Thermal barrier coatings ceramics with high temperature phase stability

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Barrier Coatings Background and Objectives

Thermal barrier coatings (TBCs) have emerged as critical components in high-temperature applications, particularly in gas turbine engines for aerospace and power generation industries. These specialized coating systems were first developed in the 1970s to protect metallic components from extreme thermal environments, enabling higher operating temperatures and improved engine efficiency. The evolution of TBCs has been closely tied to advancements in materials science, particularly in the field of ceramics engineering.

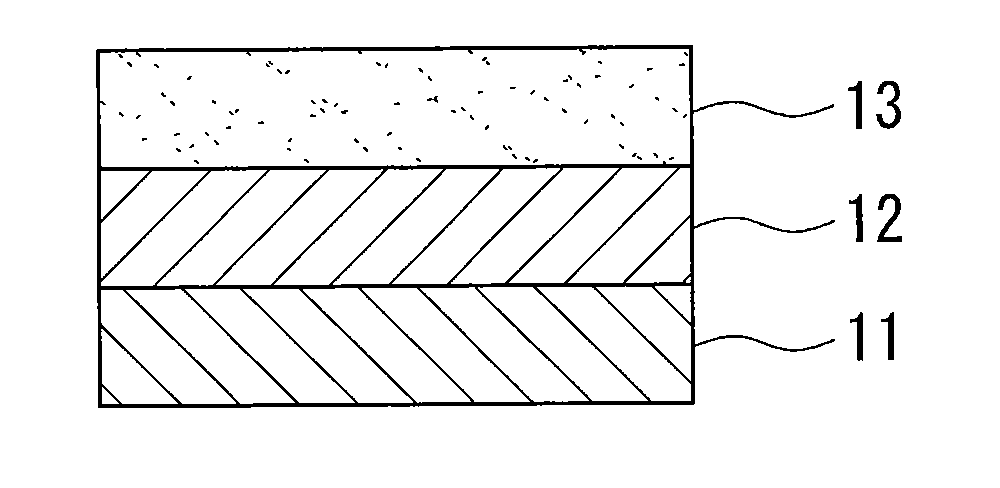

The primary function of TBCs is to provide thermal insulation to metallic substrates, creating a temperature gradient that can reduce the base metal temperature by 100-300°C. This temperature reduction significantly extends component life by mitigating thermal fatigue, oxidation, and hot corrosion. Traditional TBC systems typically consist of a ceramic top coat, a thermally grown oxide (TGO) layer, and a metallic bond coat applied to the substrate.

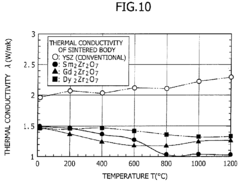

Yttria-stabilized zirconia (YSZ) with 6-8 wt% Y₂O₃ has been the industry standard ceramic material for TBCs due to its low thermal conductivity, relatively high coefficient of thermal expansion, and good mechanical properties. However, YSZ exhibits phase instability above 1200°C, limiting its application in next-generation turbine engines designed to operate at increasingly higher temperatures for improved efficiency and reduced emissions.

The technological trend in TBC development is moving toward new ceramic compositions with enhanced phase stability at ultra-high temperatures (>1300°C). This includes rare-earth zirconates, hafnates, complex perovskites, and pyrochlore structures that maintain their crystallographic integrity under extreme thermal conditions. These advanced materials aim to overcome the limitations of conventional YSZ while maintaining or improving other critical properties.

The objectives of current research on thermal barrier coatings ceramics with high temperature phase stability are multifaceted. First, to develop novel ceramic compositions that maintain structural integrity and phase stability at temperatures exceeding 1400°C. Second, to understand the fundamental mechanisms of phase transformation and sintering behavior under thermal cycling conditions. Third, to optimize coating microstructures for enhanced strain tolerance and reduced thermal conductivity.

Additionally, research aims to establish processing-structure-property relationships for these advanced ceramics, enabling tailored designs for specific applications. The ultimate goal is to enable a new generation of gas turbine engines with significantly higher operating temperatures, improved thermal efficiency, reduced fuel consumption, and lower emissions, aligning with global sustainability objectives and increasingly stringent environmental regulations.

The primary function of TBCs is to provide thermal insulation to metallic substrates, creating a temperature gradient that can reduce the base metal temperature by 100-300°C. This temperature reduction significantly extends component life by mitigating thermal fatigue, oxidation, and hot corrosion. Traditional TBC systems typically consist of a ceramic top coat, a thermally grown oxide (TGO) layer, and a metallic bond coat applied to the substrate.

Yttria-stabilized zirconia (YSZ) with 6-8 wt% Y₂O₃ has been the industry standard ceramic material for TBCs due to its low thermal conductivity, relatively high coefficient of thermal expansion, and good mechanical properties. However, YSZ exhibits phase instability above 1200°C, limiting its application in next-generation turbine engines designed to operate at increasingly higher temperatures for improved efficiency and reduced emissions.

The technological trend in TBC development is moving toward new ceramic compositions with enhanced phase stability at ultra-high temperatures (>1300°C). This includes rare-earth zirconates, hafnates, complex perovskites, and pyrochlore structures that maintain their crystallographic integrity under extreme thermal conditions. These advanced materials aim to overcome the limitations of conventional YSZ while maintaining or improving other critical properties.

The objectives of current research on thermal barrier coatings ceramics with high temperature phase stability are multifaceted. First, to develop novel ceramic compositions that maintain structural integrity and phase stability at temperatures exceeding 1400°C. Second, to understand the fundamental mechanisms of phase transformation and sintering behavior under thermal cycling conditions. Third, to optimize coating microstructures for enhanced strain tolerance and reduced thermal conductivity.

Additionally, research aims to establish processing-structure-property relationships for these advanced ceramics, enabling tailored designs for specific applications. The ultimate goal is to enable a new generation of gas turbine engines with significantly higher operating temperatures, improved thermal efficiency, reduced fuel consumption, and lower emissions, aligning with global sustainability objectives and increasingly stringent environmental regulations.

Market Analysis for High-Temperature Resistant Materials

The global market for high-temperature resistant materials, particularly thermal barrier coatings (TBCs) with phase stability, has experienced significant growth driven by increasing demands in aerospace, power generation, and automotive industries. These industries require materials capable of withstanding extreme thermal conditions while maintaining structural integrity and performance characteristics.

The aerospace sector represents the largest market segment for high-temperature resistant ceramics, accounting for approximately 40% of the total market share. This dominance stems from the critical need for materials that can protect turbine blades and combustion chambers in aircraft engines, where temperatures can exceed 1200°C. The commercial aviation market's projected growth rate of 4.7% annually through 2030 will further drive demand for advanced TBCs.

Power generation follows as the second-largest application sector, particularly in gas turbines for electricity production. With global energy demand rising and the transition toward more efficient power generation systems, the market for high-temperature stable ceramics in this sector is expected to grow at a compound annual growth rate of 5.3% over the next five years.

Automotive applications, especially in high-performance vehicles and electric vehicle battery thermal management systems, represent an emerging market with substantial growth potential. The shift toward more fuel-efficient engines operating at higher temperatures has created new opportunities for thermal barrier coatings with enhanced phase stability.

Regionally, North America and Europe currently dominate the market due to their established aerospace and power generation industries. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate, driven by rapid industrialization, increasing defense spending, and expanding automotive manufacturing capabilities.

Market analysis indicates that yttria-stabilized zirconia (YSZ) remains the most widely used TBC material, holding approximately 65% of the current market. However, newer materials with superior phase stability at ultra-high temperatures, such as rare-earth zirconates and hafnates, are gaining market share due to their enhanced performance characteristics.

The market is also witnessing a shift toward multi-layered coating systems that combine different ceramic materials to achieve optimal thermal and mechanical properties. This trend is expected to continue as manufacturers seek to extend component lifespans and improve system efficiency in high-temperature applications.

Price sensitivity varies significantly across application sectors, with aerospace customers willing to pay premium prices for materials with proven reliability and performance, while automotive and industrial sectors remain more cost-conscious. This market dynamic is driving research toward cost-effective manufacturing processes for advanced ceramic formulations.

The aerospace sector represents the largest market segment for high-temperature resistant ceramics, accounting for approximately 40% of the total market share. This dominance stems from the critical need for materials that can protect turbine blades and combustion chambers in aircraft engines, where temperatures can exceed 1200°C. The commercial aviation market's projected growth rate of 4.7% annually through 2030 will further drive demand for advanced TBCs.

Power generation follows as the second-largest application sector, particularly in gas turbines for electricity production. With global energy demand rising and the transition toward more efficient power generation systems, the market for high-temperature stable ceramics in this sector is expected to grow at a compound annual growth rate of 5.3% over the next five years.

Automotive applications, especially in high-performance vehicles and electric vehicle battery thermal management systems, represent an emerging market with substantial growth potential. The shift toward more fuel-efficient engines operating at higher temperatures has created new opportunities for thermal barrier coatings with enhanced phase stability.

Regionally, North America and Europe currently dominate the market due to their established aerospace and power generation industries. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate, driven by rapid industrialization, increasing defense spending, and expanding automotive manufacturing capabilities.

Market analysis indicates that yttria-stabilized zirconia (YSZ) remains the most widely used TBC material, holding approximately 65% of the current market. However, newer materials with superior phase stability at ultra-high temperatures, such as rare-earth zirconates and hafnates, are gaining market share due to their enhanced performance characteristics.

The market is also witnessing a shift toward multi-layered coating systems that combine different ceramic materials to achieve optimal thermal and mechanical properties. This trend is expected to continue as manufacturers seek to extend component lifespans and improve system efficiency in high-temperature applications.

Price sensitivity varies significantly across application sectors, with aerospace customers willing to pay premium prices for materials with proven reliability and performance, while automotive and industrial sectors remain more cost-conscious. This market dynamic is driving research toward cost-effective manufacturing processes for advanced ceramic formulations.

Current Status and Challenges in TBC Ceramics

Thermal Barrier Coatings (TBCs) have reached a significant level of technological maturity, with yttria-stabilized zirconia (YSZ) remaining the industry standard for high-temperature applications. Current commercial TBC systems typically employ 7-8 wt% YSZ due to its excellent combination of low thermal conductivity, relatively high coefficient of thermal expansion, and good mechanical properties. However, the temperature limitation of conventional YSZ (approximately 1200°C) presents a critical challenge as modern gas turbine engines push toward higher operating temperatures to improve efficiency.

The global research landscape shows concentrated efforts in the United States, Europe, Japan, and China, with significant contributions from both academic institutions and industrial research centers. Recent advancements have focused on developing new ceramic compositions with enhanced phase stability at elevated temperatures. Notable progress has been made with rare-earth zirconates (particularly gadolinium and lanthanum zirconates), which demonstrate superior phase stability up to 1500°C but suffer from lower fracture toughness compared to YSZ.

A major technical challenge facing TBC ceramics is the trade-off between thermal insulation performance and mechanical durability. Materials exhibiting excellent thermal properties often demonstrate compromised mechanical integrity under thermal cycling conditions. This balance becomes increasingly difficult to maintain as operating temperatures rise, with phase transformation, sintering, and interdiffusion phenomena accelerating at higher temperatures.

The CMAS (Calcium-Magnesium-Alumino-Silicate) attack represents another significant challenge, particularly for aircraft engines operating in dusty environments. These environmental contaminants melt at high temperatures and infiltrate the porous TBC structure, causing severe degradation through chemical reactions and mechanical damage upon cooling. Current TBC systems show limited resistance to CMAS infiltration, necessitating the development of new ceramic compositions or protective strategies.

Manufacturing scalability presents additional challenges, as promising laboratory-scale materials often face difficulties in transitioning to industrial production. Techniques such as air plasma spraying (APS) and electron beam physical vapor deposition (EB-PVD) have different requirements for feedstock materials and produce coatings with distinct microstructures, affecting both performance and cost considerations.

Recent research has increasingly focused on multilayer and functionally graded TBC systems that combine different ceramic materials to optimize performance across the temperature gradient. These complex architectures aim to address multiple challenges simultaneously but introduce new complications in manufacturing control and long-term stability prediction. Computational modeling has become essential in predicting the behavior of these advanced systems, though validation through experimental testing remains critical.

The global research landscape shows concentrated efforts in the United States, Europe, Japan, and China, with significant contributions from both academic institutions and industrial research centers. Recent advancements have focused on developing new ceramic compositions with enhanced phase stability at elevated temperatures. Notable progress has been made with rare-earth zirconates (particularly gadolinium and lanthanum zirconates), which demonstrate superior phase stability up to 1500°C but suffer from lower fracture toughness compared to YSZ.

A major technical challenge facing TBC ceramics is the trade-off between thermal insulation performance and mechanical durability. Materials exhibiting excellent thermal properties often demonstrate compromised mechanical integrity under thermal cycling conditions. This balance becomes increasingly difficult to maintain as operating temperatures rise, with phase transformation, sintering, and interdiffusion phenomena accelerating at higher temperatures.

The CMAS (Calcium-Magnesium-Alumino-Silicate) attack represents another significant challenge, particularly for aircraft engines operating in dusty environments. These environmental contaminants melt at high temperatures and infiltrate the porous TBC structure, causing severe degradation through chemical reactions and mechanical damage upon cooling. Current TBC systems show limited resistance to CMAS infiltration, necessitating the development of new ceramic compositions or protective strategies.

Manufacturing scalability presents additional challenges, as promising laboratory-scale materials often face difficulties in transitioning to industrial production. Techniques such as air plasma spraying (APS) and electron beam physical vapor deposition (EB-PVD) have different requirements for feedstock materials and produce coatings with distinct microstructures, affecting both performance and cost considerations.

Recent research has increasingly focused on multilayer and functionally graded TBC systems that combine different ceramic materials to optimize performance across the temperature gradient. These complex architectures aim to address multiple challenges simultaneously but introduce new complications in manufacturing control and long-term stability prediction. Computational modeling has become essential in predicting the behavior of these advanced systems, though validation through experimental testing remains critical.

Current Phase Stability Solutions for High-Temperature TBCs

01 Yttria-stabilized zirconia (YSZ) thermal barrier coatings

Yttria-stabilized zirconia (YSZ) is widely used in thermal barrier coatings due to its excellent phase stability at high temperatures. The addition of yttria to zirconia helps stabilize the tetragonal phase, preventing phase transformations that could lead to coating failure. These coatings provide effective thermal insulation for components operating in high-temperature environments, such as gas turbine engines. The phase stability of YSZ coatings can be further enhanced through controlled deposition methods and post-treatment processes.- Yttria-stabilized zirconia (YSZ) thermal barrier coatings: Yttria-stabilized zirconia (YSZ) is widely used in thermal barrier coatings due to its excellent thermal insulation properties and phase stability at high temperatures. The addition of yttria to zirconia helps stabilize the tetragonal phase, preventing detrimental phase transformations during thermal cycling. These coatings provide effective thermal protection for underlying metal components in high-temperature environments such as gas turbine engines.

- Rare earth element doping for enhanced phase stability: Incorporating rare earth elements such as lanthanum, gadolinium, and ytterbium into ceramic thermal barrier coatings significantly improves their phase stability at elevated temperatures. These dopants modify the crystal structure and reduce the rate of sintering and phase transformation, resulting in coatings with longer service life and better resistance to thermal cycling. The rare earth elements can be added in specific concentrations to optimize the balance between phase stability and other desirable properties.

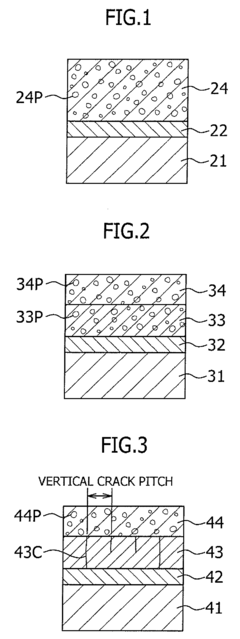

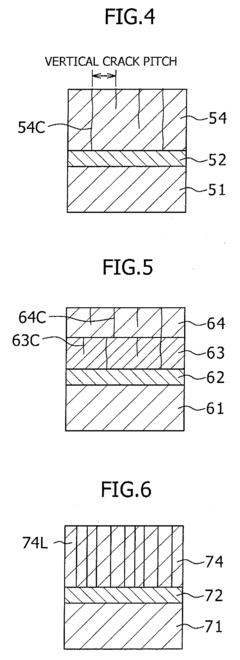

- Multi-layered ceramic coating structures: Multi-layered ceramic coating structures provide enhanced phase stability and thermal protection compared to single-layer coatings. These systems typically consist of different ceramic compositions in each layer, with carefully engineered interfaces that help accommodate thermal stresses and prevent crack propagation. The gradient or discrete layering approach allows for optimization of both thermal insulation and phase stability properties throughout the coating thickness.

- Novel ceramic compositions for improved phase stability: Advanced ceramic compositions have been developed to overcome the phase stability limitations of conventional thermal barrier materials. These include pyrochlore structures, hexaaluminates, and perovskite-based ceramics that maintain their crystal structure at extremely high temperatures. Some compositions incorporate multiple stabilizing oxides to create complex solid solutions that resist phase transformation even under severe thermal cycling conditions.

- Processing techniques for phase-stable ceramic coatings: Specialized processing techniques have been developed to enhance the phase stability of ceramic thermal barrier coatings. These include controlled deposition parameters during plasma spraying or electron beam physical vapor deposition, post-deposition heat treatments to stabilize the microstructure, and surface modifications to improve coating durability. The processing conditions significantly influence the resulting crystal structure, porosity distribution, and interfacial characteristics, all of which affect long-term phase stability.

02 Rare earth element doping for enhanced phase stability

Incorporating rare earth elements into ceramic thermal barrier coatings significantly improves their phase stability under extreme temperature conditions. Elements such as lanthanum, gadolinium, and cerium can be added to traditional ceramic compositions to inhibit grain growth and phase transformations. These dopants occupy specific lattice positions in the ceramic structure, creating distortions that enhance the material's resistance to sintering and phase changes. This approach extends the service life of thermal barrier coatings in high-temperature applications while maintaining their thermal insulation properties.Expand Specific Solutions03 Multi-layer ceramic coating structures

Multi-layer ceramic coating systems provide enhanced phase stability through the strategic arrangement of different ceramic compositions. These systems typically consist of a bond coat, an intermediate layer, and a top ceramic layer, each serving specific functions. The intermediate layers often contain gradient compositions that help manage thermal stresses and prevent phase transformations. By distributing thermal loads across multiple layers with complementary properties, these coating systems maintain structural integrity and phase stability even under thermal cycling conditions, significantly extending component lifetimes.Expand Specific Solutions04 Novel ceramic compositions for improved phase stability

Advanced ceramic compositions have been developed specifically to address phase stability issues in thermal barrier coatings. These include pyrochlore structures, hexaaluminates, and perovskite-based ceramics that demonstrate superior phase stability compared to conventional materials. These novel compositions are engineered at the atomic level to resist phase transformations even at extremely high temperatures. Some formulations incorporate complex oxide systems that create inherently stable crystallographic structures, resulting in coatings that maintain their protective properties throughout extended high-temperature exposure.Expand Specific Solutions05 Processing techniques for enhanced phase stability

Specialized processing techniques significantly impact the phase stability of ceramic thermal barrier coatings. Methods such as solution precursor plasma spraying, controlled atmosphere electron beam physical vapor deposition, and advanced sintering protocols can create microstructures with enhanced resistance to phase transformations. Post-deposition heat treatments are often employed to stabilize the desired crystalline phases before the coating enters service. These processing approaches control grain size, porosity distribution, and interfacial characteristics, all of which contribute to maintaining phase stability under the extreme conditions experienced in high-temperature applications.Expand Specific Solutions

Leading Organizations in TBC Ceramic Development

The thermal barrier coatings (TBC) ceramics market is currently in a growth phase, driven by increasing demand in aerospace, power generation, and automotive industries. The global market size is estimated to reach $1.5 billion by 2025, with a CAGR of approximately 6.5%. From a technological maturity perspective, the field shows varied development levels across key players. Industry leaders like Mitsubishi Heavy Industries, General Electric, and Siemens AG have established advanced R&D capabilities in high-temperature phase stability ceramics, while academic institutions such as Tsinghua University and Beihang University are contributing significant fundamental research. Companies including Praxair S.T. Technology and IHI Corp have developed proprietary coating technologies, while emerging players like Shaanxi Tianxuan Coating Technology are focusing on specialized applications. The competitive landscape reflects a mix of established industrial giants and specialized research-focused entities working to overcome the technical challenges of phase stability at extreme temperatures.

Mitsubishi Heavy Industries, Ltd.

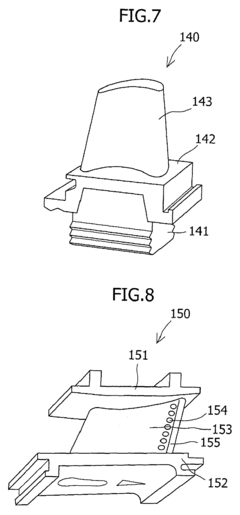

Technical Solution: Mitsubishi Heavy Industries has developed advanced thermal barrier coating systems utilizing lanthanum zirconate-based ceramics with exceptional phase stability at temperatures exceeding 1300°C. Their proprietary "MHITBC" system employs a gradient structure transitioning from conventional YSZ near the bond coat to lanthanum zirconate at the surface, effectively addressing thermal expansion mismatch while maintaining phase stability. MHI's manufacturing process combines controlled atmosphere plasma spraying with specialized heat treatments to optimize microstructure. Their research has demonstrated that these coatings maintain phase stability for over 10,000 hours at 1250°C, significantly outperforming conventional YSZ coatings. MHI has also pioneered the use of nano-structured bond coats with platinum group metal additions to enhance oxidation resistance and coating adhesion during thermal cycling.

Strengths: Superior CMAS (calcium-magnesium-alumino-silicate) resistance; excellent phase stability at ultra-high temperatures; proven performance in actual gas turbine operations. Weaknesses: Higher raw material costs due to rare earth element content; more complex manufacturing process requiring specialized equipment.

United Technologies Corp.

Technical Solution: United Technologies Corporation (now part of Raytheon Technologies) has developed advanced thermal barrier coating systems utilizing pyrochlore-structured ceramics, particularly gadolinium zirconate and samarium zirconate, which demonstrate exceptional phase stability at temperatures exceeding 1300°C. Their proprietary "DuraCoat" system employs a multi-layered architecture with compositional gradients to optimize thermal properties while maintaining phase stability. UTC utilizes a combination of solution precursor plasma spray and electron beam physical vapor deposition techniques to create coatings with controlled porosity and columnar microstructure. Their research has demonstrated that these coatings maintain phase stability for over 3,000 hours at 1350°C with minimal sintering and densification. UTC has also pioneered the development of "smart" thermal barrier coatings with embedded sensor capabilities that allow real-time monitoring of coating temperature and degradation state.

Strengths: Excellent resistance to sintering at ultra-high temperatures; superior erosion resistance; advanced in-situ monitoring capabilities. Weaknesses: Higher manufacturing costs; complex quality control requirements; limited compatibility with certain substrate materials.

Key Technical Innovations in Phase-Stable Ceramic Materials

Thermal barrier coating material, thermal barrier coating, turbine member, and gas turbine

PatentInactiveUS20110262770A1

Innovation

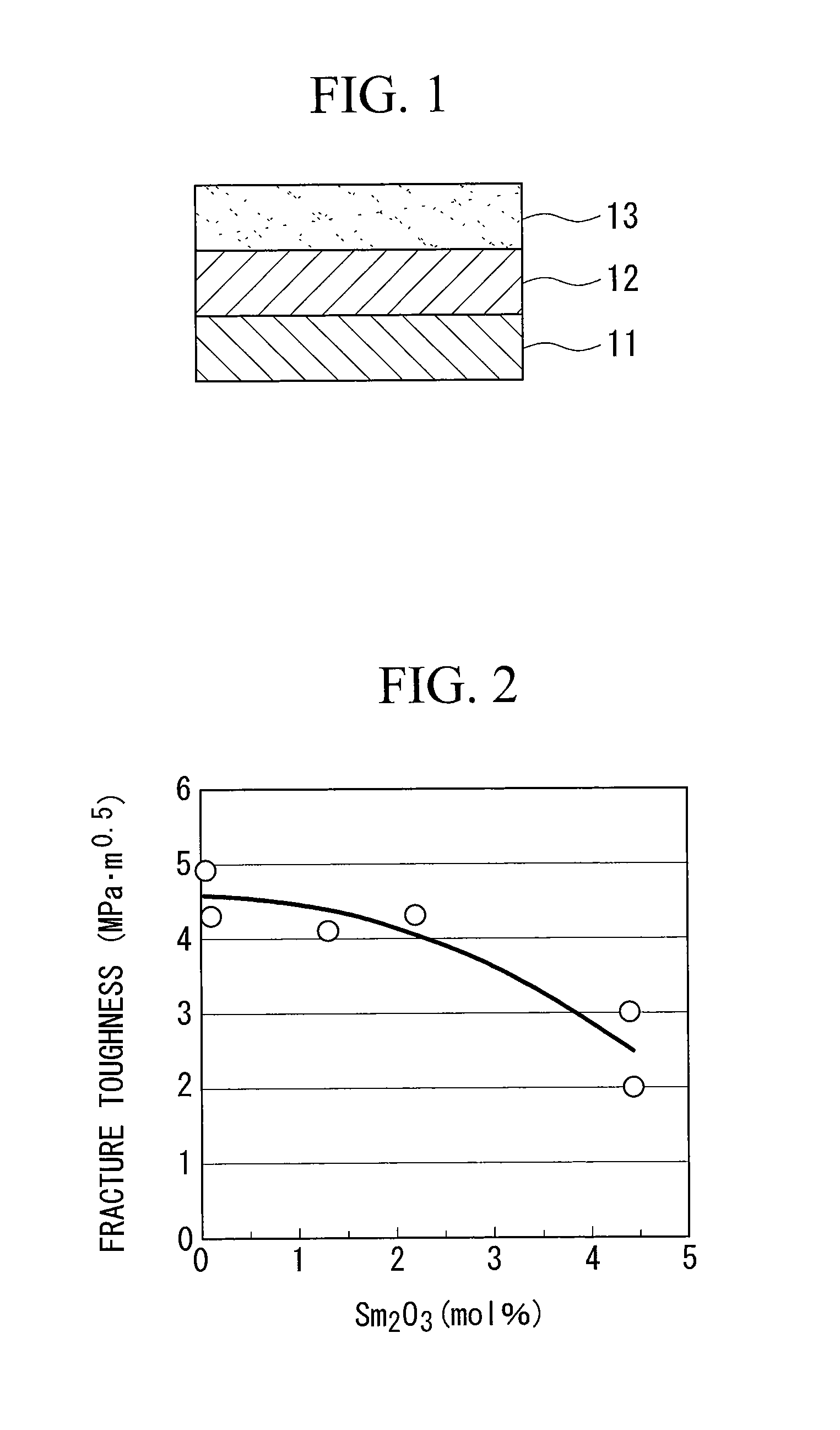

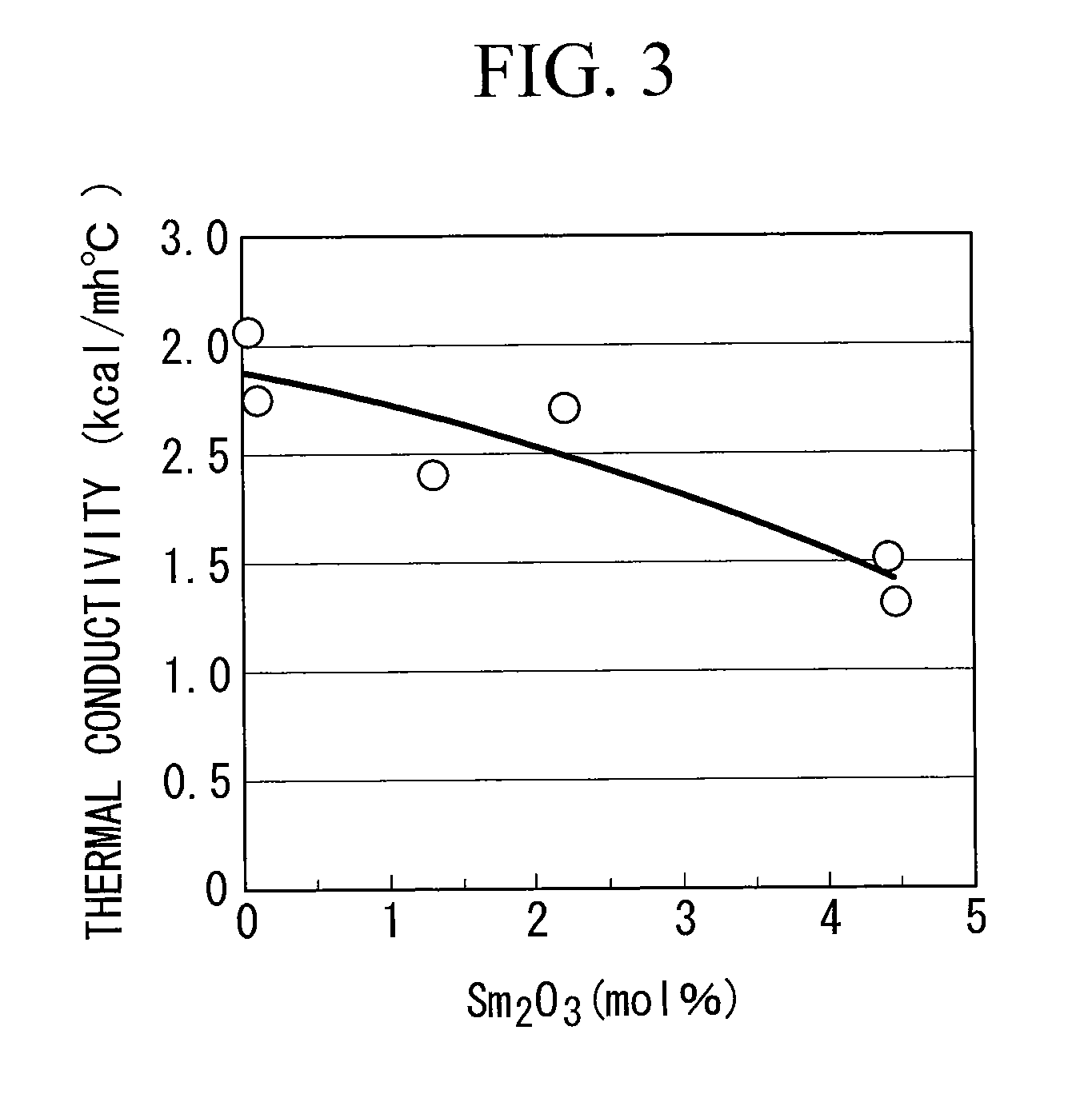

- A thermal barrier coating material comprising ZrO2 with Yb2O3 and Sm2O3 as stabilizers, within specific mole percentage ranges (2-7 mol% for both and 0.1-2.5 mol% for Sm2O3), which enhances crystal stability, fracture toughness, and lowers thermal conductivity, thereby improving durability and heat cycling resistance.

Thermal barrier coating material, thermal barrier member, and member coated with thermal barrier and method for manufacturing the same

PatentActiveEP1674663A2

Innovation

- A thermal barrier coating material comprising a ceramic layer of Sm2Zr2O7 or Gd2Zr2O7 with a bond coat layer and a zirconia-containing layer, featuring porosity and vertical cracks to enhance durability and thermal cycle resistance, is applied to a heat-resistant substrate using methods like electron beam physical vapor deposition.

Environmental Impact and Sustainability Considerations

The environmental footprint of thermal barrier coating (TBC) production and application processes has become increasingly significant in the aerospace and energy sectors. Traditional manufacturing of high temperature phase stable ceramics often involves energy-intensive processes that generate substantial carbon emissions. The production of yttria-stabilized zirconia (YSZ), the most widely used TBC material, requires temperatures exceeding 1400°C during sintering, contributing to considerable energy consumption and associated greenhouse gas emissions.

Material resource efficiency presents another critical environmental consideration. Rare earth elements used in advanced TBCs, particularly gadolinium, ytterbium, and lanthanum, face supply constraints and geopolitical challenges. Mining and processing these elements generate significant environmental impacts including habitat destruction, water pollution, and toxic waste generation. Recent life cycle assessments indicate that the environmental burden of rare earth extraction can offset the efficiency gains provided by TBCs in certain applications.

Coating deposition techniques such as electron beam physical vapor deposition (EB-PVD) and atmospheric plasma spraying (APS) consume substantial energy and may utilize environmentally problematic precursors. The development of more sustainable alternatives, including water-based slurry processes and sol-gel methods, shows promise for reducing environmental impact while maintaining coating performance. These emerging techniques typically operate at lower temperatures and reduce hazardous waste generation by 30-45% compared to conventional methods.

End-of-life considerations for TBC components remain underdeveloped in current research. The complex multi-material nature of coated components complicates recycling efforts, often resulting in valuable materials being downcycled or discarded. Innovative approaches to material recovery, including selective dissolution techniques and advanced mechanical separation, are being explored to address this sustainability gap.

The environmental benefits of TBCs must be evaluated holistically across their entire lifecycle. While they enable higher operating temperatures and improved efficiency in turbines and engines—potentially reducing fuel consumption by 1-3%—these benefits must be weighed against production impacts. Recent studies suggest that the environmental payback period for advanced TBCs ranges from 1.5 to 4 years depending on application conditions and coating composition.

Regulatory frameworks increasingly influence TBC development, with restrictions on certain manufacturing chemicals under REACH legislation in Europe and similar regulations globally driving innovation toward more environmentally benign formulations and processes. This regulatory landscape is accelerating research into bio-inspired coating designs and environmentally compatible precursor materials.

Material resource efficiency presents another critical environmental consideration. Rare earth elements used in advanced TBCs, particularly gadolinium, ytterbium, and lanthanum, face supply constraints and geopolitical challenges. Mining and processing these elements generate significant environmental impacts including habitat destruction, water pollution, and toxic waste generation. Recent life cycle assessments indicate that the environmental burden of rare earth extraction can offset the efficiency gains provided by TBCs in certain applications.

Coating deposition techniques such as electron beam physical vapor deposition (EB-PVD) and atmospheric plasma spraying (APS) consume substantial energy and may utilize environmentally problematic precursors. The development of more sustainable alternatives, including water-based slurry processes and sol-gel methods, shows promise for reducing environmental impact while maintaining coating performance. These emerging techniques typically operate at lower temperatures and reduce hazardous waste generation by 30-45% compared to conventional methods.

End-of-life considerations for TBC components remain underdeveloped in current research. The complex multi-material nature of coated components complicates recycling efforts, often resulting in valuable materials being downcycled or discarded. Innovative approaches to material recovery, including selective dissolution techniques and advanced mechanical separation, are being explored to address this sustainability gap.

The environmental benefits of TBCs must be evaluated holistically across their entire lifecycle. While they enable higher operating temperatures and improved efficiency in turbines and engines—potentially reducing fuel consumption by 1-3%—these benefits must be weighed against production impacts. Recent studies suggest that the environmental payback period for advanced TBCs ranges from 1.5 to 4 years depending on application conditions and coating composition.

Regulatory frameworks increasingly influence TBC development, with restrictions on certain manufacturing chemicals under REACH legislation in Europe and similar regulations globally driving innovation toward more environmentally benign formulations and processes. This regulatory landscape is accelerating research into bio-inspired coating designs and environmentally compatible precursor materials.

Performance Testing and Qualification Standards

Performance testing and qualification standards for thermal barrier coatings (TBCs) with high temperature phase stability are critical for ensuring their reliability in extreme operating environments. These standards encompass a comprehensive suite of tests designed to evaluate the thermal, mechanical, and chemical properties of ceramic coatings under conditions that simulate or exceed actual service environments.

Thermal cycling tests represent the cornerstone of TBC performance evaluation, typically involving rapid heating to temperatures between 1100°C and 1400°C followed by forced cooling. These cycles, often repeated thousands of times, assess the coating's resistance to spallation and delamination under thermal stress conditions. The number of cycles a coating can withstand before failure serves as a primary performance metric.

Isothermal oxidation testing complements cycling tests by exposing coatings to constant high temperatures for extended periods, typically ranging from 100 to 1000 hours. This methodology evaluates the growth rate of thermally grown oxide (TGO) layers and the coating's resistance to phase transformations that could compromise structural integrity.

Erosion resistance testing utilizes particle impingement at various angles and velocities to quantify material loss rates. Standard procedures often employ alumina particles at controlled feed rates to simulate particulate environments in turbine engines. The resulting erosion rate, measured in material volume loss per gram of erodent, provides a comparative metric across different coating formulations.

Hot corrosion testing exposes specimens to molten salt environments (typically Na2SO4 and V2O5 mixtures) at elevated temperatures to evaluate resistance to chemical attack. Weight change measurements and post-test microstructural analysis reveal degradation mechanisms and corrosion penetration depths.

Mechanical property characterization includes hardness testing (nano-indentation), adhesion strength measurement (using tensile or scratch tests), and fracture toughness evaluation. These properties must remain stable after thermal exposure to ensure coating longevity.

Qualification standards typically require multi-parameter testing matrices that evaluate performance across various temperature regimes, thermal gradients, and mechanical loading conditions. International standards such as ASTM C633 for adhesion strength and ASTM G76 for erosion resistance provide standardized methodologies, while industry-specific standards from aerospace manufacturers often impose more stringent requirements tailored to specific applications.

Advanced characterization techniques including X-ray diffraction (XRD) for phase stability monitoring, scanning electron microscopy (SEM) for microstructural evaluation, and thermal diffusivity measurements complete the qualification process by providing fundamental understanding of performance-limiting mechanisms.

Thermal cycling tests represent the cornerstone of TBC performance evaluation, typically involving rapid heating to temperatures between 1100°C and 1400°C followed by forced cooling. These cycles, often repeated thousands of times, assess the coating's resistance to spallation and delamination under thermal stress conditions. The number of cycles a coating can withstand before failure serves as a primary performance metric.

Isothermal oxidation testing complements cycling tests by exposing coatings to constant high temperatures for extended periods, typically ranging from 100 to 1000 hours. This methodology evaluates the growth rate of thermally grown oxide (TGO) layers and the coating's resistance to phase transformations that could compromise structural integrity.

Erosion resistance testing utilizes particle impingement at various angles and velocities to quantify material loss rates. Standard procedures often employ alumina particles at controlled feed rates to simulate particulate environments in turbine engines. The resulting erosion rate, measured in material volume loss per gram of erodent, provides a comparative metric across different coating formulations.

Hot corrosion testing exposes specimens to molten salt environments (typically Na2SO4 and V2O5 mixtures) at elevated temperatures to evaluate resistance to chemical attack. Weight change measurements and post-test microstructural analysis reveal degradation mechanisms and corrosion penetration depths.

Mechanical property characterization includes hardness testing (nano-indentation), adhesion strength measurement (using tensile or scratch tests), and fracture toughness evaluation. These properties must remain stable after thermal exposure to ensure coating longevity.

Qualification standards typically require multi-parameter testing matrices that evaluate performance across various temperature regimes, thermal gradients, and mechanical loading conditions. International standards such as ASTM C633 for adhesion strength and ASTM G76 for erosion resistance provide standardized methodologies, while industry-specific standards from aerospace manufacturers often impose more stringent requirements tailored to specific applications.

Advanced characterization techniques including X-ray diffraction (XRD) for phase stability monitoring, scanning electron microscopy (SEM) for microstructural evaluation, and thermal diffusivity measurements complete the qualification process by providing fundamental understanding of performance-limiting mechanisms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!