Thermal barrier coatings ceramics for next-generation jet engines

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TBC Evolution and Performance Targets

Thermal barrier coatings (TBCs) have undergone significant evolution since their initial development in the 1970s. The first-generation TBCs primarily consisted of yttria-stabilized zirconia (YSZ) with 7-8 wt% Y2O3, which offered a good balance of thermal conductivity reduction and phase stability. These early coatings provided temperature reductions of approximately 100-150°C across the coating thickness, enabling modest increases in turbine inlet temperatures.

By the 1990s, second-generation TBCs emerged with improved microstructural control through advanced deposition techniques such as electron beam physical vapor deposition (EB-PVD), which created columnar structures that enhanced strain tolerance while maintaining low thermal conductivity. These advancements allowed for temperature reductions of 150-200°C and significantly extended coating lifespans under cyclic thermal conditions.

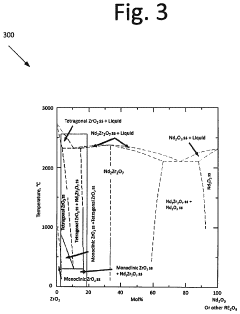

The early 2000s saw the development of third-generation TBCs incorporating rare-earth zirconates (e.g., Gd2Zr2O7, La2Zr2O7) and co-doped YSZ systems, which further reduced thermal conductivity by introducing complex crystal structures and increased phonon scattering sites. These materials achieved temperature reductions exceeding 200°C but often sacrificed mechanical properties compared to traditional YSZ.

Current state-of-the-art TBCs utilize multilayer architectures and functionally graded compositions to optimize both thermal and mechanical performance. These systems can provide temperature reductions of 250-300°C while maintaining acceptable durability under extreme operating conditions.

For next-generation jet engines, which aim to operate at temperatures approaching 1700°C for improved efficiency and reduced emissions, TBC performance targets have become increasingly demanding. Future TBCs must achieve temperature reductions of 300-350°C while withstanding higher thermal gradients, more frequent thermal cycling, and increased exposure to contaminants such as calcium-magnesium-alumino-silicates (CMAS).

Key performance targets for next-generation TBC ceramics include thermal conductivity values below 1.0 W/m·K (compared to ~2.0-2.3 W/m·K for conventional YSZ), phase stability up to 1500°C for extended periods (>10,000 hours), enhanced sintering resistance to maintain porosity at elevated temperatures, and improved resistance to CMAS infiltration and erosion from particulate matter.

Additionally, these advanced TBCs must maintain excellent adhesion to underlying bond coats despite increased thermal expansion mismatch stresses, demonstrate self-healing capabilities to mitigate crack propagation, and provide effective oxygen diffusion barriers to protect underlying components from oxidation. These ambitious targets necessitate fundamental innovations in ceramic material design, processing techniques, and coating architectures.

By the 1990s, second-generation TBCs emerged with improved microstructural control through advanced deposition techniques such as electron beam physical vapor deposition (EB-PVD), which created columnar structures that enhanced strain tolerance while maintaining low thermal conductivity. These advancements allowed for temperature reductions of 150-200°C and significantly extended coating lifespans under cyclic thermal conditions.

The early 2000s saw the development of third-generation TBCs incorporating rare-earth zirconates (e.g., Gd2Zr2O7, La2Zr2O7) and co-doped YSZ systems, which further reduced thermal conductivity by introducing complex crystal structures and increased phonon scattering sites. These materials achieved temperature reductions exceeding 200°C but often sacrificed mechanical properties compared to traditional YSZ.

Current state-of-the-art TBCs utilize multilayer architectures and functionally graded compositions to optimize both thermal and mechanical performance. These systems can provide temperature reductions of 250-300°C while maintaining acceptable durability under extreme operating conditions.

For next-generation jet engines, which aim to operate at temperatures approaching 1700°C for improved efficiency and reduced emissions, TBC performance targets have become increasingly demanding. Future TBCs must achieve temperature reductions of 300-350°C while withstanding higher thermal gradients, more frequent thermal cycling, and increased exposure to contaminants such as calcium-magnesium-alumino-silicates (CMAS).

Key performance targets for next-generation TBC ceramics include thermal conductivity values below 1.0 W/m·K (compared to ~2.0-2.3 W/m·K for conventional YSZ), phase stability up to 1500°C for extended periods (>10,000 hours), enhanced sintering resistance to maintain porosity at elevated temperatures, and improved resistance to CMAS infiltration and erosion from particulate matter.

Additionally, these advanced TBCs must maintain excellent adhesion to underlying bond coats despite increased thermal expansion mismatch stresses, demonstrate self-healing capabilities to mitigate crack propagation, and provide effective oxygen diffusion barriers to protect underlying components from oxidation. These ambitious targets necessitate fundamental innovations in ceramic material design, processing techniques, and coating architectures.

Aerospace Market Demand Analysis

The aerospace industry is witnessing a significant surge in demand for advanced thermal barrier coatings (TBCs) ceramics, driven primarily by the development of next-generation jet engines. Market analysis indicates that the global aerospace TBC market is projected to grow at a compound annual growth rate of 6.8% through 2030, with the military and commercial aviation segments being the primary contributors to this expansion.

Commercial aviation represents the largest market segment, accounting for approximately 65% of the total demand for thermal barrier coatings. This is attributed to the increasing production rates of narrow-body and wide-body aircraft, particularly in emerging markets across Asia-Pacific and the Middle East. Boeing and Airbus forecast delivery of over 40,000 new commercial aircraft over the next two decades, creating substantial demand for advanced engine technologies incorporating ceramic TBCs.

Military aviation constitutes the second-largest market segment, with defense spending on advanced fighter jets and military transport aircraft driving demand for high-performance thermal barrier coatings. The F-35 Joint Strike Fighter program alone represents a significant market opportunity, with over 3,000 aircraft planned for production, each requiring advanced ceramic TBCs for their engine components.

The business jet and regional aircraft segments are smaller but growing markets for TBC ceramics, collectively representing about 15% of the total market share. These segments are increasingly adopting technologies previously reserved for larger commercial aircraft, creating new opportunities for thermal barrier coating applications.

Geographically, North America dominates the market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the highest growth rates are expected in China and India, where rapid expansion of domestic aerospace manufacturing capabilities and increasing defense budgets are creating new demand centers for advanced materials.

Key market drivers include the push for fuel efficiency, with airlines seeking to reduce operating costs and meet increasingly stringent environmental regulations. Each 1% improvement in fuel efficiency can translate to millions in savings for airlines, making investment in advanced TBC technologies economically justified despite higher initial costs.

Another significant market driver is the trend toward higher operating temperatures in jet engines. Modern turbofan engines are pushing thermal limits to achieve greater thermodynamic efficiency, with core temperatures now exceeding 1600°C in the most advanced designs. This creates demand for ceramic TBCs capable of withstanding these extreme conditions while maintaining structural integrity over thousands of flight cycles.

Commercial aviation represents the largest market segment, accounting for approximately 65% of the total demand for thermal barrier coatings. This is attributed to the increasing production rates of narrow-body and wide-body aircraft, particularly in emerging markets across Asia-Pacific and the Middle East. Boeing and Airbus forecast delivery of over 40,000 new commercial aircraft over the next two decades, creating substantial demand for advanced engine technologies incorporating ceramic TBCs.

Military aviation constitutes the second-largest market segment, with defense spending on advanced fighter jets and military transport aircraft driving demand for high-performance thermal barrier coatings. The F-35 Joint Strike Fighter program alone represents a significant market opportunity, with over 3,000 aircraft planned for production, each requiring advanced ceramic TBCs for their engine components.

The business jet and regional aircraft segments are smaller but growing markets for TBC ceramics, collectively representing about 15% of the total market share. These segments are increasingly adopting technologies previously reserved for larger commercial aircraft, creating new opportunities for thermal barrier coating applications.

Geographically, North America dominates the market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the highest growth rates are expected in China and India, where rapid expansion of domestic aerospace manufacturing capabilities and increasing defense budgets are creating new demand centers for advanced materials.

Key market drivers include the push for fuel efficiency, with airlines seeking to reduce operating costs and meet increasingly stringent environmental regulations. Each 1% improvement in fuel efficiency can translate to millions in savings for airlines, making investment in advanced TBC technologies economically justified despite higher initial costs.

Another significant market driver is the trend toward higher operating temperatures in jet engines. Modern turbofan engines are pushing thermal limits to achieve greater thermodynamic efficiency, with core temperatures now exceeding 1600°C in the most advanced designs. This creates demand for ceramic TBCs capable of withstanding these extreme conditions while maintaining structural integrity over thousands of flight cycles.

Global TBC Technology Assessment

The global landscape of Thermal Barrier Coating (TBC) technology demonstrates significant regional variations in research focus, industrial application, and technological maturity. North America, particularly the United States, maintains leadership in advanced TBC development through substantial aerospace and defense investments. Major corporations like GE Aviation, Pratt & Whitney, and Honeywell have established robust research ecosystems in partnership with national laboratories and academic institutions, focusing on novel ceramic compositions and deposition techniques.

European TBC development is characterized by strong collaborative frameworks between industry, academia, and government research centers. The European Union's Horizon programs have specifically targeted high-temperature coatings for aerospace applications, with notable contributions from Rolls-Royce in the UK, Safran in France, and MTU Aero Engines in Germany. These entities have pioneered advancements in electron beam physical vapor deposition (EB-PVD) techniques and gadolinium zirconate-based TBCs.

Asia presents a rapidly evolving TBC technology landscape with distinct regional characteristics. Japan has established excellence in ceramic engineering through companies like IHI Corporation and Mitsubishi Heavy Industries, focusing on precision manufacturing and quality control in TBC production. China has dramatically increased its research output in the past decade, with institutions like the Chinese Academy of Sciences prioritizing indigenous development of advanced TBCs for both civil and military applications.

The global TBC patent landscape reveals interesting patterns, with approximately 45% of patents originating from North America, 30% from Europe, 20% from Asia, and 5% from other regions. Recent years have shown accelerated patent filing from Chinese entities, suggesting an intensifying global competition in this strategic technology area.

From a technological standpoint, current global TBC development focuses on several key areas: rare-earth doped zirconia systems for enhanced phase stability, multilayer architectures to improve thermal cycling resistance, nanostructured coatings for reduced thermal conductivity, and environmental barrier additions to protect against calcium-magnesium-alumino-silicate (CMAS) degradation.

International collaboration in TBC research has increased significantly, with multinational projects addressing fundamental challenges like coating durability under extreme thermal cycling and resistance to volcanic ash contamination. These collaborative efforts have been particularly valuable in establishing standardized testing protocols and performance benchmarks for next-generation TBC systems.

The global supply chain for TBC materials and processing equipment remains concentrated, with specialized powder suppliers and coating equipment manufacturers forming critical nodes in the production ecosystem. This concentration presents both opportunities for quality control and risks related to supply chain resilience, particularly for rare-earth elements essential to advanced TBC formulations.

European TBC development is characterized by strong collaborative frameworks between industry, academia, and government research centers. The European Union's Horizon programs have specifically targeted high-temperature coatings for aerospace applications, with notable contributions from Rolls-Royce in the UK, Safran in France, and MTU Aero Engines in Germany. These entities have pioneered advancements in electron beam physical vapor deposition (EB-PVD) techniques and gadolinium zirconate-based TBCs.

Asia presents a rapidly evolving TBC technology landscape with distinct regional characteristics. Japan has established excellence in ceramic engineering through companies like IHI Corporation and Mitsubishi Heavy Industries, focusing on precision manufacturing and quality control in TBC production. China has dramatically increased its research output in the past decade, with institutions like the Chinese Academy of Sciences prioritizing indigenous development of advanced TBCs for both civil and military applications.

The global TBC patent landscape reveals interesting patterns, with approximately 45% of patents originating from North America, 30% from Europe, 20% from Asia, and 5% from other regions. Recent years have shown accelerated patent filing from Chinese entities, suggesting an intensifying global competition in this strategic technology area.

From a technological standpoint, current global TBC development focuses on several key areas: rare-earth doped zirconia systems for enhanced phase stability, multilayer architectures to improve thermal cycling resistance, nanostructured coatings for reduced thermal conductivity, and environmental barrier additions to protect against calcium-magnesium-alumino-silicate (CMAS) degradation.

International collaboration in TBC research has increased significantly, with multinational projects addressing fundamental challenges like coating durability under extreme thermal cycling and resistance to volcanic ash contamination. These collaborative efforts have been particularly valuable in establishing standardized testing protocols and performance benchmarks for next-generation TBC systems.

The global supply chain for TBC materials and processing equipment remains concentrated, with specialized powder suppliers and coating equipment manufacturers forming critical nodes in the production ecosystem. This concentration presents both opportunities for quality control and risks related to supply chain resilience, particularly for rare-earth elements essential to advanced TBC formulations.

Current TBC Systems Architecture

01 Yttria-stabilized zirconia (YSZ) thermal barrier coatings

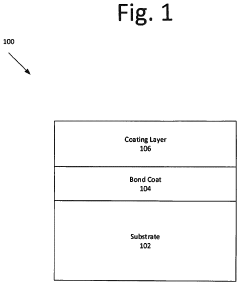

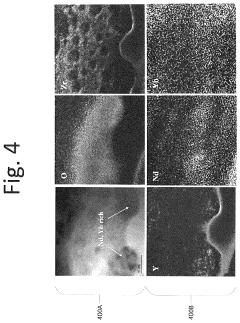

Yttria-stabilized zirconia (YSZ) is widely used as a thermal barrier coating material due to its excellent thermal insulation properties and high temperature stability. These coatings typically consist of a ceramic top coat of YSZ applied over a metallic bond coat. The YSZ provides thermal protection to the underlying metal components in high-temperature environments such as gas turbine engines. Various deposition techniques including plasma spraying and electron beam physical vapor deposition (EB-PVD) are used to apply these coatings.- Yttria-stabilized zirconia (YSZ) thermal barrier coatings: Yttria-stabilized zirconia (YSZ) is widely used as a thermal barrier coating material due to its excellent thermal insulation properties and high-temperature stability. These coatings typically consist of a ceramic top coat of YSZ applied over a metallic bond coat. The YSZ provides thermal protection to the underlying metal components in high-temperature environments such as gas turbine engines. Various deposition techniques including plasma spraying and electron beam physical vapor deposition (EB-PVD) are used to apply these coatings.

- Advanced ceramic compositions for enhanced thermal barrier performance: Novel ceramic compositions have been developed to enhance the performance of thermal barrier coatings beyond traditional YSZ. These include rare earth zirconates, hafnates, and complex oxides that offer improved phase stability, lower thermal conductivity, and better resistance to sintering at elevated temperatures. Some compositions incorporate multiple dopants or layered structures to optimize the balance between thermal insulation and mechanical durability. These advanced ceramics are designed to withstand more extreme operating conditions and extend component lifetimes.

- Deposition methods for ceramic thermal barrier coatings: Various deposition techniques are employed to apply ceramic thermal barrier coatings to components. These include atmospheric plasma spraying (APS), suspension plasma spraying (SPS), electron beam physical vapor deposition (EB-PVD), and chemical vapor deposition (CVD). Each method produces coatings with different microstructures, porosity levels, and strain tolerance characteristics. The selection of deposition method significantly impacts coating adhesion, durability, and thermal insulation efficiency. Process parameters can be optimized to control coating thickness, density, and microstructural features.

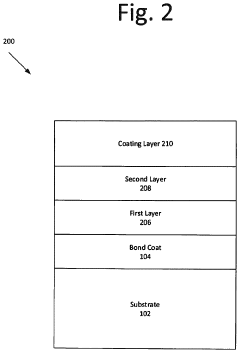

- Multilayer and functionally graded ceramic coating systems: Multilayer and functionally graded coating systems combine different ceramic materials or vary composition through the coating thickness to optimize performance. These systems typically include a bond coat, transition layers, and a ceramic top coat with engineered interfaces. The gradual transition in properties helps mitigate thermal expansion mismatch stresses and improve coating durability. Some designs incorporate porosity gradients or compositional variations to enhance strain tolerance while maintaining thermal insulation properties. These sophisticated coating architectures are tailored for specific operating environments and failure mechanisms.

- Environmental barrier aspects of ceramic thermal coatings: Ceramic thermal barrier coatings are designed not only for thermal insulation but also to provide protection against environmental degradation. These coatings incorporate elements that enhance resistance to oxidation, hot corrosion, calcium-magnesium-alumino-silicate (CMAS) infiltration, and erosion. Some formulations include self-healing capabilities or sacrificial components that preferentially react with contaminants. The environmental barrier aspects are particularly important in applications involving combustion environments, where the coatings must withstand both high temperatures and chemical attack from combustion products and airborne contaminants.

02 Advanced ceramic compositions for enhanced thermal barrier performance

Novel ceramic compositions have been developed to enhance the performance of thermal barrier coatings beyond traditional YSZ. These include rare earth zirconates, hafnates, and complex oxides that offer improved phase stability, lower thermal conductivity, and better resistance to sintering at elevated temperatures. Some compositions incorporate multiple dopants or layered structures to optimize both thermal and mechanical properties. These advanced ceramics can extend component life and enable higher operating temperatures in turbine engines.Expand Specific Solutions03 Deposition methods for ceramic thermal barrier coatings

Various deposition techniques are employed to apply ceramic thermal barrier coatings to components. These include atmospheric plasma spraying (APS), suspension plasma spraying (SPS), electron beam physical vapor deposition (EB-PVD), and solution precursor plasma spray (SPPS). Each method produces coatings with different microstructures, such as columnar structures from EB-PVD or lamellar structures from plasma spraying, which affect thermal and mechanical properties. Process parameters can be optimized to control porosity, crack networks, and coating thickness for specific applications.Expand Specific Solutions04 Multilayer and functionally graded ceramic coatings

Multilayer and functionally graded ceramic coatings represent an advanced approach to thermal barrier design. These systems incorporate multiple ceramic layers with different compositions or gradually changing properties throughout the coating thickness. This design strategy helps mitigate thermal expansion mismatch stresses, improve strain tolerance, and optimize both thermal insulation and erosion resistance. Some designs include dense outer layers for erosion protection with porous inner layers for thermal insulation, or gradual transitions between different ceramic compositions.Expand Specific Solutions05 Environmental barrier additions to ceramic thermal coatings

Environmental barrier additions are incorporated into ceramic thermal barrier coatings to protect against degradation mechanisms such as calcium-magnesium-alumino-silicate (CMAS) infiltration, hot corrosion, and water vapor attack. These additions include rare earth oxides, alumina, silica, or other compounds that react with environmental contaminants to form protective phases. Some coatings feature sacrificial layers designed to react with molten deposits and prevent them from reaching the underlying ceramic layers, thereby extending coating lifetime in harsh operating environments.Expand Specific Solutions

Leading Aerospace Materials Manufacturers

The thermal barrier coatings (TBCs) ceramics market for next-generation jet engines is in a growth phase, driven by increasing demands for higher engine operating temperatures and improved fuel efficiency. The global market is expanding steadily, with projections indicating significant growth as aerospace manufacturers seek advanced materials to enhance engine performance. Technologically, industry leaders like General Electric, Rolls-Royce, RTX Corp (formerly United Technologies), and Pratt & Whitney are at the forefront, developing sophisticated ceramic coating solutions that can withstand extreme temperatures. Research institutions including Beihang University and NASA are contributing breakthrough innovations in ceramic compositions and application techniques. The competitive landscape features established aerospace giants alongside specialized materials companies like Praxair S.T. Technology, with collaboration between industry and academia accelerating technological maturation toward more durable, lightweight, and heat-resistant coating systems.

General Electric Company

Technical Solution: General Electric has developed advanced thermal barrier coatings (TBCs) using yttria-stabilized zirconia (YSZ) with enhanced strain tolerance through engineered microstructures. Their proprietary Dense Vertical Crack (DVC) coating system creates controlled segmentation in the ceramic layer, allowing for greater thermal expansion mismatch accommodation between the coating and metal substrate[1]. GE has also pioneered the use of solution precursor plasma spray (SPPS) techniques to create highly porous, strain-tolerant microstructures with superior durability at temperatures exceeding 1200°C[2]. Their recent innovations include gadolinium zirconate-based TBCs with lower thermal conductivity and improved phase stability at extreme temperatures, enabling higher operating temperatures in their latest LEAP and GE9X engines[3]. GE's coatings incorporate rare-earth silicates and hafnium-based ceramics to enhance resistance against calcium-magnesium-alumino-silicate (CMAS) infiltration, a critical failure mode in modern engines operating in diverse environments[4].

Strengths: Industry-leading manufacturing capabilities for complex TBC systems at scale; extensive real-world testing data from commercial engine fleet; proprietary DVC technology offers superior strain tolerance. Weaknesses: Higher production costs compared to conventional coatings; complex manufacturing processes require specialized equipment; some advanced compositions face raw material supply chain challenges.

ROLLS ROYCE PLC

Technical Solution: Rolls-Royce has developed a multi-layered thermal barrier coating system utilizing gadolinium zirconate (Gd2Zr2O7) as the outer ceramic layer, which demonstrates significantly lower thermal conductivity and superior phase stability at temperatures above 1300°C compared to traditional YSZ coatings[1]. Their proprietary "columnar microstructure" deposition technique creates vertically-oriented ceramic grains that enhance strain tolerance during thermal cycling, reducing spallation failures in high-stress engine environments[2]. Rolls-Royce has integrated nano-structured bond coats with carefully controlled aluminum reservoirs that extend coating lifetimes through optimized oxidation resistance[3]. Their recent innovations include rare-earth pyrochlore compositions with engineered porosity gradients that provide both thermal insulation and erosion resistance, addressing a traditional trade-off in TBC design[4]. The company has also pioneered advanced non-destructive evaluation techniques using infrared thermography and photoluminescence spectroscopy for in-service monitoring of coating degradation, enabling predictive maintenance approaches for their Trent engine family[5].

Strengths: Advanced columnar microstructure technology provides exceptional strain tolerance; integrated coating-substrate design approach optimizes overall system performance; sophisticated in-service monitoring capabilities. Weaknesses: Higher initial manufacturing costs compared to conventional plasma-sprayed coatings; complex deposition processes require precise control; some advanced compositions have limited field service history.

Advanced Ceramic Materials Research

Calcium-magnesium aluminosilicate (CMAS) resistant thermal and environmental barrier coatings

PatentActiveUS11958786B1

Innovation

- A CMAS-resistant barrier coating system comprising a substrate, bond coat, and barrier layer with specific compositions such as RE-doped mullite, RE silicate doped rare aluminum garnets, and RE aluminosilicate oxygen barrier layer, along with dopants like CaO, ZrO2, and HfO2, to enhance durability and resistance against CMAS infiltration.

Thermal barrier coatings with low thermal conductivity comprising lanthanide sesquioxides

PatentInactiveEP1953268A1

Innovation

- Development of thermal barrier coatings comprising at least 15 mol% lanthanide sesquioxides, such as La2O3, Pr2O3, and Yb2O3, combined with zirconia, hafnia, or ceria, which create oxygen vacancies to reduce thermal conductivity and improve insulation, while maintaining structural integrity and minimizing weight.

Environmental Impact Assessment

The environmental impact of thermal barrier coatings (TBCs) for next-generation jet engines represents a critical consideration in aerospace technology advancement. These ceramic coatings significantly improve engine efficiency by allowing higher operating temperatures, directly translating to reduced fuel consumption. Studies indicate that advanced TBC systems can contribute to 1-2% improvement in fuel efficiency, which across the global aviation fleet could reduce carbon emissions by millions of tons annually.

Manufacturing processes for ceramic TBCs, however, present notable environmental challenges. Traditional plasma spraying techniques consume substantial energy and often utilize materials requiring energy-intensive mining and processing. Yttria-stabilized zirconia (YSZ), the most common TBC material, requires extensive processing that generates considerable carbon footprint. Recent life cycle assessments reveal that the environmental impact of TBC production may be offset within 1-2 years of engine operation through efficiency gains.

Water consumption and waste generation during TBC manufacturing also warrant attention. The production process typically requires significant water for cooling and cleaning, while generating hazardous waste containing heavy metals and ceramic particulates. Advanced manufacturing methods such as solution precursor plasma spray and suspension plasma spray are emerging as more environmentally friendly alternatives, reducing waste by up to 30% compared to conventional techniques.

End-of-life considerations for TBC-coated components present recycling challenges due to the complex multi-material nature of these systems. The bonding between metallic substrates and ceramic coatings complicates material separation and recovery. Research into environmentally responsible disposal and recycling methods remains underdeveloped, with only 20-30% of coating materials currently recoverable through existing processes.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of aerospace materials. The European Union's REACH regulations and similar frameworks in North America and Asia are imposing stricter controls on hazardous substances used in TBC production. This regulatory landscape is driving innovation toward greener manufacturing processes and more environmentally benign material compositions.

Future research directions include development of rare-earth-free TBC formulations to reduce dependence on environmentally problematic mining operations, and exploration of bio-inspired ceramic structures that could achieve similar thermal properties with reduced material usage. These innovations could potentially decrease the environmental footprint of TBC production by 40-50% while maintaining or improving performance characteristics.

Manufacturing processes for ceramic TBCs, however, present notable environmental challenges. Traditional plasma spraying techniques consume substantial energy and often utilize materials requiring energy-intensive mining and processing. Yttria-stabilized zirconia (YSZ), the most common TBC material, requires extensive processing that generates considerable carbon footprint. Recent life cycle assessments reveal that the environmental impact of TBC production may be offset within 1-2 years of engine operation through efficiency gains.

Water consumption and waste generation during TBC manufacturing also warrant attention. The production process typically requires significant water for cooling and cleaning, while generating hazardous waste containing heavy metals and ceramic particulates. Advanced manufacturing methods such as solution precursor plasma spray and suspension plasma spray are emerging as more environmentally friendly alternatives, reducing waste by up to 30% compared to conventional techniques.

End-of-life considerations for TBC-coated components present recycling challenges due to the complex multi-material nature of these systems. The bonding between metallic substrates and ceramic coatings complicates material separation and recovery. Research into environmentally responsible disposal and recycling methods remains underdeveloped, with only 20-30% of coating materials currently recoverable through existing processes.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of aerospace materials. The European Union's REACH regulations and similar frameworks in North America and Asia are imposing stricter controls on hazardous substances used in TBC production. This regulatory landscape is driving innovation toward greener manufacturing processes and more environmentally benign material compositions.

Future research directions include development of rare-earth-free TBC formulations to reduce dependence on environmentally problematic mining operations, and exploration of bio-inspired ceramic structures that could achieve similar thermal properties with reduced material usage. These innovations could potentially decrease the environmental footprint of TBC production by 40-50% while maintaining or improving performance characteristics.

High-Temperature Testing Methodologies

The evaluation of thermal barrier coatings (TBCs) for next-generation jet engines requires sophisticated high-temperature testing methodologies that accurately simulate extreme operational conditions. Current testing protocols employ a combination of laboratory and simulated engine environments to assess coating performance under thermal cycling, oxidation, and mechanical stress.

Furnace cycling tests represent the foundation of TBC evaluation, subjecting specimens to rapid temperature fluctuations between ambient and operating temperatures (typically 1100-1400°C). These tests reveal coating durability through repeated thermal expansion and contraction cycles, with failure mechanisms carefully documented through microscopic analysis after predetermined cycle intervals.

Burner rig testing provides a more engine-representative environment by exposing coatings to high-velocity combustion gases. This methodology evaluates erosion resistance, thermal shock behavior, and hot corrosion susceptibility simultaneously. Advanced burner rigs incorporate controlled introduction of contaminants such as CMAS (calcium-magnesium-alumino-silicates) to simulate volcanic ash or desert sand ingestion scenarios that increasingly challenge modern engines.

Laser thermal gradient testing has emerged as a cutting-edge methodology for precise thermal gradient evaluation across coating systems. By applying concentrated laser energy to the coating surface while actively cooling the substrate, researchers can establish temperature differentials exceeding 300°C across coating thicknesses of less than 500 micrometers. This approach enables real-time monitoring of coating response to thermal gradients similar to those experienced in service.

Mechanical property characterization at elevated temperatures presents unique challenges requiring specialized equipment. Instrumented indentation testing performed at temperatures up to 1500°C provides critical data on coating hardness and elastic modulus degradation. Similarly, high-temperature adhesion testing using modified tensile or shear configurations reveals interfacial strength evolution during thermal exposure.

Non-destructive evaluation techniques have advanced significantly, with thermal imaging and photoluminescence piezospectroscopy now capable of in-situ stress measurement during thermal cycling. These methodologies enable early detection of coating failure precursors before catastrophic delamination occurs.

Standardization efforts through organizations like ASTM International and ISO have improved test reproducibility, though significant variations in methodology still exist between research institutions and engine manufacturers. The development of unified testing protocols represents a critical need for accelerating next-generation TBC qualification and implementation in advanced engine designs.

Furnace cycling tests represent the foundation of TBC evaluation, subjecting specimens to rapid temperature fluctuations between ambient and operating temperatures (typically 1100-1400°C). These tests reveal coating durability through repeated thermal expansion and contraction cycles, with failure mechanisms carefully documented through microscopic analysis after predetermined cycle intervals.

Burner rig testing provides a more engine-representative environment by exposing coatings to high-velocity combustion gases. This methodology evaluates erosion resistance, thermal shock behavior, and hot corrosion susceptibility simultaneously. Advanced burner rigs incorporate controlled introduction of contaminants such as CMAS (calcium-magnesium-alumino-silicates) to simulate volcanic ash or desert sand ingestion scenarios that increasingly challenge modern engines.

Laser thermal gradient testing has emerged as a cutting-edge methodology for precise thermal gradient evaluation across coating systems. By applying concentrated laser energy to the coating surface while actively cooling the substrate, researchers can establish temperature differentials exceeding 300°C across coating thicknesses of less than 500 micrometers. This approach enables real-time monitoring of coating response to thermal gradients similar to those experienced in service.

Mechanical property characterization at elevated temperatures presents unique challenges requiring specialized equipment. Instrumented indentation testing performed at temperatures up to 1500°C provides critical data on coating hardness and elastic modulus degradation. Similarly, high-temperature adhesion testing using modified tensile or shear configurations reveals interfacial strength evolution during thermal exposure.

Non-destructive evaluation techniques have advanced significantly, with thermal imaging and photoluminescence piezospectroscopy now capable of in-situ stress measurement during thermal cycling. These methodologies enable early detection of coating failure precursors before catastrophic delamination occurs.

Standardization efforts through organizations like ASTM International and ISO have improved test reproducibility, though significant variations in methodology still exist between research institutions and engine manufacturers. The development of unified testing protocols represents a critical need for accelerating next-generation TBC qualification and implementation in advanced engine designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!