What role does porosity play in thermal barrier coatings ceramics performance

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Porosity in TBC Ceramics: Background and Objectives

Thermal Barrier Coatings (TBCs) have emerged as critical components in high-temperature applications, particularly in gas turbine engines for aerospace and power generation industries. These specialized ceramic coatings provide thermal insulation to metallic components operating in extreme temperature environments, extending component life and enabling higher operating temperatures for improved efficiency. The evolution of TBC technology spans over five decades, with significant advancements in materials science, deposition techniques, and performance optimization.

Porosity represents one of the most influential microstructural features in TBC ceramics, fundamentally affecting their thermal and mechanical properties. Historically, early TBC systems utilized dense ceramic structures, but research gradually revealed that controlled porosity could dramatically enhance thermal insulation capabilities. This recognition has driven a systematic exploration of porosity engineering in TBC development since the 1980s, with accelerated research in the past two decades.

The technological trajectory of TBC development shows a clear trend toward sophisticated porosity control at multiple scales. From macro-porosity visible to the naked eye to nano-scale pores requiring advanced microscopy, researchers have progressively refined their understanding of how different pore morphologies, distributions, and interconnectivity affect coating performance. This evolution has been enabled by advances in manufacturing processes, particularly air plasma spray (APS) and electron beam physical vapor deposition (EB-PVD), which offer distinct approaches to porosity creation.

The primary technical objective in porosity engineering for TBCs is to achieve an optimal balance between thermal insulation and mechanical durability. Lower thermal conductivity through increased porosity must be balanced against potential reductions in erosion resistance, bond strength, and overall coating integrity. This delicate balance represents the central challenge in TBC development and drives ongoing research efforts worldwide.

Current research aims to develop next-generation TBCs with tailored porosity architectures that can withstand increasingly demanding operating conditions. Specific technical goals include achieving thermal conductivity below 1 W/m·K while maintaining adequate mechanical properties, extending coating lifespans beyond 30,000 hours of operation, and developing systems capable of withstanding temperatures exceeding 1300°C for advanced engine designs.

The field is now moving toward biomimetic approaches, drawing inspiration from natural thermal insulation systems, and exploring hierarchical porosity structures that combine benefits at multiple length scales. These innovations represent promising pathways for overcoming the traditional trade-offs between thermal and mechanical properties in TBC systems.

Porosity represents one of the most influential microstructural features in TBC ceramics, fundamentally affecting their thermal and mechanical properties. Historically, early TBC systems utilized dense ceramic structures, but research gradually revealed that controlled porosity could dramatically enhance thermal insulation capabilities. This recognition has driven a systematic exploration of porosity engineering in TBC development since the 1980s, with accelerated research in the past two decades.

The technological trajectory of TBC development shows a clear trend toward sophisticated porosity control at multiple scales. From macro-porosity visible to the naked eye to nano-scale pores requiring advanced microscopy, researchers have progressively refined their understanding of how different pore morphologies, distributions, and interconnectivity affect coating performance. This evolution has been enabled by advances in manufacturing processes, particularly air plasma spray (APS) and electron beam physical vapor deposition (EB-PVD), which offer distinct approaches to porosity creation.

The primary technical objective in porosity engineering for TBCs is to achieve an optimal balance between thermal insulation and mechanical durability. Lower thermal conductivity through increased porosity must be balanced against potential reductions in erosion resistance, bond strength, and overall coating integrity. This delicate balance represents the central challenge in TBC development and drives ongoing research efforts worldwide.

Current research aims to develop next-generation TBCs with tailored porosity architectures that can withstand increasingly demanding operating conditions. Specific technical goals include achieving thermal conductivity below 1 W/m·K while maintaining adequate mechanical properties, extending coating lifespans beyond 30,000 hours of operation, and developing systems capable of withstanding temperatures exceeding 1300°C for advanced engine designs.

The field is now moving toward biomimetic approaches, drawing inspiration from natural thermal insulation systems, and exploring hierarchical porosity structures that combine benefits at multiple length scales. These innovations represent promising pathways for overcoming the traditional trade-offs between thermal and mechanical properties in TBC systems.

Market Analysis of Porous TBC Systems

The global market for Thermal Barrier Coatings (TBCs) with controlled porosity has been experiencing significant growth, driven by increasing demands in aerospace, power generation, and automotive industries. Currently valued at approximately $2.3 billion, the porous TBC market segment is projected to grow at a compound annual growth rate of 6.8% through 2028, outpacing the broader thermal coating market's growth rate of 4.5%.

Aerospace remains the dominant application sector, accounting for nearly 42% of the total market share. This dominance stems from the critical need for high-performance thermal protection in aircraft and spacecraft engines operating under extreme temperature conditions. The power generation sector follows closely at 31% market share, with particular growth observed in gas turbine applications where efficiency improvements directly correlate with operating temperature capabilities.

Regional analysis reveals North America and Europe as market leaders, collectively representing 58% of global consumption. However, the Asia-Pacific region, particularly China and India, demonstrates the fastest growth trajectory with annual expansion rates exceeding 9%. This growth is primarily attributed to rapid industrialization, increasing energy demands, and expanding aerospace manufacturing capabilities in these regions.

Market segmentation by porosity characteristics shows that controlled microporosity systems (pore sizes 1-10 μm) command premium pricing, with an average 30% price premium over conventional TBCs. This premium reflects the enhanced performance characteristics, including superior strain tolerance and reduced thermal conductivity, which directly translate to extended component lifespans and improved system efficiency.

Customer demand analysis indicates a clear shift toward customized porosity profiles tailored to specific application requirements. End-users increasingly prioritize total lifecycle cost benefits over initial acquisition costs, recognizing that optimized porosity structures can extend maintenance intervals by up to 40% compared to traditional coatings.

Competitive landscape assessment identifies three distinct market tiers: global industrial conglomerates offering standardized solutions (42% market share), specialized coating technology providers focusing on high-performance applications (35% market share), and emerging technology startups developing next-generation porous ceramic formulations (23% market share). Market concentration remains moderate with the top five suppliers controlling approximately 48% of global market volume.

Future market growth will likely be driven by innovations in porosity control technologies, particularly those enabling gradient and zonal porosity distributions that can be tailored to specific thermal and mechanical stress profiles within components.

Aerospace remains the dominant application sector, accounting for nearly 42% of the total market share. This dominance stems from the critical need for high-performance thermal protection in aircraft and spacecraft engines operating under extreme temperature conditions. The power generation sector follows closely at 31% market share, with particular growth observed in gas turbine applications where efficiency improvements directly correlate with operating temperature capabilities.

Regional analysis reveals North America and Europe as market leaders, collectively representing 58% of global consumption. However, the Asia-Pacific region, particularly China and India, demonstrates the fastest growth trajectory with annual expansion rates exceeding 9%. This growth is primarily attributed to rapid industrialization, increasing energy demands, and expanding aerospace manufacturing capabilities in these regions.

Market segmentation by porosity characteristics shows that controlled microporosity systems (pore sizes 1-10 μm) command premium pricing, with an average 30% price premium over conventional TBCs. This premium reflects the enhanced performance characteristics, including superior strain tolerance and reduced thermal conductivity, which directly translate to extended component lifespans and improved system efficiency.

Customer demand analysis indicates a clear shift toward customized porosity profiles tailored to specific application requirements. End-users increasingly prioritize total lifecycle cost benefits over initial acquisition costs, recognizing that optimized porosity structures can extend maintenance intervals by up to 40% compared to traditional coatings.

Competitive landscape assessment identifies three distinct market tiers: global industrial conglomerates offering standardized solutions (42% market share), specialized coating technology providers focusing on high-performance applications (35% market share), and emerging technology startups developing next-generation porous ceramic formulations (23% market share). Market concentration remains moderate with the top five suppliers controlling approximately 48% of global market volume.

Future market growth will likely be driven by innovations in porosity control technologies, particularly those enabling gradient and zonal porosity distributions that can be tailored to specific thermal and mechanical stress profiles within components.

Current Porosity Control Challenges in TBC Development

Despite significant advancements in thermal barrier coating (TBC) technology, controlling porosity remains one of the most challenging aspects in TBC development. Current manufacturing processes struggle to achieve precise and reproducible porosity distributions within ceramic coatings. Atmospheric plasma spraying (APS) and electron beam physical vapor deposition (EB-PVD), the two predominant deposition techniques, each present unique challenges in porosity control.

APS processes inherently create splat-based microstructures with inter-splat porosity, but achieving consistent pore size distribution and spatial arrangement remains difficult. Process parameters such as plasma power, spray distance, powder feed rate, and carrier gas flow significantly influence porosity outcomes, creating a complex multi-variable optimization problem. Even minor variations in these parameters can lead to substantial differences in coating porosity characteristics.

EB-PVD techniques offer columnar structures with inter-columnar porosity, but controlling the width and distribution of these columnar gaps presents technical difficulties. The relationship between deposition parameters and resultant porosity is highly non-linear, making predictive modeling challenging. Additionally, substrate rotation speed and temperature gradients during deposition create variability in porosity profiles through the coating thickness.

Post-processing treatments intended to modify porosity, such as sintering or infiltration processes, often produce unintended microstructural changes that can compromise other critical TBC properties. The trade-off between porosity optimization and maintaining phase stability represents a significant technical hurdle.

Advanced characterization of porosity also presents challenges. Traditional 2D cross-sectional analysis fails to capture the true 3D interconnectivity of pore networks. While X-ray tomography offers improved insights, resolution limitations restrict detailed analysis of nano-scale porosity features that significantly impact thermal conductivity.

Computational modeling of porosity effects on thermal and mechanical properties has advanced considerably but still struggles with accurate representation of real-world microstructures. Most models rely on idealized pore geometries that inadequately capture the complex, irregular pore networks found in actual TBCs.

The industry also faces challenges in establishing standardized metrics for porosity characterization. Different measurement techniques and reporting methodologies make cross-comparison between research findings difficult, hampering collaborative progress in the field. This lack of standardization impedes the development of universal design guidelines for optimized porosity structures.

APS processes inherently create splat-based microstructures with inter-splat porosity, but achieving consistent pore size distribution and spatial arrangement remains difficult. Process parameters such as plasma power, spray distance, powder feed rate, and carrier gas flow significantly influence porosity outcomes, creating a complex multi-variable optimization problem. Even minor variations in these parameters can lead to substantial differences in coating porosity characteristics.

EB-PVD techniques offer columnar structures with inter-columnar porosity, but controlling the width and distribution of these columnar gaps presents technical difficulties. The relationship between deposition parameters and resultant porosity is highly non-linear, making predictive modeling challenging. Additionally, substrate rotation speed and temperature gradients during deposition create variability in porosity profiles through the coating thickness.

Post-processing treatments intended to modify porosity, such as sintering or infiltration processes, often produce unintended microstructural changes that can compromise other critical TBC properties. The trade-off between porosity optimization and maintaining phase stability represents a significant technical hurdle.

Advanced characterization of porosity also presents challenges. Traditional 2D cross-sectional analysis fails to capture the true 3D interconnectivity of pore networks. While X-ray tomography offers improved insights, resolution limitations restrict detailed analysis of nano-scale porosity features that significantly impact thermal conductivity.

Computational modeling of porosity effects on thermal and mechanical properties has advanced considerably but still struggles with accurate representation of real-world microstructures. Most models rely on idealized pore geometries that inadequately capture the complex, irregular pore networks found in actual TBCs.

The industry also faces challenges in establishing standardized metrics for porosity characterization. Different measurement techniques and reporting methodologies make cross-comparison between research findings difficult, hampering collaborative progress in the field. This lack of standardization impedes the development of universal design guidelines for optimized porosity structures.

Current Porosity Optimization Approaches for TBC Performance

01 Ceramic material selection for thermal barrier coatings

Various ceramic materials can be used in thermal barrier coatings to provide effective heat insulation. These materials include yttria-stabilized zirconia (YSZ), gadolinium zirconate, and other rare earth-based ceramics. The selection of ceramic material significantly impacts the coating's thermal conductivity, phase stability, and overall performance at high temperatures. Advanced ceramic compositions can be engineered to withstand extreme thermal cycling while maintaining structural integrity.- Porosity control in ceramic thermal barrier coatings: Controlling porosity in ceramic thermal barrier coatings is essential for optimizing thermal insulation properties. Various techniques can be employed to create and control pores within the ceramic matrix, including the use of specific deposition parameters, pore-forming agents, and post-processing treatments. Engineered porosity structures can significantly enhance the thermal barrier performance while maintaining necessary mechanical properties for high-temperature applications.

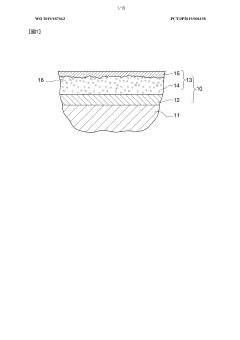

- Multi-layered ceramic coating structures: Multi-layered ceramic coating systems provide enhanced thermal protection through strategically designed layer compositions and thicknesses. These systems typically include a bond coat, a thermally grown oxide layer, and a ceramic top coat with controlled porosity. The layered structure helps manage thermal expansion mismatches, improve adhesion, and extend coating lifespans under extreme temperature cycling conditions. Advanced multi-layer designs can incorporate gradient porosity or composition to optimize performance.

- Novel ceramic materials for thermal barrier applications: Development of advanced ceramic materials with superior thermal insulation properties is crucial for next-generation thermal barrier coatings. These materials include rare-earth zirconates, hafnates, complex perovskites, and pyrochlore structures that offer lower thermal conductivity and better phase stability at elevated temperatures compared to conventional yttria-stabilized zirconia. The incorporation of these novel ceramics, often with engineered porosity, can significantly improve coating performance in extreme environments.

- Deposition techniques for porous ceramic coatings: Various deposition methods are employed to create porous ceramic thermal barrier coatings with controlled microstructures. These include atmospheric plasma spraying, electron beam physical vapor deposition, suspension plasma spraying, and solution precursor plasma spraying. Each technique offers distinct advantages in terms of porosity control, columnar structure formation, and coating adhesion. Modified deposition parameters and specialized equipment configurations can be used to tailor the porosity characteristics for specific thermal barrier requirements.

- Porosity-enhancing additives and post-treatments: Incorporating specific additives and applying post-deposition treatments can enhance and stabilize porosity in ceramic thermal barrier coatings. Fugitive materials that burn out during processing, polymer microspheres, and sacrificial particles can create controlled pore networks. Post-treatments such as laser processing, chemical etching, and thermal cycling can further modify porosity characteristics. These approaches help optimize the balance between thermal insulation properties and mechanical durability in high-temperature applications.

02 Porosity control methods in thermal barrier coatings

Controlling porosity in thermal barrier coatings is crucial for optimizing thermal insulation properties. Various techniques can be employed to create and control porosity, including specific deposition parameters, use of fugitive materials, and post-deposition treatments. Engineered porosity distribution, including micro and nano-porosity, can significantly reduce thermal conductivity while maintaining mechanical strength. The size, shape, and distribution of pores can be tailored to enhance coating performance under thermal cycling conditions.Expand Specific Solutions03 Deposition techniques for porous ceramic coatings

Various deposition methods can be used to create porous ceramic thermal barrier coatings with controlled microstructure. These include atmospheric plasma spraying (APS), electron beam physical vapor deposition (EB-PVD), suspension plasma spraying, and solution precursor plasma spraying. Each technique produces different pore architectures and coating morphologies, affecting thermal and mechanical properties. Advanced deposition parameters can be optimized to create columnar structures, segmentation cracks, or layered architectures that enhance strain tolerance and thermal insulation.Expand Specific Solutions04 Multi-layer and graded porosity structures

Thermal barrier coatings with multi-layer structures or graded porosity distributions can provide enhanced performance. These designs feature varying porosity levels throughout the coating thickness, with higher porosity in the outer layers for thermal insulation and lower porosity in inner layers for mechanical strength. Functionally graded materials can optimize the balance between thermal insulation and mechanical properties. These structures help mitigate thermal stresses and improve coating durability under thermal cycling conditions.Expand Specific Solutions05 Porosity effects on thermal and mechanical properties

The relationship between porosity and thermal barrier coating performance is complex and critical. Increased porosity generally reduces thermal conductivity but can compromise mechanical strength and erosion resistance. Optimizing pore size, shape, and distribution is essential for balancing thermal insulation with mechanical durability. Engineered porosity can enhance strain tolerance, reduce thermal stresses, and improve coating longevity. Advanced testing methods can characterize the effects of porosity on coating performance under simulated service conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in TBC Technology

Porosity plays a critical role in thermal barrier coatings (TBCs) ceramics performance by significantly influencing thermal conductivity, strain tolerance, and durability. The competitive landscape of this technology is characterized by a mature market with established players like Siemens Energy, Mitsubishi Heavy Industries, and Oerlikon Metco leading industrial applications, while research institutions such as Xi'an Jiaotong University and NASA drive innovation. The global TBC market is substantial, estimated at several billion dollars annually with steady growth projections. Technologically, while the fundamental principles are well-established, companies are competing to develop advanced microstructural control methods, with Siemens, Toshiba Energy Systems, and Mitsubishi Hitachi Power Systems focusing on optimizing porosity distribution for next-generation gas turbine applications.

Oerlikon Metco (US), Inc.

Technical Solution: Oerlikon Metco has developed sophisticated thermal barrier coating systems with precisely controlled porosity through their advanced thermal spray technologies. Their atmospheric plasma spray (APS) process creates TBCs with 10-25% porosity levels that significantly reduce thermal conductivity while maintaining adequate mechanical strength. The company's research has established that optimized pore morphology, size distribution, and interconnectivity are critical factors affecting coating performance beyond simple porosity percentage. Their HOSP (Hollow Spherical Powder) technology produces spherical particles with internal porosity that, when deposited, create coatings with multi-scale porosity architecture - from nanoscale to microscale - enhancing thermal insulation properties. Oerlikon has demonstrated that their engineered porosity TBCs can reduce thermal conductivity by up to 40% compared to dense coatings while maintaining erosion resistance through careful control of pore orientation and distribution. Their latest innovation involves suspension plasma spray techniques that enable unprecedented control over porosity features at the nanoscale.

Strengths: Industry-leading thermal spray expertise; wide range of porosity control options; ability to tailor porosity architecture for specific applications; cost-effective manufacturing processes. Weaknesses: Plasma-sprayed coatings typically have lower strain tolerance than EB-PVD alternatives; higher porosity variants may suffer from reduced erosion resistance and mechanical strength.

Corning, Inc.

Technical Solution: Corning has developed innovative thermal barrier coating ceramics with controlled porosity for high-temperature applications. Their technology leverages expertise in glass-ceramics to create TBCs with unique pore architectures that enhance thermal insulation properties. Corning's research has demonstrated that engineered porosity not only reduces thermal conductivity but also improves coating durability through enhanced strain tolerance. Their proprietary sol-gel processing techniques enable precise control over pore size distribution, morphology, and interconnectivity, resulting in optimized thermal-mechanical performance. Corning has pioneered the development of multi-functional TBCs with hierarchical porosity structures that simultaneously address thermal insulation, mechanical durability, and chemical resistance requirements. Their research has established that coatings with 20-30% porosity can reduce thermal conductivity by up to 50% compared to dense ceramics while maintaining adequate mechanical strength. Corning's advanced characterization capabilities have enabled detailed understanding of porosity evolution during thermal cycling, leading to coatings with enhanced durability under extreme temperature conditions. Their latest innovations include self-healing TBCs that utilize controlled porosity to facilitate crack arrest and material transport during high-temperature exposure.

Strengths: Exceptional materials science expertise; advanced processing techniques for precise porosity control; ability to create complex hierarchical structures; strong intellectual property portfolio. Weaknesses: Less experience in turbine applications compared to dedicated aerospace/power companies; potential challenges in scaling laboratory innovations to industrial production.

Key Patents and Research on Porosity-Performance Relationships

Thermal barrier coating, turbine member, gas turbine, and method for producing thermal barrier coating

PatentActiveUS11946147B2

Innovation

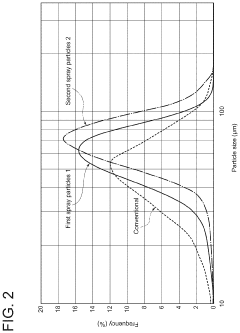

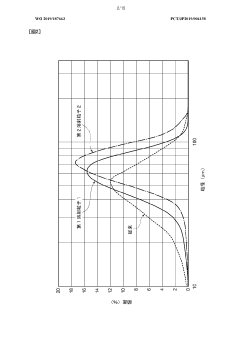

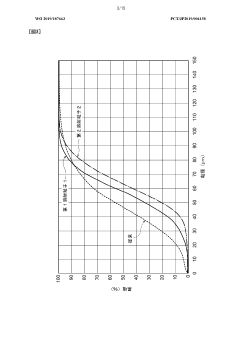

- A thermal barrier coating configuration with a bond coat layer and a ceramic layer comprising a first layer with porosity between 10% and 15% and a second layer with porosity between 0.5% and 9%, formed using specific particle size distributions and deposition methods to balance thermal conductivity and corrosive substance infiltration.

Heat shielding coating, turbine member, gas turbine, and heat shielding coating manufacturing method

PatentWO2019187663A1

Innovation

- A thermal barrier coating configuration with a bond coat layer, a first layer having porosity between 10% and 15%, and a second layer with porosity between 0.5% and 9%, both formed using specific particle size distributions and deposition methods to balance thermal conductivity and corrosive substance penetration.

Durability and Lifecycle Assessment of Porous TBC Systems

The durability and lifecycle performance of porous Thermal Barrier Coating (TBC) systems represent critical factors in determining their practical application value in high-temperature environments. Porosity distribution patterns significantly influence the longevity of these ceramic coatings, with controlled porosity structures demonstrating superior resistance to thermal cycling fatigue compared to randomly distributed pore networks.

Lifecycle assessment studies indicate that porous TBCs typically undergo three distinct degradation phases: initial settling period, stable performance window, and accelerated deterioration. The initial phase involves microstructural adjustments as the coating accommodates thermal stresses, while the stable period represents optimal performance duration. The final phase is characterized by rapid crack propagation, delamination, and eventual spallation failure.

Environmental factors substantially impact TBC durability, with CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration presenting a particularly severe challenge for porous systems. These molten deposits penetrate the porous network, solidify during cooling cycles, and compromise the strain tolerance of the coating. Research indicates that optimized porosity architectures with tortuous pathways can delay CMAS infiltration by up to 40% compared to conventional structures.

Quantitative lifecycle models have been developed to predict TBC durability based on porosity parameters. These models incorporate factors such as pore size distribution, interconnectivity, orientation, and volume fraction to estimate coating lifespan under specific operational conditions. Notably, coatings with bimodal porosity distributions (combining micro and nano-scale pores) demonstrate 25-30% longer service lives in cyclic thermal exposure tests.

Accelerated testing protocols have been established to evaluate long-term durability without requiring full-lifecycle testing. These methods include thermal shock resistance tests, erosion resistance evaluations, and hot corrosion simulations. Results consistently show that controlled porosity gradients outperform uniform porosity distributions in terms of spallation resistance and thermal shock durability.

Economic analyses reveal that while highly engineered porous TBC systems may incur higher initial manufacturing costs, their extended service life and reduced maintenance requirements typically result in 15-20% lower total lifecycle costs for critical high-temperature components. This cost-benefit advantage becomes particularly significant in applications where component replacement involves substantial system downtime.

Lifecycle assessment studies indicate that porous TBCs typically undergo three distinct degradation phases: initial settling period, stable performance window, and accelerated deterioration. The initial phase involves microstructural adjustments as the coating accommodates thermal stresses, while the stable period represents optimal performance duration. The final phase is characterized by rapid crack propagation, delamination, and eventual spallation failure.

Environmental factors substantially impact TBC durability, with CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration presenting a particularly severe challenge for porous systems. These molten deposits penetrate the porous network, solidify during cooling cycles, and compromise the strain tolerance of the coating. Research indicates that optimized porosity architectures with tortuous pathways can delay CMAS infiltration by up to 40% compared to conventional structures.

Quantitative lifecycle models have been developed to predict TBC durability based on porosity parameters. These models incorporate factors such as pore size distribution, interconnectivity, orientation, and volume fraction to estimate coating lifespan under specific operational conditions. Notably, coatings with bimodal porosity distributions (combining micro and nano-scale pores) demonstrate 25-30% longer service lives in cyclic thermal exposure tests.

Accelerated testing protocols have been established to evaluate long-term durability without requiring full-lifecycle testing. These methods include thermal shock resistance tests, erosion resistance evaluations, and hot corrosion simulations. Results consistently show that controlled porosity gradients outperform uniform porosity distributions in terms of spallation resistance and thermal shock durability.

Economic analyses reveal that while highly engineered porous TBC systems may incur higher initial manufacturing costs, their extended service life and reduced maintenance requirements typically result in 15-20% lower total lifecycle costs for critical high-temperature components. This cost-benefit advantage becomes particularly significant in applications where component replacement involves substantial system downtime.

Environmental Impact and Sustainability of TBC Manufacturing Processes

The manufacturing processes of Thermal Barrier Coatings (TBCs) present significant environmental and sustainability considerations, particularly as they relate to porosity development in ceramic layers. Traditional TBC manufacturing methods, such as Air Plasma Spray (APS) and Electron Beam Physical Vapor Deposition (EB-PVD), consume substantial energy and often utilize materials with considerable environmental footprints. The high-temperature processes required to achieve optimal porosity structures typically operate at 1000-1400°C, resulting in considerable carbon emissions and energy consumption.

Material waste represents another critical environmental concern in TBC production. Current manufacturing techniques may result in 20-30% material wastage during deposition, with materials containing rare earth elements and zirconia that have resource-intensive extraction processes. The controlled introduction of porosity, while beneficial for coating performance, often requires additional processing steps or specialized equipment that further increases the environmental burden.

Recent sustainability initiatives have focused on developing eco-friendly alternatives that maintain the beneficial porosity characteristics essential for thermal performance. Water-based slurry systems have emerged as alternatives to solvent-based processes, reducing volatile organic compound (VOC) emissions by up to 85% while still enabling the creation of controlled porous structures. Additionally, advanced manufacturing techniques like suspension plasma spraying allow for more precise porosity control with reduced material waste.

Life cycle assessments of TBC manufacturing reveal that the environmental impact extends beyond production to include the extraction of raw materials and end-of-life disposal. The mining and processing of zirconia and rare earth stabilizers used in porous TBCs contribute significantly to their overall environmental footprint, with estimates suggesting these activities account for 40-50% of the total environmental impact.

Recycling and reuse strategies for TBC materials remain challenging due to the complex multi-material nature of these coatings and the degradation they undergo during service. However, emerging technologies for selective material recovery show promise for reducing the environmental burden of TBC disposal, with potential recovery rates of up to 60% for valuable components.

The sustainability of TBC manufacturing is increasingly being addressed through process optimization that balances porosity requirements with environmental considerations. Computational modeling approaches now enable manufacturers to predict optimal porosity distributions while minimizing material and energy usage. These advancements have demonstrated potential energy savings of 15-25% while maintaining or even enhancing the thermal insulation properties that porosity provides in TBC systems.

Material waste represents another critical environmental concern in TBC production. Current manufacturing techniques may result in 20-30% material wastage during deposition, with materials containing rare earth elements and zirconia that have resource-intensive extraction processes. The controlled introduction of porosity, while beneficial for coating performance, often requires additional processing steps or specialized equipment that further increases the environmental burden.

Recent sustainability initiatives have focused on developing eco-friendly alternatives that maintain the beneficial porosity characteristics essential for thermal performance. Water-based slurry systems have emerged as alternatives to solvent-based processes, reducing volatile organic compound (VOC) emissions by up to 85% while still enabling the creation of controlled porous structures. Additionally, advanced manufacturing techniques like suspension plasma spraying allow for more precise porosity control with reduced material waste.

Life cycle assessments of TBC manufacturing reveal that the environmental impact extends beyond production to include the extraction of raw materials and end-of-life disposal. The mining and processing of zirconia and rare earth stabilizers used in porous TBCs contribute significantly to their overall environmental footprint, with estimates suggesting these activities account for 40-50% of the total environmental impact.

Recycling and reuse strategies for TBC materials remain challenging due to the complex multi-material nature of these coatings and the degradation they undergo during service. However, emerging technologies for selective material recovery show promise for reducing the environmental burden of TBC disposal, with potential recovery rates of up to 60% for valuable components.

The sustainability of TBC manufacturing is increasingly being addressed through process optimization that balances porosity requirements with environmental considerations. Computational modeling approaches now enable manufacturers to predict optimal porosity distributions while minimizing material and energy usage. These advancements have demonstrated potential energy savings of 15-25% while maintaining or even enhancing the thermal insulation properties that porosity provides in TBC systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!