Thermal barrier coatings ceramics under high thermal cycling conditions

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Barrier Coatings Background and Objectives

Thermal barrier coatings (TBCs) have emerged as a critical technology in high-temperature applications, particularly in aerospace, power generation, and automotive industries. These specialized ceramic coatings provide thermal insulation to metallic components operating in extreme temperature environments, effectively extending component lifespan and enabling higher operating temperatures for improved system efficiency. The evolution of TBC technology can be traced back to the 1950s, with significant advancements occurring during the 1970s and 1980s as jet engine manufacturers sought materials capable of withstanding increasingly demanding thermal conditions.

The primary function of TBCs is to create a temperature gradient across the coating thickness, reducing the temperature experienced by the underlying metal substrate. This thermal management capability has become increasingly important as modern gas turbines and engines push toward higher operating temperatures to achieve greater thermodynamic efficiency. The historical progression of TBC development shows a clear trend toward materials with lower thermal conductivity, enhanced phase stability, and improved resistance to sintering and erosion.

Current state-of-the-art TBC systems typically employ yttria-stabilized zirconia (YSZ) as the ceramic top coat, which has become the industry standard due to its excellent combination of low thermal conductivity, relatively high coefficient of thermal expansion, and phase stability. However, as operating temperatures continue to rise beyond 1200°C in advanced systems, traditional YSZ coatings approach their functional limits, creating an urgent need for next-generation ceramic materials capable of withstanding more extreme thermal cycling conditions.

The technical objectives of current research focus on developing advanced ceramic compositions that maintain structural integrity under severe thermal cycling, where rapid temperature fluctuations induce significant thermal stresses. Key performance targets include reducing thermal conductivity below 1 W/m·K, extending coating lifespans beyond 10,000 thermal cycles, and maintaining phase stability at temperatures exceeding 1300°C. Additionally, researchers aim to enhance strain tolerance and crack resistance while minimizing sintering rates at elevated temperatures.

Another critical research direction involves understanding the fundamental degradation mechanisms of ceramic TBCs under high-frequency thermal cycling conditions. This includes investigating the evolution of microstructural features, phase transformations, and interfacial phenomena that ultimately lead to coating failure. The knowledge gained from these investigations will inform the development of predictive models for coating lifespan and guide the design of more durable ceramic compositions.

The ultimate goal of current TBC research is to enable a new generation of high-efficiency energy conversion systems by providing thermal protection solutions that can withstand increasingly extreme operating environments. This includes not only improving the ceramic top coat but also developing compatible bond coats and innovative manufacturing techniques that together form integrated thermal management systems capable of meeting the demands of future high-temperature applications.

The primary function of TBCs is to create a temperature gradient across the coating thickness, reducing the temperature experienced by the underlying metal substrate. This thermal management capability has become increasingly important as modern gas turbines and engines push toward higher operating temperatures to achieve greater thermodynamic efficiency. The historical progression of TBC development shows a clear trend toward materials with lower thermal conductivity, enhanced phase stability, and improved resistance to sintering and erosion.

Current state-of-the-art TBC systems typically employ yttria-stabilized zirconia (YSZ) as the ceramic top coat, which has become the industry standard due to its excellent combination of low thermal conductivity, relatively high coefficient of thermal expansion, and phase stability. However, as operating temperatures continue to rise beyond 1200°C in advanced systems, traditional YSZ coatings approach their functional limits, creating an urgent need for next-generation ceramic materials capable of withstanding more extreme thermal cycling conditions.

The technical objectives of current research focus on developing advanced ceramic compositions that maintain structural integrity under severe thermal cycling, where rapid temperature fluctuations induce significant thermal stresses. Key performance targets include reducing thermal conductivity below 1 W/m·K, extending coating lifespans beyond 10,000 thermal cycles, and maintaining phase stability at temperatures exceeding 1300°C. Additionally, researchers aim to enhance strain tolerance and crack resistance while minimizing sintering rates at elevated temperatures.

Another critical research direction involves understanding the fundamental degradation mechanisms of ceramic TBCs under high-frequency thermal cycling conditions. This includes investigating the evolution of microstructural features, phase transformations, and interfacial phenomena that ultimately lead to coating failure. The knowledge gained from these investigations will inform the development of predictive models for coating lifespan and guide the design of more durable ceramic compositions.

The ultimate goal of current TBC research is to enable a new generation of high-efficiency energy conversion systems by providing thermal protection solutions that can withstand increasingly extreme operating environments. This includes not only improving the ceramic top coat but also developing compatible bond coats and innovative manufacturing techniques that together form integrated thermal management systems capable of meeting the demands of future high-temperature applications.

Market Analysis for High-Temperature Applications

The thermal barrier coatings (TBCs) market for high-temperature applications has witnessed substantial growth in recent years, primarily driven by increasing demand from aerospace, power generation, and automotive industries. The global TBC market was valued at approximately $1.5 billion in 2022 and is projected to reach $2.3 billion by 2028, growing at a CAGR of 7.2% during the forecast period.

Aerospace remains the dominant application segment, accounting for over 40% of the total market share. The continuous pursuit of higher operating temperatures in aircraft engines to improve fuel efficiency and reduce emissions has significantly boosted the demand for advanced ceramic TBCs capable of withstanding extreme thermal cycling conditions. Major aircraft engine manufacturers have increased their R&D investments in next-generation TBCs by 15% annually since 2020.

The power generation sector represents the second-largest market for high-temperature TBCs, particularly in gas turbines where efficiency improvements directly correlate with operating temperature capabilities. With the global transition toward cleaner energy sources, combined-cycle gas turbine plants are gaining prominence, creating a steady demand growth of approximately 8% annually for advanced ceramic TBCs that can maintain structural integrity under frequent thermal cycling.

Industrial gas turbines and diesel engines in the automotive sector, especially in heavy-duty vehicles and racing applications, constitute emerging application areas with growth rates exceeding 10% annually. The increasing stringency of emission regulations worldwide has accelerated the adoption of thermal barrier coatings to improve combustion efficiency and reduce harmful emissions.

Regionally, North America and Europe currently dominate the high-temperature TBC market with a combined share of 65%, attributed to their advanced aerospace and power generation industries. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate of 9.5% annually due to rapid industrialization and expanding aerospace sectors.

Customer requirements are evolving toward TBCs with enhanced durability under thermal cycling conditions, with industry surveys indicating that 78% of end-users prioritize coating longevity over initial cost considerations. This trend has created a premium segment within the market for advanced ceramic formulations that can withstand 1000+ thermal cycles without significant degradation, commanding price premiums of 30-40% over conventional coatings.

Market forecasts suggest that zirconia-based ceramics will continue to dominate with approximately 70% market share, while emerging materials like gadolinium zirconate and lanthanum pyrochlores are expected to grow at twice the market rate due to their superior thermal cycling resistance properties.

Aerospace remains the dominant application segment, accounting for over 40% of the total market share. The continuous pursuit of higher operating temperatures in aircraft engines to improve fuel efficiency and reduce emissions has significantly boosted the demand for advanced ceramic TBCs capable of withstanding extreme thermal cycling conditions. Major aircraft engine manufacturers have increased their R&D investments in next-generation TBCs by 15% annually since 2020.

The power generation sector represents the second-largest market for high-temperature TBCs, particularly in gas turbines where efficiency improvements directly correlate with operating temperature capabilities. With the global transition toward cleaner energy sources, combined-cycle gas turbine plants are gaining prominence, creating a steady demand growth of approximately 8% annually for advanced ceramic TBCs that can maintain structural integrity under frequent thermal cycling.

Industrial gas turbines and diesel engines in the automotive sector, especially in heavy-duty vehicles and racing applications, constitute emerging application areas with growth rates exceeding 10% annually. The increasing stringency of emission regulations worldwide has accelerated the adoption of thermal barrier coatings to improve combustion efficiency and reduce harmful emissions.

Regionally, North America and Europe currently dominate the high-temperature TBC market with a combined share of 65%, attributed to their advanced aerospace and power generation industries. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate of 9.5% annually due to rapid industrialization and expanding aerospace sectors.

Customer requirements are evolving toward TBCs with enhanced durability under thermal cycling conditions, with industry surveys indicating that 78% of end-users prioritize coating longevity over initial cost considerations. This trend has created a premium segment within the market for advanced ceramic formulations that can withstand 1000+ thermal cycles without significant degradation, commanding price premiums of 30-40% over conventional coatings.

Market forecasts suggest that zirconia-based ceramics will continue to dominate with approximately 70% market share, while emerging materials like gadolinium zirconate and lanthanum pyrochlores are expected to grow at twice the market rate due to their superior thermal cycling resistance properties.

Current TBC Ceramic Technologies and Challenges

Thermal Barrier Coatings (TBCs) represent a critical technology in high-temperature applications, particularly in gas turbine engines for aerospace and power generation. The current state-of-the-art TBC systems typically employ a multilayer structure consisting of a metallic bond coat, a thermally grown oxide (TGO) layer, and a ceramic top coat. The most widely used ceramic material for TBCs is yttria-stabilized zirconia (YSZ), typically containing 7-8 wt% Y2O3, which offers an optimal combination of low thermal conductivity, relatively high coefficient of thermal expansion, and phase stability.

Despite the widespread adoption of YSZ, this material faces significant limitations under extreme thermal cycling conditions. When exposed to temperatures exceeding 1200°C for extended periods, YSZ undergoes phase transformations from the metastable tetragonal (t') phase to the equilibrium tetragonal and cubic phases, which subsequently transform to monoclinic upon cooling. This phase transformation is accompanied by a volume change of approximately 3-5%, leading to cracking and spallation of the coating.

Another major challenge for current TBC ceramics is sintering at elevated temperatures, which causes densification of the microstructure, elimination of porosity, and consequently increases thermal conductivity. This significantly compromises the thermal insulation capability of the coating system. Additionally, calcium-magnesium-alumino-silicate (CMAS) infiltration presents a severe degradation mechanism for TBCs operating in environments containing siliceous minerals, such as desert sand or volcanic ash.

Recent developments have focused on alternative ceramic materials to overcome these limitations. Gadolinium zirconate (Gd2Zr2O7) and other rare-earth zirconates have demonstrated superior phase stability and CMAS resistance compared to YSZ, but suffer from lower fracture toughness and thermal expansion mismatch with the underlying substrate. Lanthanum-based ceramics, such as lanthanum hexaaluminate (LHA), offer excellent high-temperature stability but present processing challenges for conventional deposition methods.

Multilayer and functionally graded TBC designs have emerged as promising approaches to combine the beneficial properties of different ceramic materials. For instance, a double-layer system with YSZ as the inner layer and gadolinium zirconate as the outer layer can provide both good mechanical properties and enhanced CMAS resistance. However, interfacial stresses between dissimilar materials remain a significant concern under thermal cycling conditions.

Advanced processing techniques, including suspension plasma spray (SPS) and solution precursor plasma spray (SPPS), are being explored to create tailored microstructures with enhanced strain tolerance and reduced thermal conductivity. These methods allow for the introduction of engineered porosity and crack networks that can accommodate thermal expansion mismatch stresses during cycling.

Despite the widespread adoption of YSZ, this material faces significant limitations under extreme thermal cycling conditions. When exposed to temperatures exceeding 1200°C for extended periods, YSZ undergoes phase transformations from the metastable tetragonal (t') phase to the equilibrium tetragonal and cubic phases, which subsequently transform to monoclinic upon cooling. This phase transformation is accompanied by a volume change of approximately 3-5%, leading to cracking and spallation of the coating.

Another major challenge for current TBC ceramics is sintering at elevated temperatures, which causes densification of the microstructure, elimination of porosity, and consequently increases thermal conductivity. This significantly compromises the thermal insulation capability of the coating system. Additionally, calcium-magnesium-alumino-silicate (CMAS) infiltration presents a severe degradation mechanism for TBCs operating in environments containing siliceous minerals, such as desert sand or volcanic ash.

Recent developments have focused on alternative ceramic materials to overcome these limitations. Gadolinium zirconate (Gd2Zr2O7) and other rare-earth zirconates have demonstrated superior phase stability and CMAS resistance compared to YSZ, but suffer from lower fracture toughness and thermal expansion mismatch with the underlying substrate. Lanthanum-based ceramics, such as lanthanum hexaaluminate (LHA), offer excellent high-temperature stability but present processing challenges for conventional deposition methods.

Multilayer and functionally graded TBC designs have emerged as promising approaches to combine the beneficial properties of different ceramic materials. For instance, a double-layer system with YSZ as the inner layer and gadolinium zirconate as the outer layer can provide both good mechanical properties and enhanced CMAS resistance. However, interfacial stresses between dissimilar materials remain a significant concern under thermal cycling conditions.

Advanced processing techniques, including suspension plasma spray (SPS) and solution precursor plasma spray (SPPS), are being explored to create tailored microstructures with enhanced strain tolerance and reduced thermal conductivity. These methods allow for the introduction of engineered porosity and crack networks that can accommodate thermal expansion mismatch stresses during cycling.

State-of-the-Art TBC Ceramic Solutions

01 Ceramic material compositions for thermal barrier coatings

Various ceramic materials are used in thermal barrier coatings to enhance thermal cycling resistance. These include yttria-stabilized zirconia (YSZ), gadolinium zirconate, and other rare earth element-based ceramics. The specific composition of these ceramics significantly affects their thermal cycling performance, with certain formulations offering superior resistance to thermal fatigue and spallation during repeated heating and cooling cycles.- Ceramic material composition for thermal barrier coatings: Various ceramic materials are used in thermal barrier coatings to enhance thermal cycling resistance. These include yttria-stabilized zirconia (YSZ), gadolinium zirconate, and other rare earth element-based ceramics. The specific composition of these ceramics significantly affects their thermal cycling performance, with certain formulations providing superior resistance to thermal stress and strain during cycling. Optimized ceramic compositions can prevent crack propagation and spallation under extreme temperature fluctuations.

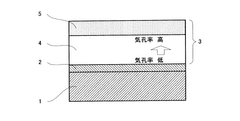

- Multi-layer coating structures for improved thermal cycling resistance: Multi-layered thermal barrier coating systems incorporate different ceramic layers with complementary properties to enhance thermal cycling resistance. These systems typically include a bond coat, a thermally grown oxide layer, and one or more ceramic top coats. The layered structure helps accommodate thermal expansion mismatches between the substrate and coating, distributes thermal stresses, and prevents crack propagation across the entire coating thickness. Gradient or segmented structures can further improve performance by creating smoother transitions between materials with different thermal expansion coefficients.

- Deposition methods affecting thermal cycling performance: The method used to deposit ceramic thermal barrier coatings significantly impacts their thermal cycling resistance. Techniques such as electron beam physical vapor deposition (EB-PVD), air plasma spray (APS), solution precursor plasma spray, and suspension plasma spray produce coatings with different microstructures. EB-PVD typically creates columnar structures that accommodate strain better during thermal cycling, while optimized plasma spray parameters can create beneficial porosity distributions. The deposition parameters control critical features like porosity level, pore distribution, and interfacial characteristics that determine thermal cycling durability.

- Microstructural design for enhanced thermal cycling resistance: Engineered microstructures in ceramic thermal barrier coatings can significantly improve thermal cycling resistance. Features such as controlled porosity, segmentation cracks, and columnar structures allow for strain tolerance during thermal expansion and contraction. Vertically aligned pores or cracks can accommodate strain without compromising the coating integrity, while horizontally oriented features can disrupt crack propagation paths. Advanced microstructural designs include feathery structures, nano-sized grains, and deliberately introduced discontinuities that enhance the coating's ability to withstand repeated thermal cycling without failure.

- Additives and dopants for improved thermal cycling durability: Incorporating specific additives and dopants into ceramic thermal barrier coatings can significantly enhance their thermal cycling resistance. Elements such as lanthanum, gadolinium, ytterbium, and other rare earth elements can stabilize crystal structures at high temperatures. These additives modify the sintering behavior, phase stability, and thermal expansion characteristics of the coating. Some dopants create beneficial defect structures that improve toughness and crack resistance, while others form secondary phases that can heal microcracks during thermal cycling, extending the overall service life of the coating system.

02 Multi-layer coating structures for improved thermal cycling

Multi-layered thermal barrier coating systems provide enhanced thermal cycling resistance through the strategic arrangement of different ceramic materials. These systems typically include a bond coat, a thermally grown oxide layer, and a ceramic top coat. The interfaces between these layers are engineered to accommodate thermal expansion mismatches and reduce stress accumulation during thermal cycling, thereby improving overall coating durability and longevity.Expand Specific Solutions03 Deposition techniques for enhanced coating performance

Various deposition methods are employed to create thermal barrier coatings with superior thermal cycling resistance. These include electron beam physical vapor deposition (EB-PVD), plasma spraying, and solution precursor plasma spraying. Each technique produces coatings with distinct microstructures that influence thermal cycling behavior. For instance, EB-PVD typically creates columnar structures that better accommodate thermal expansion, while plasma spraying can create porous structures that reduce thermal conductivity.Expand Specific Solutions04 Microstructure engineering for thermal cycling resistance

The microstructure of ceramic thermal barrier coatings significantly impacts their thermal cycling resistance. Engineered features such as controlled porosity, segmentation cracks, and columnar structures help accommodate thermal expansion stresses. Advanced microstructural designs incorporate strain-tolerant features that allow the coating to flex during thermal cycling without developing catastrophic cracks, thereby extending the coating's operational life under severe thermal cycling conditions.Expand Specific Solutions05 Novel ceramic compositions and additives for improved performance

Research has led to the development of novel ceramic compositions and additives that enhance thermal cycling resistance. These include rare earth zirconates, pyrochlore structures, and composite ceramics with tailored thermal expansion coefficients. Additionally, certain dopants and sintering aids are incorporated to improve phase stability and reduce sintering rates at high temperatures, which helps maintain the coating's protective properties during repeated thermal cycling.Expand Specific Solutions

Leading Companies and Research Institutions in TBC Field

The thermal barrier coatings (TBC) ceramics market under high thermal cycling conditions is in a growth phase, driven by increasing demands in aerospace, power generation, and automotive sectors. The global market is expanding significantly due to advancements in coating technologies and rising applications in high-temperature environments. Leading players include established industrial giants like Siemens Energy, General Electric, Mitsubishi Heavy Industries, and Praxair S.T. Technology, who possess mature TBC technologies. Academic institutions such as Beihang University and Harbin Institute of Technology are contributing significant research innovations. The technology is approaching maturity in traditional applications but continues to evolve with new ceramic compositions and deposition methods being developed to withstand increasingly extreme thermal cycling conditions.

General Electric Company

Technical Solution: GE has developed advanced thermal barrier coating (TBC) systems utilizing yttria-stabilized zirconia (YSZ) with enhanced strain tolerance through sophisticated microstructural engineering. Their proprietary electron beam physical vapor deposition (EB-PVD) process creates columnar microstructures that significantly improve coating durability under extreme thermal cycling conditions. GE's research has focused on developing multi-layered TBC systems with gradient compositions that better accommodate thermal expansion mismatches between the ceramic top coat and metallic substrate. Their recent innovations include rare-earth doped zirconia compositions that demonstrate up to 2x improvement in thermal cycling lifetime compared to conventional YSZ coatings, and advanced bond coat systems that enhance oxidation resistance at temperatures exceeding 1200°C.

Strengths: Industry-leading manufacturing capabilities for complex TBC systems; extensive field testing data from gas turbine applications; proprietary composition formulations with superior thermal cycling resistance. Weaknesses: Higher production costs compared to conventional plasma spray methods; limited public disclosure of specific material compositions due to IP protection.

Mitsubishi Heavy Industries, Ltd.

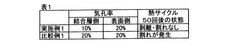

Technical Solution: Mitsubishi Heavy Industries has pioneered advanced thermal barrier coating systems utilizing gadolinia-stabilized zirconia (GdZ) that demonstrates superior phase stability under extreme thermal cycling conditions. Their research has focused on developing ceramic compositions with lower thermal conductivity and enhanced sintering resistance, achieving approximately 20% reduction in thermal conductivity compared to conventional YSZ coatings. MHI employs a hybrid manufacturing approach combining atmospheric plasma spraying (APS) with controlled segmentation techniques to create microcrack networks that accommodate thermal expansion stresses. Their latest generation of TBCs incorporates nanoscale dispersed oxide particles within the ceramic matrix, which act as anchoring sites to inhibit crack propagation during thermal cycling, resulting in coatings that maintain structural integrity for over 1000 cycles under conditions simulating industrial gas turbine operation.

Strengths: Excellent thermal cycling durability in high-temperature steam environments; cost-effective manufacturing processes suitable for large components; strong integration with turbine design teams. Weaknesses: Relatively higher porosity levels may compromise erosion resistance; technology primarily optimized for power generation rather than aerospace applications.

Critical Patents and Research on Thermal Cycling Resistance

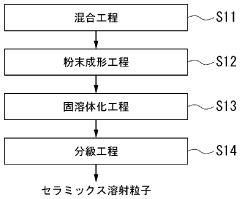

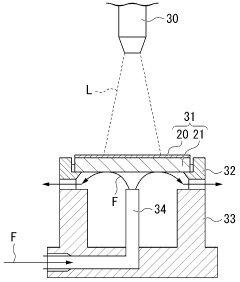

Ceramic thermal spray particles and method for forming thermal barrier coating layer

PatentWO2023248784A1

Innovation

- The method involves forming ceramic spray particles composed of ZrO2 and Yb2O3 with a standard deviation of 2% to 7% by mass, which are then used to create a thermal barrier coating layer with a metal bonding layer, achieving low thermal conductivity and enhanced thermal cycle durability through specific manufacturing processes like plasma spraying.

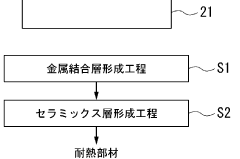

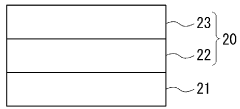

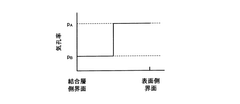

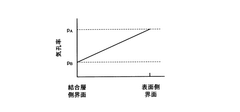

Thermal barrier coating and power generation system

PatentWO2016147282A1

Innovation

- A thermal barrier coating with a ceramic layer and a bonding layer, where the porosity increases from the bonding layer side interface to the surface side interface, reducing thermal expansion differences and shear stress, thereby enhancing durability and preventing cracking and peeling.

Environmental Impact and Sustainability Considerations

The environmental impact of thermal barrier coating (TBC) ceramics under high thermal cycling conditions extends beyond their primary function of thermal protection. As these coatings are increasingly deployed in high-temperature applications such as gas turbines and aerospace components, their environmental footprint throughout their lifecycle becomes a critical consideration for sustainable engineering practices.

Manufacturing processes for advanced ceramic TBCs typically involve energy-intensive methods such as plasma spraying, electron beam physical vapor deposition (EB-PVD), or solution precursor plasma spraying. These processes consume significant energy and may release harmful emissions, particularly when producing complex compositions like yttria-stabilized zirconia (YSZ) or gadolinium zirconate. Optimization of these manufacturing techniques to reduce energy consumption represents a key sustainability challenge.

Raw material extraction for TBC ceramics presents another environmental concern. Rare earth elements commonly used in advanced TBCs, such as yttrium, gadolinium, and lanthanum, involve mining operations with substantial environmental impacts including habitat disruption, water pollution, and energy-intensive processing. The geopolitical concentration of these resources further complicates sustainable sourcing strategies.

During service life, TBCs contribute positively to environmental sustainability by improving thermal efficiency in combustion systems. By enabling higher operating temperatures in gas turbines, these coatings facilitate reduced fuel consumption and lower CO2 emissions. Research indicates that advanced TBCs can improve turbine efficiency by 1-2%, translating to significant emission reductions in large-scale applications.

End-of-life considerations for TBC components present unique challenges. The composite nature of coated components—typically involving metallic substrates, bond coats, and ceramic top coats—complicates recycling efforts. Current disposal practices often result in landfilling of spent components, representing a loss of valuable materials and potential environmental contamination.

Emerging research directions include development of more environmentally benign coating compositions that maintain performance under high thermal cycling conditions while reducing dependence on critical raw materials. Bio-inspired ceramic structures and novel processing routes that minimize energy consumption show promise for reducing environmental impact while maintaining or enhancing coating performance.

Life cycle assessment (LCA) studies specifically targeting TBC systems under high thermal cycling conditions remain limited. Comprehensive cradle-to-grave analyses are needed to quantify environmental tradeoffs between manufacturing impacts and in-service benefits, particularly as coating compositions evolve to meet increasingly demanding thermal cycling requirements.

Manufacturing processes for advanced ceramic TBCs typically involve energy-intensive methods such as plasma spraying, electron beam physical vapor deposition (EB-PVD), or solution precursor plasma spraying. These processes consume significant energy and may release harmful emissions, particularly when producing complex compositions like yttria-stabilized zirconia (YSZ) or gadolinium zirconate. Optimization of these manufacturing techniques to reduce energy consumption represents a key sustainability challenge.

Raw material extraction for TBC ceramics presents another environmental concern. Rare earth elements commonly used in advanced TBCs, such as yttrium, gadolinium, and lanthanum, involve mining operations with substantial environmental impacts including habitat disruption, water pollution, and energy-intensive processing. The geopolitical concentration of these resources further complicates sustainable sourcing strategies.

During service life, TBCs contribute positively to environmental sustainability by improving thermal efficiency in combustion systems. By enabling higher operating temperatures in gas turbines, these coatings facilitate reduced fuel consumption and lower CO2 emissions. Research indicates that advanced TBCs can improve turbine efficiency by 1-2%, translating to significant emission reductions in large-scale applications.

End-of-life considerations for TBC components present unique challenges. The composite nature of coated components—typically involving metallic substrates, bond coats, and ceramic top coats—complicates recycling efforts. Current disposal practices often result in landfilling of spent components, representing a loss of valuable materials and potential environmental contamination.

Emerging research directions include development of more environmentally benign coating compositions that maintain performance under high thermal cycling conditions while reducing dependence on critical raw materials. Bio-inspired ceramic structures and novel processing routes that minimize energy consumption show promise for reducing environmental impact while maintaining or enhancing coating performance.

Life cycle assessment (LCA) studies specifically targeting TBC systems under high thermal cycling conditions remain limited. Comprehensive cradle-to-grave analyses are needed to quantify environmental tradeoffs between manufacturing impacts and in-service benefits, particularly as coating compositions evolve to meet increasingly demanding thermal cycling requirements.

Aerospace and Energy Industry Implementation Case Studies

The aerospace industry has been at the forefront of implementing thermal barrier coatings (TBCs) under high thermal cycling conditions, with NASA and ESA pioneering advanced ceramic coatings for space shuttle heat shields and rocket engine components. These implementations have demonstrated remarkable durability, with some coatings withstanding over 1,000 thermal cycles between -150°C and 1,300°C during reentry simulations. The success of these applications has led to widespread adoption in commercial aviation, where GE Aviation and Rolls-Royce have incorporated yttria-stabilized zirconia (YSZ) coatings into high-pressure turbine blades, extending component life by up to 300% and enabling higher operating temperatures.

In parallel, the energy sector has leveraged similar technologies for gas turbine applications. Siemens Energy's implementation of multi-layered ceramic TBCs in their SGT-8000H series gas turbines has resulted in efficiency improvements of 2-3 percentage points while reducing NOx emissions by approximately 25%. These coatings, specifically engineered to withstand the harsh thermal cycling of daily start-stop operations, have demonstrated an average lifespan extension of 15,000 hours between major overhauls.

A particularly noteworthy case study comes from Mitsubishi Power's J-series gas turbines, where gadolinium zirconate-based TBCs have been implemented to withstand temperatures exceeding 1,600°C. Field data collected over five years of operation shows these coatings maintain structural integrity after more than 500 start-stop cycles, significantly outperforming previous generation materials.

In the concentrated solar power (CSP) sector, Abengoa Solar has implemented ceramic TBCs on receiver tubes that experience extreme daily thermal cycling. These specialized coatings have improved solar-to-electricity conversion efficiency by 7% while extending receiver tube life from 3 to 7 years under harsh desert conditions with temperature fluctuations of over 500°C daily.

The nuclear industry has also adopted TBCs for accident-tolerant fuel cladding, with Westinghouse Electric Company's implementation of chromia-doped YSZ coatings showing promising results in simulated loss-of-coolant scenarios. Testing at Idaho National Laboratory demonstrated these coatings can withstand over 300 thermal shock cycles between 300°C and 1,200°C while maintaining structural integrity and preventing hydrogen generation.

These case studies collectively demonstrate the cross-industry value of advanced ceramic TBCs, with implementations consistently showing improvements in efficiency, component longevity, and system reliability under high thermal cycling conditions.

In parallel, the energy sector has leveraged similar technologies for gas turbine applications. Siemens Energy's implementation of multi-layered ceramic TBCs in their SGT-8000H series gas turbines has resulted in efficiency improvements of 2-3 percentage points while reducing NOx emissions by approximately 25%. These coatings, specifically engineered to withstand the harsh thermal cycling of daily start-stop operations, have demonstrated an average lifespan extension of 15,000 hours between major overhauls.

A particularly noteworthy case study comes from Mitsubishi Power's J-series gas turbines, where gadolinium zirconate-based TBCs have been implemented to withstand temperatures exceeding 1,600°C. Field data collected over five years of operation shows these coatings maintain structural integrity after more than 500 start-stop cycles, significantly outperforming previous generation materials.

In the concentrated solar power (CSP) sector, Abengoa Solar has implemented ceramic TBCs on receiver tubes that experience extreme daily thermal cycling. These specialized coatings have improved solar-to-electricity conversion efficiency by 7% while extending receiver tube life from 3 to 7 years under harsh desert conditions with temperature fluctuations of over 500°C daily.

The nuclear industry has also adopted TBCs for accident-tolerant fuel cladding, with Westinghouse Electric Company's implementation of chromia-doped YSZ coatings showing promising results in simulated loss-of-coolant scenarios. Testing at Idaho National Laboratory demonstrated these coatings can withstand over 300 thermal shock cycles between 300°C and 1,200°C while maintaining structural integrity and preventing hydrogen generation.

These case studies collectively demonstrate the cross-industry value of advanced ceramic TBCs, with implementations consistently showing improvements in efficiency, component longevity, and system reliability under high thermal cycling conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!