Thermal barrier coatings ceramics under corrosive environmental exposure

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Barrier Coatings Background and Objectives

Thermal barrier coatings (TBCs) have emerged as a critical technology in high-temperature applications, particularly in aerospace, power generation, and automotive industries. These specialized ceramic coatings were first developed in the 1970s to protect metal components from extreme thermal conditions, extending their operational lifespan and enhancing performance efficiency. The evolution of TBCs has been marked by continuous improvements in material composition, deposition techniques, and structural design to meet increasingly demanding operational requirements.

The primary function of TBCs is to create a thermal gradient between the hot gas environment and the underlying metal substrate, effectively reducing the temperature experienced by the metal component. This thermal insulation capability has become increasingly important as operating temperatures in modern gas turbines and engines continue to rise in pursuit of greater efficiency and performance. Traditional TBC systems typically consist of a ceramic top coat, usually yttria-stabilized zirconia (YSZ), and a metallic bond coat that provides oxidation resistance and improves adhesion.

Recent technological advancements have focused on enhancing the durability and reliability of TBCs under complex operational conditions, particularly in corrosive environments. The presence of contaminants such as sulfates, chlorides, and vanadium compounds can significantly accelerate the degradation of conventional TBC systems through mechanisms like hot corrosion, chemical reactions, and phase destabilization. This has necessitated the development of more resistant ceramic compositions and protective strategies.

The global research landscape has witnessed a shift toward multi-functional TBC systems that can simultaneously provide thermal insulation, corrosion resistance, and mechanical stability. Novel ceramic materials including rare-earth zirconates, hafnates, and complex perovskites have demonstrated promising properties for next-generation TBCs. Additionally, the incorporation of nanostructured features and compositional gradients has emerged as an effective approach to enhance coating performance under corrosive conditions.

The objectives of current research on TBCs under corrosive environmental exposure are multifaceted. First, to develop fundamental understanding of degradation mechanisms in corrosive environments at the microstructural and atomic levels. Second, to design and synthesize novel ceramic compositions with inherent resistance to various corrosive species. Third, to establish predictive models for lifetime assessment under combined thermal cycling and corrosive attack. Fourth, to develop innovative processing techniques that can produce TBCs with optimized microstructures and enhanced durability. Finally, to validate the performance of advanced TBC systems under realistic service conditions that simulate the complex interplay of thermal, mechanical, and chemical stresses.

The primary function of TBCs is to create a thermal gradient between the hot gas environment and the underlying metal substrate, effectively reducing the temperature experienced by the metal component. This thermal insulation capability has become increasingly important as operating temperatures in modern gas turbines and engines continue to rise in pursuit of greater efficiency and performance. Traditional TBC systems typically consist of a ceramic top coat, usually yttria-stabilized zirconia (YSZ), and a metallic bond coat that provides oxidation resistance and improves adhesion.

Recent technological advancements have focused on enhancing the durability and reliability of TBCs under complex operational conditions, particularly in corrosive environments. The presence of contaminants such as sulfates, chlorides, and vanadium compounds can significantly accelerate the degradation of conventional TBC systems through mechanisms like hot corrosion, chemical reactions, and phase destabilization. This has necessitated the development of more resistant ceramic compositions and protective strategies.

The global research landscape has witnessed a shift toward multi-functional TBC systems that can simultaneously provide thermal insulation, corrosion resistance, and mechanical stability. Novel ceramic materials including rare-earth zirconates, hafnates, and complex perovskites have demonstrated promising properties for next-generation TBCs. Additionally, the incorporation of nanostructured features and compositional gradients has emerged as an effective approach to enhance coating performance under corrosive conditions.

The objectives of current research on TBCs under corrosive environmental exposure are multifaceted. First, to develop fundamental understanding of degradation mechanisms in corrosive environments at the microstructural and atomic levels. Second, to design and synthesize novel ceramic compositions with inherent resistance to various corrosive species. Third, to establish predictive models for lifetime assessment under combined thermal cycling and corrosive attack. Fourth, to develop innovative processing techniques that can produce TBCs with optimized microstructures and enhanced durability. Finally, to validate the performance of advanced TBC systems under realistic service conditions that simulate the complex interplay of thermal, mechanical, and chemical stresses.

Market Analysis for Corrosion-Resistant TBC Applications

The global market for thermal barrier coatings (TBCs) with enhanced corrosion resistance capabilities is experiencing robust growth, driven primarily by increasing demands in aerospace, power generation, and automotive industries. Current market valuation stands at approximately 11.2 billion USD, with projections indicating a compound annual growth rate of 6.8% through 2028, significantly outpacing traditional coating technologies.

Aerospace remains the dominant application sector, accounting for nearly 42% of the total market share. This dominance stems from the critical need for high-performance TBCs in aircraft engines operating in diverse and often corrosive environments, including marine air exposure and volcanic ash encounters. The commercial aviation segment shows particularly strong demand growth as fleet modernization efforts accelerate globally.

Power generation represents the second-largest market segment at 31%, with particular emphasis on gas turbines for electricity production. The transition toward cleaner energy has paradoxically increased the corrosion challenges in many power systems, as alternative fuels often introduce new corrosive elements into combustion environments. This has created substantial market opportunities for advanced corrosion-resistant TBCs.

Regionally, North America and Europe currently dominate the market with a combined share of 58%, largely due to their established aerospace and power generation industries. However, the Asia-Pacific region is demonstrating the fastest growth rate at 8.7% annually, driven by rapid industrialization in China and India, alongside expanding aerospace manufacturing capabilities.

Customer requirements are evolving toward multi-functional TBCs that simultaneously provide thermal insulation, corrosion resistance, and mechanical durability. This trend is reshaping the competitive landscape, favoring suppliers with advanced R&D capabilities and comprehensive testing facilities. Market research indicates that customers are increasingly willing to pay premium prices for coatings with demonstrated long-term performance in corrosive environments.

The market exhibits a notable price sensitivity differential across sectors. While aerospace customers prioritize performance over cost considerations, industrial applications demonstrate higher price elasticity, creating distinct market segments with different value propositions. This bifurcation has strategic implications for product development and marketing approaches.

Supply chain considerations have gained prominence following recent global disruptions, with manufacturers increasingly focused on securing reliable sources of rare earth elements and other critical materials used in advanced ceramic formulations. This has accelerated interest in alternative material systems that maintain performance while reducing dependency on supply-constrained elements.

Aerospace remains the dominant application sector, accounting for nearly 42% of the total market share. This dominance stems from the critical need for high-performance TBCs in aircraft engines operating in diverse and often corrosive environments, including marine air exposure and volcanic ash encounters. The commercial aviation segment shows particularly strong demand growth as fleet modernization efforts accelerate globally.

Power generation represents the second-largest market segment at 31%, with particular emphasis on gas turbines for electricity production. The transition toward cleaner energy has paradoxically increased the corrosion challenges in many power systems, as alternative fuels often introduce new corrosive elements into combustion environments. This has created substantial market opportunities for advanced corrosion-resistant TBCs.

Regionally, North America and Europe currently dominate the market with a combined share of 58%, largely due to their established aerospace and power generation industries. However, the Asia-Pacific region is demonstrating the fastest growth rate at 8.7% annually, driven by rapid industrialization in China and India, alongside expanding aerospace manufacturing capabilities.

Customer requirements are evolving toward multi-functional TBCs that simultaneously provide thermal insulation, corrosion resistance, and mechanical durability. This trend is reshaping the competitive landscape, favoring suppliers with advanced R&D capabilities and comprehensive testing facilities. Market research indicates that customers are increasingly willing to pay premium prices for coatings with demonstrated long-term performance in corrosive environments.

The market exhibits a notable price sensitivity differential across sectors. While aerospace customers prioritize performance over cost considerations, industrial applications demonstrate higher price elasticity, creating distinct market segments with different value propositions. This bifurcation has strategic implications for product development and marketing approaches.

Supply chain considerations have gained prominence following recent global disruptions, with manufacturers increasingly focused on securing reliable sources of rare earth elements and other critical materials used in advanced ceramic formulations. This has accelerated interest in alternative material systems that maintain performance while reducing dependency on supply-constrained elements.

Current Challenges in TBC Performance Under Corrosive Environments

Thermal Barrier Coatings (TBCs) face significant performance challenges when exposed to corrosive environments, particularly in advanced gas turbine applications. The conventional YSZ (Yttria-Stabilized Zirconia) systems, while effective at thermal insulation, demonstrate limited resistance to chemical degradation when subjected to contaminants such as calcium-magnesium-alumino-silicates (CMAS), volcanic ash, and various fuel impurities.

A primary challenge is the accelerated degradation of the ceramic top coat through hot corrosion mechanisms. When molten salts and CMAS infiltrate the porous microstructure of TBCs, they cause dissolution of the ceramic material and subsequent reprecipitation upon cooling, leading to structural destabilization. This phenomenon is particularly problematic in the temperature range of 900-1200°C, where many modern turbines operate.

The thermochemical compatibility between the ceramic top coat and the thermally grown oxide (TGO) layer becomes compromised under corrosive conditions. Studies have shown that sulfur-containing species can accelerate the growth rate of the TGO layer, leading to premature spallation failure. This interfacial degradation mechanism remains difficult to predict and mitigate in real-world operating conditions.

Another significant challenge is the sintering behavior of ceramic coatings under combined thermal cycling and corrosive attack. The presence of corrosive species often lowers the sintering temperature of the ceramic material, resulting in accelerated densification, reduced strain tolerance, and diminished thermal insulation properties. This effect is particularly pronounced in newer TBC compositions designed for higher temperature capabilities.

The interdependent failure modes triggered by corrosive environments create complex degradation pathways that are not adequately addressed by current testing protocols. Standard laboratory evaluations often fail to replicate the synergistic effects of thermal cycling, mechanical loading, and chemical attack that occur simultaneously in service conditions.

From a manufacturing perspective, developing TBC systems with enhanced corrosion resistance while maintaining thermal protection and mechanical durability presents significant technical hurdles. Attempts to modify coating composition or architecture to improve corrosion resistance often compromise other critical properties such as thermal expansion match, phase stability, or erosion resistance.

The lack of standardized accelerated testing methodologies that accurately predict long-term performance under corrosive conditions remains a major obstacle for the industry. Current qualification procedures typically require thousands of hours of testing, which significantly delays the implementation of new, potentially more resistant coating systems.

A primary challenge is the accelerated degradation of the ceramic top coat through hot corrosion mechanisms. When molten salts and CMAS infiltrate the porous microstructure of TBCs, they cause dissolution of the ceramic material and subsequent reprecipitation upon cooling, leading to structural destabilization. This phenomenon is particularly problematic in the temperature range of 900-1200°C, where many modern turbines operate.

The thermochemical compatibility between the ceramic top coat and the thermally grown oxide (TGO) layer becomes compromised under corrosive conditions. Studies have shown that sulfur-containing species can accelerate the growth rate of the TGO layer, leading to premature spallation failure. This interfacial degradation mechanism remains difficult to predict and mitigate in real-world operating conditions.

Another significant challenge is the sintering behavior of ceramic coatings under combined thermal cycling and corrosive attack. The presence of corrosive species often lowers the sintering temperature of the ceramic material, resulting in accelerated densification, reduced strain tolerance, and diminished thermal insulation properties. This effect is particularly pronounced in newer TBC compositions designed for higher temperature capabilities.

The interdependent failure modes triggered by corrosive environments create complex degradation pathways that are not adequately addressed by current testing protocols. Standard laboratory evaluations often fail to replicate the synergistic effects of thermal cycling, mechanical loading, and chemical attack that occur simultaneously in service conditions.

From a manufacturing perspective, developing TBC systems with enhanced corrosion resistance while maintaining thermal protection and mechanical durability presents significant technical hurdles. Attempts to modify coating composition or architecture to improve corrosion resistance often compromise other critical properties such as thermal expansion match, phase stability, or erosion resistance.

The lack of standardized accelerated testing methodologies that accurately predict long-term performance under corrosive conditions remains a major obstacle for the industry. Current qualification procedures typically require thousands of hours of testing, which significantly delays the implementation of new, potentially more resistant coating systems.

Existing TBC Solutions for Corrosive Environment Protection

01 Yttria-stabilized zirconia (YSZ) based thermal barrier coatings

Yttria-stabilized zirconia (YSZ) is widely used as a thermal barrier coating material due to its excellent thermal insulation properties and high-temperature stability. These coatings can be enhanced with additional elements or compounds to improve their corrosion resistance, particularly against molten salts and oxidizing environments. The microstructure of YSZ coatings can be optimized to reduce thermal conductivity while maintaining mechanical integrity at high temperatures.- Yttria-stabilized zirconia (YSZ) based thermal barrier coatings: Yttria-stabilized zirconia (YSZ) is widely used as a thermal barrier coating material due to its excellent thermal insulation properties and phase stability at high temperatures. These coatings provide effective thermal protection for metal components in high-temperature environments. The addition of yttria to zirconia stabilizes the crystal structure, preventing phase transformations that could lead to coating failure. YSZ-based thermal barrier coatings can be further enhanced with additional elements or layers to improve corrosion resistance and durability.

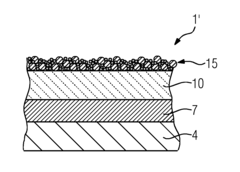

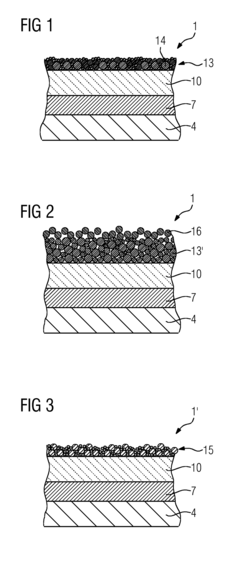

- Multi-layer ceramic coating systems for enhanced corrosion resistance: Multi-layer ceramic coating systems combine different materials to provide both thermal insulation and corrosion resistance. These systems typically include a bond coat, a thermally grown oxide layer, and a ceramic top coat. The bond coat provides adhesion and oxidation resistance, while the ceramic top coat provides thermal insulation. Intermediate layers can be added to enhance corrosion resistance against various environmental contaminants. The multi-layer approach allows for customization of the coating system to meet specific environmental challenges while maintaining thermal barrier properties.

- Rare earth element doped ceramic coatings: Incorporating rare earth elements into ceramic thermal barrier coatings significantly enhances their corrosion resistance and durability. Elements such as lanthanum, cerium, gadolinium, and ytterbium can be used as dopants to improve the coating's resistance to molten salt attack, sulfidation, and other forms of high-temperature corrosion. These rare earth elements can stabilize the coating microstructure, reduce oxygen diffusion, and form protective oxide scales that prevent further corrosion. The improved corrosion resistance extends the service life of components in harsh operating environments.

- Novel deposition techniques for enhanced coating properties: Advanced deposition techniques such as electron beam physical vapor deposition (EB-PVD), suspension plasma spraying, and solution precursor plasma spraying are used to create ceramic thermal barrier coatings with superior properties. These techniques allow for precise control over the coating microstructure, including porosity, columnar structure, and grain size, which directly affects thermal conductivity and strain tolerance. Specialized deposition methods can create segmented or columnar structures that accommodate thermal expansion mismatch between the coating and substrate, improving durability while maintaining excellent thermal insulation and corrosion resistance properties.

- Environmental barrier coatings for ceramic matrix composites: Environmental barrier coatings (EBCs) are specifically designed to protect ceramic matrix composites (CMCs) from high-temperature oxidation and corrosion. These specialized coatings typically consist of rare-earth silicates, mullite, or other silica-forming compounds that provide protection against water vapor and other corrosive species present in combustion environments. EBCs prevent the degradation of the underlying CMC substrate by forming stable, protective oxide scales and limiting the diffusion of harmful species. The integration of EBCs with thermal barrier coatings creates comprehensive protection systems that offer both thermal insulation and corrosion resistance for advanced high-temperature applications.

02 Multi-layer ceramic coating systems

Multi-layer ceramic coating systems consist of different functional layers that work together to provide enhanced thermal protection and corrosion resistance. These systems typically include a bond coat, a thermally grown oxide layer, and a ceramic top coat. The bond coat provides adhesion and oxidation resistance, while the ceramic top coat provides thermal insulation. The interfaces between these layers are critical for the overall performance and durability of the coating system.Expand Specific Solutions03 Rare earth element doped ceramic coatings

Incorporating rare earth elements into ceramic thermal barrier coatings can significantly improve their corrosion resistance and thermal stability. Elements such as lanthanum, cerium, gadolinium, and ytterbium can be used as dopants to enhance the performance of traditional ceramic coatings. These elements can stabilize the crystal structure, reduce sintering rates, and improve resistance to molten salt attack, making the coatings more durable in harsh operating environments.Expand Specific Solutions04 Novel ceramic compositions for enhanced corrosion resistance

Advanced ceramic compositions have been developed specifically to enhance corrosion resistance in thermal barrier coatings. These include pyrochlore structures, hexaaluminates, perovskites, and other complex oxides that offer superior resistance to molten salt attack and high-temperature oxidation. These novel compositions often feature tailored microstructures and phase compositions that maintain stability under thermal cycling and corrosive environments, extending the service life of components in extreme conditions.Expand Specific Solutions05 Deposition techniques for optimized ceramic coating properties

Various deposition techniques can be employed to optimize the properties of ceramic thermal barrier coatings. These include atmospheric plasma spraying, electron beam physical vapor deposition, solution precursor plasma spray, and suspension plasma spray. The choice of deposition method significantly affects the microstructure, porosity, and adhesion of the coating, which in turn influences its thermal insulation properties and corrosion resistance. Post-deposition treatments can further enhance the coating performance by sealing porosity or modifying the surface chemistry.Expand Specific Solutions

Leading Organizations in TBC Research and Development

The thermal barrier coatings (TBC) ceramics market under corrosive environmental exposure is currently in a growth phase, with increasing demand driven by aerospace, power generation, and industrial applications. The global market size is estimated to exceed $1.5 billion, expanding at approximately 6-7% CAGR. Leading players demonstrate varying levels of technical maturity: established aerospace and energy corporations like General Electric, Rolls-Royce, Siemens Energy, and Mitsubishi Heavy Industries possess advanced TBC technologies with proven field performance, while academic institutions such as Beihang University and Xi'an Jiaotong University are advancing fundamental research. Specialized companies like Praxair S.T. Technology and Directed Vapor Technologies focus on innovative deposition techniques, creating a competitive landscape balanced between industrial giants and specialized technology providers.

General Electric Company

Technical Solution: GE has developed advanced thermal barrier coating (TBC) systems specifically designed to withstand corrosive environments in gas turbine applications. Their technology employs a multi-layered approach with yttria-stabilized zirconia (YSZ) top coats modified with rare earth elements to enhance phase stability and corrosion resistance. GE's research has focused on addressing calcium-magnesium-alumino-silicate (CMAS) infiltration issues through the development of gadolinium zirconate-based coatings that form apatite phases upon reaction with molten CMAS, effectively arresting further infiltration[1]. Their proprietary electron beam physical vapor deposition (EB-PVD) process creates columnar microstructures that enhance strain tolerance while maintaining thermal insulation properties. GE has also pioneered the use of aluminum-platinum diffusion bond coats with controlled oxide growth to improve adhesion and durability under thermal cycling in corrosive environments[2].

Strengths: Industry-leading manufacturing capabilities for complex TBC systems; extensive field testing data from power generation and aviation applications; proprietary composition formulations with enhanced CMAS resistance. Weaknesses: Higher production costs compared to conventional coating technologies; requires specialized equipment for application; some solutions may be limited to specific operating temperature ranges.

Praxair S.T. Technology, Inc.

Technical Solution: Praxair S.T. Technology has developed advanced thermal barrier coating systems specifically engineered to withstand corrosive environmental exposure in high-temperature applications. Their technology centers on solution precursor plasma spray (SPPS) processes that create unique microstructures with segmented vertical cracks and controlled porosity distribution, enhancing both strain tolerance and corrosion resistance[5]. Praxair's coatings incorporate rare-earth zirconates and hafnates with tailored compositions that form protective reaction products when exposed to molten salts and CMAS (calcium-magnesium-alumino-silicate) deposits. Their research has demonstrated that these specialized ceramic formulations can effectively mitigate hot corrosion through the formation of stable apatite phases that prevent further infiltration. Praxair has also pioneered the development of composite TBC systems that combine the benefits of conventional yttria-stabilized zirconia with more corrosion-resistant ceramics in layered or graded structures, optimizing both thermal insulation and environmental protection properties[6]. Their manufacturing processes include proprietary powder preparation techniques that ensure consistent particle morphology and chemistry, critical for coating performance in aggressive environments.

Strengths: Industry-leading thermal spray technology and equipment; extensive materials science expertise in ceramic formulations; ability to tailor coating solutions for specific corrosive environments. Weaknesses: Some advanced coating solutions may have higher application costs; certain specialized compositions may have limited commercial deployment history; potential challenges in scaling production for some newer material systems.

Critical Patents and Innovations in Corrosion-Resistant Ceramics

Method for producing a corrosion protection layer for thermal insulation layers made of hollow aluminum oxide balls and glass layer as outer layer and component

PatentInactiveUS20180066367A1

Innovation

- A layer system comprising aluminum particles applied via slip, combined with a low-melting glass layer containing SiO2 and elements like magnesium, calcium, or boron, which forms a corrosion protection layer with aluminum oxide spheres and optional glass, preventing CMAS intrusion and nickel deposits through heat treatment.

Thermal barrier coating, thermal barrier member, and steam device

PatentInactiveJP2016222992A

Innovation

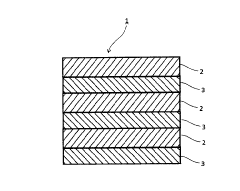

- A thermal barrier coating composed of alternately laminated ceramic and metal layers, with specific material compositions and interface properties to enhance thermal resistance, reduce thermal stress, and prevent peeling.

Environmental Impact Assessment of TBC Materials

The environmental impact of Thermal Barrier Coating (TBC) materials extends beyond their primary function of thermal protection, encompassing their entire lifecycle from raw material extraction to disposal. Traditional TBC systems often contain materials like yttria-stabilized zirconia (YSZ) and nickel-based alloys, which require energy-intensive mining and processing operations. These activities contribute significantly to carbon emissions and landscape disruption in mining regions, raising concerns about the ecological footprint of TBC production.

During application processes, particularly plasma spraying and electron beam physical vapor deposition, substantial energy consumption occurs alongside the potential release of fine particulate matter. These particles may contain heavy metals and ceramic compounds that pose respiratory hazards to workers and nearby communities if not properly controlled through advanced filtration systems and workplace safety protocols.

The operational phase of TBCs presents a more positive environmental profile, as these coatings enable higher operating temperatures in turbines and engines, thereby increasing thermodynamic efficiency and reducing fuel consumption. Studies indicate that advanced TBC systems can improve engine efficiency by 1-2%, translating to substantial reductions in greenhouse gas emissions over the operational lifetime of aerospace and power generation equipment.

End-of-life considerations for TBC materials reveal additional environmental challenges. The complex multi-layer structure of TBCs, often incorporating rare earth elements and transition metals, complicates recycling efforts. Current disposal practices frequently result in these materials entering landfills, where potential leaching of metals into groundwater presents long-term environmental risks that remain inadequately studied.

Recent research has focused on developing more environmentally benign TBC alternatives, including rare-earth-free compositions and bio-inspired ceramic structures with reduced environmental impact. Additionally, advancements in manufacturing technologies are enabling more material-efficient deposition processes that minimize waste generation and energy consumption.

Life cycle assessment (LCA) studies comparing traditional YSZ coatings with newer environmental-friendly alternatives demonstrate that while production impacts may be similar, the enhanced durability and efficiency gains of advanced TBCs can offset initial environmental costs through extended service life and improved system performance. However, comprehensive cradle-to-grave assessments remain limited, highlighting a critical research gap in understanding the full environmental implications of TBC materials under various operational conditions and corrosive environments.

During application processes, particularly plasma spraying and electron beam physical vapor deposition, substantial energy consumption occurs alongside the potential release of fine particulate matter. These particles may contain heavy metals and ceramic compounds that pose respiratory hazards to workers and nearby communities if not properly controlled through advanced filtration systems and workplace safety protocols.

The operational phase of TBCs presents a more positive environmental profile, as these coatings enable higher operating temperatures in turbines and engines, thereby increasing thermodynamic efficiency and reducing fuel consumption. Studies indicate that advanced TBC systems can improve engine efficiency by 1-2%, translating to substantial reductions in greenhouse gas emissions over the operational lifetime of aerospace and power generation equipment.

End-of-life considerations for TBC materials reveal additional environmental challenges. The complex multi-layer structure of TBCs, often incorporating rare earth elements and transition metals, complicates recycling efforts. Current disposal practices frequently result in these materials entering landfills, where potential leaching of metals into groundwater presents long-term environmental risks that remain inadequately studied.

Recent research has focused on developing more environmentally benign TBC alternatives, including rare-earth-free compositions and bio-inspired ceramic structures with reduced environmental impact. Additionally, advancements in manufacturing technologies are enabling more material-efficient deposition processes that minimize waste generation and energy consumption.

Life cycle assessment (LCA) studies comparing traditional YSZ coatings with newer environmental-friendly alternatives demonstrate that while production impacts may be similar, the enhanced durability and efficiency gains of advanced TBCs can offset initial environmental costs through extended service life and improved system performance. However, comprehensive cradle-to-grave assessments remain limited, highlighting a critical research gap in understanding the full environmental implications of TBC materials under various operational conditions and corrosive environments.

Lifecycle Analysis and Sustainability Considerations

Thermal barrier coating (TBC) systems represent a critical technology in high-temperature applications, particularly in aerospace and power generation industries. When examining these systems through a lifecycle analysis framework, several key environmental and sustainability considerations emerge that warrant careful attention from both researchers and industry stakeholders.

The production phase of thermal barrier coatings involves energy-intensive processes including plasma spraying, electron beam physical vapor deposition, and various surface preparation techniques. These manufacturing methods typically consume significant energy and may utilize rare earth elements such as yttrium and zirconium, raising concerns about resource depletion and supply chain vulnerabilities. Recent studies indicate that the embodied energy in advanced TBC systems can be reduced by up to 30% through process optimization and material substitution strategies.

During the operational phase, TBCs deliver substantial sustainability benefits by improving energy efficiency in turbine systems. By enabling higher operating temperatures while protecting underlying components, these coatings can increase thermal efficiency by 1-2 percentage points in modern gas turbines, translating to significant fuel savings and reduced carbon emissions over the service life of the equipment. This operational benefit often outweighs the environmental impact of their production.

The degradation of TBCs under corrosive environmental exposure presents particular challenges for lifecycle assessment. Salt, sulfur, and vanadium contaminants accelerate coating deterioration, potentially shortening component lifespans and necessitating more frequent replacement. Research indicates that advanced ceramic compositions with improved corrosion resistance could extend service intervals by 20-40%, significantly reducing waste generation and resource consumption associated with component replacement.

End-of-life considerations for TBC systems remain underdeveloped in current research. The complex multi-layer structures and contamination from service environments complicate recycling efforts. Innovative approaches to selective recovery of valuable elements from spent coatings are emerging, though commercial-scale implementation remains limited. Circular economy principles suggest potential pathways for recovering zirconia and other valuable materials from decommissioned components.

Comprehensive lifecycle assessment methodologies specific to high-temperature coating systems are still evolving. Current models often fail to adequately account for the unique operational benefits and failure mechanisms of TBCs in corrosive environments. Standardized metrics that balance production impacts against operational efficiency gains would provide valuable decision support tools for technology developers and end users seeking to optimize environmental performance across the entire product lifecycle.

The production phase of thermal barrier coatings involves energy-intensive processes including plasma spraying, electron beam physical vapor deposition, and various surface preparation techniques. These manufacturing methods typically consume significant energy and may utilize rare earth elements such as yttrium and zirconium, raising concerns about resource depletion and supply chain vulnerabilities. Recent studies indicate that the embodied energy in advanced TBC systems can be reduced by up to 30% through process optimization and material substitution strategies.

During the operational phase, TBCs deliver substantial sustainability benefits by improving energy efficiency in turbine systems. By enabling higher operating temperatures while protecting underlying components, these coatings can increase thermal efficiency by 1-2 percentage points in modern gas turbines, translating to significant fuel savings and reduced carbon emissions over the service life of the equipment. This operational benefit often outweighs the environmental impact of their production.

The degradation of TBCs under corrosive environmental exposure presents particular challenges for lifecycle assessment. Salt, sulfur, and vanadium contaminants accelerate coating deterioration, potentially shortening component lifespans and necessitating more frequent replacement. Research indicates that advanced ceramic compositions with improved corrosion resistance could extend service intervals by 20-40%, significantly reducing waste generation and resource consumption associated with component replacement.

End-of-life considerations for TBC systems remain underdeveloped in current research. The complex multi-layer structures and contamination from service environments complicate recycling efforts. Innovative approaches to selective recovery of valuable elements from spent coatings are emerging, though commercial-scale implementation remains limited. Circular economy principles suggest potential pathways for recovering zirconia and other valuable materials from decommissioned components.

Comprehensive lifecycle assessment methodologies specific to high-temperature coating systems are still evolving. Current models often fail to adequately account for the unique operational benefits and failure mechanisms of TBCs in corrosive environments. Standardized metrics that balance production impacts against operational efficiency gains would provide valuable decision support tools for technology developers and end users seeking to optimize environmental performance across the entire product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!