Comparative testing of thick versus thin thermal barrier coatings ceramics

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TBC Evolution and Research Objectives

Thermal Barrier Coatings (TBCs) have evolved significantly since their initial development in the 1960s for aerospace applications. Originally designed as thin protective layers, TBCs have undergone substantial transformation in composition, structure, and application methods to meet increasingly demanding operational environments. The evolution from simple single-layer systems to sophisticated multi-layered architectures represents a critical advancement in high-temperature materials science.

The historical progression of TBC technology reveals a continuous pursuit of enhanced thermal insulation properties while maintaining mechanical integrity. Early TBCs featured thicknesses of 100-300 μm, primarily composed of yttria-stabilized zirconia (YSZ). As engine operating temperatures increased to improve efficiency, the demand for more effective thermal barriers drove research toward thicker coatings exceeding 500 μm, introducing new challenges in adhesion, durability, and thermal stress management.

Current research indicates a technological divergence between thick and thin TBC systems, each offering distinct advantages and limitations. Thick coatings (>500 μm) provide superior thermal insulation, potentially allowing temperature reductions of 150-200°C at the metal substrate. However, they frequently exhibit reduced durability due to increased residual stresses and higher susceptibility to spallation under thermal cycling conditions.

Thin coatings (<300 μm), while offering less thermal protection, demonstrate superior mechanical stability, better erosion resistance, and longer operational lifespans in certain applications. The trade-off between thermal performance and mechanical integrity represents a fundamental challenge in TBC design that requires systematic comparative analysis.

The primary objective of this technical research is to conduct comprehensive comparative testing between thick and thin ceramic TBCs across multiple performance parameters. This investigation aims to establish quantitative relationships between coating thickness and critical performance metrics including thermal conductivity, strain tolerance, erosion resistance, and cyclic durability under simulated service conditions.

Secondary objectives include identifying optimal thickness thresholds for specific application environments, evaluating novel ceramic compositions that may alter the traditional thickness-performance relationship, and developing predictive models for TBC performance based on thickness variations. The research will also explore advanced manufacturing techniques that might overcome current limitations in thick coating applications.

By systematically addressing these objectives, this research seeks to provide engineering guidelines for TBC thickness selection based on specific operational requirements, potentially enabling more tailored thermal protection solutions for next-generation turbine engines and other high-temperature applications.

The historical progression of TBC technology reveals a continuous pursuit of enhanced thermal insulation properties while maintaining mechanical integrity. Early TBCs featured thicknesses of 100-300 μm, primarily composed of yttria-stabilized zirconia (YSZ). As engine operating temperatures increased to improve efficiency, the demand for more effective thermal barriers drove research toward thicker coatings exceeding 500 μm, introducing new challenges in adhesion, durability, and thermal stress management.

Current research indicates a technological divergence between thick and thin TBC systems, each offering distinct advantages and limitations. Thick coatings (>500 μm) provide superior thermal insulation, potentially allowing temperature reductions of 150-200°C at the metal substrate. However, they frequently exhibit reduced durability due to increased residual stresses and higher susceptibility to spallation under thermal cycling conditions.

Thin coatings (<300 μm), while offering less thermal protection, demonstrate superior mechanical stability, better erosion resistance, and longer operational lifespans in certain applications. The trade-off between thermal performance and mechanical integrity represents a fundamental challenge in TBC design that requires systematic comparative analysis.

The primary objective of this technical research is to conduct comprehensive comparative testing between thick and thin ceramic TBCs across multiple performance parameters. This investigation aims to establish quantitative relationships between coating thickness and critical performance metrics including thermal conductivity, strain tolerance, erosion resistance, and cyclic durability under simulated service conditions.

Secondary objectives include identifying optimal thickness thresholds for specific application environments, evaluating novel ceramic compositions that may alter the traditional thickness-performance relationship, and developing predictive models for TBC performance based on thickness variations. The research will also explore advanced manufacturing techniques that might overcome current limitations in thick coating applications.

By systematically addressing these objectives, this research seeks to provide engineering guidelines for TBC thickness selection based on specific operational requirements, potentially enabling more tailored thermal protection solutions for next-generation turbine engines and other high-temperature applications.

Market Analysis for Thermal Barrier Coating Applications

The global thermal barrier coating (TBC) market is experiencing robust growth, valued at approximately $16.9 billion in 2022 and projected to reach $22.4 billion by 2027, representing a compound annual growth rate (CAGR) of 5.8%. This expansion is primarily driven by increasing demand across aerospace, power generation, automotive, and industrial sectors where components are exposed to extreme thermal conditions.

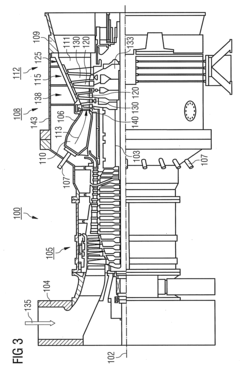

Aerospace remains the dominant application segment, accounting for nearly 40% of the total market share. The continuous push for higher operating temperatures in aircraft engines to improve fuel efficiency and reduce emissions has intensified the need for advanced TBC solutions. Commercial aviation's recovery post-pandemic and growing defense budgets worldwide are further accelerating this demand.

The power generation sector represents the second-largest market segment at 28%, with gas turbines being the primary application. As global energy demands rise and efficiency standards become more stringent, power generation companies are increasingly adopting TBC technologies to extend component lifespans and improve operational efficiency.

Regional analysis reveals North America and Europe as market leaders, collectively holding approximately 58% of the global market share. However, the Asia-Pacific region is demonstrating the fastest growth rate at 7.2% annually, driven by rapid industrialization in China and India, expanding aerospace manufacturing capabilities, and increasing energy infrastructure investments.

A significant market trend is the growing preference for customized coating solutions optimized for specific applications. This has created distinct market segments for both thick (>500 μm) and thin (<300 μm) thermal barrier coatings, each serving different operational requirements. Thick coatings currently dominate with 65% market share due to their superior thermal insulation properties, while thin coatings are gaining traction in applications where weight considerations are paramount.

Customer demand is increasingly focused on coatings that offer multifunctional benefits beyond thermal protection, including erosion resistance, CMAS (calcium-magnesium-alumino-silicate) attack protection, and reduced oxygen permeability. This trend is driving premium pricing for advanced formulations, with specialized coatings commanding 30-40% higher prices than standard offerings.

Market challenges include volatile raw material prices, particularly for rare earth elements used in advanced ceramic formulations, and increasingly stringent environmental regulations regarding coating processes. Additionally, the high initial investment required for coating equipment and the technical expertise needed for proper application represent significant barriers to entry for smaller market players.

Aerospace remains the dominant application segment, accounting for nearly 40% of the total market share. The continuous push for higher operating temperatures in aircraft engines to improve fuel efficiency and reduce emissions has intensified the need for advanced TBC solutions. Commercial aviation's recovery post-pandemic and growing defense budgets worldwide are further accelerating this demand.

The power generation sector represents the second-largest market segment at 28%, with gas turbines being the primary application. As global energy demands rise and efficiency standards become more stringent, power generation companies are increasingly adopting TBC technologies to extend component lifespans and improve operational efficiency.

Regional analysis reveals North America and Europe as market leaders, collectively holding approximately 58% of the global market share. However, the Asia-Pacific region is demonstrating the fastest growth rate at 7.2% annually, driven by rapid industrialization in China and India, expanding aerospace manufacturing capabilities, and increasing energy infrastructure investments.

A significant market trend is the growing preference for customized coating solutions optimized for specific applications. This has created distinct market segments for both thick (>500 μm) and thin (<300 μm) thermal barrier coatings, each serving different operational requirements. Thick coatings currently dominate with 65% market share due to their superior thermal insulation properties, while thin coatings are gaining traction in applications where weight considerations are paramount.

Customer demand is increasingly focused on coatings that offer multifunctional benefits beyond thermal protection, including erosion resistance, CMAS (calcium-magnesium-alumino-silicate) attack protection, and reduced oxygen permeability. This trend is driving premium pricing for advanced formulations, with specialized coatings commanding 30-40% higher prices than standard offerings.

Market challenges include volatile raw material prices, particularly for rare earth elements used in advanced ceramic formulations, and increasingly stringent environmental regulations regarding coating processes. Additionally, the high initial investment required for coating equipment and the technical expertise needed for proper application represent significant barriers to entry for smaller market players.

Current Challenges in TBC Thickness Optimization

The optimization of thermal barrier coating (TBC) thickness represents one of the most significant challenges in high-temperature applications, particularly in aerospace and power generation industries. Engineers and materials scientists face a complex balancing act between thermal protection and mechanical integrity when determining optimal TBC thickness. Thicker coatings generally provide enhanced thermal insulation, potentially allowing higher operating temperatures and improved engine efficiency, but they simultaneously introduce structural vulnerabilities.

A primary challenge in thickness optimization stems from the inherent trade-off between thermal resistance and mechanical durability. As coating thickness increases, the thermal gradient across the coating becomes steeper, generating higher thermal stresses during thermal cycling. These stresses concentrate at the interface between the ceramic top coat and the metallic bond coat, often leading to premature delamination and spallation failure in thicker coatings.

Manufacturing consistency presents another significant obstacle. Current deposition techniques, including air plasma spray (APS) and electron beam physical vapor deposition (EB-PVD), struggle to maintain uniform thickness and microstructural homogeneity across complex component geometries when producing thicker coatings. This inconsistency introduces weak points and unpredictable performance variations that complicate qualification testing and service life prediction.

The sintering behavior of ceramic TBCs introduces additional complexity to thickness optimization. Thicker coatings tend to experience more pronounced sintering effects during high-temperature exposure, resulting in increased thermal conductivity over time—precisely the opposite of their intended function. This progressive degradation of thermal performance is particularly problematic for long-duration applications where maintenance intervals are extended.

Weight considerations further constrain thickness optimization, especially in rotating components where additional mass increases centrifugal loads and reduces overall system efficiency. For aerospace applications, every gram of additional coating weight must be justified by corresponding performance benefits, creating a stringent engineering constraint that often limits maximum practical thickness.

Testing methodologies for comparative evaluation of different thickness regimes remain inadequate. Current accelerated testing protocols frequently fail to accurately replicate the complex failure mechanisms observed in service conditions, particularly for thicker coatings where thermal gradients and stress distributions differ significantly from thin coating benchmarks. This testing gap hampers data-driven optimization and increases reliance on conservative design approaches.

Finally, economic considerations significantly influence thickness decisions. Thicker coatings require longer deposition times and more raw materials, increasing production costs. Without reliable lifetime prediction models that accurately quantify the performance benefits of increased thickness, manufacturers struggle to justify the additional expense, particularly in cost-sensitive market segments.

A primary challenge in thickness optimization stems from the inherent trade-off between thermal resistance and mechanical durability. As coating thickness increases, the thermal gradient across the coating becomes steeper, generating higher thermal stresses during thermal cycling. These stresses concentrate at the interface between the ceramic top coat and the metallic bond coat, often leading to premature delamination and spallation failure in thicker coatings.

Manufacturing consistency presents another significant obstacle. Current deposition techniques, including air plasma spray (APS) and electron beam physical vapor deposition (EB-PVD), struggle to maintain uniform thickness and microstructural homogeneity across complex component geometries when producing thicker coatings. This inconsistency introduces weak points and unpredictable performance variations that complicate qualification testing and service life prediction.

The sintering behavior of ceramic TBCs introduces additional complexity to thickness optimization. Thicker coatings tend to experience more pronounced sintering effects during high-temperature exposure, resulting in increased thermal conductivity over time—precisely the opposite of their intended function. This progressive degradation of thermal performance is particularly problematic for long-duration applications where maintenance intervals are extended.

Weight considerations further constrain thickness optimization, especially in rotating components where additional mass increases centrifugal loads and reduces overall system efficiency. For aerospace applications, every gram of additional coating weight must be justified by corresponding performance benefits, creating a stringent engineering constraint that often limits maximum practical thickness.

Testing methodologies for comparative evaluation of different thickness regimes remain inadequate. Current accelerated testing protocols frequently fail to accurately replicate the complex failure mechanisms observed in service conditions, particularly for thicker coatings where thermal gradients and stress distributions differ significantly from thin coating benchmarks. This testing gap hampers data-driven optimization and increases reliance on conservative design approaches.

Finally, economic considerations significantly influence thickness decisions. Thicker coatings require longer deposition times and more raw materials, increasing production costs. Without reliable lifetime prediction models that accurately quantify the performance benefits of increased thickness, manufacturers struggle to justify the additional expense, particularly in cost-sensitive market segments.

Comparative Testing Methodologies for TBC Thickness Evaluation

01 Optimal thickness ranges for thermal barrier coatings

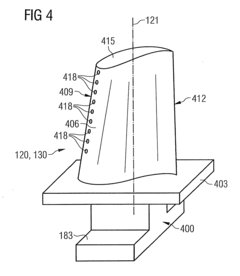

The thickness of thermal barrier coatings (TBCs) is a critical parameter that affects their performance. Optimal thickness ranges have been established for different ceramic materials to provide effective thermal insulation while maintaining structural integrity. These ranges typically vary from 100 to 500 micrometers depending on the specific application and operating conditions. The thickness must be carefully controlled to balance thermal protection with coating durability and adhesion to the substrate.- Ceramic material selection for thermal barrier coatings: Various ceramic materials can be used for thermal barrier coatings to provide effective thermal insulation. These materials include yttria-stabilized zirconia (YSZ), gadolinium zirconate, and other rare earth zirconates which offer excellent thermal resistance properties. The selection of ceramic material significantly impacts the coating's performance, durability, and thermal conductivity. Advanced ceramic compositions can provide enhanced protection against high-temperature environments while maintaining structural integrity.

- Thickness optimization for thermal barrier coatings: The thickness of thermal barrier coatings is a critical parameter that affects their performance. Optimal thickness ranges typically vary between 100-500 micrometers depending on the application requirements. Thicker coatings generally provide better thermal insulation but may compromise mechanical properties and adhesion. The thickness must be carefully controlled during the deposition process to ensure uniform coverage and consistent thermal protection while avoiding issues such as spallation or cracking under thermal cycling conditions.

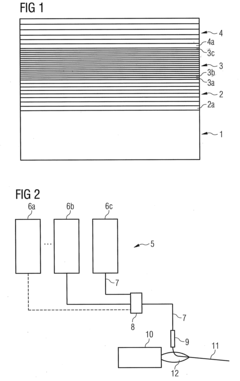

- Deposition methods for ceramic thermal barrier coatings: Various deposition techniques can be employed to apply ceramic thermal barrier coatings with controlled thickness. These methods include atmospheric plasma spraying (APS), electron beam physical vapor deposition (EB-PVD), suspension plasma spraying, and solution precursor plasma spraying. Each technique offers different advantages in terms of microstructure control, deposition rate, and coating quality. The selection of an appropriate deposition method significantly impacts the coating's microstructure, porosity, and ultimately its thermal insulation performance and durability.

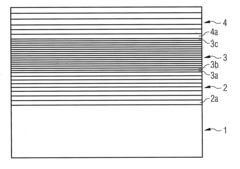

- Multilayer and graded thermal barrier coating systems: Advanced thermal barrier coating systems often employ multilayer or functionally graded designs to optimize performance. These systems typically consist of a bond coat, a thermally grown oxide layer, and a ceramic top coat with carefully controlled thickness. The multilayer approach allows for tailored properties throughout the coating thickness, with composition and porosity gradients that can enhance thermal cycling resistance and extend coating lifetime. Such designs can better accommodate the thermal expansion mismatch between the substrate and the ceramic coating.

- Novel ceramic compositions for enhanced thermal barrier performance: Research into novel ceramic compositions aims to develop thermal barrier coatings with improved temperature capability and longer service life. These include doped zirconia systems, pyrochlore structures, and composite ceramics with engineered microstructures. By incorporating specific dopants or creating composite structures, these advanced ceramics can achieve lower thermal conductivity, better phase stability, and enhanced resistance to sintering at elevated temperatures. The thickness of these novel coatings can be optimized based on their unique thermal and mechanical properties.

02 Multi-layer ceramic coating structures

Multi-layer ceramic coating structures are designed to enhance the performance of thermal barrier coatings. These structures typically consist of a bond coat, a thermally grown oxide layer, and a ceramic top coat. Each layer serves a specific function, with the ceramic top coat providing thermal insulation while the underlying layers enhance adhesion and oxidation resistance. The thickness of each layer is carefully controlled to optimize the overall performance of the coating system under high-temperature conditions.Expand Specific Solutions03 Advanced ceramic materials for thermal barrier coatings

Various advanced ceramic materials are used in thermal barrier coatings to provide superior thermal insulation properties. These materials include yttria-stabilized zirconia (YSZ), gadolinium zirconate, lanthanum zirconate, and other rare-earth element-based ceramics. The selection of ceramic material affects the optimal coating thickness, with some advanced materials allowing for thinner coatings while maintaining equivalent thermal protection. These materials are engineered to have low thermal conductivity and high temperature stability.Expand Specific Solutions04 Deposition techniques and thickness control

Various deposition techniques are employed to apply ceramic thermal barrier coatings with precise thickness control. These techniques include atmospheric plasma spraying (APS), electron beam physical vapor deposition (EB-PVD), and solution precursor plasma spray (SPPS). Each method offers different advantages in terms of coating microstructure, density, and thickness uniformity. Advanced monitoring and control systems are used during the deposition process to ensure that the coating thickness meets the specified requirements for optimal thermal protection.Expand Specific Solutions05 Thickness-dependent performance characteristics

The performance characteristics of thermal barrier coatings are highly dependent on their thickness. As coating thickness increases, thermal insulation generally improves, but other properties such as strain tolerance, thermal cycling resistance, and spallation resistance may be compromised. Research has focused on understanding these thickness-dependent relationships to optimize coating performance. Factors such as thermal gradient, thermal expansion mismatch, and sintering behavior are all influenced by coating thickness and must be considered in the design of effective thermal barrier systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions in TBC Industry

The thermal barrier coatings (TBC) market is currently in a growth phase, with increasing demand driven by aerospace, power generation, and automotive applications. The global TBC market is estimated to reach $25 billion by 2027, growing at a CAGR of approximately 6.5%. Technologically, comparative testing between thick and thin ceramic TBCs represents a critical research area where industry leaders like Siemens Energy, GE, and Mitsubishi Heavy Industries are competing for performance advantages. Academic institutions including Xi'an Jiaotong University and Beihang University are collaborating with these companies to advance coating technologies. The technology maturity varies significantly between thin coatings (highly mature) and thick coatings (emerging), with companies like Praxair S.T. Technology and HRL Laboratories developing next-generation solutions that balance thermal protection with mechanical durability for extreme operating environments.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed a dual-approach thermal barrier coating (TBC) system with both thick and thin ceramic variants optimized for different turbine applications. Their thin TBC system (150-300μm) utilizes electron beam physical vapor deposition (EB-PVD) with carefully controlled yttria content in zirconia (7-8% YSZ) to maximize phase stability while maintaining fracture toughness. For stationary components, MHI has pioneered thick TBCs (500-1000μm) using atmospheric plasma spray (APS) with proprietary powder formulations that include rare earth dopants to enhance sintering resistance and thermal stability. Their comparative testing methodology includes thermal gradient mechanical fatigue (TGMF) testing that simultaneously applies thermal gradients and mechanical loads to simulate actual service conditions. MHI's research has demonstrated that their thick TBCs can provide temperature reductions of up to 170°C compared to uncoated components, while their thin coatings excel in environments with rapid thermal cycling. They've also developed specialized interlayer technologies to improve adhesion between the bond coat and ceramic layer in thick coating systems.

Strengths: MHI's thick TBCs provide exceptional thermal insulation performance, enabling higher operating temperatures or extended component life. Their rare earth doping technology improves high-temperature stability and resistance to sintering. Weaknesses: The complex manufacturing process for their advanced thick coatings increases production costs and time. Thick coatings also face challenges with internal stress management during thermal cycling.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed comprehensive thermal barrier coating (TBC) solutions with both thick and thin ceramic variants optimized for different turbine components. Their thin TBCs (150-300μm) utilize electron beam physical vapor deposition (EB-PVD) to create columnar microstructures with exceptional strain tolerance for high-stress applications like rotating blades. For stationary components, Siemens has pioneered thick TBCs (500-2000μm) using atmospheric plasma spray (APS) with segmentation cracking to enhance strain tolerance while maximizing thermal insulation. Their comparative testing program evaluates coating performance under simulated service conditions, including thermal cycling, hot corrosion, and erosion resistance. Siemens' research has shown that their thick TBCs can reduce metal temperatures by up to 150°C compared to thin coatings, but require careful design to manage stress accumulation. They've also developed advanced bond coat systems with improved oxidation resistance and thermal expansion compatibility to support thicker ceramic layers without premature failure.

Strengths: Siemens' thick TBCs provide superior thermal insulation and potential for extended component life through reduced metal temperatures. Their segmented coating architecture improves strain tolerance compared to conventional thick coatings. Weaknesses: The manufacturing process for thick segmented coatings requires precise control parameters, increasing production complexity and cost. Thick coatings may also be more susceptible to foreign object damage in service.

Critical Patents and Literature on TBC Thickness Performance

a multilayer COATING SERVING A THERMAL BARRIER WHICH HAS A HIGH POROSITY, AND A PART

PatentInactiveRU2008143997A

Innovation

- Multi-layer thermal barrier coating structure with three distinct ceramic layers (inner, intermediate, and outer) with specific thickness parameters to optimize thermal protection.

- High porosity outer ceramic thermal barrier layer (13) with thickness of 150-2000 μm (preferably 1-2 mm) providing enhanced thermal insulation properties.

- Specific composition of intermediate metal layer consisting of nickel or cobalt-based alloys with precise elemental ratios to ensure proper adhesion between substrate and ceramic layers.

Method for coating a component

PatentInactiveUS20100086757A1

Innovation

- Increasing the grain size of ceramic particles with each layer applied, while adjusting the power of the coating burner to control porosity, ensures a consistent porosity and adhesion across layers, allowing for thicker ceramic coatings with improved thermal insulation and mechanical stability.

Material Science Innovations for Enhanced TBC Performance

Recent advancements in material science have opened new frontiers for enhancing Thermal Barrier Coating (TBC) performance. The evolution of ceramic compositions represents one of the most significant breakthroughs, with researchers developing novel formulations that exhibit superior thermal insulation properties while maintaining structural integrity under extreme conditions. Traditional yttria-stabilized zirconia (YSZ) remains the industry standard, but newer compositions incorporating rare earth elements such as gadolinium, erbium, and lanthanum have demonstrated remarkable improvements in phase stability and thermal cycling resistance.

Microstructural engineering has emerged as another critical innovation pathway. By precisely controlling the porosity distribution and columnar structure of ceramic coatings, engineers can now create TBCs with significantly reduced thermal conductivity without compromising mechanical strength. Advanced manufacturing techniques, including suspension plasma spraying and solution precursor plasma spraying, enable the creation of tailored microstructures with engineered defects that effectively scatter phonons and reduce heat transfer.

Multilayer and functionally graded coating architectures represent a paradigm shift in TBC design philosophy. Rather than relying on a single homogeneous ceramic layer, these systems incorporate gradual transitions in composition and properties throughout the coating thickness. This approach minimizes thermal expansion mismatch stresses and enhances coating durability during thermal cycling. Some cutting-edge designs feature discrete layers with complementary properties, such as erosion-resistant outer layers combined with highly insulating intermediate layers.

Nanostructured ceramics constitute another frontier in TBC material science. By incorporating nanoscale features such as embedded nanoparticles, nanolaminates, or nanocolumnar structures, researchers have achieved unprecedented combinations of thermal and mechanical properties. These nanoengineered coatings exhibit exceptional strain tolerance and can accommodate substantial thermal expansion differences between the ceramic top coat and metallic substrate.

Surface modification technologies have also contributed significantly to TBC performance enhancement. Techniques such as laser texturing, selective infiltration, and controlled crystallization enable the creation of specialized surface features that improve erosion resistance, reduce CMAS (calcium-magnesium-alumino-silicate) infiltration, and enhance radiative properties. These innovations are particularly valuable for applications in environments containing airborne contaminants or volcanic ash.

Microstructural engineering has emerged as another critical innovation pathway. By precisely controlling the porosity distribution and columnar structure of ceramic coatings, engineers can now create TBCs with significantly reduced thermal conductivity without compromising mechanical strength. Advanced manufacturing techniques, including suspension plasma spraying and solution precursor plasma spraying, enable the creation of tailored microstructures with engineered defects that effectively scatter phonons and reduce heat transfer.

Multilayer and functionally graded coating architectures represent a paradigm shift in TBC design philosophy. Rather than relying on a single homogeneous ceramic layer, these systems incorporate gradual transitions in composition and properties throughout the coating thickness. This approach minimizes thermal expansion mismatch stresses and enhances coating durability during thermal cycling. Some cutting-edge designs feature discrete layers with complementary properties, such as erosion-resistant outer layers combined with highly insulating intermediate layers.

Nanostructured ceramics constitute another frontier in TBC material science. By incorporating nanoscale features such as embedded nanoparticles, nanolaminates, or nanocolumnar structures, researchers have achieved unprecedented combinations of thermal and mechanical properties. These nanoengineered coatings exhibit exceptional strain tolerance and can accommodate substantial thermal expansion differences between the ceramic top coat and metallic substrate.

Surface modification technologies have also contributed significantly to TBC performance enhancement. Techniques such as laser texturing, selective infiltration, and controlled crystallization enable the creation of specialized surface features that improve erosion resistance, reduce CMAS (calcium-magnesium-alumino-silicate) infiltration, and enhance radiative properties. These innovations are particularly valuable for applications in environments containing airborne contaminants or volcanic ash.

Environmental Impact and Sustainability of TBC Technologies

The environmental impact of Thermal Barrier Coating (TBC) technologies has become increasingly significant as industries strive for sustainable manufacturing processes. When comparing thick versus thin TBCs, several environmental considerations emerge that affect their overall sustainability profile.

Thick TBCs typically require more raw ceramic materials during production, resulting in higher resource consumption and extraction impacts. The manufacturing process for these coatings often demands more energy for deposition and curing, particularly when using traditional plasma spray techniques. This increased energy requirement translates to a larger carbon footprint compared to thinner alternatives. However, thick coatings generally offer longer service lifetimes, which can offset initial environmental costs through reduced replacement frequency.

Thin TBCs, conversely, utilize fewer raw materials and typically require less energy during application processes. Advanced deposition methods like electron beam physical vapor deposition (EB-PVD) for thin coatings have become more energy-efficient in recent years, further reducing their environmental impact. The reduced material usage also translates to less waste generation at end-of-life, though this advantage may be partially negated by more frequent replacement cycles.

Both coating types involve the use of rare earth elements and zirconia-based ceramics, which present sustainability challenges related to mining impacts and limited resource availability. Recent research has focused on developing alternative ceramic compositions that reduce dependence on scarce materials while maintaining performance characteristics. Recycling opportunities remain limited for both thick and thin TBCs due to contamination issues and the difficulty of separating coating materials from substrates.

Life cycle assessment (LCA) studies comparing the two approaches indicate that the environmental preference depends heavily on application context. For components with frequent thermal cycling, thin coatings may require more frequent replacement, increasing lifetime environmental impact despite lower initial footprint. In contrast, thick coatings may be preferable for stable, long-duration applications where their durability advantages can be fully realized.

Emerging sustainable innovations in TBC technology include water-based slurry applications that reduce volatile organic compound emissions, bio-inspired ceramic structures that enhance performance while using less material, and hybrid coating systems that optimize thickness profiles based on localized thermal requirements. These developments are gradually improving the environmental profile of both thick and thin coating technologies.

Regulatory frameworks increasingly influence TBC selection, with stricter emissions standards and material restrictions driving manufacturers toward more sustainable coating solutions. This regulatory pressure, combined with corporate sustainability initiatives, is accelerating research into environmentally optimized TBC systems that balance performance requirements with reduced ecological impact.

Thick TBCs typically require more raw ceramic materials during production, resulting in higher resource consumption and extraction impacts. The manufacturing process for these coatings often demands more energy for deposition and curing, particularly when using traditional plasma spray techniques. This increased energy requirement translates to a larger carbon footprint compared to thinner alternatives. However, thick coatings generally offer longer service lifetimes, which can offset initial environmental costs through reduced replacement frequency.

Thin TBCs, conversely, utilize fewer raw materials and typically require less energy during application processes. Advanced deposition methods like electron beam physical vapor deposition (EB-PVD) for thin coatings have become more energy-efficient in recent years, further reducing their environmental impact. The reduced material usage also translates to less waste generation at end-of-life, though this advantage may be partially negated by more frequent replacement cycles.

Both coating types involve the use of rare earth elements and zirconia-based ceramics, which present sustainability challenges related to mining impacts and limited resource availability. Recent research has focused on developing alternative ceramic compositions that reduce dependence on scarce materials while maintaining performance characteristics. Recycling opportunities remain limited for both thick and thin TBCs due to contamination issues and the difficulty of separating coating materials from substrates.

Life cycle assessment (LCA) studies comparing the two approaches indicate that the environmental preference depends heavily on application context. For components with frequent thermal cycling, thin coatings may require more frequent replacement, increasing lifetime environmental impact despite lower initial footprint. In contrast, thick coatings may be preferable for stable, long-duration applications where their durability advantages can be fully realized.

Emerging sustainable innovations in TBC technology include water-based slurry applications that reduce volatile organic compound emissions, bio-inspired ceramic structures that enhance performance while using less material, and hybrid coating systems that optimize thickness profiles based on localized thermal requirements. These developments are gradually improving the environmental profile of both thick and thin coating technologies.

Regulatory frameworks increasingly influence TBC selection, with stricter emissions standards and material restrictions driving manufacturers toward more sustainable coating solutions. This regulatory pressure, combined with corporate sustainability initiatives, is accelerating research into environmentally optimized TBC systems that balance performance requirements with reduced ecological impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!