How microstructure affects durability of thermal barrier coatings ceramics

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Barrier Coatings Microstructure Evolution and Objectives

Thermal barrier coatings (TBCs) have evolved significantly over the past five decades, transitioning from simple protective layers to sophisticated multi-layered systems engineered at the microstructural level. Initially developed in the 1970s for aerospace applications, TBCs have become critical components in gas turbines, diesel engines, and various high-temperature industrial applications. The evolution of these coatings has been driven by the increasing demand for higher operating temperatures in energy generation and propulsion systems, as higher temperatures directly correlate with improved thermodynamic efficiency.

The microstructural development of TBCs has followed several distinct technological waves. Early generations featured relatively simple structures with limited temperature capabilities (typically below 1000°C). Current state-of-the-art systems incorporate complex columnar structures, engineered porosity, and multi-layered architectures capable of withstanding temperatures exceeding 1300°C while maintaining structural integrity under extreme thermal cycling conditions.

Recent advancements in TBC technology have focused on nano-engineered microstructures, including the development of strain-tolerant features such as vertical cracks, segmentation patterns, and controlled porosity distributions. These innovations have significantly enhanced coating durability by accommodating thermal expansion mismatches and reducing stress accumulation during thermal cycling. Additionally, the incorporation of rare earth elements has led to improved phase stability and sintering resistance, addressing key degradation mechanisms that previously limited coating lifespans.

The primary objective of current TBC research is to develop microstructures that can simultaneously address multiple failure mechanisms, including thermal fatigue, oxidation, hot corrosion, erosion, and CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration. This requires a fundamental understanding of how microstructural features—such as grain size, porosity distribution, interface characteristics, and phase composition—evolve under service conditions and how these evolutions ultimately affect coating durability.

Looking forward, the field is moving toward predictive design approaches that leverage computational modeling to engineer microstructures with tailored properties. The integration of machine learning algorithms with materials science principles is enabling researchers to explore vast design spaces and identify optimal microstructural configurations that maximize durability under specific operating conditions. This represents a paradigm shift from traditional empirical development methods to knowledge-based design strategies.

The ultimate goal is to develop TBCs with "self-healing" capabilities and adaptive microstructures that can respond dynamically to changing environmental conditions, potentially doubling or tripling the current service life of these critical components while enabling even higher operating temperatures for next-generation energy systems.

The microstructural development of TBCs has followed several distinct technological waves. Early generations featured relatively simple structures with limited temperature capabilities (typically below 1000°C). Current state-of-the-art systems incorporate complex columnar structures, engineered porosity, and multi-layered architectures capable of withstanding temperatures exceeding 1300°C while maintaining structural integrity under extreme thermal cycling conditions.

Recent advancements in TBC technology have focused on nano-engineered microstructures, including the development of strain-tolerant features such as vertical cracks, segmentation patterns, and controlled porosity distributions. These innovations have significantly enhanced coating durability by accommodating thermal expansion mismatches and reducing stress accumulation during thermal cycling. Additionally, the incorporation of rare earth elements has led to improved phase stability and sintering resistance, addressing key degradation mechanisms that previously limited coating lifespans.

The primary objective of current TBC research is to develop microstructures that can simultaneously address multiple failure mechanisms, including thermal fatigue, oxidation, hot corrosion, erosion, and CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration. This requires a fundamental understanding of how microstructural features—such as grain size, porosity distribution, interface characteristics, and phase composition—evolve under service conditions and how these evolutions ultimately affect coating durability.

Looking forward, the field is moving toward predictive design approaches that leverage computational modeling to engineer microstructures with tailored properties. The integration of machine learning algorithms with materials science principles is enabling researchers to explore vast design spaces and identify optimal microstructural configurations that maximize durability under specific operating conditions. This represents a paradigm shift from traditional empirical development methods to knowledge-based design strategies.

The ultimate goal is to develop TBCs with "self-healing" capabilities and adaptive microstructures that can respond dynamically to changing environmental conditions, potentially doubling or tripling the current service life of these critical components while enabling even higher operating temperatures for next-generation energy systems.

Market Analysis for High-Durability TBC Applications

The global market for Thermal Barrier Coatings (TBCs) continues to expand significantly, driven primarily by the aerospace, power generation, and automotive industries. Current market valuations place the TBC sector at approximately 1.5 billion USD, with projections indicating growth to reach 2.3 billion USD by 2028, representing a compound annual growth rate of 7.4%. This growth trajectory is particularly pronounced in regions with established aerospace and energy infrastructure, including North America, Western Europe, and increasingly, East Asia.

High-durability TBCs represent a premium segment within this market, commanding higher price points due to their extended service life and superior performance characteristics. The aerospace sector remains the dominant consumer, accounting for roughly 45% of high-durability TBC applications, followed by industrial gas turbines at 30% and automotive applications at 15%.

Market demand for enhanced TBC durability is being driven by several converging factors. First, the continuous push for higher operating temperatures in gas turbines to improve thermodynamic efficiency has created demand for coatings capable of withstanding more extreme thermal conditions. Modern turbine engines now routinely operate at temperatures exceeding 1400°C, necessitating TBCs with superior thermal stability and microstructural integrity.

Second, maintenance cost reduction has emerged as a critical market driver. The replacement of turbine components represents a significant operational expense for end-users, with some estimates suggesting that coating-related maintenance accounts for up to 30% of total engine maintenance costs in commercial aviation. Coatings with improved durability directly translate to extended service intervals and reduced lifecycle costs.

Third, environmental regulations are increasingly influencing market dynamics. Stringent emissions standards are pushing manufacturers toward more efficient combustion processes, which typically involve higher operating temperatures. This regulatory pressure creates additional demand for advanced TBCs with enhanced durability characteristics.

The market exhibits notable regional variations in adoption patterns. North American and European markets typically prioritize performance characteristics and lifecycle cost benefits, while emerging markets in Asia often balance performance requirements against initial acquisition costs. This regional differentiation has led to the development of tiered product offerings by major suppliers, with premium high-durability solutions targeted at mature markets and more cost-effective alternatives for price-sensitive regions.

Customer requirements are increasingly focused on demonstrable improvements in coating lifespan, with particular emphasis on resistance to thermal cycling fatigue, oxidation protection, and erosion resistance. These performance metrics directly correlate with microstructural characteristics, creating market pull for advanced manufacturing techniques that can precisely control coating microstructure.

High-durability TBCs represent a premium segment within this market, commanding higher price points due to their extended service life and superior performance characteristics. The aerospace sector remains the dominant consumer, accounting for roughly 45% of high-durability TBC applications, followed by industrial gas turbines at 30% and automotive applications at 15%.

Market demand for enhanced TBC durability is being driven by several converging factors. First, the continuous push for higher operating temperatures in gas turbines to improve thermodynamic efficiency has created demand for coatings capable of withstanding more extreme thermal conditions. Modern turbine engines now routinely operate at temperatures exceeding 1400°C, necessitating TBCs with superior thermal stability and microstructural integrity.

Second, maintenance cost reduction has emerged as a critical market driver. The replacement of turbine components represents a significant operational expense for end-users, with some estimates suggesting that coating-related maintenance accounts for up to 30% of total engine maintenance costs in commercial aviation. Coatings with improved durability directly translate to extended service intervals and reduced lifecycle costs.

Third, environmental regulations are increasingly influencing market dynamics. Stringent emissions standards are pushing manufacturers toward more efficient combustion processes, which typically involve higher operating temperatures. This regulatory pressure creates additional demand for advanced TBCs with enhanced durability characteristics.

The market exhibits notable regional variations in adoption patterns. North American and European markets typically prioritize performance characteristics and lifecycle cost benefits, while emerging markets in Asia often balance performance requirements against initial acquisition costs. This regional differentiation has led to the development of tiered product offerings by major suppliers, with premium high-durability solutions targeted at mature markets and more cost-effective alternatives for price-sensitive regions.

Customer requirements are increasingly focused on demonstrable improvements in coating lifespan, with particular emphasis on resistance to thermal cycling fatigue, oxidation protection, and erosion resistance. These performance metrics directly correlate with microstructural characteristics, creating market pull for advanced manufacturing techniques that can precisely control coating microstructure.

Current Challenges in TBC Microstructural Engineering

Despite significant advancements in thermal barrier coating (TBC) technology, several critical challenges persist in microstructural engineering that limit the durability and performance of these ceramic systems. The primary challenge involves controlling the formation and evolution of microstructural defects during manufacturing processes. Conventional plasma spraying and electron beam physical vapor deposition (EB-PVD) techniques often introduce inconsistent porosity distributions, microcracks, and interfacial irregularities that become failure initiation sites during thermal cycling.

The optimization of strain tolerance mechanisms presents another significant hurdle. While columnar structures in EB-PVD coatings offer superior strain accommodation, they typically exhibit lower thermal insulation efficiency compared to more porous air plasma spray (APS) coatings. Engineering microstructures that simultaneously maximize both strain tolerance and thermal resistance remains elusive, particularly as coating systems are pushed to operate at increasingly higher temperatures.

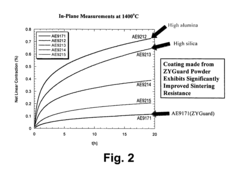

Phase stability at elevated temperatures constitutes a persistent challenge. The transformation of metastable tetragonal zirconia to monoclinic phase during thermal cycling induces volume changes of approximately 3-5%, generating destructive stresses within the coating. Although yttria stabilization mitigates this issue partially, long-term exposure to extreme temperatures still triggers phase segregation and destabilization, particularly at grain boundaries where elemental diffusion is accelerated.

Interfacial degradation mechanisms between the ceramic topcoat and metallic bond coat represent another critical concern. The thermally grown oxide (TGO) layer that forms at this interface grows progressively during service, creating stress concentrations that lead to spallation failure. Controlling the microstructural features that influence TGO growth kinetics and adhesion properties remains challenging, especially when considering the complex chemical interactions occurring at these interfaces.

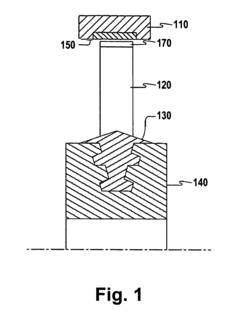

Sintering-induced densification during high-temperature exposure progressively eliminates the beneficial porosity network within TBCs, compromising strain tolerance and thermal insulation properties. Current microstructural designs struggle to maintain stable pore architectures throughout the coating lifetime, particularly in next-generation TBCs designed for temperatures exceeding 1200°C.

The integration of multi-functional capabilities into TBC microstructures presents additional complexity. Modern applications demand coatings that simultaneously provide thermal protection, erosion resistance, CMAS (calcium-magnesium-alumino-silicate) infiltration resistance, and self-healing capabilities. Engineering hierarchical microstructures that can accommodate these sometimes competing requirements without compromising the primary thermal barrier function remains a significant technical challenge.

The optimization of strain tolerance mechanisms presents another significant hurdle. While columnar structures in EB-PVD coatings offer superior strain accommodation, they typically exhibit lower thermal insulation efficiency compared to more porous air plasma spray (APS) coatings. Engineering microstructures that simultaneously maximize both strain tolerance and thermal resistance remains elusive, particularly as coating systems are pushed to operate at increasingly higher temperatures.

Phase stability at elevated temperatures constitutes a persistent challenge. The transformation of metastable tetragonal zirconia to monoclinic phase during thermal cycling induces volume changes of approximately 3-5%, generating destructive stresses within the coating. Although yttria stabilization mitigates this issue partially, long-term exposure to extreme temperatures still triggers phase segregation and destabilization, particularly at grain boundaries where elemental diffusion is accelerated.

Interfacial degradation mechanisms between the ceramic topcoat and metallic bond coat represent another critical concern. The thermally grown oxide (TGO) layer that forms at this interface grows progressively during service, creating stress concentrations that lead to spallation failure. Controlling the microstructural features that influence TGO growth kinetics and adhesion properties remains challenging, especially when considering the complex chemical interactions occurring at these interfaces.

Sintering-induced densification during high-temperature exposure progressively eliminates the beneficial porosity network within TBCs, compromising strain tolerance and thermal insulation properties. Current microstructural designs struggle to maintain stable pore architectures throughout the coating lifetime, particularly in next-generation TBCs designed for temperatures exceeding 1200°C.

The integration of multi-functional capabilities into TBC microstructures presents additional complexity. Modern applications demand coatings that simultaneously provide thermal protection, erosion resistance, CMAS (calcium-magnesium-alumino-silicate) infiltration resistance, and self-healing capabilities. Engineering hierarchical microstructures that can accommodate these sometimes competing requirements without compromising the primary thermal barrier function remains a significant technical challenge.

Contemporary Microstructure-Durability Correlation Approaches

01 Ceramic composition for thermal barrier coatings

Various ceramic compositions can be used in thermal barrier coatings to enhance durability. These include yttria-stabilized zirconia (YSZ), rare earth oxides, and other advanced ceramic materials that provide excellent thermal insulation properties. The specific composition of these ceramics significantly affects the coating's resistance to thermal cycling, oxidation, and mechanical stress, thereby improving the overall durability of the thermal barrier system.- Composition of ceramic thermal barrier coatings: Ceramic materials such as yttria-stabilized zirconia (YSZ) are commonly used in thermal barrier coatings due to their excellent thermal insulation properties. These coatings typically consist of a ceramic top coat and a metallic bond coat. The composition of the ceramic material significantly affects the durability of the coating, with various additives and stabilizers being incorporated to enhance performance under high-temperature conditions. Advanced ceramic compositions may include rare earth oxides or complex oxide systems to improve phase stability and thermal cycling resistance.

- Microstructure engineering for enhanced durability: The microstructure of ceramic thermal barrier coatings plays a crucial role in determining their durability. Engineered porosity, columnar structures, and controlled grain boundaries can significantly enhance strain tolerance and thermal shock resistance. Advanced processing techniques are employed to create specific microstructures that can accommodate thermal expansion mismatch between the coating and substrate. Nano-structured ceramics and layered architectures are developed to improve erosion resistance and extend coating lifetime under severe operating conditions.

- Novel deposition techniques for improved coating performance: Various deposition methods are utilized to apply ceramic thermal barrier coatings with enhanced durability characteristics. These include electron beam physical vapor deposition (EB-PVD), plasma spraying, solution precursor plasma spray, and suspension plasma spray. Each technique produces coatings with distinct microstructural features that affect thermal cycling behavior, erosion resistance, and overall durability. Advanced deposition processes can create strain-tolerant structures or graded compositions that better withstand thermal and mechanical stresses during service.

- Environmental barrier additions for harsh operating conditions: To enhance durability in harsh operating environments, thermal barrier coatings are often modified with environmental barrier components. These additions protect against degradation mechanisms such as calcium-magnesium-alumino-silicate (CMAS) infiltration, hot corrosion, and oxidation. Rare earth silicates, alumina, and other protective oxides can be incorporated into the coating system to react with environmental contaminants and form protective reaction products. These modifications significantly extend coating lifetime in applications exposed to volcanic ash, sea salt, or industrial contaminants.

- Bond coat optimization and interface engineering: The durability of ceramic thermal barrier coatings is heavily influenced by the properties of the bond coat and the interfaces within the coating system. Advanced bond coat compositions, such as MCrAlY alloys or platinum-modified aluminides, are developed to improve adhesion and oxidation resistance. Interface engineering techniques, including the creation of thermally grown oxide layers with controlled growth rates and the addition of interlayers with specific compositions, help mitigate spallation failure mechanisms. These approaches address the critical weak points in thermal barrier coating systems, significantly enhancing overall durability and service life.

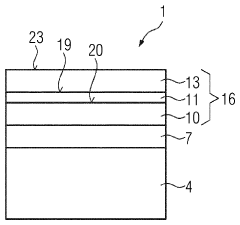

02 Multilayer coating structures for enhanced durability

Multilayer thermal barrier coating systems incorporate different ceramic layers with complementary properties to enhance overall durability. These systems typically include a bond coat, a thermally grown oxide layer, and one or more ceramic top coats. The multilayer structure helps distribute thermal stresses, improve adhesion, and provide better protection against environmental degradation, resulting in significantly extended service life under extreme temperature conditions.Expand Specific Solutions03 Deposition methods affecting coating durability

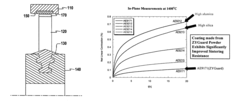

The method used to deposit ceramic thermal barrier coatings significantly impacts their durability. Techniques such as electron beam physical vapor deposition (EB-PVD), plasma spraying, and solution precursor plasma spray create different microstructures that affect strain tolerance, thermal cycling resistance, and erosion resistance. Advanced deposition methods can produce columnar structures or controlled porosity that enhance the coating's ability to withstand thermal shock and mechanical stresses.Expand Specific Solutions04 Surface treatments and interface engineering

Surface treatments and interface engineering techniques are employed to enhance the durability of ceramic thermal barrier coatings. These include laser surface modification, grit blasting, chemical treatments, and the creation of engineered interfaces between coating layers. Such treatments improve adhesion, reduce interfacial stresses, and enhance resistance to spallation and delamination, thereby extending the service life of the thermal barrier coating system under extreme operating conditions.Expand Specific Solutions05 Additives and dopants for enhanced thermal stability

Incorporating specific additives and dopants into ceramic thermal barrier coatings can significantly enhance their thermal stability and durability. Elements such as rare earth oxides, tantalum, hafnium, and silicon-based compounds can be added to the ceramic matrix to inhibit sintering, improve phase stability, and enhance resistance to calcium-magnesium-alumino-silicate (CMAS) infiltration. These additives help maintain the coating's insulating properties and structural integrity during prolonged exposure to high temperatures.Expand Specific Solutions

Leading Manufacturers and Research Institutions in TBC Industry

The thermal barrier coatings (TBC) ceramics market is in a growth phase, with increasing demand driven by aerospace, power generation, and automotive industries. The global market size is projected to expand significantly due to rising energy efficiency requirements and high-temperature applications. Technologically, the field is advancing rapidly with major players focusing on microstructure optimization to enhance durability. Companies like Siemens Energy, Rolls-Royce, and GE lead commercial applications, while Oerlikon Metco and Honeywell International are advancing coating technologies. Research institutions including Shanghai Jiao Tong University and Beihang University collaborate with industry leaders such as Mitsubishi Heavy Industries and Pratt & Whitney to develop next-generation coatings with improved thermal cycling resistance, oxidation protection, and mechanical stability under extreme conditions.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed sophisticated thermal barrier coating systems with microstructurally engineered ceramics optimized for industrial gas turbine applications. Their technology centers on dense vertically cracked (DVC) microstructures produced through advanced atmospheric plasma spray techniques, creating controlled segmentation patterns that enhance strain compliance while maintaining coating integrity[1]. MHI's research has demonstrated that precise control of crack density (typically 8-12 cracks per cm) and distribution significantly improves thermal cycling durability, with their latest coatings achieving over 3000 cycles before failure in standardized tests. Their proprietary ceramic formulations incorporate lanthanum zirconate and ceria-stabilized zirconia in specific regions to create thermal conductivity gradients through the coating thickness, optimizing thermal protection while managing interfacial stresses[2]. MHI has pioneered microstructural modifications that include nano-scale dispersed phases within the ceramic matrix, which effectively pin grain boundaries and inhibit sintering-induced densification at elevated temperatures. Their coating systems feature carefully engineered interface roughness profiles between the thermally grown oxide layer and ceramic topcoat, with amplitude parameters optimized to balance mechanical adhesion with stress concentration mitigation[3].

Strengths: Dense vertically cracked structure provides excellent balance between thermal insulation and mechanical durability; advanced ceramic formulations resist sintering and phase destabilization; optimized interface engineering enhances coating adhesion and longevity. Weaknesses: Higher oxygen permeability through vertical cracks may accelerate bond coat oxidation; manufacturing consistency challenges across large components; potential for crack network evolution during service affecting long-term performance.

Oerlikon Metco (US), Inc.

Technical Solution: Oerlikon Metco has developed advanced thermal barrier coating systems with engineered microstructures specifically designed to enhance durability in extreme thermal environments. Their technology leverages suspension plasma spray (SPS) processes to create columnar microstructures with controlled inter-columnar spacing and intra-columnar porosity, achieving strain tolerance comparable to EB-PVD coatings but at significantly lower manufacturing costs[1]. Oerlikon's research has established that optimizing the feathery edges of these columns creates mechanical interlocking zones that enhance coating cohesion while maintaining beneficial strain isolation between columns. Their proprietary ceramic formulations incorporate carefully selected dopants that segregate to grain boundaries, effectively inhibiting grain growth and sintering at elevated temperatures, thereby preserving the coating's thermal insulation properties throughout component lifetime[2]. Oerlikon Metco has pioneered hybrid microstructures that combine dense layers with porous regions in specific arrangements to optimize the balance between erosion resistance and thermal insulation. Their latest innovation includes functionally graded structures with porosity gradients (ranging from 5% to 25%) through the coating thickness, creating optimized thermal and mechanical property transitions that significantly enhance thermal cycling durability, with test results showing up to 40% improvement over conventional coatings[3].

Strengths: Cost-effective columnar microstructures provide excellent strain tolerance; hybrid structures optimize balance between thermal insulation and erosion resistance; advanced manufacturing processes allow precise control of microstructural features. Weaknesses: Potential for higher erosion rates in certain columnar structures compared to dense alternatives; manufacturing consistency challenges across complex geometries; possible accelerated degradation in highly contaminated environments.

Critical Patents and Research on TBC Microstructural Enhancement

High purity ceramic abradable coatings

PatentActiveUS7955707B2

Innovation

- A high purity zirconia and/or hafnia-based ceramic coating system with a superalloy substrate and oxidation-resistant bond coat, incorporating a fugitive material for increased porosity and sintering resistance, applied using thermal spray methods to achieve a balanced microstructure and extended service life.

Bilayer thermal barrier coatings with an advanced interface

PatentActiveUS20230383393A1

Innovation

- A ceramic coating system with a partially stabilized Zirconia lower coating and a fully stabilized Zirconia upper coating, enhanced by a rough intermediate coating achieved through adjusting spraying parameters or using coarser particles to increase surface roughness and mechanical interlocking without compromising microstructure.

Environmental Impact and Sustainability of Advanced TBCs

The environmental impact of Thermal Barrier Coatings (TBCs) extends beyond their primary function of thermal protection, encompassing their entire lifecycle from raw material extraction to disposal. Advanced TBCs contribute significantly to sustainability through improved engine efficiency, reduced fuel consumption, and decreased emissions of harmful pollutants such as NOx, CO2, and particulate matter. These environmental benefits are directly linked to the microstructural durability of TBC ceramics.

Microstructurally optimized TBCs enable higher operating temperatures in turbine engines, improving thermodynamic efficiency by 1-2% per 50°C increase. This efficiency gain translates to substantial reductions in fossil fuel consumption and greenhouse gas emissions across aviation, power generation, and industrial sectors. For instance, modern gas turbines with advanced TBCs can achieve up to 15% lower CO2 emissions compared to uncoated systems.

The manufacturing processes for TBCs also present environmental considerations. Traditional methods like Air Plasma Spray (APS) and Electron Beam Physical Vapor Deposition (EB-PVD) consume significant energy and may utilize environmentally problematic materials. Recent innovations in solution precursor plasma spray and suspension plasma spray techniques have reduced energy requirements by approximately 30% while creating microstructures with enhanced durability and longer service life.

Lifecycle assessment studies indicate that the environmental benefits of TBCs outweigh their production impacts by a factor of 5-10 when considering their contribution to efficiency improvements over their operational lifetime. However, end-of-life management remains challenging due to the complex multi-material nature of coated components. The ceramic top coats, typically yttria-stabilized zirconia (YSZ), are not easily recyclable when bonded to metallic substrates.

Emerging research focuses on developing environmentally benign TBC systems with reduced rare earth content, as the mining and processing of these elements carry significant environmental burdens. Alternative compositions utilizing more abundant elements while maintaining microstructural stability are showing promise, with some experimental formulations achieving comparable thermal cycling performance using 40% less rare earth content.

The sustainability of TBCs is further enhanced through microstructural modifications that extend service life. Columnar microstructures with engineered porosity distributions have demonstrated up to 3x longer lifespans in cyclic thermal exposure tests compared to conventional coatings, reducing the frequency of replacement and associated material consumption. This longevity directly correlates with reduced environmental impact through resource conservation and waste minimization.

Microstructurally optimized TBCs enable higher operating temperatures in turbine engines, improving thermodynamic efficiency by 1-2% per 50°C increase. This efficiency gain translates to substantial reductions in fossil fuel consumption and greenhouse gas emissions across aviation, power generation, and industrial sectors. For instance, modern gas turbines with advanced TBCs can achieve up to 15% lower CO2 emissions compared to uncoated systems.

The manufacturing processes for TBCs also present environmental considerations. Traditional methods like Air Plasma Spray (APS) and Electron Beam Physical Vapor Deposition (EB-PVD) consume significant energy and may utilize environmentally problematic materials. Recent innovations in solution precursor plasma spray and suspension plasma spray techniques have reduced energy requirements by approximately 30% while creating microstructures with enhanced durability and longer service life.

Lifecycle assessment studies indicate that the environmental benefits of TBCs outweigh their production impacts by a factor of 5-10 when considering their contribution to efficiency improvements over their operational lifetime. However, end-of-life management remains challenging due to the complex multi-material nature of coated components. The ceramic top coats, typically yttria-stabilized zirconia (YSZ), are not easily recyclable when bonded to metallic substrates.

Emerging research focuses on developing environmentally benign TBC systems with reduced rare earth content, as the mining and processing of these elements carry significant environmental burdens. Alternative compositions utilizing more abundant elements while maintaining microstructural stability are showing promise, with some experimental formulations achieving comparable thermal cycling performance using 40% less rare earth content.

The sustainability of TBCs is further enhanced through microstructural modifications that extend service life. Columnar microstructures with engineered porosity distributions have demonstrated up to 3x longer lifespans in cyclic thermal exposure tests compared to conventional coatings, reducing the frequency of replacement and associated material consumption. This longevity directly correlates with reduced environmental impact through resource conservation and waste minimization.

Failure Mechanism Analysis in TBC Ceramic Systems

Thermal Barrier Coating (TBC) systems exhibit complex failure mechanisms that are intrinsically linked to their microstructural characteristics. The predominant failure modes include spallation, delamination, and progressive degradation, which typically originate from the interplay between thermal cycling, oxidation processes, and mechanical stresses. These failure mechanisms are not isolated events but rather interconnected processes that evolve throughout the service life of the coating.

The thermally grown oxide (TGO) layer formation at the bond coat/ceramic interface represents a critical factor in TBC failure. As this oxide layer grows, it generates significant stress concentrations that can initiate cracks parallel to the interface. The rate and uniformity of TGO growth are directly influenced by the microstructural features of both the ceramic top coat and the underlying bond coat, particularly porosity distribution and grain boundary characteristics.

Sintering-induced densification during thermal cycling constitutes another significant failure mechanism. The initially porous microstructure of plasma-sprayed coatings undergoes gradual densification at elevated temperatures, resulting in increased elastic modulus and thermal conductivity while reducing strain tolerance. This microstructural evolution compromises the fundamental properties that make TBCs effective thermal insulators and mechanically compliant layers.

Phase destabilization represents a particularly concerning failure mechanism in yttria-stabilized zirconia (YSZ) coatings. The tetragonal prime (t') phase, which provides optimal mechanical properties, can transform to monoclinic and cubic phases during thermal cycling. This transformation is accompanied by a volume change that induces microcracks and accelerates coating degradation. The stability of these phases is heavily dependent on the initial microstructure, particularly the distribution of yttria within the zirconia matrix.

Foreign object damage (FOD) and erosion mechanisms interact with the microstructural features to accelerate failure. The columnar structure in electron beam physical vapor deposition (EB-PVD) coatings and the lamellar structure in air plasma sprayed (APS) coatings respond differently to impact events. The propagation of damage from these events is governed by the cohesive strength between splats in APS coatings or columns in EB-PVD coatings.

Interfacial rumpling, a phenomenon where the bond coat surface develops undulations during thermal cycling, creates significant stress concentrations at the ceramic/bond coat interface. The severity of rumpling is influenced by the microstructural characteristics of both layers, particularly the bond coat composition and the mechanical compliance of the ceramic layer, which is determined by its porosity and crack network.

The thermally grown oxide (TGO) layer formation at the bond coat/ceramic interface represents a critical factor in TBC failure. As this oxide layer grows, it generates significant stress concentrations that can initiate cracks parallel to the interface. The rate and uniformity of TGO growth are directly influenced by the microstructural features of both the ceramic top coat and the underlying bond coat, particularly porosity distribution and grain boundary characteristics.

Sintering-induced densification during thermal cycling constitutes another significant failure mechanism. The initially porous microstructure of plasma-sprayed coatings undergoes gradual densification at elevated temperatures, resulting in increased elastic modulus and thermal conductivity while reducing strain tolerance. This microstructural evolution compromises the fundamental properties that make TBCs effective thermal insulators and mechanically compliant layers.

Phase destabilization represents a particularly concerning failure mechanism in yttria-stabilized zirconia (YSZ) coatings. The tetragonal prime (t') phase, which provides optimal mechanical properties, can transform to monoclinic and cubic phases during thermal cycling. This transformation is accompanied by a volume change that induces microcracks and accelerates coating degradation. The stability of these phases is heavily dependent on the initial microstructure, particularly the distribution of yttria within the zirconia matrix.

Foreign object damage (FOD) and erosion mechanisms interact with the microstructural features to accelerate failure. The columnar structure in electron beam physical vapor deposition (EB-PVD) coatings and the lamellar structure in air plasma sprayed (APS) coatings respond differently to impact events. The propagation of damage from these events is governed by the cohesive strength between splats in APS coatings or columns in EB-PVD coatings.

Interfacial rumpling, a phenomenon where the bond coat surface develops undulations during thermal cycling, creates significant stress concentrations at the ceramic/bond coat interface. The severity of rumpling is influenced by the microstructural characteristics of both layers, particularly the bond coat composition and the mechanical compliance of the ceramic layer, which is determined by its porosity and crack network.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!