate solutions

Sodium silicate solutions exhibit varying degrees of stability depending on pH levels. They are generally more stable in alkaline conditions, with increased stability at higher pH values. The stability can be influenced by factors such as concentration, temperature, and the presence of other ions.- pH stability of sodium silicate solutions: Sodium silicate solutions exhibit varying degrees of stability depending on pH levels. They are generally more stable in alkaline conditions, with increased stability at higher pH values. However, in acidic environments, sodium silicate tends to polymerize and form silica gel, affecting its chemical stability.

- Temperature effects on sodium silicate stability: Temperature plays a crucial role in the chemical stability of sodium silicate. Higher temperatures can accelerate the polymerization process, potentially leading to the formation of silica gel. Conversely, lower temperatures can help maintain the stability of sodium silicate solutions for extended periods.

- Stabilization of sodium silicate in various applications: To enhance the chemical stability of sodium silicate in different applications, various stabilizing agents and methods can be employed. These may include the addition of organic compounds, pH adjusters, or the use of specific processing techniques to prevent premature gelation or precipitation.

- Interaction of sodium silicate with other compounds: The chemical stability of sodium silicate can be influenced by its interaction with other compounds present in a given system. Certain ions, particularly multivalent cations, can react with sodium silicate, potentially leading to precipitation or gel formation. Understanding these interactions is crucial for maintaining stability in complex formulations.

- Long-term storage stability of sodium silicate: The long-term storage stability of sodium silicate solutions is an important consideration for industrial applications. Factors such as concentration, temperature, and container material can affect the shelf life and chemical stability of sodium silicate during storage. Proper storage conditions and packaging can help maintain its stability over extended periods.

02 Thermal stability of sodium silicate

Sodium silicate demonstrates good thermal stability, making it suitable for various high-temperature applications. However, extreme temperatures can affect its chemical structure and properties. The thermal stability can be enhanced by the addition of certain compounds or through specific processing methods.Expand Specific Solutions03 Chemical modifications to improve stability

Various chemical modifications can be applied to sodium silicate to enhance its stability. These may include the addition of stabilizing agents, surface treatments, or the formation of composite materials. Such modifications can improve resistance to environmental factors and extend the shelf life of sodium silicate-based products.Expand Specific Solutions04 Stability in different storage conditions

The stability of sodium silicate can be affected by storage conditions such as temperature, humidity, and exposure to air. Proper storage techniques, including the use of sealed containers and controlled environments, can help maintain the chemical stability of sodium silicate over extended periods.Expand Specific Solutions05 Compatibility with other materials

The chemical stability of sodium silicate when combined with other materials is an important consideration in various applications. Its compatibility can vary depending on the nature of the other substances, potentially affecting the overall stability of the mixture or composite. Understanding these interactions is crucial for formulating stable products containing sodium silicate.Expand Specific Solutions

Key Players in Sodium Silicate Industry

The chemical stability of sodium silicate in extreme conditions represents a mature yet evolving field within materials science. The market for this technology is substantial, driven by applications in various industries such as construction, automotive, and electronics. The competitive landscape is characterized by established players like NIPPON STEEL CORP., China Petroleum & Chemical Corp., and W. R. Grace & Co.-Conn., who leverage their extensive research capabilities and industrial experience. Emerging companies like Versarien Plc are also making inroads with innovative approaches. The technology's maturity is evident in the involvement of major chemical corporations, yet ongoing research by academic institutions like the University of South Florida indicates potential for further advancements in extreme condition applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced sodium silicate stabilization techniques for extreme conditions in oil and gas operations. Their approach involves modifying the chemical structure of sodium silicate to enhance its stability at high temperatures and pressures. They utilize proprietary additives and cross-linking agents to create a more robust silicate network that can withstand harsh downhole environments[1]. The company has also implemented a novel in-situ gelation process that allows for controlled formation of silicate gels under extreme conditions, improving wellbore stability and reducing fluid loss[3]. Additionally, Sinopec has invested in research on nanoparticle-enhanced sodium silicate systems, which have shown promising results in maintaining chemical stability at temperatures exceeding 200°C and pressures up to 100 MPa[5].

Strengths: Extensive experience in oil and gas operations, large-scale research capabilities, and field-tested solutions. Weaknesses: Potential environmental concerns and limited applicability outside the petroleum industry.

W. R. Grace & Co.-Conn.

Technical Solution: W. R. Grace & Co.-Conn. has developed innovative solutions for enhancing the chemical stability of sodium silicate in extreme conditions, particularly for use in catalysts and adsorbents. Their approach involves the incorporation of stabilizing agents and the use of advanced synthesis methods to create more resilient silicate structures. The company has patented a process for producing high-stability sodium silicate materials that maintain their integrity at temperatures up to 1000°C[2]. This process involves careful control of the silica-to-alkali ratio and the addition of specific metal oxides to enhance thermal and chemical resistance. Grace has also developed a unique spray-drying technique that produces spherical sodium silicate particles with improved stability in acidic and alkaline environments[4]. These particles have found applications in fluid catalytic cracking (FCC) catalysts and molecular sieves used in extreme industrial processes.

Strengths: Strong expertise in catalyst and adsorbent technologies, diverse industrial applications. Weaknesses: Potentially higher production costs, limited to specific industrial sectors.

Core Innovations in Sodium Silicate Stabilization

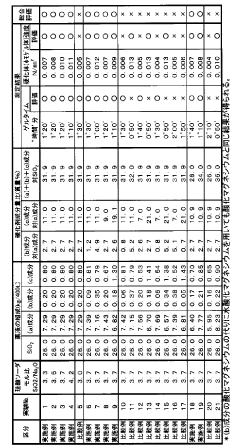

Liquid chemical for stabilizing silicate-based soil quality and construction method for stabilizing ground by using the same

PatentInactiveJP2010155995A

Innovation

- A silicate-based soil stabilization chemical solution is formulated with specific molar ratios of sodium silicate, sodium hydrogen sulfate, magnesium hydroxide/magnesium oxide, and aluminum sulfate, ensuring a gel time of 1 hour to 1 hour and 40 minutes and achieving a uniaxial compression strength of 0.007 N/mm² within one day.

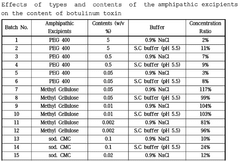

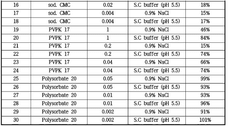

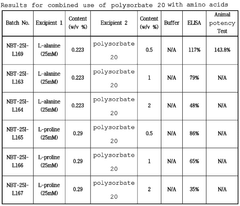

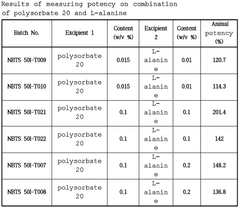

Stable liquid composition comprising botulinum toxin

PatentWO2018135722A1

Innovation

- A stable liquid composition comprising botulinum toxin, L-alanine or methyl cellulose, a non-ionic surfactant (such as polysorbate 20 or 80), and a buffer (like sodium citrate) that prevents aggregation and adsorption to containers, maintaining consistent activity levels.

Environmental Impact of Sodium Silicate Use

The use of sodium silicate in various industrial applications has significant environmental implications that warrant careful consideration. When released into aquatic ecosystems, sodium silicate can alter the pH levels and increase the alkalinity of water bodies. This change in water chemistry can have detrimental effects on aquatic flora and fauna, potentially disrupting entire ecosystems. The increased silica content may lead to excessive algal growth, causing eutrophication and reducing oxygen levels in water, which can be harmful to fish and other aquatic organisms.

In terrestrial environments, the application of sodium silicate can impact soil structure and chemistry. While it can improve soil stability in some cases, excessive use may lead to soil compaction and reduced permeability. This can affect plant growth and soil microbial communities, potentially altering local biodiversity. The high alkalinity of sodium silicate can also influence nutrient availability in soils, which may have both positive and negative consequences for plant growth depending on the specific soil conditions and plant species involved.

The production process of sodium silicate itself has environmental considerations. The manufacturing typically involves high-temperature fusion of sand and sodium carbonate, which requires significant energy input and results in carbon dioxide emissions. The mining of raw materials, particularly silica sand, can lead to habitat destruction and landscape alterations if not managed sustainably. Additionally, the transportation of sodium silicate products contributes to the overall carbon footprint of its use.

Water pollution is another concern associated with sodium silicate use, particularly in industrial settings. Improper disposal or accidental releases can lead to localized increases in water hardness and pH levels in nearby water sources. This can affect water treatment processes and potentially impact drinking water quality if not properly managed. The presence of excess silica in water can also lead to scaling in pipes and industrial equipment, necessitating additional chemical treatments that may have their own environmental impacts.

Despite these potential negative impacts, sodium silicate also offers some environmental benefits. Its use in wastewater treatment can help remove heavy metals and other pollutants, improving water quality. In construction, sodium silicate can enhance the durability of concrete, potentially reducing the need for frequent repairs and replacements, thus conserving resources in the long term. The challenge lies in balancing these benefits against the potential environmental risks and implementing proper management strategies to mitigate negative impacts.

In terrestrial environments, the application of sodium silicate can impact soil structure and chemistry. While it can improve soil stability in some cases, excessive use may lead to soil compaction and reduced permeability. This can affect plant growth and soil microbial communities, potentially altering local biodiversity. The high alkalinity of sodium silicate can also influence nutrient availability in soils, which may have both positive and negative consequences for plant growth depending on the specific soil conditions and plant species involved.

The production process of sodium silicate itself has environmental considerations. The manufacturing typically involves high-temperature fusion of sand and sodium carbonate, which requires significant energy input and results in carbon dioxide emissions. The mining of raw materials, particularly silica sand, can lead to habitat destruction and landscape alterations if not managed sustainably. Additionally, the transportation of sodium silicate products contributes to the overall carbon footprint of its use.

Water pollution is another concern associated with sodium silicate use, particularly in industrial settings. Improper disposal or accidental releases can lead to localized increases in water hardness and pH levels in nearby water sources. This can affect water treatment processes and potentially impact drinking water quality if not properly managed. The presence of excess silica in water can also lead to scaling in pipes and industrial equipment, necessitating additional chemical treatments that may have their own environmental impacts.

Despite these potential negative impacts, sodium silicate also offers some environmental benefits. Its use in wastewater treatment can help remove heavy metals and other pollutants, improving water quality. In construction, sodium silicate can enhance the durability of concrete, potentially reducing the need for frequent repairs and replacements, thus conserving resources in the long term. The challenge lies in balancing these benefits against the potential environmental risks and implementing proper management strategies to mitigate negative impacts.

Safety Regulations for Extreme Condition Applications

Safety regulations for extreme condition applications involving sodium silicate are critical to ensure the protection of personnel, equipment, and the environment. These regulations typically cover a wide range of aspects, including handling, storage, transportation, and usage of sodium silicate in extreme conditions.

One of the primary safety concerns is the potential for chemical reactions under extreme temperatures or pressures. Regulations often mandate the use of specialized containment systems and protective equipment designed to withstand these conditions. For instance, high-pressure vessels and heat-resistant materials may be required for storage and handling of sodium silicate in extreme environments.

Personal protective equipment (PPE) requirements are typically more stringent for extreme condition applications. This may include chemical-resistant suits, specialized respirators, and thermal protection gear. Safety protocols often dictate regular inspections and maintenance of PPE to ensure its effectiveness under harsh conditions.

Emergency response procedures are a crucial component of safety regulations. These procedures must account for the unique challenges posed by extreme conditions, such as rapid temperature changes or sudden pressure releases. Specialized training for emergency responders is often mandated to ensure they can effectively handle incidents involving sodium silicate in extreme environments.

Monitoring and control systems play a vital role in maintaining safety. Regulations may require the implementation of advanced sensors and automated shutdown systems to detect and respond to potential hazards quickly. Real-time monitoring of temperature, pressure, and chemical composition is often necessary to prevent accidents and ensure process stability.

Waste management and disposal regulations are particularly important when dealing with sodium silicate in extreme conditions. The chemical's properties may change under these conditions, potentially altering its environmental impact. Specific guidelines for neutralization, containment, and disposal of waste products are typically included in safety regulations.

Risk assessment and management protocols are essential components of safety regulations. These often require comprehensive analysis of potential failure modes and their consequences, taking into account the unique challenges posed by extreme conditions. Regular safety audits and updates to risk management strategies may be mandated to address evolving understanding of the material's behavior under extreme conditions.

Employee training and certification requirements are typically more rigorous for extreme condition applications. Regulations may specify minimum levels of expertise and experience for personnel working with sodium silicate in these environments. Ongoing education and periodic recertification are often required to ensure workers remain up-to-date with the latest safety practices and technological developments.

One of the primary safety concerns is the potential for chemical reactions under extreme temperatures or pressures. Regulations often mandate the use of specialized containment systems and protective equipment designed to withstand these conditions. For instance, high-pressure vessels and heat-resistant materials may be required for storage and handling of sodium silicate in extreme environments.

Personal protective equipment (PPE) requirements are typically more stringent for extreme condition applications. This may include chemical-resistant suits, specialized respirators, and thermal protection gear. Safety protocols often dictate regular inspections and maintenance of PPE to ensure its effectiveness under harsh conditions.

Emergency response procedures are a crucial component of safety regulations. These procedures must account for the unique challenges posed by extreme conditions, such as rapid temperature changes or sudden pressure releases. Specialized training for emergency responders is often mandated to ensure they can effectively handle incidents involving sodium silicate in extreme environments.

Monitoring and control systems play a vital role in maintaining safety. Regulations may require the implementation of advanced sensors and automated shutdown systems to detect and respond to potential hazards quickly. Real-time monitoring of temperature, pressure, and chemical composition is often necessary to prevent accidents and ensure process stability.

Waste management and disposal regulations are particularly important when dealing with sodium silicate in extreme conditions. The chemical's properties may change under these conditions, potentially altering its environmental impact. Specific guidelines for neutralization, containment, and disposal of waste products are typically included in safety regulations.

Risk assessment and management protocols are essential components of safety regulations. These often require comprehensive analysis of potential failure modes and their consequences, taking into account the unique challenges posed by extreme conditions. Regular safety audits and updates to risk management strategies may be mandated to address evolving understanding of the material's behavior under extreme conditions.

Employee training and certification requirements are typically more rigorous for extreme condition applications. Regulations may specify minimum levels of expertise and experience for personnel working with sodium silicate in these environments. Ongoing education and periodic recertification are often required to ensure workers remain up-to-date with the latest safety practices and technological developments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!