Comparative analysis of plasma-sprayed versus EB-PVD thermal barrier coatings ceramics

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TBC Evolution and Objectives

Thermal Barrier Coatings (TBCs) have evolved significantly since their inception in the 1960s, initially developed for aerospace applications to protect engine components from extreme temperatures. The evolution of TBCs represents a critical advancement in materials science, enabling gas turbines to operate at higher temperatures and thereby increasing efficiency and performance. Early TBC systems consisted primarily of simple ceramic layers with limited durability and thermal resistance properties.

The technological progression of TBCs has been driven by the continuous demand for higher operating temperatures in turbine engines, with each advancement pushing the temperature capability further. From the 1970s to 1990s, significant improvements were made in coating composition, particularly with the standardization of yttria-stabilized zirconia (YSZ) as the primary ceramic material due to its exceptional thermal insulation properties and phase stability at high temperatures.

The application methods for TBCs have evolved along two primary paths: plasma spraying (PS) and electron beam physical vapor deposition (EB-PVD). Plasma spraying, developed earlier, offered a cost-effective solution with good thermal insulation but faced challenges with erosion resistance and strain tolerance. EB-PVD emerged later as a premium alternative, providing superior strain tolerance through its columnar microstructure, albeit at higher production costs.

Recent technological trends show increasing research focus on developing advanced ceramic compositions beyond traditional YSZ, including gadolinium zirconate and lanthanum zirconate, which offer improved phase stability and reduced thermal conductivity. Additionally, there is growing interest in multilayer and functionally graded coating architectures that can better accommodate thermal stresses and extend coating lifespans.

The primary objective of current TBC research is to enhance durability while maintaining or improving thermal insulation properties. This includes developing coatings that resist sintering at high temperatures, maintain phase stability during thermal cycling, and provide improved resistance to environmental contaminants such as calcium-magnesium-alumino-silicates (CMAS) that can cause severe degradation.

Another critical goal is to develop more efficient and cost-effective deposition methods that combine the advantages of both PS and EB-PVD techniques. This includes exploring hybrid approaches and novel deposition technologies that can achieve the columnar structure of EB-PVD coatings at costs closer to those of plasma spraying.

Understanding the fundamental differences between plasma-sprayed and EB-PVD coatings in terms of microstructure, thermal properties, and failure mechanisms remains essential for advancing TBC technology and meeting the increasingly demanding requirements of modern high-temperature applications.

The technological progression of TBCs has been driven by the continuous demand for higher operating temperatures in turbine engines, with each advancement pushing the temperature capability further. From the 1970s to 1990s, significant improvements were made in coating composition, particularly with the standardization of yttria-stabilized zirconia (YSZ) as the primary ceramic material due to its exceptional thermal insulation properties and phase stability at high temperatures.

The application methods for TBCs have evolved along two primary paths: plasma spraying (PS) and electron beam physical vapor deposition (EB-PVD). Plasma spraying, developed earlier, offered a cost-effective solution with good thermal insulation but faced challenges with erosion resistance and strain tolerance. EB-PVD emerged later as a premium alternative, providing superior strain tolerance through its columnar microstructure, albeit at higher production costs.

Recent technological trends show increasing research focus on developing advanced ceramic compositions beyond traditional YSZ, including gadolinium zirconate and lanthanum zirconate, which offer improved phase stability and reduced thermal conductivity. Additionally, there is growing interest in multilayer and functionally graded coating architectures that can better accommodate thermal stresses and extend coating lifespans.

The primary objective of current TBC research is to enhance durability while maintaining or improving thermal insulation properties. This includes developing coatings that resist sintering at high temperatures, maintain phase stability during thermal cycling, and provide improved resistance to environmental contaminants such as calcium-magnesium-alumino-silicates (CMAS) that can cause severe degradation.

Another critical goal is to develop more efficient and cost-effective deposition methods that combine the advantages of both PS and EB-PVD techniques. This includes exploring hybrid approaches and novel deposition technologies that can achieve the columnar structure of EB-PVD coatings at costs closer to those of plasma spraying.

Understanding the fundamental differences between plasma-sprayed and EB-PVD coatings in terms of microstructure, thermal properties, and failure mechanisms remains essential for advancing TBC technology and meeting the increasingly demanding requirements of modern high-temperature applications.

Market Demand Analysis for Advanced TBCs

The global market for Thermal Barrier Coatings (TBCs) has been experiencing robust growth, driven by increasing demand across aerospace, power generation, and automotive industries. Current market valuations place the TBC sector at approximately 1.5 billion USD, with projections indicating a compound annual growth rate of 6.8% through 2028.

Aerospace remains the dominant application segment, accounting for nearly 40% of the total TBC market. This dominance stems from the critical need for high-performance coatings that can withstand extreme operating temperatures in aircraft engines, where efficiency improvements directly correlate with temperature capabilities. Commercial aviation's recovery post-pandemic has further accelerated demand for advanced TBCs that can extend component lifespans and reduce maintenance costs.

The power generation sector represents the second-largest market for TBCs, particularly in gas turbine applications. As global energy demands rise and efficiency standards become more stringent, power generation companies are increasingly investing in advanced coating technologies that can improve thermal efficiency and reduce emissions. This sector has shown particular interest in comparing plasma-sprayed versus EB-PVD coating technologies to optimize performance-to-cost ratios.

Regional analysis reveals that North America and Europe currently lead the TBC market, collectively holding approximately 60% market share. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate due to expanding aerospace manufacturing capabilities and increasing power generation infrastructure development.

Customer requirements are evolving beyond traditional performance metrics. While thermal conductivity and temperature resistance remain primary considerations, there is growing emphasis on coating durability, erosion resistance, and lifecycle cost analysis. This shift has intensified interest in comparative analyses between plasma-sprayed and EB-PVD ceramic coatings, with customers seeking quantifiable data on long-term performance under various operating conditions.

Industry surveys indicate that approximately 70% of end-users are willing to pay premium prices for TBCs that demonstrably extend component life by at least 20%. This value proposition is particularly strong in aerospace applications, where component replacement and maintenance downtime carry substantial financial implications.

Environmental regulations are also shaping market demand, with increasing pressure to reduce emissions driving interest in coatings that enable higher operating temperatures and improved combustion efficiency. This regulatory landscape favors advanced TBCs that can withstand more extreme thermal cycling while maintaining structural integrity.

Aerospace remains the dominant application segment, accounting for nearly 40% of the total TBC market. This dominance stems from the critical need for high-performance coatings that can withstand extreme operating temperatures in aircraft engines, where efficiency improvements directly correlate with temperature capabilities. Commercial aviation's recovery post-pandemic has further accelerated demand for advanced TBCs that can extend component lifespans and reduce maintenance costs.

The power generation sector represents the second-largest market for TBCs, particularly in gas turbine applications. As global energy demands rise and efficiency standards become more stringent, power generation companies are increasingly investing in advanced coating technologies that can improve thermal efficiency and reduce emissions. This sector has shown particular interest in comparing plasma-sprayed versus EB-PVD coating technologies to optimize performance-to-cost ratios.

Regional analysis reveals that North America and Europe currently lead the TBC market, collectively holding approximately 60% market share. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate due to expanding aerospace manufacturing capabilities and increasing power generation infrastructure development.

Customer requirements are evolving beyond traditional performance metrics. While thermal conductivity and temperature resistance remain primary considerations, there is growing emphasis on coating durability, erosion resistance, and lifecycle cost analysis. This shift has intensified interest in comparative analyses between plasma-sprayed and EB-PVD ceramic coatings, with customers seeking quantifiable data on long-term performance under various operating conditions.

Industry surveys indicate that approximately 70% of end-users are willing to pay premium prices for TBCs that demonstrably extend component life by at least 20%. This value proposition is particularly strong in aerospace applications, where component replacement and maintenance downtime carry substantial financial implications.

Environmental regulations are also shaping market demand, with increasing pressure to reduce emissions driving interest in coatings that enable higher operating temperatures and improved combustion efficiency. This regulatory landscape favors advanced TBCs that can withstand more extreme thermal cycling while maintaining structural integrity.

Current State and Challenges of Coating Technologies

Thermal Barrier Coatings (TBCs) have become essential components in high-temperature applications, particularly in gas turbine engines. Currently, two dominant technologies exist in the market: Plasma-Sprayed (PS) and Electron Beam Physical Vapor Deposition (EB-PVD) coatings. The global market for these advanced ceramic coatings reached approximately $11 billion in 2022, with a projected CAGR of 7.2% through 2028, indicating significant industrial interest and investment.

Plasma-sprayed coatings currently dominate the market with approximately 65% share due to their cost-effectiveness and established manufacturing infrastructure. These coatings feature a characteristic splat-like microstructure with 15-25% porosity and inter-splat boundaries that provide thermal insulation benefits. However, they exhibit lower strain tolerance compared to EB-PVD alternatives, limiting their durability in applications with frequent thermal cycling.

EB-PVD coatings, representing about 30% of the market, feature a distinctive columnar microstructure that provides superior strain tolerance and erosion resistance. This technology has seen accelerated adoption in aerospace applications, particularly in high-performance military and commercial aircraft engines. The remaining 5% of the market consists of emerging technologies such as suspension plasma spray and solution precursor plasma spray methods.

A significant technical challenge facing both technologies is the trade-off between thermal insulation performance and mechanical durability. Higher porosity improves thermal insulation but typically compromises structural integrity. Recent research has focused on developing compositionally graded structures and novel ceramic compositions to overcome this limitation, with yttria-stabilized zirconia (YSZ) remaining the industry standard material despite its temperature limitations.

Geographical distribution of these technologies shows concentration in North America (35%), Europe (30%), and Asia-Pacific (25%), with emerging markets accounting for the remainder. The United States, Germany, Japan, and China lead in both research output and patent filings, with China showing the most rapid growth in technological capabilities over the past decade.

Manufacturing scalability presents another significant challenge, particularly for EB-PVD technology, which requires sophisticated vacuum equipment and precise process control. Current EB-PVD systems have limited deposition rates (typically 3-5 μm/min) compared to plasma spray methods (10-15 μm/min), creating production bottlenecks for high-volume applications.

Environmental considerations are increasingly influencing technology development, with regulatory pressure to reduce hazardous materials usage and energy consumption. Plasma spray processes typically consume 30-40% more energy than EB-PVD per unit area coated, though recent advancements in equipment efficiency have narrowed this gap.

Plasma-sprayed coatings currently dominate the market with approximately 65% share due to their cost-effectiveness and established manufacturing infrastructure. These coatings feature a characteristic splat-like microstructure with 15-25% porosity and inter-splat boundaries that provide thermal insulation benefits. However, they exhibit lower strain tolerance compared to EB-PVD alternatives, limiting their durability in applications with frequent thermal cycling.

EB-PVD coatings, representing about 30% of the market, feature a distinctive columnar microstructure that provides superior strain tolerance and erosion resistance. This technology has seen accelerated adoption in aerospace applications, particularly in high-performance military and commercial aircraft engines. The remaining 5% of the market consists of emerging technologies such as suspension plasma spray and solution precursor plasma spray methods.

A significant technical challenge facing both technologies is the trade-off between thermal insulation performance and mechanical durability. Higher porosity improves thermal insulation but typically compromises structural integrity. Recent research has focused on developing compositionally graded structures and novel ceramic compositions to overcome this limitation, with yttria-stabilized zirconia (YSZ) remaining the industry standard material despite its temperature limitations.

Geographical distribution of these technologies shows concentration in North America (35%), Europe (30%), and Asia-Pacific (25%), with emerging markets accounting for the remainder. The United States, Germany, Japan, and China lead in both research output and patent filings, with China showing the most rapid growth in technological capabilities over the past decade.

Manufacturing scalability presents another significant challenge, particularly for EB-PVD technology, which requires sophisticated vacuum equipment and precise process control. Current EB-PVD systems have limited deposition rates (typically 3-5 μm/min) compared to plasma spray methods (10-15 μm/min), creating production bottlenecks for high-volume applications.

Environmental considerations are increasingly influencing technology development, with regulatory pressure to reduce hazardous materials usage and energy consumption. Plasma spray processes typically consume 30-40% more energy than EB-PVD per unit area coated, though recent advancements in equipment efficiency have narrowed this gap.

Comparative Analysis of PS vs EB-PVD Solutions

01 Yttria-stabilized zirconia (YSZ) thermal barrier coatings

Yttria-stabilized zirconia (YSZ) is widely used as a thermal barrier coating material due to its excellent thermal insulation properties and phase stability at high temperatures. These coatings are typically applied using techniques such as plasma spraying or electron beam physical vapor deposition (EB-PVD) to create a ceramic layer that protects underlying metal components from extreme temperatures in gas turbines and other high-temperature applications.- Yttria-stabilized zirconia (YSZ) thermal barrier coatings: Yttria-stabilized zirconia (YSZ) is widely used as a thermal barrier coating material due to its excellent thermal insulation properties and high temperature stability. These coatings provide protection for metal components in high-temperature environments such as gas turbine engines. The addition of yttria to zirconia stabilizes the crystal structure and prevents phase transformations that could lead to coating failure during thermal cycling.

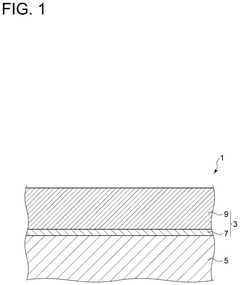

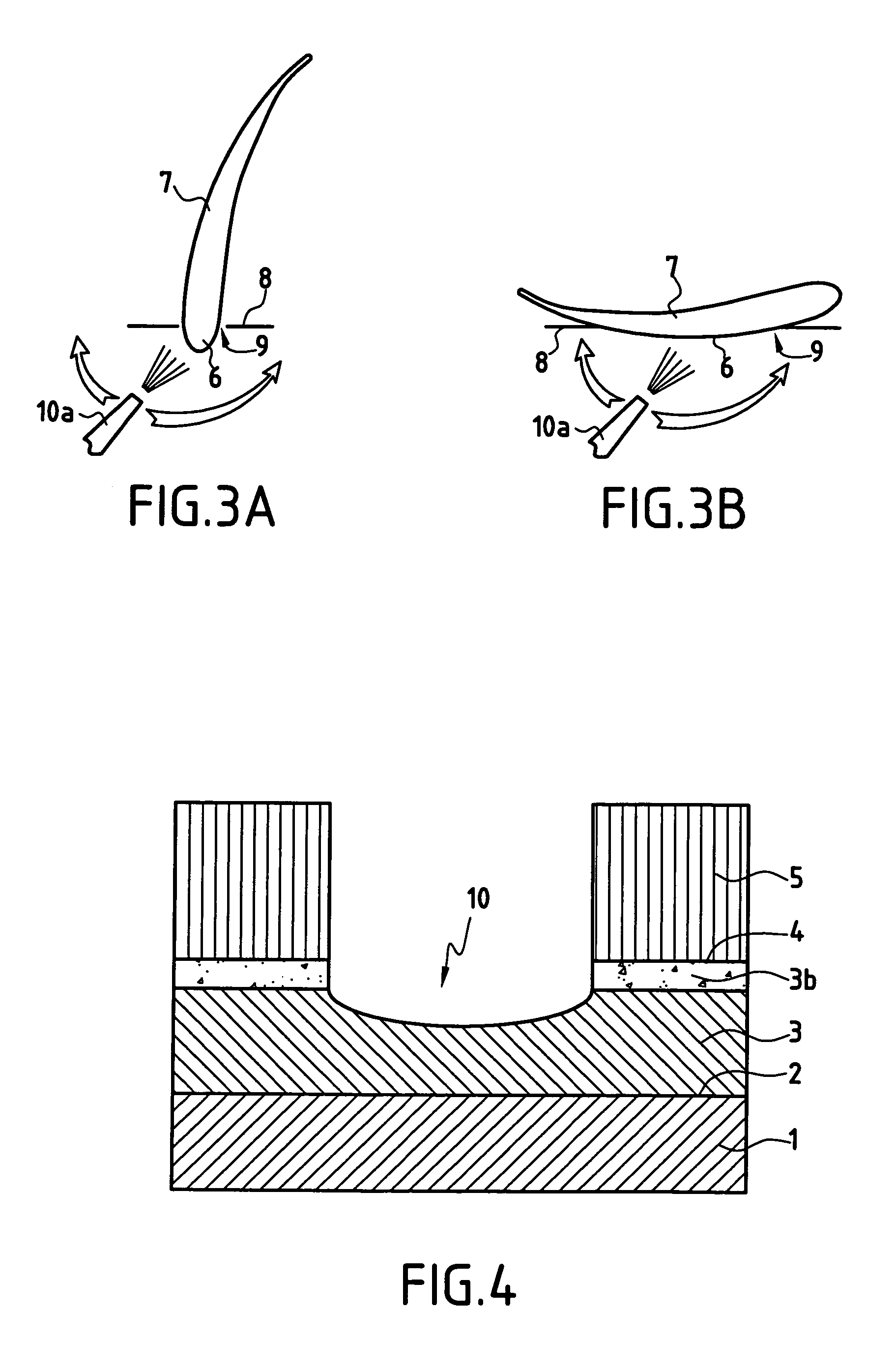

- Multi-layer ceramic thermal barrier coating systems: Multi-layer ceramic coating systems consist of different ceramic layers with complementary properties to enhance overall thermal barrier performance. These systems typically include a bond coat layer, a thermally grown oxide layer, and a ceramic top coat. The multi-layer approach allows for optimization of properties such as thermal insulation, erosion resistance, and adhesion to the substrate, resulting in improved durability and longer service life of components exposed to extreme temperatures.

- Advanced deposition techniques for ceramic thermal barrier coatings: Various deposition techniques are employed to apply ceramic thermal barrier coatings, including plasma spraying, electron beam physical vapor deposition (EB-PVD), and solution precursor plasma spray. These methods control the microstructure of the coating, which directly affects its thermal insulation properties and durability. Advanced deposition techniques can create columnar structures, segmented microstructures, or porosity gradients that enhance strain tolerance and reduce thermal conductivity of the ceramic coating.

- Novel ceramic compositions for enhanced thermal barrier performance: Research on novel ceramic compositions focuses on developing materials with lower thermal conductivity and higher temperature capability than conventional yttria-stabilized zirconia. These include rare-earth zirconates, hafnates, pyrochlores, and perovskites. The incorporation of rare-earth elements and the creation of complex oxide structures can significantly reduce thermal conductivity while maintaining necessary mechanical properties and phase stability at elevated temperatures, leading to more efficient thermal barrier systems.

- Self-healing and environmental barrier ceramic coatings: Advanced ceramic thermal barrier coatings incorporate self-healing mechanisms and environmental barrier properties to extend service life in harsh operating conditions. These coatings can repair damage caused by thermal cycling, erosion, or foreign object impacts through mechanisms such as viscous flow of glass phases or oxidation-induced volume expansion. Additionally, they provide protection against water vapor, molten salts, and other corrosive environments that can degrade conventional ceramic coatings, particularly important for components in next-generation turbine engines.

02 Multi-layer ceramic thermal barrier coating systems

Multi-layer thermal barrier coating systems consist of different ceramic layers with complementary properties to enhance overall performance. These systems typically include a bond coat, a thermally grown oxide layer, and one or more ceramic top coats. The layered structure helps to accommodate thermal expansion mismatch, improve adhesion, and provide better thermal protection while maintaining mechanical integrity during thermal cycling.Expand Specific Solutions03 Advanced ceramic compositions for enhanced thermal barrier performance

Novel ceramic compositions are being developed to overcome the limitations of traditional thermal barrier materials. These include rare-earth zirconates, hafnates, and pyrochlore structures that offer lower thermal conductivity and better phase stability at elevated temperatures. Some compositions incorporate multiple oxides or dopants to create complex crystal structures that scatter phonons more effectively, resulting in superior thermal insulation properties.Expand Specific Solutions04 Deposition methods for ceramic thermal barrier coatings

Various deposition techniques are employed to apply ceramic thermal barrier coatings, each resulting in different microstructures and properties. These methods include atmospheric plasma spraying (APS), suspension plasma spraying (SPS), electron beam physical vapor deposition (EB-PVD), and solution precursor plasma spray (SPPS). The choice of deposition method significantly affects coating porosity, columnar structure, strain tolerance, and thermal cycling performance.Expand Specific Solutions05 Nanostructured ceramic thermal barrier coatings

Nanostructured ceramic thermal barrier coatings incorporate nanoscale features to enhance performance characteristics. These coatings may contain nanopores, nanoparticles, or nanolayers that reduce thermal conductivity while maintaining mechanical strength. The nanoscale features create additional interfaces that scatter phonons and impede heat transfer, resulting in improved thermal insulation efficiency compared to conventional microstructured coatings.Expand Specific Solutions

Key Industry Players and Manufacturers

The thermal barrier coatings (TBC) market is currently in a growth phase, with plasma-sprayed and EB-PVD technologies representing two competing approaches. The global TBC market is estimated to exceed $1.5 billion, driven by aerospace, power generation, and automotive applications. Plasma spray technology, championed by Oerlikon Metco, Sulzer-Metco, and TOCALO, offers cost-effective solutions with moderate durability. Meanwhile, EB-PVD technology, advanced by Praxair S.T. Technology, Safran Aircraft Engines, and MTU Aero Engines, provides superior strain tolerance and surface finish but at higher costs. Major aerospace players like RTX Corp., IHI Corp., and Mitsubishi Heavy Industries are investing in both technologies, while research institutions such as Beihang University and Forschungszentrum Jülich are developing hybrid approaches to combine advantages of both coating methods.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell International Technologies has developed sophisticated thermal barrier coating systems using both plasma spray and EB-PVD technologies for aerospace applications. Their plasma spray approach utilizes controlled atmosphere plasma spray (CAPS) to create coatings with optimized microstructures featuring 12-18% porosity and thicknesses of 250-400 μm[1]. For high-performance applications, Honeywell's EB-PVD technology produces columnar-structured YSZ coatings with superior strain tolerance and erosion resistance. Their comparative testing has demonstrated that while plasma-sprayed coatings provide thermal conductivity values of approximately 0.9-1.4 W/m·K, their EB-PVD coatings achieve 1.7-2.0 W/m·K but with significantly enhanced durability under thermal cycling and erosion conditions[2]. Honeywell has pioneered advanced bond coat technologies for both coating methods, including platinum-modified aluminide diffusion coatings and MCrAlY overlay coatings optimized for specific operating environments. Their research has established that EB-PVD coatings maintain structural integrity for approximately 1200-1500 thermal cycles versus 500-700 cycles for optimized plasma spray coatings in simulated engine operating conditions[3]. Honeywell implements a component-specific approach, selecting the optimal coating technology based on operating conditions, performance requirements, and economic considerations.

Strengths: Honeywell's EB-PVD coatings demonstrate superior thermal cycling durability (2-3x better than plasma spray) and excellent erosion resistance, making them ideal for high-stress rotating components. Their specialized bond coat technologies enhance adhesion and oxidation resistance. Weaknesses: Higher thermal conductivity in EB-PVD coatings (approximately 40-50% higher than plasma spray), significantly higher production costs (3-4x more expensive), and more complex manufacturing infrastructure requirements.

Siemens AG

Technical Solution: Siemens AG has conducted extensive research comparing plasma-sprayed and EB-PVD thermal barrier coatings for gas turbine applications. Their plasma spray technology employs atmospheric and vacuum plasma spray processes with optimized parameters to create coatings with 15-20% porosity and thicknesses ranging from 250-500 μm[1]. For critical high-temperature components, Siemens has developed EB-PVD coatings with columnar microstructures that demonstrate superior strain tolerance. Their comparative analysis has shown that while plasma-sprayed coatings provide better thermal insulation with thermal conductivity values of 0.8-1.2 W/m·K, their EB-PVD coatings (1.6-1.9 W/m·K) offer 2-3 times longer lifetimes under thermal cycling conditions[2]. Siemens has pioneered hybrid coating systems that combine the advantages of both technologies, using plasma spray for the base layer and EB-PVD for the top layer, achieving improved performance in industrial gas turbine applications. Their research has established that plasma-sprayed coatings are more suitable for stationary components, while EB-PVD coatings provide superior performance for rotating parts experiencing higher mechanical stresses[3]. Siemens has also developed specialized ceramic compositions with reduced sintering rates and improved phase stability for both coating technologies.

Strengths: Siemens' hybrid coating systems combine cost-effectiveness with enhanced performance. Their EB-PVD coatings demonstrate superior strain compliance and erosion resistance, with documented 2-3x lifetime improvements in high-stress applications. Weaknesses: Higher manufacturing complexity and cost for EB-PVD and hybrid systems, limited coating thickness capabilities for EB-PVD compared to plasma spray, and challenges in quality control consistency across large production volumes.

Critical Patents and Technical Literature Review

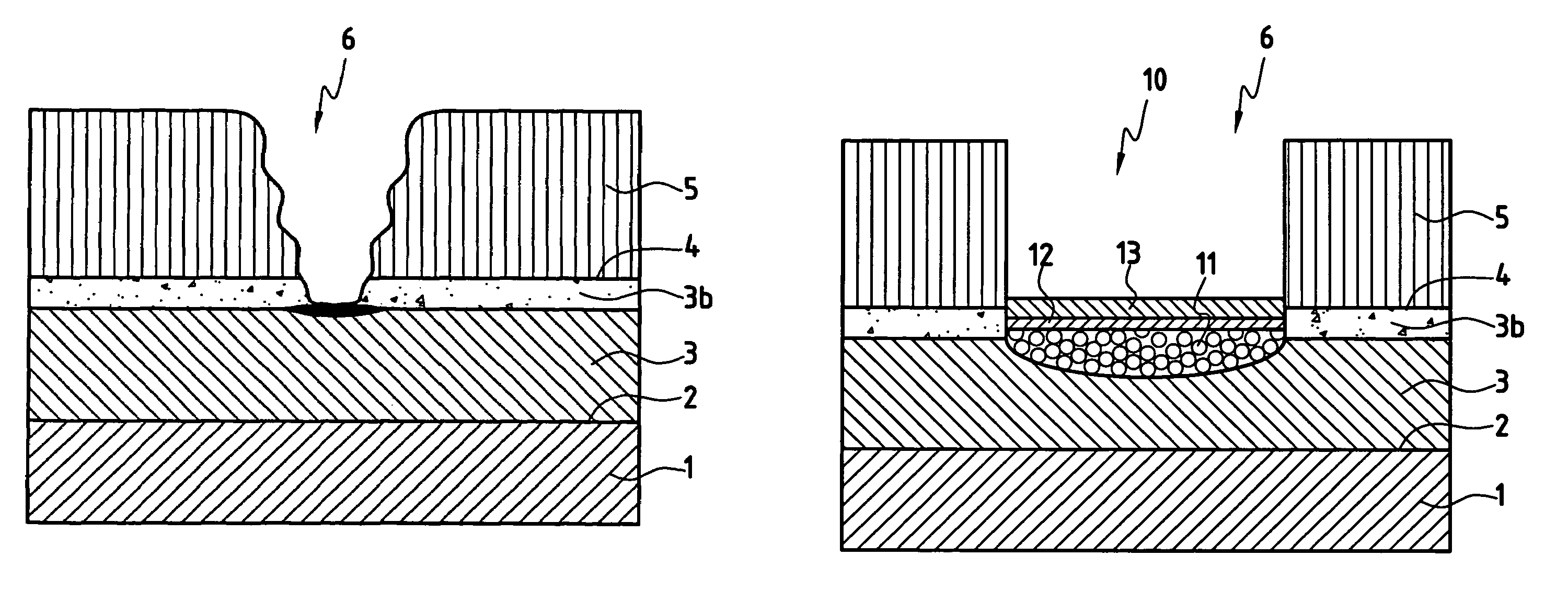

Method for applying thermal barrier coating and heat-resistant member

PatentPendingUS20250092502A1

Innovation

- A method involving thermal spraying of a ceramic powder suspension with atmospheric pressure plasma spraying, where water is used to cool the plasma flame at a rate of 25-100 ml/min, forming a top coat layer on a bond coat layer over a heat-resistant alloy base material.

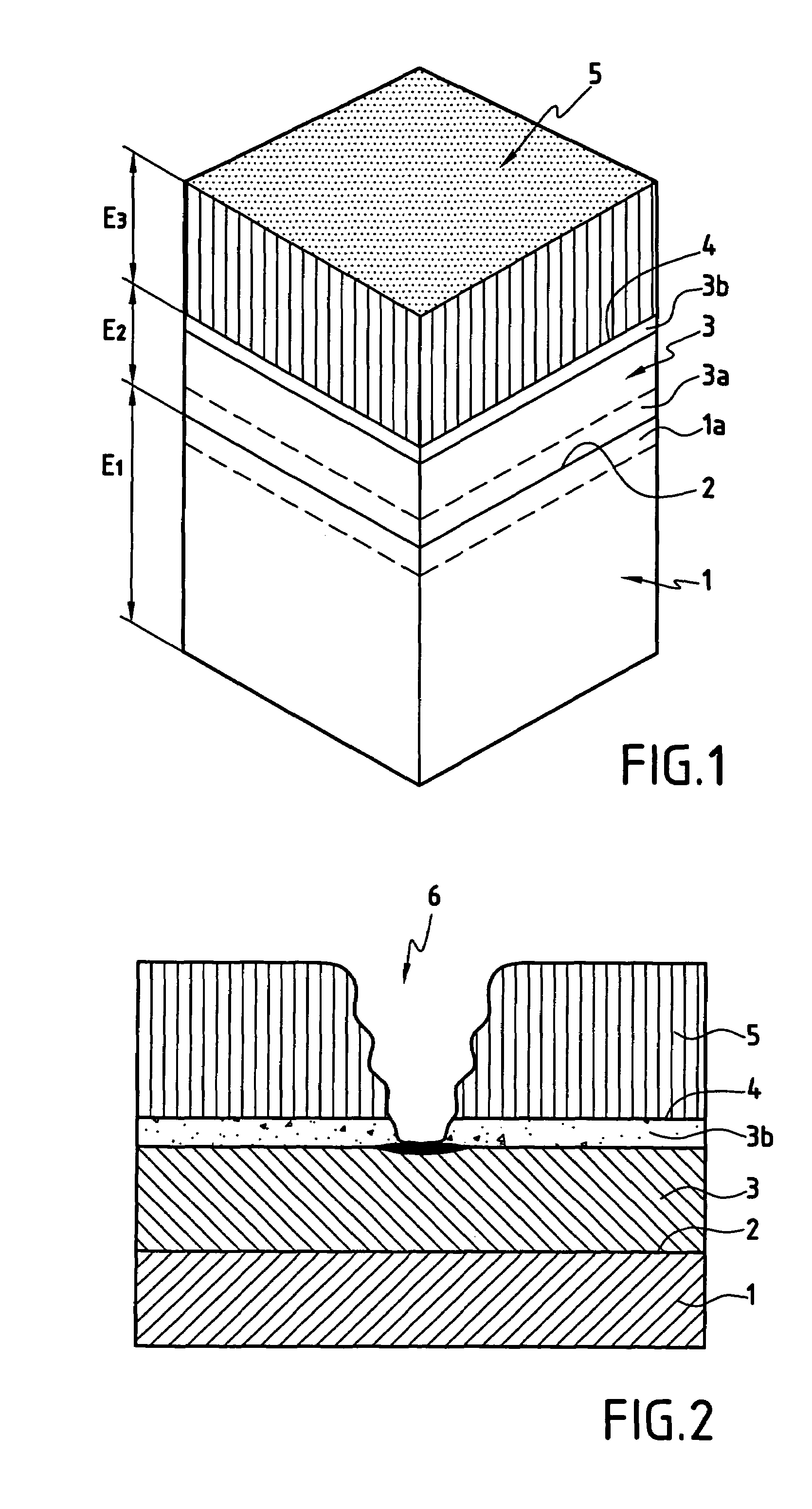

Method of locally repairing parts covered with a thermal barrier

PatentInactiveUS7008522B2

Innovation

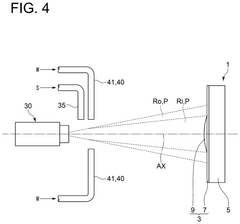

- A method for locally repairing thermal barrier coatings involves defining the damaged zone, scouring to remove ceramic and underlayer damage, depositing repair metals via electrical methods, and heat treatment to diffuse metals and form a new alumina layer, followed by reconstituting the ceramic outer layer using electron bombardment to achieve a columnar structure.

Performance Metrics and Testing Methodologies

The evaluation of thermal barrier coatings (TBCs) requires standardized performance metrics and rigorous testing methodologies to ensure reliability and consistency across different applications. For both plasma-sprayed and EB-PVD ceramic coatings, thermal conductivity stands as a primary performance indicator, typically measured using laser flash analysis or steady-state heat flow methods under controlled temperature gradients.

Thermal cycling resistance represents another critical metric, assessed through rapid temperature change tests where coatings undergo repeated heating and cooling cycles between ambient temperature and operational temperatures (often 1100-1300°C). The number of cycles until failure provides quantitative data on coating durability, with EB-PVD coatings generally demonstrating superior performance in this aspect.

Erosion resistance testing employs particle impingement at controlled velocities and angles, measuring material loss rates under standardized conditions. This metric is particularly important for aerospace applications where airborne particulates pose significant threats to coating integrity. Complementary to this, bond strength testing utilizes adhesion pull tests or scratch tests to quantify the interfacial strength between the ceramic layer and bond coat.

Microstructural stability evaluation involves high-temperature exposure tests followed by detailed analysis using scanning electron microscopy (SEM) and X-ray diffraction (XRD) to track phase transformations and sintering behavior. These analyses reveal critical differences between columnar structures of EB-PVD coatings and the lamellar morphology of plasma-sprayed variants.

Oxidation resistance testing employs isothermal and cyclic oxidation protocols in controlled atmospheres, with thermogravimetric analysis (TGA) providing quantitative data on oxidation kinetics. The growth rate of the thermally grown oxide (TGO) layer serves as a key indicator of coating performance under oxidative conditions.

Advanced characterization techniques such as impedance spectroscopy and acoustic emission monitoring enable real-time assessment of coating degradation mechanisms during thermal cycling. Additionally, non-destructive evaluation methods including infrared thermography and ultrasonic testing allow for in-service inspection of coatings without component removal.

Standardized testing protocols from organizations like ASTM International and ISO ensure comparability of results across different research institutions and manufacturing facilities, facilitating meaningful comparative analysis between plasma-sprayed and EB-PVD ceramic thermal barrier coatings.

Thermal cycling resistance represents another critical metric, assessed through rapid temperature change tests where coatings undergo repeated heating and cooling cycles between ambient temperature and operational temperatures (often 1100-1300°C). The number of cycles until failure provides quantitative data on coating durability, with EB-PVD coatings generally demonstrating superior performance in this aspect.

Erosion resistance testing employs particle impingement at controlled velocities and angles, measuring material loss rates under standardized conditions. This metric is particularly important for aerospace applications where airborne particulates pose significant threats to coating integrity. Complementary to this, bond strength testing utilizes adhesion pull tests or scratch tests to quantify the interfacial strength between the ceramic layer and bond coat.

Microstructural stability evaluation involves high-temperature exposure tests followed by detailed analysis using scanning electron microscopy (SEM) and X-ray diffraction (XRD) to track phase transformations and sintering behavior. These analyses reveal critical differences between columnar structures of EB-PVD coatings and the lamellar morphology of plasma-sprayed variants.

Oxidation resistance testing employs isothermal and cyclic oxidation protocols in controlled atmospheres, with thermogravimetric analysis (TGA) providing quantitative data on oxidation kinetics. The growth rate of the thermally grown oxide (TGO) layer serves as a key indicator of coating performance under oxidative conditions.

Advanced characterization techniques such as impedance spectroscopy and acoustic emission monitoring enable real-time assessment of coating degradation mechanisms during thermal cycling. Additionally, non-destructive evaluation methods including infrared thermography and ultrasonic testing allow for in-service inspection of coatings without component removal.

Standardized testing protocols from organizations like ASTM International and ISO ensure comparability of results across different research institutions and manufacturing facilities, facilitating meaningful comparative analysis between plasma-sprayed and EB-PVD ceramic thermal barrier coatings.

Environmental Impact and Sustainability Considerations

The environmental footprint of thermal barrier coating (TBC) processes has become increasingly significant as industries face stricter regulations and sustainability demands. Plasma-sprayed and EB-PVD coating technologies differ substantially in their environmental impacts across multiple dimensions.

Energy consumption represents a primary environmental concern, with EB-PVD typically requiring 2-3 times more energy than plasma spraying due to its high-vacuum operating conditions and electron beam generation requirements. This translates to approximately 45-60 kWh/kg of coating for EB-PVD compared to 15-25 kWh/kg for plasma spraying, resulting in higher carbon emissions for EB-PVD processes.

Material efficiency also varies significantly between these technologies. Plasma spraying demonstrates material utilization rates of 50-70%, with substantial overspray that becomes waste. In contrast, EB-PVD achieves higher efficiency at 70-90%, reducing raw material consumption and associated environmental impacts from ceramic material production and processing.

Waste generation patterns differ markedly between these technologies. Plasma spraying produces particulate waste requiring filtration and disposal, while EB-PVD generates less physical waste but more complex chemical byproducts from vapor deposition processes. Both technologies utilize hazardous materials including rare earth elements and zirconia, requiring specialized handling and disposal protocols.

Lifecycle assessment studies indicate that while EB-PVD coatings have higher initial environmental costs during production, their superior durability (typically 2-3 times longer service life) may offset these impacts through reduced replacement frequency and associated maintenance operations. This extended service life translates to fewer recoating cycles and lower lifetime environmental impact for critical components.

Recent sustainability innovations are addressing these environmental challenges. Advanced plasma spray systems now incorporate closed-loop material recovery, capturing and reprocessing up to 40% of overspray materials. Similarly, EB-PVD facilities are implementing energy recovery systems that capture and reuse waste heat, reducing net energy consumption by 15-25%. Water-based slurry alternatives for certain coating applications are reducing volatile organic compound emissions by up to 80% compared to traditional methods.

Regulatory compliance is increasingly shaping technology selection, with stricter emissions standards in Europe and North America influencing coating technology choices. The environmental performance gap between these technologies continues to narrow as manufacturers respond to sustainability pressures with process optimizations and material innovations.

Energy consumption represents a primary environmental concern, with EB-PVD typically requiring 2-3 times more energy than plasma spraying due to its high-vacuum operating conditions and electron beam generation requirements. This translates to approximately 45-60 kWh/kg of coating for EB-PVD compared to 15-25 kWh/kg for plasma spraying, resulting in higher carbon emissions for EB-PVD processes.

Material efficiency also varies significantly between these technologies. Plasma spraying demonstrates material utilization rates of 50-70%, with substantial overspray that becomes waste. In contrast, EB-PVD achieves higher efficiency at 70-90%, reducing raw material consumption and associated environmental impacts from ceramic material production and processing.

Waste generation patterns differ markedly between these technologies. Plasma spraying produces particulate waste requiring filtration and disposal, while EB-PVD generates less physical waste but more complex chemical byproducts from vapor deposition processes. Both technologies utilize hazardous materials including rare earth elements and zirconia, requiring specialized handling and disposal protocols.

Lifecycle assessment studies indicate that while EB-PVD coatings have higher initial environmental costs during production, their superior durability (typically 2-3 times longer service life) may offset these impacts through reduced replacement frequency and associated maintenance operations. This extended service life translates to fewer recoating cycles and lower lifetime environmental impact for critical components.

Recent sustainability innovations are addressing these environmental challenges. Advanced plasma spray systems now incorporate closed-loop material recovery, capturing and reprocessing up to 40% of overspray materials. Similarly, EB-PVD facilities are implementing energy recovery systems that capture and reuse waste heat, reducing net energy consumption by 15-25%. Water-based slurry alternatives for certain coating applications are reducing volatile organic compound emissions by up to 80% compared to traditional methods.

Regulatory compliance is increasingly shaping technology selection, with stricter emissions standards in Europe and North America influencing coating technology choices. The environmental performance gap between these technologies continues to narrow as manufacturers respond to sustainability pressures with process optimizations and material innovations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!