Thermal barrier coatings ceramics with advanced rare-earth dopants

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Barrier Coatings Evolution and Objectives

Thermal barrier coatings (TBCs) have evolved significantly since their inception in the 1950s, initially developed for aerospace applications to protect metal components from extreme temperatures. The early TBCs consisted of simple ceramic layers with limited durability and thermal resistance. By the 1970s, the introduction of yttria-stabilized zirconia (YSZ) marked a pivotal advancement, establishing YSZ as the industry standard due to its exceptional thermal insulation properties and phase stability.

The 1980s and 1990s witnessed substantial improvements in deposition techniques, particularly the refinement of air plasma spray (APS) and electron beam physical vapor deposition (EB-PVD) methods, which enhanced coating microstructure and performance. During this period, researchers began exploring the potential of rare-earth elements as dopants to address the inherent limitations of conventional YSZ coatings, especially regarding high-temperature stability and sintering resistance.

The early 2000s saw accelerated research into advanced TBC systems incorporating rare-earth elements such as lanthanum, gadolinium, and cerium. These elements demonstrated promising capabilities in modifying the crystal structure of ceramic coatings, improving phase stability, and reducing thermal conductivity. The incorporation of rare-earth dopants represented a paradigm shift in TBC technology, enabling operation at temperatures exceeding traditional limits.

Current research focuses on multi-component rare-earth doped ceramic systems that can withstand temperatures above 1300°C while maintaining structural integrity and thermal insulation properties. The evolution of these advanced materials has been driven by increasingly demanding performance requirements in aerospace, power generation, and automotive industries, where efficiency improvements directly correlate with higher operating temperatures.

The primary objectives of contemporary research on rare-earth doped TBCs include extending service life beyond 30,000 hours under extreme thermal cycling conditions, reducing thermal conductivity to below 1 W/m·K, enhancing erosion resistance, and developing coatings compatible with next-generation substrate materials. Additionally, researchers aim to establish predictive models for coating degradation mechanisms and optimize rare-earth dopant concentrations for specific application environments.

Another critical objective is the development of environmentally sustainable and cost-effective manufacturing processes for these advanced ceramic coatings, addressing concerns about the supply chain vulnerability of rare-earth elements. The ultimate goal remains creating TBC systems that enable significant improvements in energy efficiency and performance across multiple industries while reducing environmental impact through lower emissions and resource consumption.

The 1980s and 1990s witnessed substantial improvements in deposition techniques, particularly the refinement of air plasma spray (APS) and electron beam physical vapor deposition (EB-PVD) methods, which enhanced coating microstructure and performance. During this period, researchers began exploring the potential of rare-earth elements as dopants to address the inherent limitations of conventional YSZ coatings, especially regarding high-temperature stability and sintering resistance.

The early 2000s saw accelerated research into advanced TBC systems incorporating rare-earth elements such as lanthanum, gadolinium, and cerium. These elements demonstrated promising capabilities in modifying the crystal structure of ceramic coatings, improving phase stability, and reducing thermal conductivity. The incorporation of rare-earth dopants represented a paradigm shift in TBC technology, enabling operation at temperatures exceeding traditional limits.

Current research focuses on multi-component rare-earth doped ceramic systems that can withstand temperatures above 1300°C while maintaining structural integrity and thermal insulation properties. The evolution of these advanced materials has been driven by increasingly demanding performance requirements in aerospace, power generation, and automotive industries, where efficiency improvements directly correlate with higher operating temperatures.

The primary objectives of contemporary research on rare-earth doped TBCs include extending service life beyond 30,000 hours under extreme thermal cycling conditions, reducing thermal conductivity to below 1 W/m·K, enhancing erosion resistance, and developing coatings compatible with next-generation substrate materials. Additionally, researchers aim to establish predictive models for coating degradation mechanisms and optimize rare-earth dopant concentrations for specific application environments.

Another critical objective is the development of environmentally sustainable and cost-effective manufacturing processes for these advanced ceramic coatings, addressing concerns about the supply chain vulnerability of rare-earth elements. The ultimate goal remains creating TBC systems that enable significant improvements in energy efficiency and performance across multiple industries while reducing environmental impact through lower emissions and resource consumption.

Market Analysis for Advanced TBC Applications

The global market for Thermal Barrier Coatings (TBCs) has been experiencing robust growth, driven primarily by the aerospace, power generation, and automotive industries. The market value reached approximately $1.5 billion in 2022 and is projected to grow at a CAGR of 6.8% through 2030, potentially reaching $2.4 billion by the end of the forecast period. This growth trajectory is significantly influenced by the increasing demand for high-performance engines operating at elevated temperatures.

The aerospace sector remains the dominant application area for advanced TBCs, accounting for nearly 45% of the total market share. This dominance stems from the critical need for thermal protection in aircraft engines, where efficiency improvements directly correlate with higher operating temperatures. Commercial aviation's recovery post-pandemic and the growing defense spending worldwide have further accelerated this segment's growth.

Power generation represents the second-largest application segment, constituting approximately 30% of the market. The transition toward cleaner energy production has paradoxically increased the demand for more efficient gas turbines, which require advanced TBC systems to maintain structural integrity at higher combustion temperatures. This sector is particularly interested in rare-earth doped ceramic coatings due to their enhanced thermal cycling resistance and longer service life.

Regionally, North America and Europe currently lead the market with combined shares exceeding 60%, primarily due to their established aerospace and power generation industries. However, the Asia-Pacific region is emerging as the fastest-growing market with an estimated CAGR of 8.2%, driven by China's and India's expanding industrial base and increasing investments in advanced manufacturing technologies.

The automotive industry represents a rapidly expanding application area for TBCs, particularly in high-performance vehicles and racing applications. This segment is expected to grow at a CAGR of 7.5%, outpacing the overall market growth rate. The integration of TBCs in turbochargers, exhaust systems, and engine components is becoming increasingly common as automotive manufacturers seek to enhance fuel efficiency and reduce emissions.

End-users across all sectors are demonstrating a growing preference for TBCs with enhanced durability and performance characteristics, creating a premium market segment for rare-earth doped ceramic coatings. This trend is reflected in the pricing structure, with advanced formulations commanding a 20-30% premium over conventional coatings, yet still providing superior value through extended service intervals and improved system efficiency.

The aerospace sector remains the dominant application area for advanced TBCs, accounting for nearly 45% of the total market share. This dominance stems from the critical need for thermal protection in aircraft engines, where efficiency improvements directly correlate with higher operating temperatures. Commercial aviation's recovery post-pandemic and the growing defense spending worldwide have further accelerated this segment's growth.

Power generation represents the second-largest application segment, constituting approximately 30% of the market. The transition toward cleaner energy production has paradoxically increased the demand for more efficient gas turbines, which require advanced TBC systems to maintain structural integrity at higher combustion temperatures. This sector is particularly interested in rare-earth doped ceramic coatings due to their enhanced thermal cycling resistance and longer service life.

Regionally, North America and Europe currently lead the market with combined shares exceeding 60%, primarily due to their established aerospace and power generation industries. However, the Asia-Pacific region is emerging as the fastest-growing market with an estimated CAGR of 8.2%, driven by China's and India's expanding industrial base and increasing investments in advanced manufacturing technologies.

The automotive industry represents a rapidly expanding application area for TBCs, particularly in high-performance vehicles and racing applications. This segment is expected to grow at a CAGR of 7.5%, outpacing the overall market growth rate. The integration of TBCs in turbochargers, exhaust systems, and engine components is becoming increasingly common as automotive manufacturers seek to enhance fuel efficiency and reduce emissions.

End-users across all sectors are demonstrating a growing preference for TBCs with enhanced durability and performance characteristics, creating a premium market segment for rare-earth doped ceramic coatings. This trend is reflected in the pricing structure, with advanced formulations commanding a 20-30% premium over conventional coatings, yet still providing superior value through extended service intervals and improved system efficiency.

Current Status and Challenges in Rare-Earth Doped Ceramics

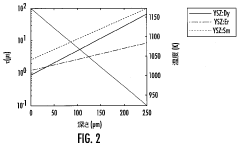

The global landscape of rare-earth doped thermal barrier coatings (TBCs) has witnessed significant advancements in recent years, with research centers across North America, Europe, and Asia contributing to the field. Currently, yttria-stabilized zirconia (YSZ) doped with various rare-earth elements represents the state-of-the-art in high-temperature ceramic coatings. These materials have demonstrated superior thermal insulation properties and enhanced durability in extreme environments, making them crucial for aerospace, power generation, and automotive applications.

Despite these advancements, several critical challenges persist in the development and implementation of rare-earth doped ceramics for TBCs. The primary technical hurdle remains the phase stability at elevated temperatures, particularly above 1200°C, where conventional YSZ systems begin to experience phase transformations that compromise structural integrity. Rare-earth dopants such as gadolinium, samarium, and neodymium have shown promise in stabilizing the desired tetragonal phase, but complete prevention of phase degradation during thermal cycling remains elusive.

Another significant challenge is the sintering behavior of these advanced ceramics during prolonged high-temperature exposure. Rare-earth dopants modify grain boundary energetics, which can either accelerate or inhibit sintering depending on concentration and distribution. This phenomenon directly impacts coating porosity and thermal conductivity, which are critical parameters for TBC performance.

The complex interaction between rare-earth dopants and oxygen vacancies presents both opportunities and challenges. While these interactions can enhance oxygen ion conductivity and improve coating durability, they also introduce complexities in predicting long-term material behavior under service conditions. Current computational models struggle to accurately capture these atomic-level interactions across multiple time and length scales.

Manufacturing consistency represents another major constraint in the field. Producing homogeneous distributions of rare-earth dopants throughout the ceramic matrix requires precise control over deposition parameters. Techniques such as electron beam physical vapor deposition (EB-PVD) and solution precursor plasma spray (SPPS) have shown promise, but scalability and cost-effectiveness remain concerns for industrial implementation.

Environmental degradation mechanisms, particularly hot corrosion from calcium-magnesium-alumino-silicate (CMAS) deposits and volcanic ash, continue to limit the service life of TBCs. While certain rare-earth dopants have demonstrated improved resistance to CMAS infiltration, a comprehensive solution that addresses multiple degradation mechanisms simultaneously has yet to be developed.

The availability and price volatility of rare-earth elements themselves constitute a non-technical but equally important challenge. Geopolitical factors affecting the supply chain of these critical materials have prompted research into optimizing dopant concentrations and exploring alternative material systems that maintain performance while reducing rare-earth content.

Despite these advancements, several critical challenges persist in the development and implementation of rare-earth doped ceramics for TBCs. The primary technical hurdle remains the phase stability at elevated temperatures, particularly above 1200°C, where conventional YSZ systems begin to experience phase transformations that compromise structural integrity. Rare-earth dopants such as gadolinium, samarium, and neodymium have shown promise in stabilizing the desired tetragonal phase, but complete prevention of phase degradation during thermal cycling remains elusive.

Another significant challenge is the sintering behavior of these advanced ceramics during prolonged high-temperature exposure. Rare-earth dopants modify grain boundary energetics, which can either accelerate or inhibit sintering depending on concentration and distribution. This phenomenon directly impacts coating porosity and thermal conductivity, which are critical parameters for TBC performance.

The complex interaction between rare-earth dopants and oxygen vacancies presents both opportunities and challenges. While these interactions can enhance oxygen ion conductivity and improve coating durability, they also introduce complexities in predicting long-term material behavior under service conditions. Current computational models struggle to accurately capture these atomic-level interactions across multiple time and length scales.

Manufacturing consistency represents another major constraint in the field. Producing homogeneous distributions of rare-earth dopants throughout the ceramic matrix requires precise control over deposition parameters. Techniques such as electron beam physical vapor deposition (EB-PVD) and solution precursor plasma spray (SPPS) have shown promise, but scalability and cost-effectiveness remain concerns for industrial implementation.

Environmental degradation mechanisms, particularly hot corrosion from calcium-magnesium-alumino-silicate (CMAS) deposits and volcanic ash, continue to limit the service life of TBCs. While certain rare-earth dopants have demonstrated improved resistance to CMAS infiltration, a comprehensive solution that addresses multiple degradation mechanisms simultaneously has yet to be developed.

The availability and price volatility of rare-earth elements themselves constitute a non-technical but equally important challenge. Geopolitical factors affecting the supply chain of these critical materials have prompted research into optimizing dopant concentrations and exploring alternative material systems that maintain performance while reducing rare-earth content.

Existing Rare-Earth Dopant Implementation Strategies

01 Yttria-stabilized zirconia (YSZ) with rare-earth dopants

Yttria-stabilized zirconia (YSZ) is a common base material for thermal barrier coatings that can be enhanced with rare-earth dopants. These dopants improve the thermal stability, reduce thermal conductivity, and enhance the phase stability of the coating. The addition of rare-earth elements like lanthanum, cerium, or gadolinium to YSZ creates complex oxide structures that effectively scatter phonons, resulting in superior thermal insulation properties for high-temperature applications in gas turbines and aerospace components.- Yttria-stabilized zirconia (YSZ) with rare-earth dopants: Yttria-stabilized zirconia (YSZ) is a common ceramic material used in thermal barrier coatings that can be enhanced with rare-earth dopants. The addition of rare-earth elements such as lanthanum, cerium, or gadolinium to YSZ can improve its thermal stability, reduce thermal conductivity, and enhance resistance to sintering at high temperatures. These dopants modify the crystal structure and create oxygen vacancies that scatter phonons, thereby improving the coating's insulating properties.

- Pyrochlore-structured ceramics with rare-earth elements: Pyrochlore-structured ceramics containing rare-earth elements offer excellent thermal barrier properties. These materials, typically composed of rare-earth zirconates or hafnates (such as La2Zr2O7 or Gd2Zr2O7), exhibit inherently low thermal conductivity and high temperature stability. The incorporation of rare-earth elements in the pyrochlore structure creates complex crystal arrangements that effectively scatter heat-carrying phonons, resulting in superior thermal insulation performance compared to conventional YSZ coatings.

- Multi-layered thermal barrier coatings with rare-earth gradients: Multi-layered thermal barrier coating systems incorporate gradients of rare-earth dopants to optimize performance. These systems typically feature different ceramic layers with varying concentrations of rare-earth elements, creating a functional gradient that maximizes thermal protection while maintaining mechanical integrity. The gradient structure helps manage thermal expansion mismatch between the substrate and coating, reduces thermal stresses, and provides enhanced durability under thermal cycling conditions.

- Rare-earth co-doping strategies for enhanced thermal properties: Co-doping thermal barrier ceramics with multiple rare-earth elements creates synergistic effects that enhance coating performance. By carefully selecting combinations of rare-earth dopants (such as La+Gd, Yb+Gd, or Sm+Nd), thermal conductivity can be further reduced beyond what is possible with single dopants. The different ionic radii of the rare-earth elements create lattice distortions and point defects that effectively scatter phonons across a broader spectrum of wavelengths, improving the overall thermal insulation properties.

- Novel deposition techniques for rare-earth doped ceramic coatings: Advanced deposition techniques have been developed to effectively incorporate rare-earth dopants into ceramic thermal barrier coatings. These include modified plasma spraying, solution precursor methods, electron beam physical vapor deposition, and sol-gel processes specifically optimized for rare-earth element incorporation. These techniques enable precise control over the microstructure, porosity, and distribution of rare-earth dopants within the ceramic matrix, resulting in coatings with superior thermal insulation properties and enhanced durability under extreme operating conditions.

02 Pyrochlore-structured rare-earth zirconates

Rare-earth zirconates with pyrochlore crystal structures, such as gadolinium zirconate or lanthanum zirconate, offer excellent thermal barrier properties. These materials feature inherently low thermal conductivity and superior phase stability at high temperatures compared to conventional YSZ coatings. The pyrochlore structure, combined with rare-earth elements, creates complex oxygen vacancy arrangements that impede heat transfer through the coating, making them particularly suitable for extreme temperature applications in advanced turbine engines.Expand Specific Solutions03 Multi-layered thermal barrier coating systems with rare-earth elements

Multi-layered thermal barrier coating systems incorporate different rare-earth doped ceramic layers to optimize performance. These systems typically include a bond coat, a thermally grown oxide layer, and multiple ceramic top layers with varying compositions of rare-earth dopants. The gradient or layered structure allows for tailored properties throughout the coating thickness, with rare-earth elements strategically distributed to enhance thermal resistance, mechanical properties, and durability under thermal cycling conditions.Expand Specific Solutions04 Rare-earth phosphates and silicates for thermal barrier applications

Rare-earth phosphates and silicates represent an emerging class of thermal barrier coating materials with exceptional high-temperature capabilities. These compounds, incorporating elements like ytterbium, lutetium, or erbium, demonstrate remarkable resistance to sintering and phase transformations at elevated temperatures. Their complex crystal structures and strong chemical bonds contribute to low thermal conductivity and excellent thermal shock resistance, making them suitable for next-generation turbine engines operating at increasingly higher temperatures.Expand Specific Solutions05 Novel deposition techniques for rare-earth doped ceramic coatings

Advanced deposition techniques have been developed specifically for applying rare-earth doped ceramic thermal barrier coatings. These include modified plasma spray processes, solution precursor methods, electron beam physical vapor deposition, and suspension plasma spray techniques. These specialized methods enable precise control over coating microstructure, porosity, and rare-earth dopant distribution, resulting in optimized thermal barrier properties. The techniques allow for the creation of columnar structures, segmented cracks, or controlled porosity that further enhance thermal insulation performance and strain tolerance.Expand Specific Solutions

Leading Organizations in Advanced Ceramic Coatings Research

The thermal barrier coatings (TBC) ceramics market with advanced rare-earth dopants is currently in a growth phase, driven by increasing demand in aerospace, power generation, and automotive industries. The global market size is estimated to exceed $1.5 billion, with projected annual growth of 6-8%. Major players include established aerospace and industrial giants like General Electric, Rolls-Royce, Honeywell, and Mitsubishi Heavy Industries, who possess mature TBC technologies. Emerging competition comes from specialized materials companies such as Grirem Advanced Materials and Shaanxi Tianxuan Coating Technology, focusing on rare-earth innovations. Research institutions like Korea Institute of Ceramic Engineering & Technology and universities in China are advancing fundamental research, creating a competitive landscape balanced between established industrial players and emerging specialized manufacturers with rare-earth expertise.

General Electric Company

Technical Solution: General Electric has developed advanced thermal barrier coating systems incorporating rare-earth dopants, particularly focusing on gadolinium, ytterbium, and samarium-doped YSZ (yttria-stabilized zirconia) coatings. Their proprietary CMAS (calcium-magnesium-alumino-silicate) resistant TBC technology utilizes rare-earth zirconates and hafnates that form apatite phases upon reaction with molten CMAS, preventing further infiltration. GE's research has demonstrated that gadolinium zirconate coatings with specific rare-earth dopant concentrations can achieve thermal conductivity reductions of up to 40% compared to conventional YSZ coatings while maintaining phase stability at temperatures exceeding 1300°C. Their electron beam physical vapor deposition (EB-PVD) technique creates columnar microstructures with enhanced strain tolerance and thermal cycling durability, extending component life in extreme temperature environments by up to 30%.

Strengths: Superior CMAS resistance through rare-earth zirconate formulations; established manufacturing infrastructure for consistent coating quality; extensive testing capabilities in actual engine environments. Weaknesses: Higher production costs compared to conventional coatings; intellectual property restrictions limiting broader application; potential supply chain vulnerabilities for certain rare-earth elements.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed thermal barrier coating systems incorporating cerium, gadolinium and ytterbium rare-earth dopants in both traditional YSZ and advanced pyrochlore structures. Their research focuses on double rare-earth doping approaches, where combinations like cerium-gadolinium provide synergistic effects on both thermal and mechanical properties. MHI's proprietary atmospheric plasma spray process achieves controlled porosity (15-25%) with optimized rare-earth distribution, resulting in thermal conductivity reductions of up to 35% compared to standard YSZ. Their coatings feature a unique microstructure with vertically-oriented microcracks that enhance strain tolerance while maintaining excellent erosion resistance. MHI has demonstrated that their cerium-doped gadolinium zirconate coatings maintain phase stability after 1000 hours at 1400°C, significantly outperforming conventional systems. The company has also developed rare-earth aluminate bond coats that form exceptionally stable thermally grown oxide layers, reducing spallation risk during thermal cycling.

Strengths: Excellent thermal cycling durability through optimized microstructure; superior phase stability at ultra-high temperatures; innovative double rare-earth doping approach. Weaknesses: Limited field service data compared to more established competitors; potential challenges in scaling production for larger components; higher material costs due to specific rare-earth element requirements.

Critical Patents and Innovations in TBC Ceramics

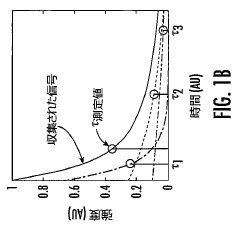

Rare earth-doped thermal barrier coating bond coat for thermally grown oxide luminescence sensing, including temperature monitoring and temperature gradient measurement

PatentActiveJP2023504040A

Innovation

- A rare earth-doped thermal barrier coating configuration with a metallic bond coat layer and a ceramic topcoat layer, incorporating rare earth luminescent dopants, enables direct luminescence sensing of the thermally grown oxide layer for real-time temperature measurements using phosphor thermometry, allowing for accurate temperature monitoring and gradient analysis.

Environmental Impact and Sustainability of Rare-Earth Materials

The extraction and processing of rare-earth elements for thermal barrier coatings (TBCs) presents significant environmental challenges that must be addressed for sustainable implementation. Mining operations for rare-earth materials typically generate substantial waste, including radioactive tailings containing thorium and uranium, which pose long-term environmental hazards if not properly managed. The extraction processes often involve aggressive chemicals such as strong acids and organic solvents that can contaminate soil and water systems if released into the environment.

Water consumption represents another critical concern, as rare-earth processing facilities require large volumes of water, potentially straining local resources in water-scarce regions. Additionally, the energy-intensive separation and purification processes contribute significantly to the carbon footprint of rare-earth production, with estimates suggesting that processing one ton of rare-earth oxides can generate 12-15 tons of CO2 emissions.

Recent sustainability initiatives have focused on developing more environmentally responsible approaches to rare-earth utilization in TBC applications. Closed-loop recycling systems are emerging as promising solutions, allowing for the recovery and reuse of rare-earth elements from end-of-life thermal barrier coatings. Research indicates that up to 85% of certain rare-earth dopants can be recovered through advanced hydrometallurgical processes, substantially reducing the need for virgin material extraction.

Alternative sourcing strategies are also gaining traction, including the extraction of rare-earth elements from industrial by-products such as phosphogypsum and red mud. These secondary sources can provide meaningful quantities of rare-earth materials while simultaneously addressing existing waste management challenges.

Life cycle assessment (LCA) studies comparing conventional yttria-stabilized zirconia coatings with advanced rare-earth doped alternatives reveal complex sustainability trade-offs. While rare-earth doped TBCs typically demonstrate superior thermal performance and longevity—potentially reducing overall material consumption through extended service life—their production phase carries higher environmental impacts. The optimal balance appears to depend on specific application parameters, particularly operating temperature and expected service duration.

Regulatory frameworks governing rare-earth mining and processing continue to evolve globally, with increasing emphasis on environmental protection and responsible sourcing. The European Union's Critical Raw Materials Act and similar initiatives in North America and Asia are establishing more stringent standards for the rare-earth supply chain, potentially reshaping the economics and environmental profile of rare-earth doped thermal barrier coatings in the coming decade.

Water consumption represents another critical concern, as rare-earth processing facilities require large volumes of water, potentially straining local resources in water-scarce regions. Additionally, the energy-intensive separation and purification processes contribute significantly to the carbon footprint of rare-earth production, with estimates suggesting that processing one ton of rare-earth oxides can generate 12-15 tons of CO2 emissions.

Recent sustainability initiatives have focused on developing more environmentally responsible approaches to rare-earth utilization in TBC applications. Closed-loop recycling systems are emerging as promising solutions, allowing for the recovery and reuse of rare-earth elements from end-of-life thermal barrier coatings. Research indicates that up to 85% of certain rare-earth dopants can be recovered through advanced hydrometallurgical processes, substantially reducing the need for virgin material extraction.

Alternative sourcing strategies are also gaining traction, including the extraction of rare-earth elements from industrial by-products such as phosphogypsum and red mud. These secondary sources can provide meaningful quantities of rare-earth materials while simultaneously addressing existing waste management challenges.

Life cycle assessment (LCA) studies comparing conventional yttria-stabilized zirconia coatings with advanced rare-earth doped alternatives reveal complex sustainability trade-offs. While rare-earth doped TBCs typically demonstrate superior thermal performance and longevity—potentially reducing overall material consumption through extended service life—their production phase carries higher environmental impacts. The optimal balance appears to depend on specific application parameters, particularly operating temperature and expected service duration.

Regulatory frameworks governing rare-earth mining and processing continue to evolve globally, with increasing emphasis on environmental protection and responsible sourcing. The European Union's Critical Raw Materials Act and similar initiatives in North America and Asia are establishing more stringent standards for the rare-earth supply chain, potentially reshaping the economics and environmental profile of rare-earth doped thermal barrier coatings in the coming decade.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for thermal barrier coatings (TBCs) with rare-earth dopants presents significant challenges and opportunities for industrial implementation. Current production methods for conventional yttria-stabilized zirconia (YSZ) coatings are well-established, but incorporating advanced rare-earth dopants introduces complexity that affects both manufacturing processes and economic viability.

Atmospheric plasma spraying (APS) remains the most cost-effective method for large-scale TBC production, with equipment costs ranging from $500,000 to $2 million depending on automation levels. When incorporating rare-earth dopants such as gadolinium, samarium, or lanthanum, powder preparation costs increase by 30-45% compared to standard YSZ powders, primarily due to the high purity requirements and complex processing of rare-earth oxides.

Electron beam physical vapor deposition (EB-PVD), while offering superior coating quality, faces even greater cost implications when using rare-earth elements. The initial investment for EB-PVD systems ($3-5 million) coupled with operational costs makes this method economically viable only for high-value applications such as advanced aircraft engines or power generation turbines where performance justifies the premium.

Material supply chain considerations significantly impact manufacturing scalability. The rare-earth market experiences price volatility and supply constraints, particularly for elements like dysprosium and ytterbium, which have seen price fluctuations of up to 200% in recent years. Diversification of supply sources beyond China, which controls approximately 85% of global rare-earth production, remains a critical challenge for ensuring manufacturing stability.

Process optimization studies indicate that incremental improvements in deposition efficiency can substantially reduce costs. Recent advancements in suspension and solution precursor plasma spraying have demonstrated 15-20% material utilization improvements for rare-earth doped coatings, potentially reducing overall production costs by 10-15% at scale.

Quality control requirements for rare-earth doped TBCs are more stringent than conventional coatings, necessitating advanced characterization techniques that add approximately $50-100 per component in testing costs. However, these costs are offset by the extended service life of components, which can be 1.5-2.5 times longer than conventional TBCs, depending on the specific rare-earth dopant combination and application environment.

For mass production scenarios, automated systems capable of processing 1000+ components annually represent the economic threshold where rare-earth doped TBCs become cost-competitive with conventional coatings on a lifecycle basis. This economic crossover point varies significantly by industry, with aerospace applications reaching parity faster than industrial gas turbine applications due to different performance requirements and operational conditions.

Atmospheric plasma spraying (APS) remains the most cost-effective method for large-scale TBC production, with equipment costs ranging from $500,000 to $2 million depending on automation levels. When incorporating rare-earth dopants such as gadolinium, samarium, or lanthanum, powder preparation costs increase by 30-45% compared to standard YSZ powders, primarily due to the high purity requirements and complex processing of rare-earth oxides.

Electron beam physical vapor deposition (EB-PVD), while offering superior coating quality, faces even greater cost implications when using rare-earth elements. The initial investment for EB-PVD systems ($3-5 million) coupled with operational costs makes this method economically viable only for high-value applications such as advanced aircraft engines or power generation turbines where performance justifies the premium.

Material supply chain considerations significantly impact manufacturing scalability. The rare-earth market experiences price volatility and supply constraints, particularly for elements like dysprosium and ytterbium, which have seen price fluctuations of up to 200% in recent years. Diversification of supply sources beyond China, which controls approximately 85% of global rare-earth production, remains a critical challenge for ensuring manufacturing stability.

Process optimization studies indicate that incremental improvements in deposition efficiency can substantially reduce costs. Recent advancements in suspension and solution precursor plasma spraying have demonstrated 15-20% material utilization improvements for rare-earth doped coatings, potentially reducing overall production costs by 10-15% at scale.

Quality control requirements for rare-earth doped TBCs are more stringent than conventional coatings, necessitating advanced characterization techniques that add approximately $50-100 per component in testing costs. However, these costs are offset by the extended service life of components, which can be 1.5-2.5 times longer than conventional TBCs, depending on the specific rare-earth dopant combination and application environment.

For mass production scenarios, automated systems capable of processing 1000+ components annually represent the economic threshold where rare-earth doped TBCs become cost-competitive with conventional coatings on a lifecycle basis. This economic crossover point varies significantly by industry, with aerospace applications reaching parity faster than industrial gas turbine applications due to different performance requirements and operational conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!