Thermal barrier coatings ceramics in additive manufacturing applications

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TBC Ceramics Background and Objectives

Thermal barrier coatings (TBCs) have evolved significantly since their inception in the 1960s, initially developed for aerospace applications to protect metal components from extreme temperatures. These ceramic-based coatings have traditionally been applied through conventional methods such as plasma spraying and electron beam physical vapor deposition (EB-PVD), enabling critical components in gas turbines and jet engines to operate at temperatures exceeding their melting points.

The integration of TBC ceramics with additive manufacturing (AM) represents a paradigm shift in high-temperature material applications. This convergence aims to overcome the limitations of traditional manufacturing processes by enabling complex geometries, functionally graded structures, and customized thermal protection solutions that were previously unattainable. The evolution of this technology has accelerated in the past decade, driven by increasing demands for more efficient energy systems and advanced aerospace applications.

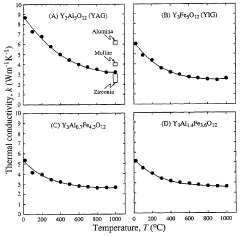

Current technical objectives in this field focus on developing TBC ceramic compositions specifically optimized for AM processes. These materials must maintain excellent thermal insulation properties while being compatible with layer-by-layer fabrication methods. Key performance targets include thermal conductivity below 1.5 W/m·K, temperature capability exceeding 1300°C, and sufficient strain tolerance to withstand thermal cycling without delamination or spallation.

Another critical objective involves addressing the microstructural challenges unique to additively manufactured TBCs. Traditional TBCs rely on specific columnar or splat-like microstructures for optimal performance, which are difficult to replicate in AM processes. Research aims to engineer novel microstructures that can provide equivalent or superior thermal protection while being achievable through AM techniques such as directed energy deposition or binder jetting.

Process integration represents a significant technical goal, as the successful implementation of TBC ceramics in AM requires precise control over numerous parameters including powder characteristics, energy input, layer thickness, and post-processing treatments. The development of standardized protocols for these parameters is essential for ensuring reproducibility and reliability in industrial applications.

Long-term objectives extend to creating multi-material systems where TBC ceramics are seamlessly integrated with metallic substrates in a single AM process, eliminating the need for secondary coating operations. This would revolutionize component design by allowing thermal protection to be incorporated as an intrinsic feature rather than an added layer, potentially leading to more efficient cooling designs and extended component lifespans in extreme thermal environments.

The integration of TBC ceramics with additive manufacturing (AM) represents a paradigm shift in high-temperature material applications. This convergence aims to overcome the limitations of traditional manufacturing processes by enabling complex geometries, functionally graded structures, and customized thermal protection solutions that were previously unattainable. The evolution of this technology has accelerated in the past decade, driven by increasing demands for more efficient energy systems and advanced aerospace applications.

Current technical objectives in this field focus on developing TBC ceramic compositions specifically optimized for AM processes. These materials must maintain excellent thermal insulation properties while being compatible with layer-by-layer fabrication methods. Key performance targets include thermal conductivity below 1.5 W/m·K, temperature capability exceeding 1300°C, and sufficient strain tolerance to withstand thermal cycling without delamination or spallation.

Another critical objective involves addressing the microstructural challenges unique to additively manufactured TBCs. Traditional TBCs rely on specific columnar or splat-like microstructures for optimal performance, which are difficult to replicate in AM processes. Research aims to engineer novel microstructures that can provide equivalent or superior thermal protection while being achievable through AM techniques such as directed energy deposition or binder jetting.

Process integration represents a significant technical goal, as the successful implementation of TBC ceramics in AM requires precise control over numerous parameters including powder characteristics, energy input, layer thickness, and post-processing treatments. The development of standardized protocols for these parameters is essential for ensuring reproducibility and reliability in industrial applications.

Long-term objectives extend to creating multi-material systems where TBC ceramics are seamlessly integrated with metallic substrates in a single AM process, eliminating the need for secondary coating operations. This would revolutionize component design by allowing thermal protection to be incorporated as an intrinsic feature rather than an added layer, potentially leading to more efficient cooling designs and extended component lifespans in extreme thermal environments.

Market Analysis for AM-Compatible TBCs

The global market for Thermal Barrier Coatings (TBCs) compatible with Additive Manufacturing (AM) is experiencing significant growth, driven by increasing demand across aerospace, power generation, and automotive industries. Current market valuation stands at approximately $2.5 billion, with projections indicating a compound annual growth rate of 7.8% through 2028, potentially reaching $3.9 billion by that time.

Aerospace remains the dominant application sector, accounting for nearly 45% of the total market share. This dominance stems from the critical need for high-temperature protection in aircraft engines and gas turbines, where AM-compatible TBCs offer substantial weight reduction and performance enhancement benefits. The power generation sector follows closely at 30% market share, with automotive applications representing about 15%.

Regional analysis reveals North America currently leads the market with approximately 38% share, followed by Europe (32%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth trajectory, particularly in China and India, where rapid industrialization and increasing aerospace manufacturing capabilities are creating expanded market opportunities.

Key market drivers include the growing adoption of additive manufacturing across industries, increasing demand for fuel-efficient engines, and stringent emission regulations pushing for higher operating temperatures in combustion systems. The integration of TBCs with AM processes offers significant cost advantages through reduced material waste and manufacturing time, estimated at 20-30% savings compared to conventional coating methods.

Customer demand patterns show increasing preference for customized TBC solutions with enhanced durability and thermal cycling resistance. Market research indicates that end-users are willing to pay premium prices for coatings that demonstrate superior performance in extreme temperature environments, particularly those exceeding 1200°C.

Emerging market segments include medical devices, where AM-compatible TBCs are finding novel applications in surgical instruments and implantable devices requiring thermal management. Additionally, the renewable energy sector is showing increased interest in these coatings for concentrated solar power systems and biomass combustion equipment.

Supply chain analysis reveals potential vulnerabilities in raw material sourcing, particularly for rare earth elements used in advanced ceramic formulations. This presents both a challenge and opportunity for market players to develop alternative material systems that maintain performance while reducing dependency on geopolitically sensitive resources.

Aerospace remains the dominant application sector, accounting for nearly 45% of the total market share. This dominance stems from the critical need for high-temperature protection in aircraft engines and gas turbines, where AM-compatible TBCs offer substantial weight reduction and performance enhancement benefits. The power generation sector follows closely at 30% market share, with automotive applications representing about 15%.

Regional analysis reveals North America currently leads the market with approximately 38% share, followed by Europe (32%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth trajectory, particularly in China and India, where rapid industrialization and increasing aerospace manufacturing capabilities are creating expanded market opportunities.

Key market drivers include the growing adoption of additive manufacturing across industries, increasing demand for fuel-efficient engines, and stringent emission regulations pushing for higher operating temperatures in combustion systems. The integration of TBCs with AM processes offers significant cost advantages through reduced material waste and manufacturing time, estimated at 20-30% savings compared to conventional coating methods.

Customer demand patterns show increasing preference for customized TBC solutions with enhanced durability and thermal cycling resistance. Market research indicates that end-users are willing to pay premium prices for coatings that demonstrate superior performance in extreme temperature environments, particularly those exceeding 1200°C.

Emerging market segments include medical devices, where AM-compatible TBCs are finding novel applications in surgical instruments and implantable devices requiring thermal management. Additionally, the renewable energy sector is showing increased interest in these coatings for concentrated solar power systems and biomass combustion equipment.

Supply chain analysis reveals potential vulnerabilities in raw material sourcing, particularly for rare earth elements used in advanced ceramic formulations. This presents both a challenge and opportunity for market players to develop alternative material systems that maintain performance while reducing dependency on geopolitically sensitive resources.

Current Challenges in AM TBC Ceramics

Despite significant advancements in additive manufacturing (AM) technologies, the implementation of thermal barrier coatings (TBCs) ceramics in AM applications faces several critical challenges. The primary obstacle remains achieving the complex microstructural requirements necessary for effective thermal protection. Conventional TBCs rely on carefully engineered porosity and columnar structures that are difficult to replicate using current AM processes, resulting in coatings with inferior thermal cycling durability.

Material compatibility presents another significant hurdle. The high-temperature ceramics used in TBCs, particularly yttria-stabilized zirconia (YSZ), exhibit poor flowability in powder-based AM systems and often require specialized processing parameters that differ substantially from those used for metallic components. This creates difficulties in multi-material printing scenarios where both the substrate and coating must be fabricated simultaneously.

Process control and repeatability continue to challenge manufacturers attempting to scale AM-produced TBCs. The thermal gradients inherent in laser-based AM processes can induce residual stresses and microcracking in ceramic materials, compromising coating integrity. Furthermore, achieving consistent thickness and uniform material distribution across complex geometries remains problematic, particularly for internal surfaces and cooling channels in turbine components.

The resolution limitations of current AM technologies also restrict the creation of optimized TBC architectures. While conventional plasma-sprayed coatings can achieve tailored porosity at multiple scales, AM processes struggle to replicate these features at the microscale. This limitation directly impacts the thermal insulation performance and strain tolerance of the resulting coatings.

Post-processing requirements further complicate the manufacturing workflow. AM-produced TBCs typically require extensive surface finishing and heat treatment to achieve desired properties, negating some of the time and cost advantages associated with additive approaches. The need for these additional steps increases production complexity and introduces potential quality control issues.

Qualification and certification represent perhaps the most significant barrier to widespread adoption. The aerospace and power generation industries, which are primary users of TBC technologies, maintain stringent performance requirements and certification protocols. The relative novelty of AM-produced TBCs means limited long-term performance data exists, creating reluctance among end-users to implement these solutions in critical applications where failure could have catastrophic consequences.

Finally, cost considerations remain a substantial challenge. While AM offers potential savings through reduced material waste and design optimization, the specialized equipment, materials, and expertise required for ceramic AM processing currently result in higher production costs compared to conventional coating methods, limiting commercial viability except for the most specialized applications.

Material compatibility presents another significant hurdle. The high-temperature ceramics used in TBCs, particularly yttria-stabilized zirconia (YSZ), exhibit poor flowability in powder-based AM systems and often require specialized processing parameters that differ substantially from those used for metallic components. This creates difficulties in multi-material printing scenarios where both the substrate and coating must be fabricated simultaneously.

Process control and repeatability continue to challenge manufacturers attempting to scale AM-produced TBCs. The thermal gradients inherent in laser-based AM processes can induce residual stresses and microcracking in ceramic materials, compromising coating integrity. Furthermore, achieving consistent thickness and uniform material distribution across complex geometries remains problematic, particularly for internal surfaces and cooling channels in turbine components.

The resolution limitations of current AM technologies also restrict the creation of optimized TBC architectures. While conventional plasma-sprayed coatings can achieve tailored porosity at multiple scales, AM processes struggle to replicate these features at the microscale. This limitation directly impacts the thermal insulation performance and strain tolerance of the resulting coatings.

Post-processing requirements further complicate the manufacturing workflow. AM-produced TBCs typically require extensive surface finishing and heat treatment to achieve desired properties, negating some of the time and cost advantages associated with additive approaches. The need for these additional steps increases production complexity and introduces potential quality control issues.

Qualification and certification represent perhaps the most significant barrier to widespread adoption. The aerospace and power generation industries, which are primary users of TBC technologies, maintain stringent performance requirements and certification protocols. The relative novelty of AM-produced TBCs means limited long-term performance data exists, creating reluctance among end-users to implement these solutions in critical applications where failure could have catastrophic consequences.

Finally, cost considerations remain a substantial challenge. While AM offers potential savings through reduced material waste and design optimization, the specialized equipment, materials, and expertise required for ceramic AM processing currently result in higher production costs compared to conventional coating methods, limiting commercial viability except for the most specialized applications.

Current AM-Compatible TBC Solutions

01 Yttria-stabilized zirconia (YSZ) based thermal barrier coatings

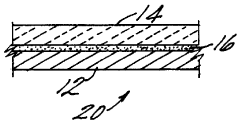

Yttria-stabilized zirconia (YSZ) is widely used as a ceramic material for thermal barrier coatings due to its excellent thermal insulation properties and phase stability at high temperatures. These coatings typically consist of a ceramic top coat of YSZ applied over a metallic bond coat. The YSZ layer provides thermal insulation while the bond coat offers oxidation resistance and improves adhesion between the ceramic layer and the metal substrate. Various deposition techniques such as plasma spraying and electron beam physical vapor deposition (EB-PVD) are used to apply these coatings.- Yttria-stabilized zirconia (YSZ) thermal barrier coatings: Yttria-stabilized zirconia (YSZ) is widely used as a thermal barrier coating material due to its excellent thermal insulation properties and high-temperature stability. These coatings are typically applied using techniques such as plasma spraying or electron beam physical vapor deposition (EB-PVD) to create a ceramic layer that protects underlying metal components from high temperatures in turbine engines and other high-temperature applications. YSZ coatings provide effective thermal insulation while maintaining mechanical integrity under thermal cycling conditions.

- Advanced ceramic compositions for enhanced thermal barrier performance: Novel ceramic compositions have been developed to enhance the performance of thermal barrier coatings beyond traditional YSZ. These include rare-earth zirconates, pyrochlores, and other complex oxide systems that offer improved high-temperature capability, reduced thermal conductivity, and better phase stability. These advanced ceramic compositions can withstand higher operating temperatures, which is crucial for increasing the efficiency of gas turbines and other high-temperature systems. The compositions often incorporate elements such as gadolinium, lanthanum, or cerium to achieve specific performance characteristics.

- Multilayer and functionally graded thermal barrier coatings: Multilayer and functionally graded thermal barrier coating systems consist of multiple ceramic layers with different compositions or microstructures to optimize performance. These systems often include a bond coat, transition layers, and a top ceramic layer, with each layer serving specific functions such as adhesion improvement, stress management, or thermal insulation. By gradually changing the composition or porosity through the coating thickness, these systems can better accommodate thermal expansion mismatches and improve durability under thermal cycling conditions while maintaining excellent thermal insulation properties.

- Deposition methods for ceramic thermal barrier coatings: Various deposition techniques are employed to apply ceramic thermal barrier coatings, each offering distinct microstructural features and performance characteristics. Common methods include atmospheric plasma spraying (APS), suspension plasma spraying (SPS), electron beam physical vapor deposition (EB-PVD), and solution precursor plasma spraying (SPPS). These techniques control important coating properties such as porosity, columnar structure, strain tolerance, and adhesion strength. The selection of deposition method significantly impacts the coating's thermal insulation efficiency, erosion resistance, and lifetime under service conditions.

- Environmental barrier aspects of ceramic thermal coatings: Environmental barrier aspects focus on protecting ceramic thermal barrier coatings from degradation caused by environmental factors such as water vapor, molten salts, calcium-magnesium-alumino-silicates (CMAS), and volcanic ash. These environmental contaminants can cause accelerated degradation through chemical reactions, phase transformations, or physical damage to the coating. Advanced coating systems incorporate protective top layers or compositional modifications that resist these environmental attacks while maintaining thermal barrier functionality. This approach extends component life in harsh operating environments such as aircraft engines, industrial gas turbines, and other high-temperature applications.

02 Advanced ceramic compositions for enhanced thermal barrier performance

Novel ceramic compositions have been developed to enhance the performance of thermal barrier coatings beyond traditional YSZ systems. These include rare earth zirconates, hafnates, and complex oxides that offer improved phase stability, lower thermal conductivity, and better resistance to sintering at elevated temperatures. Some compositions incorporate multiple dopants or form layered structures to optimize both thermal and mechanical properties. These advanced ceramics are designed to withstand more extreme temperature conditions and longer service lives in turbine engines and other high-temperature applications.Expand Specific Solutions03 Deposition methods for ceramic thermal barrier coatings

Various deposition techniques are employed to apply ceramic thermal barrier coatings, each offering distinct microstructural characteristics and performance benefits. Atmospheric plasma spraying (APS) produces coatings with splat-like structures and porosity that enhances thermal insulation. Electron beam physical vapor deposition (EB-PVD) creates columnar structures with superior strain tolerance and erosion resistance. Newer methods include suspension plasma spraying, solution precursor plasma spraying, and directed vapor deposition, which enable better control over coating architecture and thickness. The deposition parameters significantly influence the coating's thermal cycling durability and thermal conductivity.Expand Specific Solutions04 Multilayer and functionally graded ceramic coatings

Multilayer and functionally graded ceramic coatings represent an advanced approach to thermal barrier design. These systems feature strategically varied compositions and microstructures throughout the coating thickness to optimize performance. Functionally graded materials (FGMs) provide gradual transitions in properties, reducing thermal stresses and improving durability. Multilayer designs may combine different ceramics to leverage their complementary properties, such as a high-temperature resistant outer layer with a thermally insulating inner layer. These sophisticated coating architectures can be tailored to specific operating conditions and failure mechanisms.Expand Specific Solutions05 Environmental barrier additions for ceramic thermal coatings

Environmental barrier additions are incorporated into ceramic thermal barrier coatings to protect against degradation mechanisms beyond high temperatures. These include resistance to calcium-magnesium-alumino-silicate (CMAS) infiltration, which can cause premature coating failure in dusty environments. Additives such as rare earth oxides, alumina, or silica can react with molten CMAS to form crystalline phases that arrest further infiltration. Other environmental barrier elements provide protection against water vapor, salt corrosion, and oxidation. These specialized formulations extend coating lifetimes in harsh operating environments such as aircraft engines, industrial gas turbines, and power generation systems.Expand Specific Solutions

Leading Companies in TBC Ceramics for AM

Thermal barrier coatings ceramics in additive manufacturing are evolving rapidly, currently transitioning from early development to commercial adoption phase. The market is projected to grow significantly, driven by aerospace, power generation, and automotive applications, with an estimated value exceeding $500 million by 2027. Leading players demonstrate varying levels of technical maturity: established corporations like GE, Siemens Energy, RTX (formerly United Technologies), and Mitsubishi Heavy Industries possess advanced capabilities, while academic institutions including Tsinghua University, Beihang University, and Rice University contribute fundamental research. Companies like Praxair S.T. Technology and nGimat Co. offer specialized coating solutions, with emerging players from China (Jiangsu Radium, Shaanxi Tianxuan) expanding market participation, indicating a competitive landscape balancing innovation with industrial application.

Praxair S.T. Technology, Inc.

Technical Solution: Praxair S.T. Technology has developed an innovative approach to thermal barrier coatings for additive manufacturing applications through their Advanced Ceramic Powder (ACP) technology platform. Their solution focuses on specialized ceramic powder formulations with optimized morphology, size distribution, and flow characteristics specifically designed for laser powder bed fusion processes. Praxair's technology utilizes yttria-stabilized zirconia (YSZ) powders with controlled dopant levels of rare earth oxides (including gadolinia, ytterbia, and ceria) to enhance phase stability and reduce thermal conductivity[2]. The company has pioneered a process for creating spherical, hollow ceramic particles that provide exceptional flowability while reducing thermal conductivity through engineered porosity. Their manufacturing approach includes specialized post-processing techniques including controlled sintering protocols and surface treatments that enhance coating durability without compromising thermal performance. Praxair has demonstrated successful implementation of their technology in aerospace and energy applications, with reported thermal conductivity reductions of 20-30% compared to conventional solid powder feedstocks[7]. Their process enables direct printing of complex TBC geometries with integrated cooling features impossible to manufacture through traditional methods.

Strengths: Superior powder flowability enabling consistent layer deposition in additive processes; reduced thermal conductivity through engineered particle morphology; excellent batch-to-batch consistency ensuring repeatable manufacturing results. Weaknesses: Higher powder production costs compared to conventional ceramic powders; specialized handling requirements to prevent moisture absorption; limited to specific equipment platforms optimized for their powder characteristics.

Siemens AG

Technical Solution: Siemens AG has developed an advanced thermal barrier coating system specifically optimized for additive manufacturing applications in gas turbines and power generation equipment. Their technology utilizes a hybrid approach combining directed energy deposition (DED) with specialized ceramic suspensions to create gradient functional coatings with tailored properties throughout the coating thickness. Siemens' process incorporates gadolinia-zirconia compositions with engineered columnar microstructures that provide superior thermal cycling resistance compared to conventional coatings[2]. The company has implemented a digital twin approach to simulate and optimize coating performance before physical production, allowing for precise control of thermal expansion coefficients and strain tolerance. Their manufacturing process includes in-situ monitoring systems that analyze coating quality during deposition, ensuring consistent performance across complex geometries. Siemens has also developed specialized post-processing techniques including controlled heat treatments and surface finishing methods that enhance coating adhesion and durability in extreme thermal environments[4].

Strengths: Exceptional thermal cycling durability with reported lifespans 30-40% longer than conventional coatings; precise control of microstructure throughout complex geometries; integrated quality control systems ensuring consistent performance. Weaknesses: Higher initial equipment investment costs; limited to specific ceramic compositions optimized for their process; requires specialized training and expertise to operate effectively.

Key Innovations in TBC Ceramic Materials

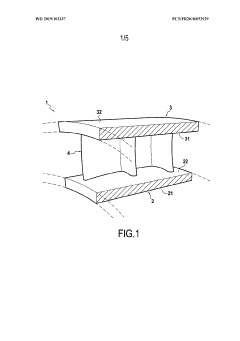

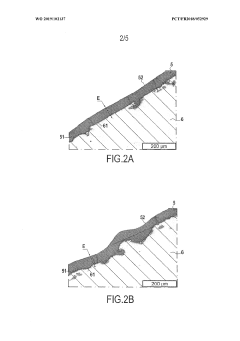

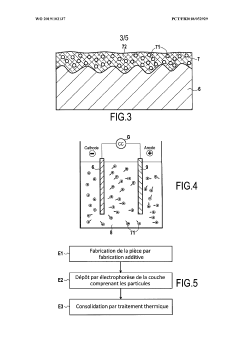

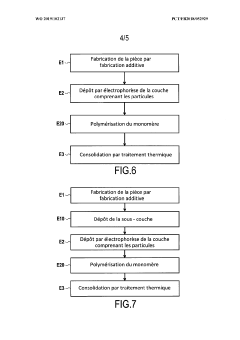

Method for producing a thermal barrier on a part of a turbomachine

PatentWO2019102137A1

Innovation

- A method involving additive manufacturing followed by electrophoretic deposition of a ceramic layer, which is then consolidated through heat treatment to form a smooth thermal barrier coating, utilizing sol-gel precursors and underlayers to enhance adhesion and smoothing effects.

Ceramic materials for thermal barrier coatings

PatentInactiveUS6015630A

Innovation

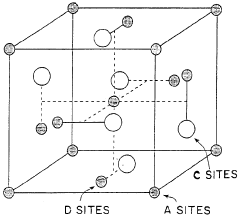

- Systematic screening of ceramic materials using criteria such as thermal conductivity, oxygen diffusivity, thermal expansion coefficient, hardness, elastic modulus, density, and chemical reactivity identifies yttrium aluminum garnet (YAG)-based ceramics as superior alternatives, which can be tailored for enhanced thermal resistivity and durability.

Material-Process Compatibility Assessment

The compatibility between thermal barrier coating (TBC) ceramic materials and additive manufacturing (AM) processes represents a critical factor determining the success of high-temperature applications. Current assessment methodologies focus on evaluating how ceramic compositions interact with specific AM techniques, particularly selective laser melting (SLM), direct energy deposition (DED), and binder jetting processes.

Yttria-stabilized zirconia (YSZ), the industry standard for TBCs, demonstrates variable compatibility across different AM platforms. When processed via SLM, YSZ requires precise parameter optimization to prevent thermal cracking and ensure adequate layer adhesion. The high melting point (2700°C) and low thermal conductivity create significant thermal gradients during laser processing, necessitating careful control of energy density and scanning strategies.

Gadolinium zirconate and lanthanum zirconate, emerging as next-generation TBC materials, exhibit improved compatibility with DED processes due to their enhanced phase stability at elevated temperatures. However, these materials present challenges related to powder flowability and uniform deposition, requiring specialized powder preparation techniques including spheroidization and size classification to achieve optimal process outcomes.

Material-process compatibility assessment protocols typically involve multi-stage evaluation frameworks. Initial screening examines fundamental material properties including particle size distribution, morphology, and flowability characteristics. Secondary assessment focuses on process-specific interactions such as laser absorptivity for SLM/DED or binder-powder interactions for binder jetting technologies. Final evaluation examines microstructural development and mechanical integrity of fabricated components.

Recent research indicates that hybrid material systems, particularly those incorporating aluminum oxide or rare-earth silicates with traditional zirconia-based ceramics, demonstrate enhanced processability in AM environments. These composite formulations offer improved thermal shock resistance while maintaining the thermal insulation properties essential for barrier coating functionality.

Process parameter optimization remains highly material-specific, with successful implementation requiring customized approaches for each ceramic composition. Preheating strategies have proven particularly effective in mitigating thermal stress development during processing of low thermal conductivity ceramics, with platform temperatures between 800-1000°C showing significant improvements in crack prevention for zirconia-based systems.

The development of specialized post-processing protocols, including controlled cooling regimes and targeted heat treatments, has further expanded the range of compatible ceramic materials for AM-produced TBCs. These approaches effectively address residual stress management and phase stabilization challenges that previously limited material selection options.

Yttria-stabilized zirconia (YSZ), the industry standard for TBCs, demonstrates variable compatibility across different AM platforms. When processed via SLM, YSZ requires precise parameter optimization to prevent thermal cracking and ensure adequate layer adhesion. The high melting point (2700°C) and low thermal conductivity create significant thermal gradients during laser processing, necessitating careful control of energy density and scanning strategies.

Gadolinium zirconate and lanthanum zirconate, emerging as next-generation TBC materials, exhibit improved compatibility with DED processes due to their enhanced phase stability at elevated temperatures. However, these materials present challenges related to powder flowability and uniform deposition, requiring specialized powder preparation techniques including spheroidization and size classification to achieve optimal process outcomes.

Material-process compatibility assessment protocols typically involve multi-stage evaluation frameworks. Initial screening examines fundamental material properties including particle size distribution, morphology, and flowability characteristics. Secondary assessment focuses on process-specific interactions such as laser absorptivity for SLM/DED or binder-powder interactions for binder jetting technologies. Final evaluation examines microstructural development and mechanical integrity of fabricated components.

Recent research indicates that hybrid material systems, particularly those incorporating aluminum oxide or rare-earth silicates with traditional zirconia-based ceramics, demonstrate enhanced processability in AM environments. These composite formulations offer improved thermal shock resistance while maintaining the thermal insulation properties essential for barrier coating functionality.

Process parameter optimization remains highly material-specific, with successful implementation requiring customized approaches for each ceramic composition. Preheating strategies have proven particularly effective in mitigating thermal stress development during processing of low thermal conductivity ceramics, with platform temperatures between 800-1000°C showing significant improvements in crack prevention for zirconia-based systems.

The development of specialized post-processing protocols, including controlled cooling regimes and targeted heat treatments, has further expanded the range of compatible ceramic materials for AM-produced TBCs. These approaches effectively address residual stress management and phase stabilization challenges that previously limited material selection options.

Sustainability and Lifecycle Analysis

The sustainability aspects of thermal barrier coatings (TBCs) in additive manufacturing applications represent a critical dimension for evaluating their long-term viability. Traditional manufacturing of TBCs typically involves energy-intensive processes with significant material waste. Additive manufacturing offers promising alternatives by enabling precise material deposition, potentially reducing waste by 30-45% compared to conventional methods.

Life cycle assessment (LCA) studies indicate that ceramic TBCs produced through additive manufacturing demonstrate reduced environmental impact across multiple categories. The carbon footprint can be decreased by approximately 25% when comparing laser-based additive processes to plasma spraying techniques. This reduction stems primarily from lower energy consumption during manufacturing and the elimination of certain pre-processing steps.

Material efficiency represents another significant sustainability advantage. Powder bed fusion and directed energy deposition methods allow for recycling of unused ceramic powders at rates exceeding 95% in controlled environments. This circular approach substantially reduces the demand for virgin materials and minimizes extraction-related environmental impacts associated with rare earth elements often used in advanced ceramic formulations.

Water consumption metrics also favor additive manufacturing approaches for TBCs. Conventional wet chemical processes may require 3-5 gallons of water per square meter of coating, while certain additive techniques can operate with minimal or zero direct water inputs. This aspect becomes increasingly important in regions facing water scarcity challenges.

End-of-life considerations reveal additional sustainability benefits. Additively manufactured ceramic TBCs can be designed with delamination features that facilitate separation from metal substrates, enhancing recyclability of both components. Current research indicates potential recovery rates of 70-85% for certain ceramic compositions, compared to 40-50% for conventionally applied coatings.

The extended service life of properly designed additive TBCs further enhances their sustainability profile. Laboratory testing demonstrates that optimized microstructures achievable through layer-by-layer deposition can increase thermal cycling resistance by 30-40%, potentially extending component lifespans in high-temperature applications. This longevity translates directly to reduced material consumption and waste generation over time.

Future sustainability improvements will likely emerge from ongoing research into bio-derived ceramic precursors and energy-efficient sintering approaches specifically tailored for additively manufactured structures. These developments could further reduce the environmental footprint while maintaining or enhancing the critical performance characteristics required for thermal barrier applications.

Life cycle assessment (LCA) studies indicate that ceramic TBCs produced through additive manufacturing demonstrate reduced environmental impact across multiple categories. The carbon footprint can be decreased by approximately 25% when comparing laser-based additive processes to plasma spraying techniques. This reduction stems primarily from lower energy consumption during manufacturing and the elimination of certain pre-processing steps.

Material efficiency represents another significant sustainability advantage. Powder bed fusion and directed energy deposition methods allow for recycling of unused ceramic powders at rates exceeding 95% in controlled environments. This circular approach substantially reduces the demand for virgin materials and minimizes extraction-related environmental impacts associated with rare earth elements often used in advanced ceramic formulations.

Water consumption metrics also favor additive manufacturing approaches for TBCs. Conventional wet chemical processes may require 3-5 gallons of water per square meter of coating, while certain additive techniques can operate with minimal or zero direct water inputs. This aspect becomes increasingly important in regions facing water scarcity challenges.

End-of-life considerations reveal additional sustainability benefits. Additively manufactured ceramic TBCs can be designed with delamination features that facilitate separation from metal substrates, enhancing recyclability of both components. Current research indicates potential recovery rates of 70-85% for certain ceramic compositions, compared to 40-50% for conventionally applied coatings.

The extended service life of properly designed additive TBCs further enhances their sustainability profile. Laboratory testing demonstrates that optimized microstructures achievable through layer-by-layer deposition can increase thermal cycling resistance by 30-40%, potentially extending component lifespans in high-temperature applications. This longevity translates directly to reduced material consumption and waste generation over time.

Future sustainability improvements will likely emerge from ongoing research into bio-derived ceramic precursors and energy-efficient sintering approaches specifically tailored for additively manufactured structures. These developments could further reduce the environmental footprint while maintaining or enhancing the critical performance characteristics required for thermal barrier applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!