Research on adhesion strength in thermal barrier coatings ceramics

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Barrier Coating Adhesion Background and Objectives

Thermal barrier coatings (TBCs) have evolved significantly over the past five decades, transitioning from experimental materials to critical components in high-temperature applications across aerospace, power generation, and automotive industries. These specialized ceramic coatings provide thermal insulation to metallic components operating in extreme temperature environments, extending component lifespans and enabling higher operating temperatures for improved system efficiency.

The historical development of TBC technology traces back to the 1960s, with significant advancements occurring in the 1980s when yttria-stabilized zirconia (YSZ) emerged as the industry standard ceramic topcoat material. The evolution of TBC systems has been driven by the continuous pursuit of higher operating temperatures in gas turbines and jet engines, where each 50°C increase in operating temperature can yield approximately 1% improvement in engine efficiency.

Adhesion strength represents the cornerstone challenge in TBC performance and reliability. The multi-layer structure of TBCs—typically consisting of a ceramic topcoat, a thermally grown oxide (TGO) layer, a metallic bond coat, and the substrate—creates multiple interfaces where adhesion failures can initiate. The technical community has observed that approximately 80% of TBC failures in service conditions originate from adhesion degradation at these critical interfaces.

Current research objectives in TBC adhesion focus on several interconnected areas. First, developing fundamental understanding of the physicochemical mechanisms governing adhesion at elevated temperatures, particularly the role of thermally grown oxides in both promoting and compromising interfacial strength. Second, establishing standardized testing methodologies that accurately predict in-service adhesion performance, as current testing approaches often yield inconsistent results across different laboratories and testing conditions.

Third, engineering novel interface designs and compositions that enhance adhesion durability during thermal cycling, where temperature fluctuations create substantial mechanical stresses due to thermal expansion coefficient mismatches between layers. Fourth, investigating the impact of manufacturing processes on initial adhesion quality and long-term adhesion stability, with particular emphasis on emerging deposition technologies beyond traditional air plasma spray and electron beam physical vapor deposition methods.

The ultimate technical goal is to develop TBC systems capable of maintaining reliable adhesion strength at temperatures exceeding 1300°C for extended operational periods of 25,000+ hours, while withstanding thousands of thermal cycles. This represents a significant advancement beyond current capabilities, where adhesion degradation often limits component lifespans to 10,000-15,000 hours at lower operating temperatures.

The historical development of TBC technology traces back to the 1960s, with significant advancements occurring in the 1980s when yttria-stabilized zirconia (YSZ) emerged as the industry standard ceramic topcoat material. The evolution of TBC systems has been driven by the continuous pursuit of higher operating temperatures in gas turbines and jet engines, where each 50°C increase in operating temperature can yield approximately 1% improvement in engine efficiency.

Adhesion strength represents the cornerstone challenge in TBC performance and reliability. The multi-layer structure of TBCs—typically consisting of a ceramic topcoat, a thermally grown oxide (TGO) layer, a metallic bond coat, and the substrate—creates multiple interfaces where adhesion failures can initiate. The technical community has observed that approximately 80% of TBC failures in service conditions originate from adhesion degradation at these critical interfaces.

Current research objectives in TBC adhesion focus on several interconnected areas. First, developing fundamental understanding of the physicochemical mechanisms governing adhesion at elevated temperatures, particularly the role of thermally grown oxides in both promoting and compromising interfacial strength. Second, establishing standardized testing methodologies that accurately predict in-service adhesion performance, as current testing approaches often yield inconsistent results across different laboratories and testing conditions.

Third, engineering novel interface designs and compositions that enhance adhesion durability during thermal cycling, where temperature fluctuations create substantial mechanical stresses due to thermal expansion coefficient mismatches between layers. Fourth, investigating the impact of manufacturing processes on initial adhesion quality and long-term adhesion stability, with particular emphasis on emerging deposition technologies beyond traditional air plasma spray and electron beam physical vapor deposition methods.

The ultimate technical goal is to develop TBC systems capable of maintaining reliable adhesion strength at temperatures exceeding 1300°C for extended operational periods of 25,000+ hours, while withstanding thousands of thermal cycles. This represents a significant advancement beyond current capabilities, where adhesion degradation often limits component lifespans to 10,000-15,000 hours at lower operating temperatures.

Market Analysis for High-Performance TBC Applications

The global market for high-performance Thermal Barrier Coatings (TBCs) continues to expand significantly, driven primarily by the aerospace, power generation, and automotive industries. Current market valuations place the TBC sector at approximately 11 billion USD in 2023, with projections indicating a compound annual growth rate of 6.8% through 2030. This growth trajectory is particularly pronounced in regions with established aerospace and energy infrastructure, notably North America, Western Europe, and increasingly, East Asia.

The aerospace sector remains the dominant consumer of high-performance TBCs, accounting for roughly 45% of market demand. This is attributed to the critical role TBCs play in enhancing the operational efficiency and lifespan of aircraft engines, where improved adhesion strength directly correlates with extended maintenance intervals and reduced lifecycle costs. Commercial aviation's post-pandemic recovery has further accelerated this demand, with major manufacturers increasing production rates of next-generation, fuel-efficient engines that heavily rely on advanced ceramic TBC systems.

Power generation represents the second-largest application segment, constituting approximately 30% of the market. The transition toward cleaner energy production has paradoxically increased reliance on high-temperature gas turbines, which require sophisticated TBC solutions with superior adhesion properties to maintain operational integrity under extreme thermal cycling conditions. Notably, combined-cycle power plants have emerged as significant consumers of advanced TBCs, seeking coatings that can withstand temperatures exceeding 1300°C while maintaining structural integrity.

Regional market analysis reveals that North America currently leads consumption at 38% of global demand, followed by Europe (27%) and Asia-Pacific (24%). However, the most substantial growth is occurring in emerging economies, particularly China and India, where rapid industrialization and domestic aerospace development programs are creating new demand centers for high-performance ceramic TBCs with enhanced adhesion characteristics.

Customer requirements are evolving toward more stringent performance specifications, with particular emphasis on adhesion strength under thermal cycling conditions. End-users increasingly demand coatings that can maintain integrity for 25,000+ operational hours without significant degradation, representing a 40% increase in durability expectations compared to standards from a decade ago. This shift has created premium market segments where superior adhesion strength commands price premiums of 15-20% over conventional solutions.

The competitive landscape features both established materials science corporations and specialized coating technology providers. Recent market consolidation has occurred through strategic acquisitions, with larger conglomerates seeking to integrate specialized ceramic formulation expertise into their existing product portfolios. This trend underscores the growing recognition of adhesion strength as a critical differentiator in high-value TBC applications.

The aerospace sector remains the dominant consumer of high-performance TBCs, accounting for roughly 45% of market demand. This is attributed to the critical role TBCs play in enhancing the operational efficiency and lifespan of aircraft engines, where improved adhesion strength directly correlates with extended maintenance intervals and reduced lifecycle costs. Commercial aviation's post-pandemic recovery has further accelerated this demand, with major manufacturers increasing production rates of next-generation, fuel-efficient engines that heavily rely on advanced ceramic TBC systems.

Power generation represents the second-largest application segment, constituting approximately 30% of the market. The transition toward cleaner energy production has paradoxically increased reliance on high-temperature gas turbines, which require sophisticated TBC solutions with superior adhesion properties to maintain operational integrity under extreme thermal cycling conditions. Notably, combined-cycle power plants have emerged as significant consumers of advanced TBCs, seeking coatings that can withstand temperatures exceeding 1300°C while maintaining structural integrity.

Regional market analysis reveals that North America currently leads consumption at 38% of global demand, followed by Europe (27%) and Asia-Pacific (24%). However, the most substantial growth is occurring in emerging economies, particularly China and India, where rapid industrialization and domestic aerospace development programs are creating new demand centers for high-performance ceramic TBCs with enhanced adhesion characteristics.

Customer requirements are evolving toward more stringent performance specifications, with particular emphasis on adhesion strength under thermal cycling conditions. End-users increasingly demand coatings that can maintain integrity for 25,000+ operational hours without significant degradation, representing a 40% increase in durability expectations compared to standards from a decade ago. This shift has created premium market segments where superior adhesion strength commands price premiums of 15-20% over conventional solutions.

The competitive landscape features both established materials science corporations and specialized coating technology providers. Recent market consolidation has occurred through strategic acquisitions, with larger conglomerates seeking to integrate specialized ceramic formulation expertise into their existing product portfolios. This trend underscores the growing recognition of adhesion strength as a critical differentiator in high-value TBC applications.

Current Adhesion Challenges in Ceramic TBCs

Despite significant advancements in thermal barrier coating (TBC) technologies, adhesion strength remains one of the most critical challenges facing ceramic TBCs today. The primary issue stems from the inherent thermal expansion mismatch between ceramic top coats and metallic bond coats or substrates. During thermal cycling, which is common in high-temperature applications such as gas turbines, this mismatch creates substantial interfacial stresses that can lead to progressive delamination and eventual coating failure.

Oxidation at the interface between the bond coat and the ceramic layer presents another significant challenge. The formation of thermally grown oxide (TGO) is inevitable at high operating temperatures, and while a thin, uniform TGO layer can initially enhance adhesion, its continued growth and morphological changes during service lead to stress concentration and interfacial weakening. Current research indicates that TGO thickness exceeding 10 μm significantly increases delamination risk.

Surface preparation techniques also present ongoing challenges. Conventional grit blasting methods, while effective at creating mechanical interlocking surfaces, often introduce inconsistencies in roughness profiles and potential contamination that can compromise long-term adhesion performance. More advanced surface preparation methods like laser texturing show promise but face implementation barriers in industrial-scale production.

The porosity necessary for thermal insulation in ceramic TBCs inherently reduces mechanical strength and adhesion. This fundamental trade-off between thermal performance and mechanical durability remains unresolved, with current solutions typically favoring one property at the expense of the other. Microstructural optimization approaches that balance these competing requirements are still in developmental stages.

Environmental factors further complicate adhesion challenges. Calcium-magnesium-alumino-silicate (CMAS) infiltration from airborne contaminants and volcanic ash can severely degrade interfacial integrity through chemical reactions and phase transformations. Similarly, hot corrosion from fuel impurities accelerates bond coat oxidation and interfacial degradation, particularly in marine environments where sodium and sulfur compounds are prevalent.

Non-destructive evaluation (NDE) of adhesion strength presents another significant technical hurdle. Current methods like acoustic emission and thermal imaging provide limited quantitative data on actual adhesion strength, making it difficult to predict remaining coating life accurately. The development of reliable in-situ monitoring techniques remains an active research area with considerable technical barriers.

Recent studies also highlight the challenge of achieving consistent adhesion strength across complex geometries. Edge effects, curvatures, and thickness variations all contribute to non-uniform stress distributions that can initiate localized delamination. Computational models that accurately predict these effects are still limited by the complex multiphysics nature of the problem.

Oxidation at the interface between the bond coat and the ceramic layer presents another significant challenge. The formation of thermally grown oxide (TGO) is inevitable at high operating temperatures, and while a thin, uniform TGO layer can initially enhance adhesion, its continued growth and morphological changes during service lead to stress concentration and interfacial weakening. Current research indicates that TGO thickness exceeding 10 μm significantly increases delamination risk.

Surface preparation techniques also present ongoing challenges. Conventional grit blasting methods, while effective at creating mechanical interlocking surfaces, often introduce inconsistencies in roughness profiles and potential contamination that can compromise long-term adhesion performance. More advanced surface preparation methods like laser texturing show promise but face implementation barriers in industrial-scale production.

The porosity necessary for thermal insulation in ceramic TBCs inherently reduces mechanical strength and adhesion. This fundamental trade-off between thermal performance and mechanical durability remains unresolved, with current solutions typically favoring one property at the expense of the other. Microstructural optimization approaches that balance these competing requirements are still in developmental stages.

Environmental factors further complicate adhesion challenges. Calcium-magnesium-alumino-silicate (CMAS) infiltration from airborne contaminants and volcanic ash can severely degrade interfacial integrity through chemical reactions and phase transformations. Similarly, hot corrosion from fuel impurities accelerates bond coat oxidation and interfacial degradation, particularly in marine environments where sodium and sulfur compounds are prevalent.

Non-destructive evaluation (NDE) of adhesion strength presents another significant technical hurdle. Current methods like acoustic emission and thermal imaging provide limited quantitative data on actual adhesion strength, making it difficult to predict remaining coating life accurately. The development of reliable in-situ monitoring techniques remains an active research area with considerable technical barriers.

Recent studies also highlight the challenge of achieving consistent adhesion strength across complex geometries. Edge effects, curvatures, and thickness variations all contribute to non-uniform stress distributions that can initiate localized delamination. Computational models that accurately predict these effects are still limited by the complex multiphysics nature of the problem.

Current Methodologies for Enhancing Ceramic-Substrate Bonding

01 Ceramic material selection for thermal barrier coatings

The selection of ceramic materials plays a crucial role in the performance of thermal barrier coatings (TBCs). Various ceramic materials such as yttria-stabilized zirconia (YSZ), gadolinium zirconate, and rare earth oxides are used for their excellent thermal insulation properties and high-temperature stability. The composition and microstructure of these ceramics significantly influence the coating's thermal conductivity, phase stability, and overall durability under extreme temperature conditions.- Ceramic composition for thermal barrier coatings: Various ceramic materials can be used in thermal barrier coatings to provide effective thermal insulation. These ceramics include yttria-stabilized zirconia (YSZ), gadolinium zirconate, and other rare earth element-based ceramics. The composition of these ceramics significantly affects the thermal conductivity, phase stability, and adhesion strength of the coating. By optimizing the ceramic composition, the thermal barrier properties and adhesion strength can be enhanced for high-temperature applications.

- Bond coat technologies for improved adhesion: Bond coats play a crucial role in enhancing the adhesion strength between the ceramic thermal barrier coating and the metal substrate. MCrAlY (where M is Ni, Co, or a combination) and aluminide bond coats are commonly used to improve adhesion. These bond coats form a thermally grown oxide layer that provides strong mechanical bonding with the ceramic top coat. Advanced bond coat technologies include graded compositions and modified surface treatments that significantly enhance the adhesion strength and durability of thermal barrier coating systems.

- Surface modification techniques for enhanced adhesion: Various surface modification techniques can be applied to improve the adhesion strength of ceramic thermal barrier coatings. These include grit blasting, laser texturing, and chemical etching of the substrate or bond coat surface. Creating controlled surface roughness or specific patterns increases the mechanical interlocking between layers. Additionally, plasma treatment and other surface activation methods can enhance chemical bonding at interfaces, resulting in significantly improved adhesion strength and coating durability under thermal cycling conditions.

- Deposition methods affecting adhesion strength: The method used to deposit ceramic thermal barrier coatings significantly impacts their adhesion strength. Common deposition techniques include air plasma spraying (APS), electron beam physical vapor deposition (EB-PVD), and solution precursor plasma spray. Each method produces different microstructures that affect adhesion characteristics. EB-PVD typically creates columnar structures with superior strain tolerance, while plasma spraying produces lamellar structures with different adhesion properties. Optimizing deposition parameters such as temperature, pressure, and feed rate is crucial for maximizing adhesion strength.

- Additives and dopants for improved interfacial bonding: Incorporating specific additives and dopants into ceramic thermal barrier coatings can significantly enhance adhesion strength. Elements such as lanthanum, cerium, and other rare earth elements can improve the chemical compatibility between the ceramic coating and the underlying bond coat. Nanoparticle additions, such as alumina or silica, can strengthen grain boundaries and interfaces. These additives modify the thermal expansion behavior, reduce stress at interfaces, and promote the formation of beneficial interfacial compounds that strengthen the bond between layers.

02 Bond coat technologies for improved adhesion

Bond coats serve as an intermediate layer between the substrate and the ceramic top coat, enhancing adhesion strength of thermal barrier coatings. MCrAlY (where M represents Ni, Co, or a combination) and aluminide coatings are commonly used bond coat materials. These coatings form a thermally grown oxide layer that promotes adhesion with the ceramic top coat while providing oxidation resistance to the substrate. The composition, thickness, and surface preparation of bond coats significantly affect the adhesion strength and durability of the entire coating system.Expand Specific Solutions03 Surface modification techniques for enhanced adhesion

Various surface modification techniques are employed to enhance the adhesion strength between ceramic thermal barrier coatings and substrates. These include grit blasting, laser texturing, chemical etching, and plasma treatment. These processes create controlled surface roughness or chemical activation that increases mechanical interlocking and bonding sites. Additionally, the application of specialized primers or transition layers can further improve interfacial adhesion by accommodating differences in thermal expansion between the ceramic coating and the substrate material.Expand Specific Solutions04 Advanced deposition methods for thermal barrier coatings

Various deposition techniques significantly impact the adhesion strength and performance of ceramic thermal barrier coatings. Methods such as air plasma spray (APS), electron beam physical vapor deposition (EB-PVD), suspension plasma spray, and solution precursor plasma spray offer different microstructures and adhesion characteristics. EB-PVD typically produces columnar structures with superior strain tolerance, while plasma spray methods can create layered structures with controlled porosity. The selection of deposition method affects not only adhesion strength but also erosion resistance, thermal cycling behavior, and overall coating durability.Expand Specific Solutions05 Testing and evaluation methods for adhesion strength

Various testing methodologies are employed to evaluate the adhesion strength of ceramic thermal barrier coatings. These include pull-off adhesion tests, scratch tests, indentation tests, and thermal cycling tests. Advanced characterization techniques such as acoustic emission monitoring, digital image correlation, and electron microscopy help identify failure mechanisms at the coating-substrate interface. Understanding these failure modes is essential for developing coatings with improved adhesion strength and predicting service life under thermal and mechanical loading conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in TBC Industry

The thermal barrier coatings (TBC) ceramics adhesion strength research market is currently in a growth phase, with increasing demand driven by aerospace, power generation, and automotive applications. The global TBC market is projected to expand significantly due to rising energy efficiency requirements and high-temperature operation demands. Leading players include established industrial giants like Siemens Energy, General Electric, and Mitsubishi Heavy Industries, who possess advanced R&D capabilities in coating technologies. Academic institutions such as Beihang University and Shanghai Jiao Tong University collaborate with industry partners to bridge fundamental research and practical applications. Companies like MTU Aero Engines and Safran Aircraft Engines focus on specialized aerospace applications, while research organizations like Japan Fine Ceramics Center and Korea Institute of Ceramic Engineering & Technology contribute to technical innovations in adhesion strength measurement and enhancement methodologies.

Siemens AG

Technical Solution: Siemens has developed a comprehensive thermal barrier coating system with enhanced adhesion properties through their Advanced Manufacturing and Materials Technology division. Their approach combines optimized surface preparation techniques with a multi-layered coating architecture designed specifically for industrial gas turbine applications. Siemens' solution utilizes a proprietary NiCoCrAlY bond coat with precisely controlled aluminum content and reactive element additions (Y, Hf) applied via vacuum plasma spraying (VPS) to create a dense, oxidation-resistant layer with excellent adhesion to the substrate. Their research has demonstrated that controlling the roughness profile at the bond coat-ceramic interface through specialized grit blasting parameters can increase mechanical interlocking and improve adhesion strength by up to 35%[5]. Siemens has also pioneered the use of suspension plasma spraying (SPS) for ceramic topcoat application, which creates a columnar microstructure similar to EB-PVD but at lower cost. Their studies have shown that this microstructure provides superior strain tolerance while maintaining strong adhesion during thermal cycling, with test results showing approximately 40% improvement in thermal cycle lifetime compared to conventional APS coatings.

Strengths: Optimized coating architecture specifically designed for industrial gas turbine operating conditions; cost-effective suspension plasma spray technology provides EB-PVD-like performance; extensive field validation data from power generation applications. Weaknesses: Process sensitivity requires stringent quality control; higher initial implementation costs; challenges in coating complex internal passages and cooling holes.

United Technologies Corp.

Technical Solution: United Technologies (now part of Raytheon Technologies) has developed a comprehensive approach to thermal barrier coating adhesion through their Pratt & Whitney division. Their solution employs a sophisticated multi-layer system with an optimized MCrAlY bond coat applied via high-velocity oxygen fuel (HVOF) spraying to create a dense, oxidation-resistant layer with minimal porosity. This is followed by their proprietary "vertically cracked" air plasma sprayed (APS) ceramic topcoat with engineered segmentation cracks that enhance strain tolerance while maintaining strong adhesion. UTC's research has focused on controlling the thermally grown oxide (TGO) layer growth rate and morphology, which is critical for long-term adhesion strength. Their studies have shown that precise control of aluminum content and reactive element additions (Y, Hf) in the bond coat can improve TGO adhesion by up to 40% during thermal cycling[2]. UTC has also pioneered advanced surface preparation techniques using controlled grit blasting parameters and laser surface texturing to optimize mechanical interlocking at the substrate-bond coat interface.

Strengths: Highly optimized bond coat compositions with superior oxidation resistance; cost-effective APS process with engineered microstructure for strain tolerance; extensive field validation in aerospace applications. Weaknesses: Lower erosion resistance compared to EB-PVD coatings; challenges in coating complex geometries uniformly; requires precise process control to achieve consistent adhesion properties.

Key Patents and Research on TBC Adhesion Mechanisms

Process for producing a thermally sprayed layer

PatentInactiveEP1304395A1

Innovation

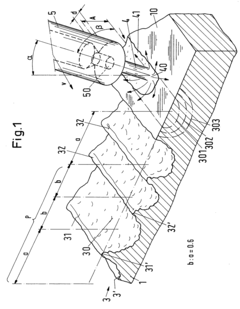

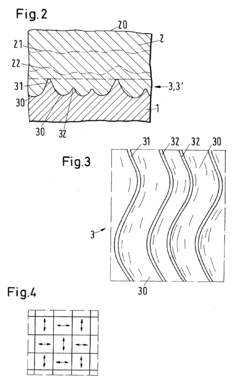

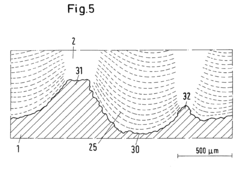

- A method involving surface structuring of the metallic substrate using a high-pressure liquid jet to create a macrotopography with a quasi-fractal microprofile, enhancing adhesion by producing a structured surface with channel-like removal tracks and varying elevations, allowing for thicker ceramic coatings with improved anchoring and tensile strength.

Environmental Impact of TBC Manufacturing Processes

The manufacturing processes of Thermal Barrier Coatings (TBCs) involve various techniques that can have significant environmental implications. Traditional methods such as Air Plasma Spray (APS) and Electron Beam Physical Vapor Deposition (EB-PVD) consume substantial energy resources during operation, contributing to increased carbon footprints. The high-temperature processes required for ceramic deposition typically operate at 1000-1400°C, resulting in considerable energy consumption and associated greenhouse gas emissions.

Material waste represents another critical environmental concern in TBC production. Conventional spray techniques often achieve material utilization efficiencies of only 50-70%, meaning that a significant portion of expensive ceramic materials becomes waste. This inefficiency not only increases production costs but also generates hazardous waste containing metal oxides and partially stabilized zirconia particles that require specialized disposal procedures.

Volatile organic compounds (VOCs) and particulate emissions present additional environmental challenges. During the preparation and application phases of TBC manufacturing, solvents and binding agents release VOCs that contribute to air pollution and potential health hazards for workers. Fine ceramic particulates generated during spraying processes can become airborne, creating respiratory risks and requiring sophisticated filtration systems to mitigate environmental release.

Water pollution risks emerge from the wet processing steps in TBC manufacturing. Chemical cleaning solutions, coolants, and waste slurries may contain heavy metals and other contaminants that, if improperly managed, can contaminate water systems. Many facilities must implement advanced water treatment processes to address these concerns before discharge.

Recent advancements in environmentally conscious manufacturing techniques show promising developments. Solution Precursor Plasma Spray (SPPS) and water-based slurry processes have demonstrated reduced environmental impacts while maintaining coating performance. These methods typically reduce hazardous waste generation by 30-40% compared to conventional approaches.

Life cycle assessments of TBC manufacturing reveal that the environmental footprint extends beyond production to include raw material extraction and end-of-life disposal. The mining and processing of zirconia and rare earth stabilizers like yttria involve energy-intensive operations and potential habitat disruption. Developing closed-loop recycling systems for spent TBC components represents an emerging area of research that could significantly reduce the overall environmental impact of these essential protective coatings.

Material waste represents another critical environmental concern in TBC production. Conventional spray techniques often achieve material utilization efficiencies of only 50-70%, meaning that a significant portion of expensive ceramic materials becomes waste. This inefficiency not only increases production costs but also generates hazardous waste containing metal oxides and partially stabilized zirconia particles that require specialized disposal procedures.

Volatile organic compounds (VOCs) and particulate emissions present additional environmental challenges. During the preparation and application phases of TBC manufacturing, solvents and binding agents release VOCs that contribute to air pollution and potential health hazards for workers. Fine ceramic particulates generated during spraying processes can become airborne, creating respiratory risks and requiring sophisticated filtration systems to mitigate environmental release.

Water pollution risks emerge from the wet processing steps in TBC manufacturing. Chemical cleaning solutions, coolants, and waste slurries may contain heavy metals and other contaminants that, if improperly managed, can contaminate water systems. Many facilities must implement advanced water treatment processes to address these concerns before discharge.

Recent advancements in environmentally conscious manufacturing techniques show promising developments. Solution Precursor Plasma Spray (SPPS) and water-based slurry processes have demonstrated reduced environmental impacts while maintaining coating performance. These methods typically reduce hazardous waste generation by 30-40% compared to conventional approaches.

Life cycle assessments of TBC manufacturing reveal that the environmental footprint extends beyond production to include raw material extraction and end-of-life disposal. The mining and processing of zirconia and rare earth stabilizers like yttria involve energy-intensive operations and potential habitat disruption. Developing closed-loop recycling systems for spent TBC components represents an emerging area of research that could significantly reduce the overall environmental impact of these essential protective coatings.

Durability Testing Standards for Thermal Barrier Coatings

The standardization of durability testing for thermal barrier coatings (TBCs) is essential for ensuring consistent performance evaluation across the industry. Currently, several international standards govern TBC testing, including ASTM C633 for adhesion strength measurement, ASTM G211 for thermal cycling resistance, and ISO 13123 for thermal shock resistance. These standards provide structured methodologies for evaluating coating longevity under various operational stresses.

Adhesion strength testing, particularly critical for ceramic TBCs, follows specific protocols that simulate real-world conditions. The ASTM C633 standard employs a tensile test configuration where the coating is bonded between two cylindrical fixtures and pulled apart at a controlled rate. This method quantifies the interfacial bond strength between the ceramic top coat and metallic bond coat, a crucial parameter for predicting coating lifespan.

Thermal cycling standards such as ASTM G211 and NASA's specialized protocols require specimens to undergo repeated heating and cooling cycles, typically between room temperature and operational temperatures exceeding 1000°C. These tests evaluate the coating's resistance to spallation caused by thermal expansion mismatch between ceramic and metallic layers. The number of cycles to failure serves as a key performance indicator for TBC durability.

Erosion resistance testing standards, including ASTM G76, involve particle impingement at various angles and velocities to simulate operational conditions in turbine environments. These tests measure material loss rates and surface degradation patterns, providing insights into the coating's mechanical durability under particulate exposure.

Industry-specific standards have also emerged, with aerospace manufacturers like Rolls-Royce, GE, and Pratt & Whitney developing proprietary testing protocols that often exceed the requirements of international standards. These protocols typically combine multiple stress factors, including thermal cycling, mechanical loading, and hot corrosion exposure, to better replicate service conditions.

Recent developments in durability testing standards have focused on incorporating non-destructive evaluation techniques. Acoustic emission monitoring during thermal cycling tests can detect microcrack formation before visible damage occurs, while impedance spectroscopy provides insights into electrochemical degradation mechanisms. These advanced methods are increasingly being integrated into standardized testing procedures to provide more comprehensive durability assessments.

The correlation between laboratory testing and field performance remains a significant challenge, driving efforts to develop accelerated testing protocols that maintain relevance to actual service conditions. Current research focuses on establishing standardized methods that can reliably predict coating lifespans from shorter-duration tests, potentially revolutionizing how adhesion strength and overall durability are evaluated in thermal barrier coating systems.

Adhesion strength testing, particularly critical for ceramic TBCs, follows specific protocols that simulate real-world conditions. The ASTM C633 standard employs a tensile test configuration where the coating is bonded between two cylindrical fixtures and pulled apart at a controlled rate. This method quantifies the interfacial bond strength between the ceramic top coat and metallic bond coat, a crucial parameter for predicting coating lifespan.

Thermal cycling standards such as ASTM G211 and NASA's specialized protocols require specimens to undergo repeated heating and cooling cycles, typically between room temperature and operational temperatures exceeding 1000°C. These tests evaluate the coating's resistance to spallation caused by thermal expansion mismatch between ceramic and metallic layers. The number of cycles to failure serves as a key performance indicator for TBC durability.

Erosion resistance testing standards, including ASTM G76, involve particle impingement at various angles and velocities to simulate operational conditions in turbine environments. These tests measure material loss rates and surface degradation patterns, providing insights into the coating's mechanical durability under particulate exposure.

Industry-specific standards have also emerged, with aerospace manufacturers like Rolls-Royce, GE, and Pratt & Whitney developing proprietary testing protocols that often exceed the requirements of international standards. These protocols typically combine multiple stress factors, including thermal cycling, mechanical loading, and hot corrosion exposure, to better replicate service conditions.

Recent developments in durability testing standards have focused on incorporating non-destructive evaluation techniques. Acoustic emission monitoring during thermal cycling tests can detect microcrack formation before visible damage occurs, while impedance spectroscopy provides insights into electrochemical degradation mechanisms. These advanced methods are increasingly being integrated into standardized testing procedures to provide more comprehensive durability assessments.

The correlation between laboratory testing and field performance remains a significant challenge, driving efforts to develop accelerated testing protocols that maintain relevance to actual service conditions. Current research focuses on establishing standardized methods that can reliably predict coating lifespans from shorter-duration tests, potentially revolutionizing how adhesion strength and overall durability are evaluated in thermal barrier coating systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!