What mechanisms control thermal conductivity in thermal barrier coatings ceramics

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Barrier Coatings Evolution and Objectives

Thermal barrier coatings (TBCs) have evolved significantly since their inception in the 1950s, initially developed for aerospace applications to protect metal components from extreme temperatures. The primary objective of these ceramic coatings has consistently been to provide thermal insulation, allowing gas turbines and other high-temperature systems to operate at higher temperatures, thereby increasing efficiency and performance while extending component lifespan.

The evolution of TBCs can be traced through several distinct phases. Early systems utilized simple ceramic compositions, primarily stabilized zirconia, applied through flame spraying techniques. By the 1970s, advancements led to the development of electron beam physical vapor deposition (EB-PVD) methods, creating columnar microstructures that significantly enhanced coating durability and thermal resistance properties.

The 1980s and 1990s witnessed the standardization of yttria-stabilized zirconia (YSZ) as the predominant TBC material due to its exceptional combination of low thermal conductivity and relatively high thermal expansion coefficient. This period also saw the introduction of sophisticated bond coat systems and thermally grown oxide (TGO) layers that improved adhesion and oxidation resistance.

Recent decades have focused on addressing the limitations of traditional YSZ coatings, particularly their phase instability above 1200°C and susceptibility to hot corrosion. Research has expanded to explore rare-earth zirconates, pyrochlores, and perovskites that offer potentially superior high-temperature stability and lower thermal conductivity.

The current technological trajectory aims to develop multi-layered, functionally graded TBC systems that can withstand temperatures exceeding 1300°C while maintaining structural integrity under thermal cycling conditions. These advanced systems incorporate nanoscale features and compositional modifications to optimize thermal conductivity mechanisms.

Looking forward, the field is moving toward "smart" TBCs with self-healing capabilities and integrated sensing functions. The ultimate objective remains consistent: to develop coating systems with precisely controlled thermal conductivity that can operate reliably in increasingly extreme thermal environments while minimizing weight penalties and manufacturing costs.

Understanding the fundamental mechanisms that control thermal conductivity in these ceramic systems has become central to achieving these objectives, as researchers seek to manipulate phonon scattering, radiation effects, and microstructural features to push the performance boundaries of next-generation thermal barrier systems.

The evolution of TBCs can be traced through several distinct phases. Early systems utilized simple ceramic compositions, primarily stabilized zirconia, applied through flame spraying techniques. By the 1970s, advancements led to the development of electron beam physical vapor deposition (EB-PVD) methods, creating columnar microstructures that significantly enhanced coating durability and thermal resistance properties.

The 1980s and 1990s witnessed the standardization of yttria-stabilized zirconia (YSZ) as the predominant TBC material due to its exceptional combination of low thermal conductivity and relatively high thermal expansion coefficient. This period also saw the introduction of sophisticated bond coat systems and thermally grown oxide (TGO) layers that improved adhesion and oxidation resistance.

Recent decades have focused on addressing the limitations of traditional YSZ coatings, particularly their phase instability above 1200°C and susceptibility to hot corrosion. Research has expanded to explore rare-earth zirconates, pyrochlores, and perovskites that offer potentially superior high-temperature stability and lower thermal conductivity.

The current technological trajectory aims to develop multi-layered, functionally graded TBC systems that can withstand temperatures exceeding 1300°C while maintaining structural integrity under thermal cycling conditions. These advanced systems incorporate nanoscale features and compositional modifications to optimize thermal conductivity mechanisms.

Looking forward, the field is moving toward "smart" TBCs with self-healing capabilities and integrated sensing functions. The ultimate objective remains consistent: to develop coating systems with precisely controlled thermal conductivity that can operate reliably in increasingly extreme thermal environments while minimizing weight penalties and manufacturing costs.

Understanding the fundamental mechanisms that control thermal conductivity in these ceramic systems has become central to achieving these objectives, as researchers seek to manipulate phonon scattering, radiation effects, and microstructural features to push the performance boundaries of next-generation thermal barrier systems.

Market Analysis for Advanced Thermal Barrier Solutions

The global market for advanced thermal barrier coatings (TBCs) is experiencing robust growth, driven primarily by increasing demands in aerospace, power generation, and automotive industries. Current market valuation stands at approximately $2.3 billion, with projections indicating a compound annual growth rate of 6.8% through 2028. This growth trajectory is underpinned by the critical role these coatings play in enhancing operational efficiency and extending component lifespans in high-temperature environments.

Aerospace remains the dominant application sector, accounting for nearly 40% of the total market share. The continuous push for more fuel-efficient aircraft engines operating at higher temperatures has intensified the demand for advanced TBCs with superior thermal conductivity control mechanisms. Gas turbine manufacturers are particularly focused on coatings that can withstand temperatures exceeding 1300°C while maintaining structural integrity.

The power generation sector represents the second-largest market segment, with significant adoption in both conventional and renewable energy systems. Industrial gas turbines benefit substantially from TBCs that can reduce cooling air requirements by up to 15%, directly translating to improved thermal efficiency. This performance enhancement has become a key selling point as energy producers face mounting pressure to reduce emissions and improve operational economics.

Regional analysis reveals North America and Europe as market leaders, collectively holding approximately 60% of the global market share. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate at 8.5% annually. This regional shift reflects the expanding industrial base and increasing technological capabilities in these emerging economies.

Customer requirements are evolving toward more specialized solutions with precisely engineered thermal conductivity properties. End-users are increasingly willing to pay premium prices for TBCs that offer demonstrable performance improvements, with particular emphasis on coatings that can maintain low thermal conductivity over extended operational periods. This trend has created a distinct market segment for advanced ceramic formulations with sophisticated microstructural control mechanisms.

Market competition is intensifying as materials science innovations enable new approaches to thermal conductivity manipulation. Traditional yttria-stabilized zirconia (YSZ) coatings are gradually being supplemented or replaced by next-generation ceramics featuring engineered porosity, layered structures, and novel dopants. Companies that can effectively translate fundamental research on phonon scattering mechanisms into commercial coating solutions are gaining competitive advantage and commanding higher market premiums.

Aerospace remains the dominant application sector, accounting for nearly 40% of the total market share. The continuous push for more fuel-efficient aircraft engines operating at higher temperatures has intensified the demand for advanced TBCs with superior thermal conductivity control mechanisms. Gas turbine manufacturers are particularly focused on coatings that can withstand temperatures exceeding 1300°C while maintaining structural integrity.

The power generation sector represents the second-largest market segment, with significant adoption in both conventional and renewable energy systems. Industrial gas turbines benefit substantially from TBCs that can reduce cooling air requirements by up to 15%, directly translating to improved thermal efficiency. This performance enhancement has become a key selling point as energy producers face mounting pressure to reduce emissions and improve operational economics.

Regional analysis reveals North America and Europe as market leaders, collectively holding approximately 60% of the global market share. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate at 8.5% annually. This regional shift reflects the expanding industrial base and increasing technological capabilities in these emerging economies.

Customer requirements are evolving toward more specialized solutions with precisely engineered thermal conductivity properties. End-users are increasingly willing to pay premium prices for TBCs that offer demonstrable performance improvements, with particular emphasis on coatings that can maintain low thermal conductivity over extended operational periods. This trend has created a distinct market segment for advanced ceramic formulations with sophisticated microstructural control mechanisms.

Market competition is intensifying as materials science innovations enable new approaches to thermal conductivity manipulation. Traditional yttria-stabilized zirconia (YSZ) coatings are gradually being supplemented or replaced by next-generation ceramics featuring engineered porosity, layered structures, and novel dopants. Companies that can effectively translate fundamental research on phonon scattering mechanisms into commercial coating solutions are gaining competitive advantage and commanding higher market premiums.

Current Challenges in Ceramic Thermal Conductivity Control

Despite significant advancements in thermal barrier coating (TBC) ceramics, several critical challenges persist in controlling thermal conductivity. The fundamental issue lies in the complex interplay between material composition, microstructure, and processing techniques. Current state-of-the-art yttria-stabilized zirconia (YSZ) coatings approach their temperature limitations at approximately 1200°C, beyond which phase destabilization occurs, compromising their thermal insulation properties.

A major technical hurdle involves the trade-off between thermal conductivity reduction and mechanical stability. While introducing porosity and defects effectively lowers thermal conductivity by scattering phonons, it simultaneously weakens the coating's structural integrity and erosion resistance. This balance becomes increasingly difficult to maintain under extreme thermal cycling conditions typical in aerospace and power generation applications.

The sintering behavior of ceramic coatings presents another significant challenge. During high-temperature operation, the metastable microstructure of TBCs tends to densify, reducing porosity and increasing thermal conductivity over time. This degradation mechanism accelerates with temperature, creating a reliability concern for long-term applications and limiting the service life of components.

Interface thermal resistance management remains problematic in multilayer coating systems. The thermal expansion mismatch between the ceramic top coat and metallic bond coat creates stress concentrations at interfaces, leading to spallation failure. Current solutions inadequately address the progressive degradation of these interfaces during thermal cycling.

Reproducibility in manufacturing processes constitutes a persistent challenge. Variations in deposition parameters during plasma spraying or electron beam physical vapor deposition significantly affect microstructural features that control thermal conductivity. The industry lacks standardized methodologies to consistently produce coatings with predictable thermal properties across different production batches.

Measurement and characterization limitations further complicate development efforts. Accurate in-situ measurement of thermal conductivity under operational conditions remains difficult, creating a gap between laboratory testing and actual performance prediction. This hampers the validation of theoretical models and slows the optimization process for new coating formulations.

Finally, the development of alternative ceramic compositions faces challenges in scalability and cost-effectiveness. While promising materials like gadolinium zirconate and lanthanum pyrochlores demonstrate lower thermal conductivity than YSZ, their implementation is hindered by processing difficulties, limited raw material availability, and insufficient long-term performance data in real-world environments.

A major technical hurdle involves the trade-off between thermal conductivity reduction and mechanical stability. While introducing porosity and defects effectively lowers thermal conductivity by scattering phonons, it simultaneously weakens the coating's structural integrity and erosion resistance. This balance becomes increasingly difficult to maintain under extreme thermal cycling conditions typical in aerospace and power generation applications.

The sintering behavior of ceramic coatings presents another significant challenge. During high-temperature operation, the metastable microstructure of TBCs tends to densify, reducing porosity and increasing thermal conductivity over time. This degradation mechanism accelerates with temperature, creating a reliability concern for long-term applications and limiting the service life of components.

Interface thermal resistance management remains problematic in multilayer coating systems. The thermal expansion mismatch between the ceramic top coat and metallic bond coat creates stress concentrations at interfaces, leading to spallation failure. Current solutions inadequately address the progressive degradation of these interfaces during thermal cycling.

Reproducibility in manufacturing processes constitutes a persistent challenge. Variations in deposition parameters during plasma spraying or electron beam physical vapor deposition significantly affect microstructural features that control thermal conductivity. The industry lacks standardized methodologies to consistently produce coatings with predictable thermal properties across different production batches.

Measurement and characterization limitations further complicate development efforts. Accurate in-situ measurement of thermal conductivity under operational conditions remains difficult, creating a gap between laboratory testing and actual performance prediction. This hampers the validation of theoretical models and slows the optimization process for new coating formulations.

Finally, the development of alternative ceramic compositions faces challenges in scalability and cost-effectiveness. While promising materials like gadolinium zirconate and lanthanum pyrochlores demonstrate lower thermal conductivity than YSZ, their implementation is hindered by processing difficulties, limited raw material availability, and insufficient long-term performance data in real-world environments.

Existing Mechanisms for Thermal Conductivity Reduction

01 Yttria-stabilized zirconia (YSZ) based thermal barrier coatings

Yttria-stabilized zirconia (YSZ) is widely used as a thermal barrier coating material due to its low thermal conductivity and high thermal stability. These coatings can be applied using various deposition techniques such as plasma spraying or electron beam physical vapor deposition. The microstructure of YSZ coatings, including porosity and crack networks, significantly affects their thermal insulation properties. Modifications to YSZ composition and structure can further reduce thermal conductivity for improved high-temperature protection of metal substrates.- Yttria-stabilized zirconia (YSZ) based thermal barrier coatings: Yttria-stabilized zirconia (YSZ) is widely used as a thermal barrier coating material due to its low thermal conductivity and high thermal stability. These coatings can be applied using various deposition techniques such as plasma spraying or electron beam physical vapor deposition. The microstructure of YSZ coatings, including porosity and crack networks, significantly affects their thermal insulation properties. Modifications to YSZ composition and structure can further reduce thermal conductivity for improved high-temperature protection of engine components.

- Rare earth oxide doped ceramic thermal barrier coatings: Incorporating rare earth oxides such as lanthanum, gadolinium, ytterbium, or cerium into ceramic thermal barrier coatings can significantly reduce thermal conductivity. These dopants create atomic-scale defects in the crystal structure that scatter phonons and impede heat transfer. Multi-component rare earth oxide systems can achieve even lower thermal conductivity values compared to conventional coatings. These advanced compositions offer enhanced thermal protection for high-temperature applications in gas turbines and aerospace components.

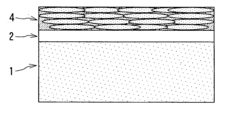

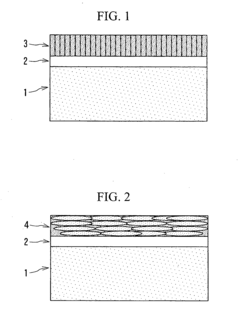

- Multilayer and functionally graded thermal barrier coatings: Multilayer thermal barrier coating systems consist of different ceramic layers with varying compositions and microstructures to optimize thermal protection. Functionally graded coatings feature a gradual transition in composition, porosity, or microstructure from the substrate to the outer surface. These designs help minimize thermal expansion mismatch stress while maximizing thermal insulation performance. The strategic layering of different ceramic materials can combine the beneficial properties of each component while mitigating their individual limitations.

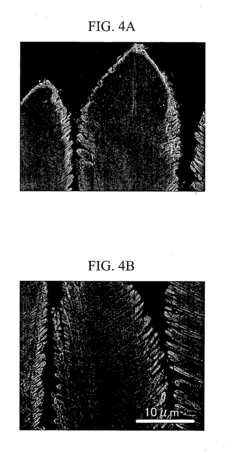

- Porous and microstructurally engineered ceramic coatings: Controlling the porosity and microstructure of ceramic thermal barrier coatings can significantly reduce thermal conductivity. Techniques such as creating columnar structures, segmentation cracks, or engineered pore distributions help disrupt heat transfer pathways. Advanced processing methods can produce coatings with nano-sized pores or layered defect structures that effectively scatter phonons. These microstructurally engineered coatings maintain mechanical integrity while providing superior thermal insulation properties.

- Novel ceramic compositions for ultra-low thermal conductivity: Research on novel ceramic compositions focuses on developing materials with intrinsically low thermal conductivity for thermal barrier applications. These include pyrochlores, perovskites, hexaaluminates, and complex oxide systems that feature large unit cells and high phonon scattering potential. Some compositions incorporate phase transformation capabilities or defect clustering mechanisms to further reduce heat transfer. These advanced materials push the boundaries of thermal insulation performance for extreme temperature environments in aerospace and energy generation applications.

02 Rare earth oxide doped ceramic thermal barrier coatings

Incorporating rare earth oxides such as lanthanum, gadolinium, ytterbium, or cerium into ceramic thermal barrier coatings can significantly reduce thermal conductivity. These dopants create oxygen vacancies and lattice distortions in the crystal structure, which scatter phonons and impede heat transfer. Multi-component rare earth oxide systems can achieve even lower thermal conductivity values compared to conventional coatings. These advanced formulations provide enhanced thermal protection for components operating in extreme temperature environments.Expand Specific Solutions03 Multilayer and functionally graded thermal barrier coatings

Multilayer and functionally graded thermal barrier coating systems consist of different ceramic layers with varying compositions and microstructures. These designs create thermal conductivity gradients that optimize heat flow management while maintaining mechanical integrity. The layered structure can include dense layers for erosion resistance combined with porous layers for thermal insulation. This approach allows for tailored thermal and mechanical properties throughout the coating thickness, improving durability and thermal performance in high-temperature applications.Expand Specific Solutions04 Pyrochlore and perovskite structured ceramics for thermal barriers

Ceramic materials with pyrochlore (A₂B₂O₇) and perovskite (ABO₃) crystal structures offer inherently low thermal conductivity for thermal barrier applications. These complex oxide structures, particularly those containing gadolinium, zirconium, or lanthanum, provide excellent phonon scattering capabilities. Their ordered crystal structure with oxygen vacancies disrupts heat transfer pathways. These advanced ceramics maintain phase stability at high temperatures and can achieve thermal conductivity values significantly lower than conventional coating materials.Expand Specific Solutions05 Porosity engineering and microstructure control for thermal conductivity reduction

Controlling the porosity and microstructure of ceramic thermal barrier coatings is an effective strategy for reducing thermal conductivity. Techniques include introducing engineered pores, columnar structures, or micro-cracks that act as barriers to heat flow. Specific deposition parameters can create desired microstructural features such as splat boundaries in plasma-sprayed coatings or columnar gaps in EB-PVD coatings. The size, shape, orientation, and distribution of these features can be optimized to minimize thermal conductivity while maintaining coating durability and erosion resistance.Expand Specific Solutions

Leading Manufacturers and Research Institutions in TBC Industry

The thermal barrier coatings (TBC) ceramics market is in a growth phase, driven by increasing demands in aerospace and energy sectors. The global market size is expanding steadily, with projections indicating significant growth due to rising applications in gas turbines and aerospace engines. Technologically, the field is moderately mature but continuously evolving, with companies like Rolls-Royce, Siemens AG, and Mitsubishi Heavy Industries leading commercial applications. Research institutions such as Xi'an Jiaotong University and NASA are advancing fundamental understanding of thermal conductivity control mechanisms. Aerospace specialists including Safran Aircraft Engines, MTU Aero Engines, and RTX Corp are developing proprietary TBC solutions, while materials science companies like HRL Laboratories focus on next-generation ceramic compositions with enhanced thermal performance.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed thermal barrier coating systems that control thermal conductivity through multiple sophisticated mechanisms. Their approach focuses on hierarchical microstructural engineering, where defects at different length scales work synergistically to impede phonon transport. MHI utilizes advanced ceramic compositions based on zirconia with carefully selected dopants that create complex crystal structures with inherently low thermal conductivity. Their coatings feature engineered interfaces between splats (in plasma-sprayed coatings) that act as thermal resistance sites. MHI has pioneered the development of functionally graded materials (FGM) where composition and microstructure gradually change throughout the coating thickness, creating multiple phonon scattering interfaces while maintaining mechanical compatibility with metallic substrates. Their manufacturing processes include controlled cooling rates that induce beneficial residual stresses and microcracking patterns that further reduce thermal conductivity.

Strengths: Strong integration with gas turbine manufacturing allowing rapid implementation of new coating technologies; extensive high-temperature testing capabilities; balanced approach to thermal and mechanical properties. Weaknesses: More conservative approach may result in slower adoption of cutting-edge materials; potential challenges with coating durability in extreme thermal cycling environments.

Siemens AG

Technical Solution: Siemens has developed thermal barrier coating systems that control thermal conductivity through multiple mechanisms. Their approach focuses on engineered defect clustering in ceramic structures, where point defects (oxygen vacancies and substitutional atoms) are strategically positioned to maximize phonon scattering without compromising mechanical integrity. Siemens utilizes pyrochlore-structured ceramics (A₂B₂O₇) with complex unit cells that inherently reduce phonon mean free paths. Their coatings incorporate controlled segmentation cracks that create discontinuities in heat flow paths while maintaining strain tolerance. Siemens has also pioneered multi-component doping strategies where carefully selected rare earth elements are introduced into the ceramic matrix to create mass contrast and elastic strain fields that effectively scatter phonons across different frequency ranges.

Strengths: Advanced manufacturing capabilities allowing precise microstructural control; extensive testing facilities for thermal cycling and performance validation; strong materials science research team. Weaknesses: Complex manufacturing processes may limit production scaling; higher initial implementation costs compared to conventional coating systems.

Critical Patents in Phonon Scattering and Microstructure Engineering

Thermal barrier coating system method of manufacturing the same

PatentInactiveUS20050129972A1

Innovation

- A thermal barrier coating system with a ceramics thermal barrier layer formed by electron beam physical vapor deposition (EB-PVD) method, incorporating 0.1 to 10 mol% lanthanum oxide (La2O3) in a columnar structure of stabilized zirconia (ZrO2) or zirconia-hafnia (ZrO2-HfO2) solid solution, which reduces thermal conductivity and enhances durability.

Reduced Thermal Conductivity Thermal Barrier Coating by Electron Beam-Physical Vapor Deposition Process

PatentActiveUS20090305866A1

Innovation

- A method involving the deposition of a ceramic matrix with a metallic dispersant that forms a refractory metal oxide within the matrix, achieved through co-evaporation and subsequent heat treatment, to create a thermal barrier coating with reduced thermal conductivity and improved strain tolerance.

High-Temperature Performance and Durability Considerations

The performance of thermal barrier coatings (TBCs) under extreme temperature conditions represents a critical factor in their practical application across aerospace, power generation, and industrial sectors. When exposed to temperatures exceeding 1000°C, these ceramic coatings must maintain their thermal insulation properties while resisting degradation mechanisms that could compromise their functionality.

Thermal cycling, a common operational condition for TBC systems, induces significant stress at the ceramic-bond coat interface due to thermal expansion coefficient mismatches. This cyclical stress pattern accelerates microstructural evolution within the ceramic layer, potentially leading to increased thermal conductivity over time. Research indicates that yttria-stabilized zirconia (YSZ) coatings can experience up to 15% increase in thermal conductivity after extended high-temperature exposure, primarily due to sintering effects and phase transformations.

Sintering phenomena become particularly pronounced at elevated temperatures, causing densification of the ceramic microstructure and elimination of the beneficial porosity that contributes to low thermal conductivity. The rate of sintering is temperature-dependent and follows an Arrhenius relationship, with activation energies typically ranging from 100-300 kJ/mol for common TBC materials. This process results in grain growth, pore coalescence, and ultimately, degraded thermal insulation performance.

Phase stability represents another crucial consideration for high-temperature durability. For instance, conventional YSZ coatings containing 7-8 wt% Y₂O₃ undergo phase transformations from the metastable tetragonal (t') to equilibrium phases (cubic and tetragonal) during prolonged exposure above 1200°C. These transformations can trigger volume changes and microcracking, further compromising thermal conductivity control mechanisms.

Chemical compatibility with underlying components becomes increasingly important at elevated temperatures. Interdiffusion between the ceramic layer and bond coat or substrate can introduce foreign elements that alter the fundamental phonon scattering mechanisms. Calcium-magnesium-alumino-silicate (CMAS) infiltration, particularly relevant in aircraft engine environments, represents a severe high-temperature degradation mechanism that can eliminate porosity and create conductive pathways through the ceramic structure.

Erosion resistance also diminishes at higher temperatures as ceramic materials often exhibit reduced fracture toughness and increased brittleness. This mechanical degradation can lead to material removal, thickness reduction, and consequently, diminished thermal insulation capability. Advanced TBC systems incorporating rare-earth zirconates or alumina-based composites demonstrate superior erosion resistance at elevated temperatures compared to conventional YSZ coatings.

Thermal cycling, a common operational condition for TBC systems, induces significant stress at the ceramic-bond coat interface due to thermal expansion coefficient mismatches. This cyclical stress pattern accelerates microstructural evolution within the ceramic layer, potentially leading to increased thermal conductivity over time. Research indicates that yttria-stabilized zirconia (YSZ) coatings can experience up to 15% increase in thermal conductivity after extended high-temperature exposure, primarily due to sintering effects and phase transformations.

Sintering phenomena become particularly pronounced at elevated temperatures, causing densification of the ceramic microstructure and elimination of the beneficial porosity that contributes to low thermal conductivity. The rate of sintering is temperature-dependent and follows an Arrhenius relationship, with activation energies typically ranging from 100-300 kJ/mol for common TBC materials. This process results in grain growth, pore coalescence, and ultimately, degraded thermal insulation performance.

Phase stability represents another crucial consideration for high-temperature durability. For instance, conventional YSZ coatings containing 7-8 wt% Y₂O₃ undergo phase transformations from the metastable tetragonal (t') to equilibrium phases (cubic and tetragonal) during prolonged exposure above 1200°C. These transformations can trigger volume changes and microcracking, further compromising thermal conductivity control mechanisms.

Chemical compatibility with underlying components becomes increasingly important at elevated temperatures. Interdiffusion between the ceramic layer and bond coat or substrate can introduce foreign elements that alter the fundamental phonon scattering mechanisms. Calcium-magnesium-alumino-silicate (CMAS) infiltration, particularly relevant in aircraft engine environments, represents a severe high-temperature degradation mechanism that can eliminate porosity and create conductive pathways through the ceramic structure.

Erosion resistance also diminishes at higher temperatures as ceramic materials often exhibit reduced fracture toughness and increased brittleness. This mechanical degradation can lead to material removal, thickness reduction, and consequently, diminished thermal insulation capability. Advanced TBC systems incorporating rare-earth zirconates or alumina-based composites demonstrate superior erosion resistance at elevated temperatures compared to conventional YSZ coatings.

Environmental Impact and Sustainability of Advanced Ceramics

The environmental impact of thermal barrier coating (TBC) ceramics extends beyond their primary function of thermal insulation. As these advanced materials continue to evolve for higher performance in controlling thermal conductivity, their sustainability aspects become increasingly important for comprehensive evaluation.

The production of TBC ceramics typically involves energy-intensive processes including high-temperature sintering and plasma spraying. These manufacturing methods contribute significantly to carbon emissions, with estimates suggesting that ceramic production can generate between 0.65 and 0.92 kg CO2 equivalent per kilogram of finished product. The environmental footprint varies considerably depending on the specific mechanisms employed to control thermal conductivity, such as engineered porosity or complex oxide structures.

Raw material extraction for TBC ceramics presents another environmental consideration. Rare earth elements commonly used in advanced TBCs, particularly yttria-stabilized zirconia (YSZ) systems, face supply chain vulnerabilities and extraction processes that can lead to habitat disruption and water pollution. The mining of zirconium and yttrium has been associated with tailings that contain radioactive elements requiring careful management.

Life cycle assessment studies indicate that the environmental benefits of TBC ceramics during operation often outweigh their production impacts. By enhancing thermal efficiency in turbines and combustion systems, these coatings reduce fuel consumption and associated emissions. Research suggests that a 1% improvement in turbine efficiency through optimized thermal barrier coatings can reduce lifetime CO2 emissions by approximately 2-3% in aerospace applications.

End-of-life considerations for TBC ceramics present both challenges and opportunities. Their chemical stability, while beneficial for durability, complicates recycling efforts. However, emerging technologies for ceramic recycling show promise, with mechanical and chemical recovery methods potentially reclaiming up to 85% of valuable materials from spent TBCs.

Recent innovations in sustainable TBC development include bio-inspired ceramic structures that mimic natural thermal regulation systems, requiring less energy-intensive processing while maintaining performance. Additionally, water-based deposition techniques are reducing the environmental impact of coating processes by eliminating volatile organic compounds traditionally used in ceramic processing.

The transition toward more sustainable TBC ceramics will require balancing thermal conductivity control mechanisms with environmental considerations, potentially leading to new design paradigms that optimize both performance and ecological footprint throughout the material lifecycle.

The production of TBC ceramics typically involves energy-intensive processes including high-temperature sintering and plasma spraying. These manufacturing methods contribute significantly to carbon emissions, with estimates suggesting that ceramic production can generate between 0.65 and 0.92 kg CO2 equivalent per kilogram of finished product. The environmental footprint varies considerably depending on the specific mechanisms employed to control thermal conductivity, such as engineered porosity or complex oxide structures.

Raw material extraction for TBC ceramics presents another environmental consideration. Rare earth elements commonly used in advanced TBCs, particularly yttria-stabilized zirconia (YSZ) systems, face supply chain vulnerabilities and extraction processes that can lead to habitat disruption and water pollution. The mining of zirconium and yttrium has been associated with tailings that contain radioactive elements requiring careful management.

Life cycle assessment studies indicate that the environmental benefits of TBC ceramics during operation often outweigh their production impacts. By enhancing thermal efficiency in turbines and combustion systems, these coatings reduce fuel consumption and associated emissions. Research suggests that a 1% improvement in turbine efficiency through optimized thermal barrier coatings can reduce lifetime CO2 emissions by approximately 2-3% in aerospace applications.

End-of-life considerations for TBC ceramics present both challenges and opportunities. Their chemical stability, while beneficial for durability, complicates recycling efforts. However, emerging technologies for ceramic recycling show promise, with mechanical and chemical recovery methods potentially reclaiming up to 85% of valuable materials from spent TBCs.

Recent innovations in sustainable TBC development include bio-inspired ceramic structures that mimic natural thermal regulation systems, requiring less energy-intensive processing while maintaining performance. Additionally, water-based deposition techniques are reducing the environmental impact of coating processes by eliminating volatile organic compounds traditionally used in ceramic processing.

The transition toward more sustainable TBC ceramics will require balancing thermal conductivity control mechanisms with environmental considerations, potentially leading to new design paradigms that optimize both performance and ecological footprint throughout the material lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!