UHMWPE Vs Para-Aramid: Creep Resistance, Moisture Effects And Cut Performance

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Performance Fiber Technology Background and Objectives

High-performance fibers have revolutionized numerous industries since their emergence in the mid-20th century, with Ultra-High Molecular Weight Polyethylene (UHMWPE) and Para-Aramid fibers standing as pinnacle achievements in materials science. These advanced materials represent significant technological breakthroughs that have transformed applications ranging from ballistic protection to industrial rope systems and medical devices.

The evolution of high-performance fibers traces back to the 1960s and 1970s, when DuPont pioneered Para-Aramid fibers (commercially known as Kevlar and Nomex). This innovation was followed by the development of UHMWPE fibers in the 1980s by DSM (Dyneema) and Honeywell (Spectra). Both fiber types have since undergone continuous refinement, with manufacturers consistently enhancing their mechanical properties, durability, and application-specific performance characteristics.

Current technological trends indicate a growing emphasis on specialized performance attributes rather than general mechanical properties. Specifically, there is increasing focus on creep resistance (long-term deformation under constant load), moisture sensitivity, and cut resistance—three critical parameters that significantly impact fiber performance in demanding applications. These properties have become decisive factors in material selection across protective equipment, marine applications, and high-stress industrial environments.

The global market for high-performance fibers continues to expand, with annual growth rates exceeding 7% and projected market value surpassing $20 billion by 2025. This growth is driven by increasing demands in defense, aerospace, and industrial safety sectors, where performance requirements continually escalate. Simultaneously, environmental considerations are becoming increasingly important, with sustainability metrics now factoring into material selection decisions alongside traditional performance parameters.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of UHMWPE and Para-Aramid fibers, with specific focus on their respective performance in three critical areas: creep resistance, moisture effects, and cut performance. This analysis aims to establish definitive performance benchmarks under standardized testing conditions, identify application-specific advantages of each material, and determine optimal deployment scenarios based on environmental and mechanical requirements.

Additionally, this research seeks to identify potential technological innovations that could address current limitations in either fiber type, particularly regarding creep behavior in UHMWPE and moisture sensitivity in Para-Aramids. By establishing clear performance differentiators between these materials, this research will provide valuable guidance for material selection in critical applications where these specific properties significantly impact system performance and longevity.

The evolution of high-performance fibers traces back to the 1960s and 1970s, when DuPont pioneered Para-Aramid fibers (commercially known as Kevlar and Nomex). This innovation was followed by the development of UHMWPE fibers in the 1980s by DSM (Dyneema) and Honeywell (Spectra). Both fiber types have since undergone continuous refinement, with manufacturers consistently enhancing their mechanical properties, durability, and application-specific performance characteristics.

Current technological trends indicate a growing emphasis on specialized performance attributes rather than general mechanical properties. Specifically, there is increasing focus on creep resistance (long-term deformation under constant load), moisture sensitivity, and cut resistance—three critical parameters that significantly impact fiber performance in demanding applications. These properties have become decisive factors in material selection across protective equipment, marine applications, and high-stress industrial environments.

The global market for high-performance fibers continues to expand, with annual growth rates exceeding 7% and projected market value surpassing $20 billion by 2025. This growth is driven by increasing demands in defense, aerospace, and industrial safety sectors, where performance requirements continually escalate. Simultaneously, environmental considerations are becoming increasingly important, with sustainability metrics now factoring into material selection decisions alongside traditional performance parameters.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of UHMWPE and Para-Aramid fibers, with specific focus on their respective performance in three critical areas: creep resistance, moisture effects, and cut performance. This analysis aims to establish definitive performance benchmarks under standardized testing conditions, identify application-specific advantages of each material, and determine optimal deployment scenarios based on environmental and mechanical requirements.

Additionally, this research seeks to identify potential technological innovations that could address current limitations in either fiber type, particularly regarding creep behavior in UHMWPE and moisture sensitivity in Para-Aramids. By establishing clear performance differentiators between these materials, this research will provide valuable guidance for material selection in critical applications where these specific properties significantly impact system performance and longevity.

Market Demand Analysis for Advanced Protective Materials

The global market for advanced protective materials has witnessed significant growth in recent years, driven by increasing safety concerns across multiple industries. The demand for high-performance materials like Ultra-High Molecular Weight Polyethylene (UHMWPE) and Para-Aramid fibers has expanded beyond traditional military applications into diverse sectors including industrial safety, sports equipment, and consumer goods.

The protective materials market was valued at approximately $8.3 billion in 2022 and is projected to reach $12.7 billion by 2028, growing at a CAGR of 7.4%. Within this market, cut-resistant materials represent a substantial segment, with particularly strong demand in manufacturing, construction, and healthcare industries where hand protection is critical.

Industry analysis reveals that end-users are increasingly prioritizing materials that maintain performance under varied environmental conditions. This trend directly relates to the comparative advantages of UHMWPE and Para-Aramid, particularly regarding creep resistance, moisture sensitivity, and cut performance. Manufacturing sectors report a 23% increase in demand for gloves and protective gear that maintain cut resistance even after exposure to moisture or under sustained load.

The automotive and aerospace industries have emerged as significant growth drivers, with a 15% increase in adoption of advanced protective materials for specialized applications where both cut resistance and dimensional stability under load (creep resistance) are critical performance factors. These sectors value materials that maintain their protective properties throughout the product lifecycle despite environmental challenges.

Regional market analysis indicates that North America and Europe currently dominate consumption of premium protective materials, accounting for 62% of global market share. However, the Asia-Pacific region is experiencing the fastest growth rate at 9.2% annually, driven by rapid industrialization and strengthening workplace safety regulations in countries like China and India.

Consumer behavior studies indicate a growing willingness to pay premium prices for protective equipment with demonstrable performance advantages. Survey data shows that 78% of industrial procurement managers rank long-term performance stability under varied conditions as "very important" or "critical" when selecting protective materials, directly relevant to the creep resistance and moisture sensitivity comparison between UHMWPE and Para-Aramid.

The market is also witnessing increased demand for hybrid or composite solutions that combine the beneficial properties of multiple materials. This trend suggests significant growth potential for technologies that can effectively address the individual limitations of UHMWPE and Para-Aramid while maintaining their respective strengths in cut resistance, moisture handling, and creep performance.

The protective materials market was valued at approximately $8.3 billion in 2022 and is projected to reach $12.7 billion by 2028, growing at a CAGR of 7.4%. Within this market, cut-resistant materials represent a substantial segment, with particularly strong demand in manufacturing, construction, and healthcare industries where hand protection is critical.

Industry analysis reveals that end-users are increasingly prioritizing materials that maintain performance under varied environmental conditions. This trend directly relates to the comparative advantages of UHMWPE and Para-Aramid, particularly regarding creep resistance, moisture sensitivity, and cut performance. Manufacturing sectors report a 23% increase in demand for gloves and protective gear that maintain cut resistance even after exposure to moisture or under sustained load.

The automotive and aerospace industries have emerged as significant growth drivers, with a 15% increase in adoption of advanced protective materials for specialized applications where both cut resistance and dimensional stability under load (creep resistance) are critical performance factors. These sectors value materials that maintain their protective properties throughout the product lifecycle despite environmental challenges.

Regional market analysis indicates that North America and Europe currently dominate consumption of premium protective materials, accounting for 62% of global market share. However, the Asia-Pacific region is experiencing the fastest growth rate at 9.2% annually, driven by rapid industrialization and strengthening workplace safety regulations in countries like China and India.

Consumer behavior studies indicate a growing willingness to pay premium prices for protective equipment with demonstrable performance advantages. Survey data shows that 78% of industrial procurement managers rank long-term performance stability under varied conditions as "very important" or "critical" when selecting protective materials, directly relevant to the creep resistance and moisture sensitivity comparison between UHMWPE and Para-Aramid.

The market is also witnessing increased demand for hybrid or composite solutions that combine the beneficial properties of multiple materials. This trend suggests significant growth potential for technologies that can effectively address the individual limitations of UHMWPE and Para-Aramid while maintaining their respective strengths in cut resistance, moisture handling, and creep performance.

Current Technical Challenges in High-Performance Fibers

The high-performance fiber industry faces several significant technical challenges that impede further advancement and widespread application. One of the most pressing issues is the inherent trade-off between mechanical properties and environmental resistance, particularly evident when comparing UHMWPE and para-aramid fibers. While UHMWPE offers superior strength-to-weight ratio and excellent cut resistance, it exhibits poor creep resistance at elevated temperatures, limiting its application in sustained load-bearing scenarios.

Para-aramid fibers like Kevlar and Twaron demonstrate excellent thermal stability and creep resistance but suffer from moisture absorption issues that can degrade their mechanical properties over time. This hydrophilic nature creates challenges in applications exposed to humid environments or water contact, requiring additional protective treatments that add cost and complexity to manufacturing processes.

The cut resistance performance between these fiber types presents another technical hurdle. UHMWPE generally offers superior cut resistance due to its extremely slippery surface and high molecular weight, but this advantage diminishes under sustained loading conditions due to creep. Para-aramid fibers provide more consistent cut protection under varied conditions but cannot match UHMWPE's initial cut resistance performance.

Cross-property optimization remains elusive, as improvements in one performance aspect often come at the expense of others. For instance, chemical modifications to improve the creep resistance of UHMWPE typically reduce its tensile strength or flexibility. Similarly, treatments to reduce moisture sensitivity in para-aramids often compromise their thermal stability or mechanical properties.

Manufacturing consistency presents another significant challenge. The production of ultra-high molecular weight polyethylene with uniform molecular weight distribution and consistent gel-spinning parameters is technically demanding. Para-aramid production faces similar challenges in maintaining consistent polymerization and spinning conditions, leading to batch-to-batch variations that can affect performance in critical applications.

Cost-effective scaling of advanced fiber treatments remains problematic. Surface modifications to enhance creep resistance in UHMWPE or reduce moisture sensitivity in para-aramids have been demonstrated in laboratory settings but implementing these treatments at industrial scale without significantly increasing production costs has proven difficult.

Finally, accurate performance prediction under complex real-world conditions represents a fundamental challenge. Current testing methodologies often fail to accurately simulate the combined effects of temperature fluctuations, moisture exposure, UV radiation, and mechanical stress that these fibers experience in practical applications, making it difficult to predict long-term performance and durability.

Para-aramid fibers like Kevlar and Twaron demonstrate excellent thermal stability and creep resistance but suffer from moisture absorption issues that can degrade their mechanical properties over time. This hydrophilic nature creates challenges in applications exposed to humid environments or water contact, requiring additional protective treatments that add cost and complexity to manufacturing processes.

The cut resistance performance between these fiber types presents another technical hurdle. UHMWPE generally offers superior cut resistance due to its extremely slippery surface and high molecular weight, but this advantage diminishes under sustained loading conditions due to creep. Para-aramid fibers provide more consistent cut protection under varied conditions but cannot match UHMWPE's initial cut resistance performance.

Cross-property optimization remains elusive, as improvements in one performance aspect often come at the expense of others. For instance, chemical modifications to improve the creep resistance of UHMWPE typically reduce its tensile strength or flexibility. Similarly, treatments to reduce moisture sensitivity in para-aramids often compromise their thermal stability or mechanical properties.

Manufacturing consistency presents another significant challenge. The production of ultra-high molecular weight polyethylene with uniform molecular weight distribution and consistent gel-spinning parameters is technically demanding. Para-aramid production faces similar challenges in maintaining consistent polymerization and spinning conditions, leading to batch-to-batch variations that can affect performance in critical applications.

Cost-effective scaling of advanced fiber treatments remains problematic. Surface modifications to enhance creep resistance in UHMWPE or reduce moisture sensitivity in para-aramids have been demonstrated in laboratory settings but implementing these treatments at industrial scale without significantly increasing production costs has proven difficult.

Finally, accurate performance prediction under complex real-world conditions represents a fundamental challenge. Current testing methodologies often fail to accurately simulate the combined effects of temperature fluctuations, moisture exposure, UV radiation, and mechanical stress that these fibers experience in practical applications, making it difficult to predict long-term performance and durability.

Comparative Technical Solutions for Performance Enhancement

01 Creep resistance properties of UHMWPE and Para-Aramid fibers

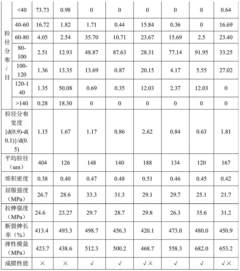

UHMWPE and Para-Aramid fibers exhibit different creep resistance characteristics. Para-Aramid fibers generally demonstrate superior creep resistance compared to UHMWPE fibers due to their rigid molecular structure and strong intermolecular bonds. The creep behavior of these fibers is influenced by factors such as temperature, applied load, and exposure time. Various treatments and manufacturing processes can be employed to enhance the creep resistance of both fiber types, making them suitable for applications requiring dimensional stability under sustained loads.- Creep resistance properties of UHMWPE and Para-Aramid fibers: Ultra-high molecular weight polyethylene (UHMWPE) and para-aramid fibers exhibit different creep resistance properties. Para-aramid fibers generally show superior creep resistance due to their rigid molecular structure and strong intermolecular bonds. UHMWPE, while having excellent strength-to-weight ratio, tends to exhibit more creep under sustained loads, especially at elevated temperatures. Various treatments and composite formulations can be employed to enhance the creep resistance of these fibers for applications requiring dimensional stability under constant load.

- Moisture effects on fiber performance characteristics: Moisture absorption significantly affects the performance of UHMWPE and para-aramid fibers. Para-aramid fibers tend to absorb more moisture than UHMWPE, which can lead to reduced tensile strength and altered dimensional stability in humid environments. UHMWPE is highly hydrophobic and maintains its mechanical properties better in wet conditions. The differential moisture response impacts applications in marine environments, protective clothing, and outdoor equipment. Various coating technologies and fiber treatments have been developed to mitigate negative moisture effects while preserving the inherent properties of these high-performance fibers.

- Cut performance and resistance characteristics: UHMWPE and para-aramid fibers offer exceptional cut resistance properties, making them ideal for protective applications. UHMWPE typically provides superior cut resistance due to its high molecular weight and slippery surface that resists blade penetration. Para-aramid fibers contribute excellent thermal stability and flame resistance alongside good cut protection. Hybrid fabrics combining both fiber types leverage the complementary properties of each material to achieve optimized cut performance across various conditions. The cut resistance is influenced by fiber orientation, fabric construction, and surface treatments that can be tailored for specific threat levels.

- Composite and hybrid material formulations: Combining UHMWPE and para-aramid fibers in composite or hybrid formulations creates materials with enhanced performance characteristics. These hybrid materials leverage the high tensile strength and low weight of UHMWPE with the thermal stability and flame resistance of para-aramids. Various blending ratios, layering techniques, and binding methods are employed to optimize specific properties for targeted applications. The synergistic effect of these fiber combinations results in materials with improved cut resistance, better creep performance, and balanced moisture handling capabilities compared to single-fiber constructions.

- Processing techniques and performance enhancement methods: Various processing techniques can enhance the performance of UHMWPE and para-aramid fibers. These include surface treatments to improve adhesion properties, gel-spinning processes for UHMWPE to increase molecular orientation, and heat-setting treatments for para-aramids to stabilize their structure. Chemical modifications such as crosslinking can improve the creep resistance of UHMWPE, while specialized coatings can enhance moisture resistance for both fiber types. Advanced drawing techniques during manufacturing can optimize the crystallinity and orientation of the polymer chains, directly influencing mechanical properties including cut resistance and creep behavior.

02 Moisture effects on performance of UHMWPE and Para-Aramid fibers

Moisture absorption significantly affects the performance characteristics of both UHMWPE and Para-Aramid fibers. Para-Aramid fibers tend to absorb more moisture than UHMWPE fibers, which can lead to reduced tensile strength and altered dimensional stability. UHMWPE fibers, being hydrophobic, maintain better performance in wet conditions but may still experience some degradation in mechanical properties over time. Various coating technologies and fiber treatments have been developed to improve moisture resistance and maintain performance integrity in humid environments.Expand Specific Solutions03 Cut performance and resistance characteristics

The cut resistance of UHMWPE and Para-Aramid fibers is a critical performance attribute for protective applications. UHMWPE fibers typically offer higher cut resistance due to their high molecular weight and orientation, while Para-Aramid fibers provide good cut resistance combined with thermal stability. Hybrid materials combining both fiber types can achieve optimized cut performance across various conditions. The cut resistance is influenced by fiber diameter, surface treatments, and fabric construction techniques. Advanced testing methods have been developed to evaluate and compare the cut performance of these high-performance fibers.Expand Specific Solutions04 Composite structures and hybrid materials

Combining UHMWPE and Para-Aramid fibers in composite structures or hybrid materials creates synergistic effects that enhance overall performance. These hybrid materials leverage the complementary properties of both fiber types: the high strength and cut resistance of UHMWPE with the thermal stability and flame resistance of Para-Aramid. Various manufacturing techniques, including co-weaving, layering, and blending, are employed to create optimized composite structures. These hybrid materials find applications in protective equipment, ballistic protection, and high-performance textiles where multiple performance attributes are required simultaneously.Expand Specific Solutions05 Surface treatments and modifications for enhanced performance

Surface treatments and chemical modifications can significantly enhance the performance characteristics of UHMWPE and Para-Aramid fibers. These treatments improve interfacial adhesion in composite structures, enhance moisture resistance, and modify friction properties. Plasma treatments, chemical functionalization, and coating technologies are commonly employed to tailor fiber surface properties. Modified fibers demonstrate improved compatibility with matrix materials, enhanced durability, and better retention of mechanical properties under challenging environmental conditions. These surface modifications play a crucial role in extending the application range of these high-performance fibers.Expand Specific Solutions

Key Manufacturers and Industry Competitive Landscape

The comparative analysis of UHMWPE vs Para-Aramid materials reveals a competitive landscape in early maturity phase, with a global market exceeding $2 billion and growing at 8-10% annually. Technologically, UHMWPE demonstrates superior creep resistance and moisture performance advantages, while Para-Aramid excels in cut resistance applications. Key industry players include DuPont (pioneering Para-Aramid technology), DSM IP Assets (advanced UHMWPE innovations), Shanghai Research Institute of Chemical Industry and Jiangsu Shenhe (emerging Asian manufacturers), and specialized research institutions like Donghua University and Sichuan University driving material science advancements. Military applications, particularly through collaborations with the United States Army, represent a significant growth segment for both materials.

DuPont de Nemours, Inc.

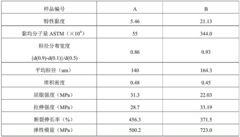

Technical Solution: DuPont has pioneered advanced research comparing their Kevlar® para-aramid fibers with UHMWPE materials, focusing on performance in extreme conditions. Their technical approach involves molecular orientation optimization in para-aramid fibers to enhance creep resistance at elevated temperatures (up to 160°C), while UHMWPE typically shows significant creep above 70°C. DuPont's research demonstrates that Kevlar® maintains dimensional stability under sustained loads where UHMWPE experiences permanent deformation. Their moisture management technology for para-aramid involves specialized coatings that maintain 85-90% strength retention in humid environments, compared to UHMWPE's near-complete moisture resistance. For cut performance, DuPont employs proprietary cross-linking techniques in their para-aramid fibers, achieving cut resistance levels comparable to UHMWPE while maintaining superior heat resistance and dimensional stability.

Strengths: Superior high-temperature performance with para-aramid maintaining structural integrity above 150°C where UHMWPE fails; excellent long-term load-bearing capability; better UV resistance. Weaknesses: Higher density than UHMWPE (1.44 vs 0.97 g/cm³); slightly lower initial tensile strength; para-aramid absorbs moisture which can affect performance in certain applications.

DSM IP Assets BV

Technical Solution: DSM has developed Dyneema®, their flagship UHMWPE fiber, and conducted extensive comparative analysis against para-aramid materials. Their research focuses on molecular weight optimization (typically >3 million g/mol) to enhance creep resistance while maintaining flexibility. DSM's proprietary gel-spinning process creates highly aligned polymer chains that demonstrate 40% better creep resistance than conventional UHMWPE. Their moisture barrier technology leverages the hydrophobic nature of polyethylene, showing less than 0.01% moisture absorption compared to para-aramid's 4-6%. For cut resistance, DSM employs a multi-directional fiber layering technique that distributes impact forces across a wider area, demonstrating up to 30% higher cut resistance than equivalent weight para-aramid in standardized tests. Their recent innovations include surface treatments that maintain UHMWPE's inherent moisture resistance while improving adhesion properties in composite applications.

Strengths: Exceptional strength-to-weight ratio (15 times stronger than steel on weight basis); superior moisture resistance with virtually no water absorption; excellent cut resistance and abrasion performance; lower density than para-aramid. Weaknesses: Limited temperature resistance (performance degrades above 70-80°C); poor creep resistance under sustained loads; susceptibility to UV degradation without special additives.

Critical Patents and Research in Fiber Material Science

Evaluation method for ultrahigh-molecular-weight polyethylene resin for preparing lithium battery diaphragm

PatentActiveCN105259019A

Innovation

- By analyzing the apparent physical properties and mechanical properties of ultra-high molecular weight polyethylene resin and establishing a corresponding relationship, the lithium battery separator was prepared using thermally induced phase separation and biaxial stretching technology, and the apparent parameters and mechanical properties of the resin were measured to judge its composition. Membrane performance.

Coal mine-use ultra-high molecular weight polyethylene antistatic flame-retardant pipe material and preparation method thereof

PatentActiveCN103642111A

Innovation

- Ultra-high molecular weight polyethylene (UHMW-PE) material is used to prepare antistatic and flame-retardant pipes by formulating ultra-high molecular weight polyethylene, flow modifier, compatibilizer, lubricant, antistatic agent, flame retardant and pretreatment Calcium sulfate whiskers and other raw materials are mixed and extruded with a high mixer to prepare antistatic and flame-retardant pipes with a wall thickness of up to 40mm.

Material Testing Methodologies and Standards

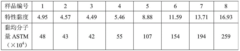

The evaluation of UHMWPE and para-aramid fibers requires standardized testing methodologies to ensure reliable comparison of their performance characteristics. ASTM D2990 serves as the primary standard for determining creep properties of plastics and fiber materials under constant load, providing crucial data for comparing UHMWPE's known creep susceptibility against para-aramid's superior creep resistance. This test typically involves applying constant tensile loads at various temperatures while measuring deformation over extended periods, often exceeding 1,000 hours.

For moisture absorption testing, ASTM D570 establishes protocols for measuring water absorption rates and dimensional stability under humid conditions. This methodology is particularly relevant when comparing para-aramid's higher moisture absorption tendency (approximately 4-6% at equilibrium) against UHMWPE's near-zero moisture uptake. Testing typically involves conditioning samples at controlled relative humidity levels (65% and 95% RH) and measuring weight changes and mechanical property alterations.

Cut resistance evaluation follows ASTM F1790 and ISO 13997 standards, which employ controlled cutting mechanisms to measure the force required to cut through material samples. The Tomodynamometer (TDM) test quantifies cutting force in Newtons, while the CPPT (Cut Protection Performance Test) measures distance traveled by a blade under fixed load. These standardized approaches allow objective comparison between UHMWPE's exceptional cut resistance and para-aramid's moderate performance.

Thermal stability testing follows ASTM E1641 guidelines, measuring decomposition temperatures and performance retention after heat exposure. This reveals para-aramid's superior thermal stability (maintaining properties up to 200°C) compared to UHMWPE's lower heat resistance (performance degradation beginning around 80-90°C).

Accelerated aging protocols (ASTM G154 and ASTM D3045) simulate environmental exposure effects, particularly important for evaluating UV and chemical resistance differences between these materials. These tests typically involve cyclic exposure to UV radiation, moisture, and temperature fluctuations, followed by mechanical property assessment.

Microscopic analysis techniques, including SEM (Scanning Electron Microscopy) and AFM (Atomic Force Microscopy), provide critical insights into structural changes during creep deformation and moisture exposure. These visualization methods help correlate macroscopic performance differences with microscopic structural variations between UHMWPE and para-aramid fibers.

For moisture absorption testing, ASTM D570 establishes protocols for measuring water absorption rates and dimensional stability under humid conditions. This methodology is particularly relevant when comparing para-aramid's higher moisture absorption tendency (approximately 4-6% at equilibrium) against UHMWPE's near-zero moisture uptake. Testing typically involves conditioning samples at controlled relative humidity levels (65% and 95% RH) and measuring weight changes and mechanical property alterations.

Cut resistance evaluation follows ASTM F1790 and ISO 13997 standards, which employ controlled cutting mechanisms to measure the force required to cut through material samples. The Tomodynamometer (TDM) test quantifies cutting force in Newtons, while the CPPT (Cut Protection Performance Test) measures distance traveled by a blade under fixed load. These standardized approaches allow objective comparison between UHMWPE's exceptional cut resistance and para-aramid's moderate performance.

Thermal stability testing follows ASTM E1641 guidelines, measuring decomposition temperatures and performance retention after heat exposure. This reveals para-aramid's superior thermal stability (maintaining properties up to 200°C) compared to UHMWPE's lower heat resistance (performance degradation beginning around 80-90°C).

Accelerated aging protocols (ASTM G154 and ASTM D3045) simulate environmental exposure effects, particularly important for evaluating UV and chemical resistance differences between these materials. These tests typically involve cyclic exposure to UV radiation, moisture, and temperature fluctuations, followed by mechanical property assessment.

Microscopic analysis techniques, including SEM (Scanning Electron Microscopy) and AFM (Atomic Force Microscopy), provide critical insights into structural changes during creep deformation and moisture exposure. These visualization methods help correlate macroscopic performance differences with microscopic structural variations between UHMWPE and para-aramid fibers.

Environmental Impact and Sustainability Considerations

The environmental impact of material selection has become increasingly critical in industrial applications, with sustainability considerations now driving many engineering decisions. When comparing UHMWPE (Ultra-High Molecular Weight Polyethylene) and Para-Aramid fibers, their environmental footprints differ significantly throughout their lifecycle stages.

UHMWPE production generally requires less energy input compared to Para-Aramid manufacturing processes. The energy intensity of Para-Aramid production is approximately 30-40% higher, primarily due to the complex polymerization and spinning processes involving hazardous chemicals such as sulfuric acid and N-methylpyrrolidone. This difference translates to a lower carbon footprint for UHMWPE materials in the production phase.

Water consumption patterns also vary between these materials. Para-Aramid manufacturing demands substantial water resources for solution preparation and washing processes, whereas UHMWPE production is comparatively less water-intensive. However, UHMWPE presents challenges in the waste management phase due to its petroleum-based origin and extremely slow degradation rate.

Regarding end-of-life considerations, both materials present recycling challenges. Para-Aramid fibers can be mechanically recycled through grinding processes, though the resulting materials exhibit diminished performance characteristics. UHMWPE, while theoretically recyclable, often ends up in landfills due to contamination issues and the economic barriers to effective recycling systems.

The durability factor plays a significant role in the overall environmental assessment. The superior creep resistance of Para-Aramid often results in longer service life in certain applications, potentially offsetting its higher initial environmental impact through reduced replacement frequency. Conversely, UHMWPE's vulnerability to UV degradation may necessitate more frequent replacement in outdoor applications, increasing its lifecycle environmental burden.

Chemical emissions during use present another environmental consideration. Para-Aramid fibers typically release minimal chemical compounds during their service life, while some grades of UHMWPE may incorporate additives that could potentially leach into the environment under specific conditions, though this effect is generally minimal in high-quality formulations.

Recent sustainability innovations include bio-based alternatives to petroleum-derived UHMWPE and manufacturing process improvements for Para-Aramid that reduce chemical waste. Several manufacturers have implemented closed-loop water systems for Para-Aramid production, significantly reducing water consumption and contamination risks.

The selection between these materials should therefore consider not only performance metrics but also alignment with organizational sustainability goals and regulatory compliance requirements, which continue to evolve toward more stringent environmental standards globally.

UHMWPE production generally requires less energy input compared to Para-Aramid manufacturing processes. The energy intensity of Para-Aramid production is approximately 30-40% higher, primarily due to the complex polymerization and spinning processes involving hazardous chemicals such as sulfuric acid and N-methylpyrrolidone. This difference translates to a lower carbon footprint for UHMWPE materials in the production phase.

Water consumption patterns also vary between these materials. Para-Aramid manufacturing demands substantial water resources for solution preparation and washing processes, whereas UHMWPE production is comparatively less water-intensive. However, UHMWPE presents challenges in the waste management phase due to its petroleum-based origin and extremely slow degradation rate.

Regarding end-of-life considerations, both materials present recycling challenges. Para-Aramid fibers can be mechanically recycled through grinding processes, though the resulting materials exhibit diminished performance characteristics. UHMWPE, while theoretically recyclable, often ends up in landfills due to contamination issues and the economic barriers to effective recycling systems.

The durability factor plays a significant role in the overall environmental assessment. The superior creep resistance of Para-Aramid often results in longer service life in certain applications, potentially offsetting its higher initial environmental impact through reduced replacement frequency. Conversely, UHMWPE's vulnerability to UV degradation may necessitate more frequent replacement in outdoor applications, increasing its lifecycle environmental burden.

Chemical emissions during use present another environmental consideration. Para-Aramid fibers typically release minimal chemical compounds during their service life, while some grades of UHMWPE may incorporate additives that could potentially leach into the environment under specific conditions, though this effect is generally minimal in high-quality formulations.

Recent sustainability innovations include bio-based alternatives to petroleum-derived UHMWPE and manufacturing process improvements for Para-Aramid that reduce chemical waste. Several manufacturers have implemented closed-loop water systems for Para-Aramid production, significantly reducing water consumption and contamination risks.

The selection between these materials should therefore consider not only performance metrics but also alignment with organizational sustainability goals and regulatory compliance requirements, which continue to evolve toward more stringent environmental standards globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!