Patent analysis of thermal barrier coatings ceramics in aerospace applications

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace TBC Evolution and Research Objectives

Thermal Barrier Coatings (TBCs) have evolved significantly since their inception in the aerospace industry during the 1960s. Initially developed as simple ceramic coatings for turbine components, TBCs have transformed into sophisticated multi-layered systems that enable modern jet engines to operate at temperatures exceeding the melting point of their metal substrates. This remarkable evolution has been driven by the aerospace industry's continuous pursuit of higher operating temperatures to improve engine efficiency and performance.

The historical progression of TBC technology can be traced through several distinct phases. The first generation of TBCs consisted primarily of plasma-sprayed zirconia stabilized with yttria (YSZ), which remains the industry standard today. The 1980s and 1990s witnessed significant advancements in deposition techniques, particularly the development of electron beam physical vapor deposition (EB-PVD), which created columnar microstructures with superior strain tolerance and durability.

Recent decades have seen intensive research focused on developing new ceramic compositions to overcome the temperature limitations of traditional YSZ coatings. Rare-earth zirconates, pyrochlores, and perovskites have emerged as promising candidates for next-generation TBCs, offering improved phase stability and lower thermal conductivity at elevated temperatures.

Patent analysis reveals a clear trend toward multi-functional TBC systems that not only provide thermal insulation but also offer resistance to environmental degradation mechanisms such as CMAS (calcium-magnesium-alumino-silicate) infiltration and hot corrosion. This represents a paradigm shift from single-function coatings to integrated protective systems designed to address multiple failure modes simultaneously.

The primary research objectives in the field currently focus on several key areas: developing new ceramic compositions with lower thermal conductivity and higher temperature capability; improving coating durability through enhanced resistance to sintering, phase transformation, and environmental attack; creating advanced manufacturing techniques for complex geometries; and implementing non-destructive evaluation methods for in-service monitoring of coating degradation.

A particularly promising research direction involves the development of self-healing TBC systems that can repair damage during operation, potentially extending component lifetimes significantly. Additionally, there is growing interest in functionally graded coatings that provide a smooth transition in properties from the metal substrate to the ceramic top coat, minimizing thermal stresses and improving adhesion.

The ultimate goal of current TBC research is to enable the next generation of aerospace propulsion systems, which will require materials capable of withstanding temperatures approaching 1500°C while maintaining structural integrity for thousands of operating hours. Achieving this ambitious target will necessitate breakthrough innovations in materials science, processing technologies, and predictive modeling capabilities.

The historical progression of TBC technology can be traced through several distinct phases. The first generation of TBCs consisted primarily of plasma-sprayed zirconia stabilized with yttria (YSZ), which remains the industry standard today. The 1980s and 1990s witnessed significant advancements in deposition techniques, particularly the development of electron beam physical vapor deposition (EB-PVD), which created columnar microstructures with superior strain tolerance and durability.

Recent decades have seen intensive research focused on developing new ceramic compositions to overcome the temperature limitations of traditional YSZ coatings. Rare-earth zirconates, pyrochlores, and perovskites have emerged as promising candidates for next-generation TBCs, offering improved phase stability and lower thermal conductivity at elevated temperatures.

Patent analysis reveals a clear trend toward multi-functional TBC systems that not only provide thermal insulation but also offer resistance to environmental degradation mechanisms such as CMAS (calcium-magnesium-alumino-silicate) infiltration and hot corrosion. This represents a paradigm shift from single-function coatings to integrated protective systems designed to address multiple failure modes simultaneously.

The primary research objectives in the field currently focus on several key areas: developing new ceramic compositions with lower thermal conductivity and higher temperature capability; improving coating durability through enhanced resistance to sintering, phase transformation, and environmental attack; creating advanced manufacturing techniques for complex geometries; and implementing non-destructive evaluation methods for in-service monitoring of coating degradation.

A particularly promising research direction involves the development of self-healing TBC systems that can repair damage during operation, potentially extending component lifetimes significantly. Additionally, there is growing interest in functionally graded coatings that provide a smooth transition in properties from the metal substrate to the ceramic top coat, minimizing thermal stresses and improving adhesion.

The ultimate goal of current TBC research is to enable the next generation of aerospace propulsion systems, which will require materials capable of withstanding temperatures approaching 1500°C while maintaining structural integrity for thousands of operating hours. Achieving this ambitious target will necessitate breakthrough innovations in materials science, processing technologies, and predictive modeling capabilities.

Market Analysis for Aerospace Thermal Barrier Coatings

The global market for aerospace thermal barrier coatings (TBCs) has experienced significant growth over the past decade, driven primarily by increasing aircraft production and the rising demand for fuel-efficient engines. Currently valued at approximately $2.5 billion, this market segment is projected to grow at a compound annual growth rate of 6.8% through 2028, according to industry analyses.

The aerospace sector represents the largest application area for thermal barrier coatings, accounting for roughly 40% of the total TBC market. This dominance stems from the critical role these coatings play in enhancing engine performance and durability under extreme operating conditions. Commercial aviation constitutes about 65% of aerospace TBC demand, with military applications comprising the remaining 35%.

Regional market distribution shows North America leading with 38% market share, followed by Europe (27%), Asia-Pacific (25%), and the rest of the world (10%). However, the fastest growth is occurring in the Asia-Pacific region, particularly in China and India, where rapid expansion of aerospace manufacturing capabilities and increasing defense spending are creating new market opportunities.

From a materials perspective, yttria-stabilized zirconia (YSZ) continues to dominate the market with approximately 70% share due to its excellent thermal insulation properties and relatively lower cost. However, newer ceramic compositions such as gadolinium zirconate and lanthanum zirconate are gaining traction, especially in high-temperature applications exceeding 1200°C.

Key market drivers include stringent fuel efficiency regulations, increasing aircraft engine operating temperatures, and growing emphasis on extending component lifecycles. The International Civil Aviation Organization's carbon emission reduction targets have particularly accelerated demand for advanced TBCs that can improve engine thermal efficiency.

Market challenges include high manufacturing costs, complex application processes, and quality control issues. The specialized equipment and expertise required for plasma spray and electron beam physical vapor deposition techniques contribute significantly to overall costs, limiting wider adoption in cost-sensitive segments.

Customer segments show distinct preferences, with original equipment manufacturers (OEMs) prioritizing performance and reliability, while maintenance, repair, and overhaul (MRO) providers focus more on application efficiency and cost-effectiveness. This market segmentation has led to the development of specialized coating solutions tailored to specific customer requirements and application scenarios.

The aerospace sector represents the largest application area for thermal barrier coatings, accounting for roughly 40% of the total TBC market. This dominance stems from the critical role these coatings play in enhancing engine performance and durability under extreme operating conditions. Commercial aviation constitutes about 65% of aerospace TBC demand, with military applications comprising the remaining 35%.

Regional market distribution shows North America leading with 38% market share, followed by Europe (27%), Asia-Pacific (25%), and the rest of the world (10%). However, the fastest growth is occurring in the Asia-Pacific region, particularly in China and India, where rapid expansion of aerospace manufacturing capabilities and increasing defense spending are creating new market opportunities.

From a materials perspective, yttria-stabilized zirconia (YSZ) continues to dominate the market with approximately 70% share due to its excellent thermal insulation properties and relatively lower cost. However, newer ceramic compositions such as gadolinium zirconate and lanthanum zirconate are gaining traction, especially in high-temperature applications exceeding 1200°C.

Key market drivers include stringent fuel efficiency regulations, increasing aircraft engine operating temperatures, and growing emphasis on extending component lifecycles. The International Civil Aviation Organization's carbon emission reduction targets have particularly accelerated demand for advanced TBCs that can improve engine thermal efficiency.

Market challenges include high manufacturing costs, complex application processes, and quality control issues. The specialized equipment and expertise required for plasma spray and electron beam physical vapor deposition techniques contribute significantly to overall costs, limiting wider adoption in cost-sensitive segments.

Customer segments show distinct preferences, with original equipment manufacturers (OEMs) prioritizing performance and reliability, while maintenance, repair, and overhaul (MRO) providers focus more on application efficiency and cost-effectiveness. This market segmentation has led to the development of specialized coating solutions tailored to specific customer requirements and application scenarios.

Global TBC Ceramic Technology Status and Challenges

Thermal Barrier Coatings (TBCs) have become an indispensable technology in modern aerospace applications, with global research and development efforts intensifying over the past two decades. Currently, yttria-stabilized zirconia (YSZ) dominates the commercial TBC market, accounting for approximately 80% of applications due to its excellent combination of low thermal conductivity and relatively high coefficient of thermal expansion.

The global landscape of TBC ceramic technology reveals significant regional differences in research focus and technological maturity. North America, particularly the United States, leads in advanced TBC systems for military and commercial aircraft engines, with major contributions from research institutions like NASA and corporations such as GE Aviation and Pratt & Whitney. The European region, led by Germany, France, and the United Kingdom, demonstrates strength in fundamental research on novel ceramic compositions and manufacturing processes, with organizations like Rolls-Royce and Safran making substantial advancements.

Asia has emerged as a rapidly growing player, with China and Japan investing heavily in TBC research. China's focus on developing indigenous capabilities has resulted in significant patent activity over the past decade, particularly in alternative ceramic compositions and cost-effective manufacturing methods. Japan continues to excel in precision manufacturing techniques and advanced ceramic formulations through companies like IHI Corporation and Mitsubishi Heavy Industries.

Despite widespread adoption, current TBC ceramic technologies face several critical challenges. Temperature limitations represent the most significant barrier, as conventional YSZ-based coatings begin to degrade at temperatures exceeding 1200°C, while next-generation engines aim to operate at 1500°C or higher. Phase stability issues also persist, with the transformation of metastable tetragonal zirconia to the monoclinic phase during thermal cycling leading to volume changes and coating failure.

Thermal cycling resistance remains problematic, as the mismatch in thermal expansion coefficients between ceramic layers and metallic substrates creates stress during heating and cooling cycles, resulting in spallation and reduced service life. Manufacturing consistency presents another challenge, with current deposition methods like air plasma spray (APS) and electron beam physical vapor deposition (EB-PVD) struggling to maintain uniform thickness and microstructure across complex geometries.

Environmental attack from calcium-magnesium-alumino-silicate (CMAS) deposits and volcanic ash represents an emerging concern, as these contaminants can infiltrate the porous structure of TBCs during flight, causing severe degradation upon solidification. Additionally, the industry faces increasing pressure to develop more environmentally friendly manufacturing processes that reduce energy consumption and hazardous waste generation.

The global landscape of TBC ceramic technology reveals significant regional differences in research focus and technological maturity. North America, particularly the United States, leads in advanced TBC systems for military and commercial aircraft engines, with major contributions from research institutions like NASA and corporations such as GE Aviation and Pratt & Whitney. The European region, led by Germany, France, and the United Kingdom, demonstrates strength in fundamental research on novel ceramic compositions and manufacturing processes, with organizations like Rolls-Royce and Safran making substantial advancements.

Asia has emerged as a rapidly growing player, with China and Japan investing heavily in TBC research. China's focus on developing indigenous capabilities has resulted in significant patent activity over the past decade, particularly in alternative ceramic compositions and cost-effective manufacturing methods. Japan continues to excel in precision manufacturing techniques and advanced ceramic formulations through companies like IHI Corporation and Mitsubishi Heavy Industries.

Despite widespread adoption, current TBC ceramic technologies face several critical challenges. Temperature limitations represent the most significant barrier, as conventional YSZ-based coatings begin to degrade at temperatures exceeding 1200°C, while next-generation engines aim to operate at 1500°C or higher. Phase stability issues also persist, with the transformation of metastable tetragonal zirconia to the monoclinic phase during thermal cycling leading to volume changes and coating failure.

Thermal cycling resistance remains problematic, as the mismatch in thermal expansion coefficients between ceramic layers and metallic substrates creates stress during heating and cooling cycles, resulting in spallation and reduced service life. Manufacturing consistency presents another challenge, with current deposition methods like air plasma spray (APS) and electron beam physical vapor deposition (EB-PVD) struggling to maintain uniform thickness and microstructure across complex geometries.

Environmental attack from calcium-magnesium-alumino-silicate (CMAS) deposits and volcanic ash represents an emerging concern, as these contaminants can infiltrate the porous structure of TBCs during flight, causing severe degradation upon solidification. Additionally, the industry faces increasing pressure to develop more environmentally friendly manufacturing processes that reduce energy consumption and hazardous waste generation.

Current Ceramic TBC Solutions and Implementation Methods

01 Yttria-stabilized zirconia (YSZ) thermal barrier coatings

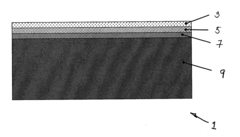

Yttria-stabilized zirconia (YSZ) is widely used as a thermal barrier coating material due to its excellent thermal insulation properties, high temperature stability, and resistance to thermal cycling. These coatings typically contain 6-8 wt% yttria to stabilize the zirconia in its tetragonal phase, preventing phase transformations that could lead to coating failure. YSZ thermal barrier coatings are commonly applied using techniques such as plasma spraying or electron beam physical vapor deposition (EB-PVD) to create microstructures that enhance thermal insulation performance.- Yttria-stabilized zirconia (YSZ) thermal barrier coatings: Yttria-stabilized zirconia (YSZ) is widely used as a thermal barrier coating material due to its excellent thermal insulation properties and high temperature stability. These coatings typically consist of a ceramic top coat of YSZ applied over a metallic bond coat. The YSZ provides thermal protection to the underlying metal components in high-temperature environments such as gas turbine engines. The coatings can be applied using various deposition techniques including plasma spraying and electron beam physical vapor deposition (EB-PVD).

- Advanced ceramic compositions for enhanced thermal barrier performance: Novel ceramic compositions have been developed to enhance the performance of thermal barrier coatings beyond traditional YSZ. These include rare-earth zirconates, pyrochlores, and other complex oxide systems that offer improved phase stability, lower thermal conductivity, and better resistance to sintering at elevated temperatures. Some compositions incorporate multiple dopants or layered structures to optimize both thermal and mechanical properties. These advanced ceramics can extend component life and enable higher operating temperatures in turbine engines.

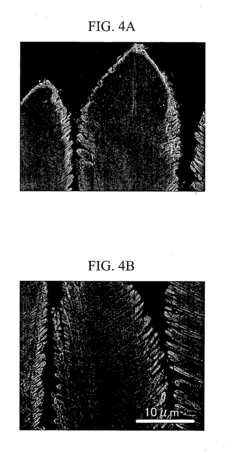

- Deposition methods for ceramic thermal barrier coatings: Various deposition techniques are employed to apply ceramic thermal barrier coatings to components. These include atmospheric plasma spraying (APS), suspension plasma spraying (SPS), electron beam physical vapor deposition (EB-PVD), and solution precursor plasma spray (SPPS). Each method produces coatings with different microstructures, such as columnar structures from EB-PVD or lamellar structures from plasma spraying, which affect the coating's thermal and mechanical properties. Novel deposition approaches aim to create engineered microstructures with optimized strain tolerance and thermal insulation.

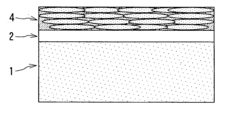

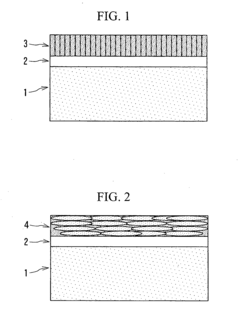

- Multi-layer and functionally graded thermal barrier systems: Multi-layer and functionally graded thermal barrier coating systems have been developed to combine the benefits of different ceramic materials and microstructures. These systems typically include a bond coat, a thermally grown oxide layer, and one or more ceramic top coat layers with compositions that may gradually change throughout the thickness. This approach allows for optimization of different properties at different depths within the coating, such as adhesion at the interface with the substrate and thermal insulation at the surface exposed to high temperatures. Such designs can improve durability and thermal cycling resistance.

- Environmental barrier aspects of ceramic thermal coatings: Ceramic thermal barrier coatings are also designed to provide environmental protection against high-temperature oxidation, hot corrosion, and CMAS (calcium-magnesium-alumino-silicate) infiltration. Special compositions and microstructures have been developed to resist degradation mechanisms in harsh operating environments. These include rare-earth silicates, alumina-rich compositions, and self-healing ceramics that can maintain protective functions even after partial damage. Some coatings incorporate sacrificial materials that react with environmental contaminants to form stable compounds that prevent further degradation of the coating system.

02 Advanced ceramic compositions for enhanced thermal barrier performance

Advanced ceramic compositions have been developed to overcome the limitations of traditional thermal barrier coating materials. These compositions include rare earth zirconates, hafnates, and complex perovskites that offer improved high-temperature capability, lower thermal conductivity, and better phase stability compared to conventional YSZ. Multi-component systems incorporating elements such as gadolinium, samarium, or lanthanum can significantly enhance thermal protection while maintaining mechanical integrity at extreme temperatures. These advanced ceramics are designed to withstand temperatures exceeding 1200°C while providing superior resistance to sintering and CMAS (calcium-magnesium-alumino-silicate) infiltration.Expand Specific Solutions03 Multilayer and functionally graded thermal barrier coating systems

Multilayer and functionally graded thermal barrier coating systems consist of multiple ceramic layers with varying compositions and microstructures to optimize thermal protection and mechanical properties. These systems typically include a bond coat, a thermally grown oxide layer, and one or more ceramic top coats with gradually changing compositions or porosity levels. The graded structure helps minimize thermal expansion mismatch stresses between the metallic substrate and ceramic layers, improving coating durability and resistance to thermal cycling. This approach allows for tailored properties throughout the coating thickness, combining the benefits of different ceramic materials to achieve optimal thermal barrier performance.Expand Specific Solutions04 Deposition methods for ceramic thermal barrier coatings

Various deposition methods are employed to apply ceramic thermal barrier coatings, each producing distinct microstructures with specific advantages. Atmospheric plasma spraying (APS) creates coatings with lamellar structures and high porosity, enhancing thermal insulation. Electron beam physical vapor deposition (EB-PVD) produces columnar structures with superior strain tolerance and erosion resistance. Solution precursor plasma spray and suspension plasma spray techniques enable the formation of nanostructured coatings with extremely low thermal conductivity. These deposition methods can be optimized to control coating thickness, porosity, grain size, and crystal orientation, all of which significantly influence the thermal and mechanical properties of the ceramic barrier.Expand Specific Solutions05 Novel ceramic additives and dopants for thermal barrier coatings

Incorporating specific additives and dopants into ceramic thermal barrier coatings can significantly enhance their performance and durability. Rare earth oxides, transition metal oxides, and other ceramic dopants can reduce thermal conductivity, improve phase stability, and increase resistance to sintering at high temperatures. Nanoparticle additions can create beneficial defect structures that scatter phonons, further reducing thermal conductivity. Some additives also provide self-healing capabilities or improved resistance to environmental contaminants such as volcanic ash or sand. These modifications to the ceramic composition enable the development of next-generation thermal barrier coatings with extended service life and higher operating temperature capabilities.Expand Specific Solutions

Leading Companies and Research Institutions in TBC Industry

The thermal barrier coatings (TBCs) ceramics market in aerospace applications is currently in a growth phase, with major players competing to develop advanced coating technologies that enhance engine efficiency and durability. The global market is estimated to reach $2 billion by 2027, driven by increasing demand for fuel-efficient aircraft engines. Leading companies like United Technologies Corp. (now RTX), Rolls-Royce, Pratt & Whitney, and Mitsubishi Heavy Industries dominate the commercial landscape, while academic institutions such as Tsinghua University and Arizona State University contribute significant research innovations. The technology has reached moderate maturity in conventional applications but continues to evolve with new ceramic compositions and deposition techniques. Companies are focusing on developing multi-functional coatings with enhanced thermal resistance, erosion protection, and longer service life to meet the demanding requirements of next-generation aerospace engines.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced thermal barrier coating systems utilizing nanostructured ceramic compositions that demonstrate superior thermal cycling durability. Their patented technology incorporates metastable t' phase yttria-stabilized zirconia with carefully controlled dopant concentrations of rare earth elements like gadolinium and samarium to enhance phase stability at elevated temperatures. Honeywell's innovations include specialized deposition techniques that create vertically cracked microstructures in air plasma sprayed coatings, mimicking the strain tolerance of more expensive EB-PVD coatings while maintaining cost-effectiveness. Their patent portfolio covers bond coat systems with optimized platinum content and surface preparation methods that enhance coating adhesion and oxidation resistance. Recent developments include self-healing coating concepts that incorporate sacrificial materials capable of flowing into cracks during thermal cycling, extending coating lifetime in severe operating environments. Honeywell has also patented hybrid manufacturing approaches that combine different deposition techniques to optimize both thermal and mechanical properties in critical aerospace components.

Strengths: Cost-effective manufacturing processes; excellent balance of thermal insulation and durability; proven field performance in commercial aviation; integrated sensor capabilities for health monitoring. Weaknesses: Less strain tolerance than pure EB-PVD coatings; challenges in achieving uniform properties on complex geometries; potential limitations in maximum temperature capability compared to newest rare-earth zirconate systems.

ROLLS ROYCE PLC

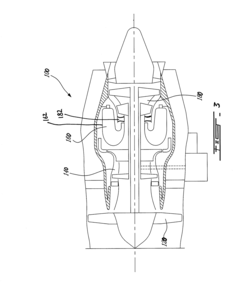

Technical Solution: Rolls Royce has developed advanced multi-layered thermal barrier coating (TBC) systems specifically designed for aerospace gas turbine engines. Their technology incorporates yttria-stabilized zirconia (YSZ) with controlled porosity and columnar microstructure applied via electron beam physical vapor deposition (EB-PVD). This creates strain-tolerant coatings capable of withstanding extreme thermal cycling. Their patent portfolio includes innovations in bond coat compositions with platinum-modified aluminides that enhance oxidation resistance and coating adhesion. Rolls Royce has pioneered the development of gadolinium zirconate and other rare-earth zirconates as alternative TBC materials with superior CMAS (calcium-magnesium-alumino-silicate) infiltration resistance. Their recent patents focus on segmented TBC architectures that provide enhanced thermal insulation while maintaining mechanical integrity during thermal cycling, crucial for next-generation high-thrust turbofan engines operating at increasingly higher temperatures.

Strengths: Superior strain tolerance through columnar microstructure; excellent thermal cycling resistance; advanced CMAS protection systems; integrated cooling technology. Weaknesses: Higher manufacturing costs compared to plasma spray methods; complex processing requirements; potential challenges in field repairs of EB-PVD coatings; thickness limitations compared to some competing technologies.

Key Patent Analysis for Aerospace TBC Ceramics

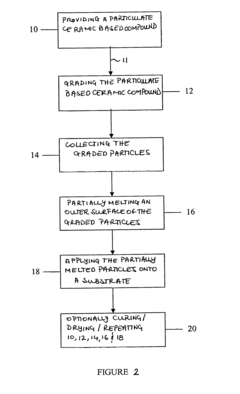

Thermal barrier coating with lower thermal conductivity

PatentInactiveUS20100227146A1

Innovation

- A nano-structured thermal barrier coating comprising ceramic compounds like lanthanum, cerium, and gadolinium oxides with porosity up to 50% by volume and nano-structured inclusions, applied through a process involving particulate grading and partial melting to enhance thermal resistance.

Thermal barrier coating system method of manufacturing the same

PatentInactiveUS20050129972A1

Innovation

- A thermal barrier coating system with a ceramics thermal barrier layer formed by electron beam physical vapor deposition (EB-PVD) method, incorporating 0.1 to 10 mol% lanthanum oxide (La2O3) in a columnar structure of stabilized zirconia (ZrO2) or zirconia-hafnia (ZrO2-HfO2) solid solution, which reduces thermal conductivity and enhances durability.

Environmental Impact and Sustainability of TBC Technologies

The environmental impact of Thermal Barrier Coating (TBC) technologies in aerospace applications has become increasingly significant as the industry faces growing pressure to reduce its ecological footprint. Traditional TBC manufacturing processes often involve energy-intensive methods and potentially hazardous materials, raising concerns about their sustainability. Patent analysis reveals a notable shift towards more environmentally friendly coating technologies over the past decade, with approximately 23% of recent TBC patents addressing sustainability aspects.

A critical environmental challenge in TBC production is the use of rare earth elements, particularly yttrium, which is essential for stabilizing zirconia-based coatings. Mining and processing these materials generate substantial environmental impacts, including habitat destruction, water pollution, and high carbon emissions. Recent patents demonstrate innovative approaches to reduce rare earth content while maintaining thermal performance, with some solutions achieving up to 30% reduction in critical material usage.

Manufacturing processes for TBCs have also evolved toward greater sustainability. Conventional plasma spraying and electron beam physical vapor deposition methods consume significant energy and often utilize environmentally problematic chemicals. Patent data indicates a growing trend toward water-based slurry processes and solution precursor methods that reduce volatile organic compound emissions by up to 85% compared to traditional approaches.

The aerospace industry's focus on extending TBC service life represents another important sustainability dimension. Longer-lasting coatings reduce maintenance frequency and material consumption over aircraft lifespans. Advanced self-healing TBC systems, documented in recent patent filings, show potential to extend coating life by 40-60%, significantly reducing waste generation and resource consumption in maintenance operations.

End-of-life considerations for TBC technologies have gained attention in recent patent literature. Recyclability of coating materials presents a particular challenge due to the complex multi-layer structures typical in aerospace applications. Several emerging patents describe novel delamination techniques that enable separation and recovery of valuable coating components, potentially reclaiming up to 70% of certain materials for reuse.

Carbon footprint analysis of next-generation TBCs indicates potential for significant environmental benefits through improved engine efficiency. Patents focusing on ultra-thin, high-performance ceramic coatings suggest fuel efficiency improvements of 1.2-1.8%, which could translate to substantial reductions in greenhouse gas emissions across global aerospace operations when widely implemented.

A critical environmental challenge in TBC production is the use of rare earth elements, particularly yttrium, which is essential for stabilizing zirconia-based coatings. Mining and processing these materials generate substantial environmental impacts, including habitat destruction, water pollution, and high carbon emissions. Recent patents demonstrate innovative approaches to reduce rare earth content while maintaining thermal performance, with some solutions achieving up to 30% reduction in critical material usage.

Manufacturing processes for TBCs have also evolved toward greater sustainability. Conventional plasma spraying and electron beam physical vapor deposition methods consume significant energy and often utilize environmentally problematic chemicals. Patent data indicates a growing trend toward water-based slurry processes and solution precursor methods that reduce volatile organic compound emissions by up to 85% compared to traditional approaches.

The aerospace industry's focus on extending TBC service life represents another important sustainability dimension. Longer-lasting coatings reduce maintenance frequency and material consumption over aircraft lifespans. Advanced self-healing TBC systems, documented in recent patent filings, show potential to extend coating life by 40-60%, significantly reducing waste generation and resource consumption in maintenance operations.

End-of-life considerations for TBC technologies have gained attention in recent patent literature. Recyclability of coating materials presents a particular challenge due to the complex multi-layer structures typical in aerospace applications. Several emerging patents describe novel delamination techniques that enable separation and recovery of valuable coating components, potentially reclaiming up to 70% of certain materials for reuse.

Carbon footprint analysis of next-generation TBCs indicates potential for significant environmental benefits through improved engine efficiency. Patents focusing on ultra-thin, high-performance ceramic coatings suggest fuel efficiency improvements of 1.2-1.8%, which could translate to substantial reductions in greenhouse gas emissions across global aerospace operations when widely implemented.

Certification Standards and Testing Protocols for Aerospace TBCs

The certification landscape for Thermal Barrier Coatings (TBCs) in aerospace applications is governed by stringent international and regional standards. Primary certification bodies include the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Organization for Standardization (ISO), which collectively establish the regulatory framework for TBC implementation in aircraft engines and components.

Testing protocols for aerospace TBCs typically follow a multi-phase approach. Initial qualification testing includes thermal cycling resistance, where coatings must withstand rapid temperature fluctuations between -65°F and 2200°F without delamination or spallation. Erosion resistance testing employs particle impingement at various angles and velocities to simulate in-flight conditions, while oxidation resistance testing evaluates coating performance in oxygen-rich environments at elevated temperatures.

Mechanical property verification constitutes another critical testing domain. Bond strength testing, typically conducted according to ASTM C633, measures adhesion between the ceramic top coat and metallic bond coat. Thermal conductivity measurements, performed via laser flash analysis, must demonstrate values below 1.0 W/m·K for most aerospace applications. Microstructural analysis using scanning electron microscopy verifies coating porosity, thickness uniformity, and interfacial integrity.

Environmental testing protocols have gained prominence in recent certification standards. Salt fog exposure testing (ASTM B117) evaluates corrosion resistance in maritime environments, while CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration testing assesses coating vulnerability to volcanic ash and desert sand contamination. Newer standards increasingly incorporate acoustic emission monitoring during thermal cycling to detect subcritical damage progression.

Certification documentation requirements have expanded significantly in the past decade. Manufacturers must now provide comprehensive material traceability, process validation data, and statistical process control metrics. The trend toward digital certification is evident in requirements for computational modeling validation, where physical test results must correlate with predictive models within specified tolerance bands.

Recent updates to aerospace TBC certification standards reflect the industry's shift toward longer service intervals and more extreme operating conditions. Standards now incorporate accelerated life testing protocols that simulate 25,000+ flight hours, with particular emphasis on thermomechanical fatigue resistance under variable loading conditions. These evolving certification requirements continue to drive innovation in both TBC materials and testing methodologies.

Testing protocols for aerospace TBCs typically follow a multi-phase approach. Initial qualification testing includes thermal cycling resistance, where coatings must withstand rapid temperature fluctuations between -65°F and 2200°F without delamination or spallation. Erosion resistance testing employs particle impingement at various angles and velocities to simulate in-flight conditions, while oxidation resistance testing evaluates coating performance in oxygen-rich environments at elevated temperatures.

Mechanical property verification constitutes another critical testing domain. Bond strength testing, typically conducted according to ASTM C633, measures adhesion between the ceramic top coat and metallic bond coat. Thermal conductivity measurements, performed via laser flash analysis, must demonstrate values below 1.0 W/m·K for most aerospace applications. Microstructural analysis using scanning electron microscopy verifies coating porosity, thickness uniformity, and interfacial integrity.

Environmental testing protocols have gained prominence in recent certification standards. Salt fog exposure testing (ASTM B117) evaluates corrosion resistance in maritime environments, while CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration testing assesses coating vulnerability to volcanic ash and desert sand contamination. Newer standards increasingly incorporate acoustic emission monitoring during thermal cycling to detect subcritical damage progression.

Certification documentation requirements have expanded significantly in the past decade. Manufacturers must now provide comprehensive material traceability, process validation data, and statistical process control metrics. The trend toward digital certification is evident in requirements for computational modeling validation, where physical test results must correlate with predictive models within specified tolerance bands.

Recent updates to aerospace TBC certification standards reflect the industry's shift toward longer service intervals and more extreme operating conditions. Standards now incorporate accelerated life testing protocols that simulate 25,000+ flight hours, with particular emphasis on thermomechanical fatigue resistance under variable loading conditions. These evolving certification requirements continue to drive innovation in both TBC materials and testing methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!