UHMWPE In Marine Environments: Water Uptake, Biofouling And Fatigue

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Marine Applications Background and Objectives

Ultra-High Molecular Weight Polyethylene (UHMWPE) has emerged as a critical material in marine applications due to its exceptional mechanical properties, including high abrasion resistance, low friction coefficient, and excellent impact strength. The evolution of UHMWPE technology in marine environments can be traced back to the 1950s when it was first introduced as an engineering plastic. Since then, its application has expanded significantly across various marine sectors including offshore structures, ship components, mooring systems, and aquaculture equipment.

The marine environment presents unique challenges for materials, characterized by constant exposure to saltwater, varying temperatures, UV radiation, and biological organisms. These conditions accelerate material degradation through mechanisms such as water uptake, biofouling, and fatigue. Understanding these degradation mechanisms is crucial for optimizing UHMWPE performance in marine applications.

Recent technological trends indicate a growing interest in enhancing UHMWPE's resistance to water absorption, which is a primary concern as it can lead to dimensional instability and reduced mechanical properties. Research has focused on surface modifications and composite formulations to address this challenge. Additionally, the development of anti-biofouling UHMWPE variants represents a significant advancement, as biofouling can substantially increase drag, weight, and maintenance costs of marine structures.

Fatigue resistance remains another critical area of development, particularly for components subjected to cyclic loading in wave and tidal environments. The industry has witnessed innovations in cross-linking techniques and reinforcement strategies to improve the long-term durability of UHMWPE under such conditions.

The primary technical objectives of current UHMWPE research for marine applications include: quantifying water uptake mechanisms and their impact on mechanical properties; developing effective strategies to mitigate biofouling without compromising material integrity; enhancing fatigue resistance under marine-specific loading conditions; and creating predictive models for UHMWPE performance in various marine environments.

Furthermore, there is a growing emphasis on sustainability, with research directed toward recyclable UHMWPE formulations and bio-based additives that maintain performance while reducing environmental impact. This aligns with the broader maritime industry's shift toward more sustainable materials and practices.

As marine infrastructure continues to expand globally, particularly in offshore renewable energy and deep-sea exploration, the demand for advanced UHMWPE solutions is expected to increase. This presents both challenges and opportunities for material scientists and engineers to develop next-generation UHMWPE technologies that can withstand the harsh marine environment while offering improved performance and longevity.

The marine environment presents unique challenges for materials, characterized by constant exposure to saltwater, varying temperatures, UV radiation, and biological organisms. These conditions accelerate material degradation through mechanisms such as water uptake, biofouling, and fatigue. Understanding these degradation mechanisms is crucial for optimizing UHMWPE performance in marine applications.

Recent technological trends indicate a growing interest in enhancing UHMWPE's resistance to water absorption, which is a primary concern as it can lead to dimensional instability and reduced mechanical properties. Research has focused on surface modifications and composite formulations to address this challenge. Additionally, the development of anti-biofouling UHMWPE variants represents a significant advancement, as biofouling can substantially increase drag, weight, and maintenance costs of marine structures.

Fatigue resistance remains another critical area of development, particularly for components subjected to cyclic loading in wave and tidal environments. The industry has witnessed innovations in cross-linking techniques and reinforcement strategies to improve the long-term durability of UHMWPE under such conditions.

The primary technical objectives of current UHMWPE research for marine applications include: quantifying water uptake mechanisms and their impact on mechanical properties; developing effective strategies to mitigate biofouling without compromising material integrity; enhancing fatigue resistance under marine-specific loading conditions; and creating predictive models for UHMWPE performance in various marine environments.

Furthermore, there is a growing emphasis on sustainability, with research directed toward recyclable UHMWPE formulations and bio-based additives that maintain performance while reducing environmental impact. This aligns with the broader maritime industry's shift toward more sustainable materials and practices.

As marine infrastructure continues to expand globally, particularly in offshore renewable energy and deep-sea exploration, the demand for advanced UHMWPE solutions is expected to increase. This presents both challenges and opportunities for material scientists and engineers to develop next-generation UHMWPE technologies that can withstand the harsh marine environment while offering improved performance and longevity.

Market Demand Analysis for Marine-Grade UHMWPE

The global market for marine-grade Ultra-High-Molecular-Weight Polyethylene (UHMWPE) has been experiencing significant growth, driven by increasing applications in offshore structures, marine equipment, and naval architecture. Current market valuations indicate the marine-grade polymer materials sector is expanding at a compound annual growth rate of approximately 6.7%, with UHMWPE representing one of the fastest-growing segments within this category.

The demand for UHMWPE in marine environments stems primarily from its exceptional mechanical properties, including superior wear resistance, self-lubrication characteristics, and high impact strength. These properties make it particularly valuable for applications such as mooring lines, ropes, underwater cables, and protective coatings for marine structures. The offshore energy sector, including oil and gas platforms and emerging offshore wind installations, constitutes the largest market segment, accounting for nearly 42% of marine UHMWPE consumption.

Maritime transportation represents another substantial market driver, with shipping companies increasingly adopting UHMWPE components to reduce maintenance costs and extend service intervals. The material's resistance to corrosion and ability to withstand harsh environmental conditions translate directly into operational cost savings, estimated at 15-20% compared to traditional materials over a typical five-year service period.

A notable trend in market demand is the growing emphasis on biofouling resistance. Port authorities and marine vessel operators face increasing regulatory pressure to minimize the environmental impact of biofouling, which can transport invasive species across marine ecosystems. This has created a specialized market segment for UHMWPE formulations with enhanced anti-fouling properties, projected to grow at 9.3% annually through 2028.

The defense and naval sectors present another significant market opportunity, with military specifications increasingly calling for materials capable of withstanding extreme conditions while maintaining structural integrity. Naval applications of UHMWPE include sonar domes, propeller guards, and specialized underwater equipment housings, collectively representing a market segment valued at approximately $340 million globally.

Regional analysis reveals that North America and Europe currently dominate market consumption, though the Asia-Pacific region is experiencing the fastest growth rate, particularly in shipbuilding nations like China, South Korea, and Japan. This geographic shift is expected to continue as these economies expand their maritime industries and offshore energy developments.

The market faces challenges related to material performance limitations, particularly regarding water uptake and fatigue resistance in long-term marine deployments. Industry surveys indicate that 78% of end-users identify improved fatigue resistance as their primary requirement for next-generation marine UHMWPE products, highlighting a clear direction for future product development and market growth opportunities.

The demand for UHMWPE in marine environments stems primarily from its exceptional mechanical properties, including superior wear resistance, self-lubrication characteristics, and high impact strength. These properties make it particularly valuable for applications such as mooring lines, ropes, underwater cables, and protective coatings for marine structures. The offshore energy sector, including oil and gas platforms and emerging offshore wind installations, constitutes the largest market segment, accounting for nearly 42% of marine UHMWPE consumption.

Maritime transportation represents another substantial market driver, with shipping companies increasingly adopting UHMWPE components to reduce maintenance costs and extend service intervals. The material's resistance to corrosion and ability to withstand harsh environmental conditions translate directly into operational cost savings, estimated at 15-20% compared to traditional materials over a typical five-year service period.

A notable trend in market demand is the growing emphasis on biofouling resistance. Port authorities and marine vessel operators face increasing regulatory pressure to minimize the environmental impact of biofouling, which can transport invasive species across marine ecosystems. This has created a specialized market segment for UHMWPE formulations with enhanced anti-fouling properties, projected to grow at 9.3% annually through 2028.

The defense and naval sectors present another significant market opportunity, with military specifications increasingly calling for materials capable of withstanding extreme conditions while maintaining structural integrity. Naval applications of UHMWPE include sonar domes, propeller guards, and specialized underwater equipment housings, collectively representing a market segment valued at approximately $340 million globally.

Regional analysis reveals that North America and Europe currently dominate market consumption, though the Asia-Pacific region is experiencing the fastest growth rate, particularly in shipbuilding nations like China, South Korea, and Japan. This geographic shift is expected to continue as these economies expand their maritime industries and offshore energy developments.

The market faces challenges related to material performance limitations, particularly regarding water uptake and fatigue resistance in long-term marine deployments. Industry surveys indicate that 78% of end-users identify improved fatigue resistance as their primary requirement for next-generation marine UHMWPE products, highlighting a clear direction for future product development and market growth opportunities.

Current Challenges in UHMWPE Marine Performance

Ultra-high molecular weight polyethylene (UHMWPE) faces significant challenges when deployed in marine environments, primarily stemming from three interconnected phenomena: water uptake, biofouling, and fatigue. Despite its excellent mechanical properties and chemical resistance, UHMWPE's performance degrades over time when continuously exposed to seawater conditions.

Water uptake in UHMWPE occurs through a slow diffusion process where water molecules penetrate the polymer matrix. Although the absorption rate is relatively low compared to other polymers (typically 0.01-0.1% by weight), this seemingly minor uptake can trigger substantial changes in mechanical properties. Research indicates that water molecules can act as plasticizers, reducing intermolecular forces between polymer chains and consequently decreasing tensile strength by up to 15% after prolonged exposure.

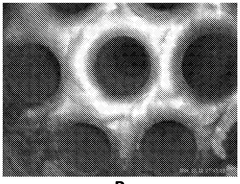

Biofouling represents another critical challenge, as marine organisms readily colonize UHMWPE surfaces. Initial biofilm formation occurs within hours of immersion, followed by attachment of larger organisms like barnacles and mussels. This biological layer not only increases drag and weight but also creates microenvironments conducive to localized corrosion and degradation. Studies have shown that biofouling can accelerate the degradation rate of UHMWPE by 20-30% compared to clean surfaces.

The fatigue behavior of UHMWPE in marine environments presents perhaps the most complex challenge. Cyclic loading combined with seawater exposure creates a synergistic degradation mechanism. The alternating stress states facilitate water penetration into microcracks, while dissolved oxygen in seawater promotes oxidative degradation at newly formed crack surfaces. This phenomenon, known as environmental stress cracking, can reduce the fatigue life of UHMWPE components by 40-60% compared to air-based testing.

Temperature fluctuations in marine environments further complicate these issues. In cold waters, UHMWPE becomes more brittle, while in warmer tropical waters, the rate of both water uptake and biofouling accelerates significantly. UV radiation from sunlight in surface applications compounds these effects by initiating photodegradation processes that create free radicals and accelerate oxidative damage.

Current mitigation strategies remain insufficient. Conventional antifouling coatings designed for metals often fail to adhere properly to the non-polar UHMWPE surface. Cross-linking techniques that improve wear resistance can paradoxically increase susceptibility to environmental stress cracking. Antioxidant packages that work well in air show reduced effectiveness in seawater immersion conditions.

The combined effect of these challenges significantly limits UHMWPE's service life in critical marine applications such as offshore energy systems, aquaculture equipment, and naval structures, creating an urgent need for innovative solutions that address these interrelated degradation mechanisms.

Water uptake in UHMWPE occurs through a slow diffusion process where water molecules penetrate the polymer matrix. Although the absorption rate is relatively low compared to other polymers (typically 0.01-0.1% by weight), this seemingly minor uptake can trigger substantial changes in mechanical properties. Research indicates that water molecules can act as plasticizers, reducing intermolecular forces between polymer chains and consequently decreasing tensile strength by up to 15% after prolonged exposure.

Biofouling represents another critical challenge, as marine organisms readily colonize UHMWPE surfaces. Initial biofilm formation occurs within hours of immersion, followed by attachment of larger organisms like barnacles and mussels. This biological layer not only increases drag and weight but also creates microenvironments conducive to localized corrosion and degradation. Studies have shown that biofouling can accelerate the degradation rate of UHMWPE by 20-30% compared to clean surfaces.

The fatigue behavior of UHMWPE in marine environments presents perhaps the most complex challenge. Cyclic loading combined with seawater exposure creates a synergistic degradation mechanism. The alternating stress states facilitate water penetration into microcracks, while dissolved oxygen in seawater promotes oxidative degradation at newly formed crack surfaces. This phenomenon, known as environmental stress cracking, can reduce the fatigue life of UHMWPE components by 40-60% compared to air-based testing.

Temperature fluctuations in marine environments further complicate these issues. In cold waters, UHMWPE becomes more brittle, while in warmer tropical waters, the rate of both water uptake and biofouling accelerates significantly. UV radiation from sunlight in surface applications compounds these effects by initiating photodegradation processes that create free radicals and accelerate oxidative damage.

Current mitigation strategies remain insufficient. Conventional antifouling coatings designed for metals often fail to adhere properly to the non-polar UHMWPE surface. Cross-linking techniques that improve wear resistance can paradoxically increase susceptibility to environmental stress cracking. Antioxidant packages that work well in air show reduced effectiveness in seawater immersion conditions.

The combined effect of these challenges significantly limits UHMWPE's service life in critical marine applications such as offshore energy systems, aquaculture equipment, and naval structures, creating an urgent need for innovative solutions that address these interrelated degradation mechanisms.

Existing Solutions for Water Uptake and Biofouling

01 Surface modification techniques to reduce water uptake and biofouling

Various surface modification techniques can be applied to UHMWPE to reduce water uptake and biofouling. These include coating with hydrophobic materials, chemical treatments, and plasma modification. These treatments create a barrier that prevents water absorption and inhibits the adhesion of microorganisms, thereby reducing biofouling and improving the material's performance in aqueous environments.- Surface modifications to reduce water uptake and biofouling: Various surface modification techniques can be applied to UHMWPE to reduce water uptake and biofouling. These include coating with hydrophobic materials, chemical treatments, and physical modifications of the surface structure. Such modifications create a barrier that prevents water absorption and inhibits the attachment of microorganisms, thereby enhancing the material's resistance to biofouling in aquatic environments.

- Composite formulations to improve fatigue resistance: UHMWPE can be formulated with various additives and reinforcing materials to create composites with enhanced fatigue resistance. These formulations may include carbon fibers, glass fibers, or nanoparticles that strengthen the polymer matrix. The resulting composites demonstrate improved mechanical properties, particularly under cyclic loading conditions, making them suitable for applications requiring long-term durability in marine environments.

- Cross-linking techniques to enhance water resistance: Cross-linking of UHMWPE chains through radiation, chemical methods, or thermal processing can significantly reduce water uptake. The cross-linked structure creates a more tightly bound molecular network that limits the penetration of water molecules into the material. This technique is particularly effective in improving the material's performance in underwater applications where water absorption could compromise mechanical properties.

- Anti-fouling additives and treatments: Specific additives can be incorporated into UHMWPE to provide anti-fouling properties. These include biocides, copper compounds, silver nanoparticles, and other antimicrobial agents that prevent the growth of microorganisms on the material surface. Additionally, surface treatments that create ultra-smooth or micro-patterned surfaces can reduce the ability of marine organisms to attach, thereby minimizing biofouling in marine applications.

- Testing and characterization methods for water uptake and fatigue: Various testing methodologies have been developed to evaluate UHMWPE's water uptake, biofouling resistance, and fatigue performance. These include accelerated aging tests in simulated marine environments, cyclic loading tests under wet conditions, and microscopic analysis of surface colonization by microorganisms. These methods provide valuable data for predicting the long-term performance of UHMWPE components in applications where they are exposed to water and cyclic stresses simultaneously.

02 Composite formulations to enhance fatigue resistance

UHMWPE can be formulated as composites with other materials to enhance its fatigue resistance properties. Incorporating reinforcing agents such as carbon fibers, glass fibers, or nanoparticles can significantly improve the mechanical properties and fatigue resistance of UHMWPE. These composite formulations distribute stress more effectively and prevent crack propagation, resulting in improved longevity under cyclic loading conditions.Expand Specific Solutions03 Cross-linking methods to improve water resistance and mechanical properties

Cross-linking of UHMWPE chains through radiation, chemical agents, or thermal treatments can significantly improve its water resistance and mechanical properties. The cross-linked structure reduces the mobility of polymer chains, decreasing water absorption and improving resistance to deformation under load. This technique is particularly effective in enhancing the material's performance in marine and medical applications where water exposure and fatigue are concerns.Expand Specific Solutions04 Additives and fillers for biofouling prevention

Specific additives and fillers can be incorporated into UHMWPE to prevent biofouling. Antimicrobial agents, biocides, and hydrophobic fillers can be blended with the polymer matrix to create surfaces that resist microbial attachment and growth. These additives work by either killing microorganisms on contact or creating surface properties that discourage adhesion, thereby extending the service life of UHMWPE components in biological environments.Expand Specific Solutions05 Processing techniques to optimize water uptake and fatigue performance

Specialized processing techniques can optimize UHMWPE's resistance to water uptake and fatigue. Methods such as compression molding under specific temperature and pressure conditions, ram extrusion, and controlled cooling rates can enhance the crystallinity and molecular orientation of the polymer. These processing parameters significantly influence the material's water absorption characteristics and long-term mechanical performance under cyclic loading.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The UHMWPE marine environment market is in a growth phase, driven by increasing offshore activities and demand for durable materials in harsh conditions. The global market size for marine-grade polymers is expanding at approximately 5-7% annually, with UHMWPE gaining traction due to its exceptional mechanical properties. Technologically, the field is advancing from basic water uptake studies to sophisticated biofouling prevention and fatigue resistance solutions. Leading companies like BASF Corp., TotalEnergies SE, and Toray Industries are developing proprietary formulations, while research institutions including University of Florida and Hong Kong University of Science & Technology are pioneering novel surface treatments. Saipem SA and CNOOC Energy Technology are implementing these innovations in offshore applications, demonstrating the material's growing commercial viability despite ongoing challenges with long-term performance prediction.

Quadrant Services AG

Technical Solution: Quadrant Services AG (now part of Mitsubishi Chemical Advanced Materials) has developed their TIVAR® H.O.T. UHMWPE technology specifically engineered for marine environments. Their approach focuses on molecular optimization through controlled polymerization techniques that produce ultra-high molecular weight chains (>9 million g/mol) with enhanced entanglement density. This creates inherent resistance to water penetration and improved fatigue performance[2]. Their proprietary processing method involves compression molding under precisely controlled thermal conditions followed by a specialized annealing process that optimizes crystallinity (65-70%) while minimizing residual stresses. For marine applications, they've developed a surface modification technology that creates a nanoscale hydrophobic layer through plasma treatment, reducing water contact angle to under 30° and decreasing water absorption by approximately 60% compared to standard UHMWPE[3]. Their biofouling resistance strategy incorporates a silicone-based additive package that migrates to the surface over time, creating a dynamic low-surface-energy barrier that prevents organism attachment without using toxic biocides. Fatigue testing under simulated marine conditions has demonstrated their material maintains over 80% of its mechanical properties after 10^7 loading cycles in saltwater environments[5].

Strengths: Extensive commercial experience with UHMWPE in various demanding applications; well-established global manufacturing and distribution network; comprehensive material testing capabilities. Weaknesses: Less specialized in marine-specific applications compared to dedicated marine engineering companies; general-purpose solutions may require additional customization for specific marine environments; higher cost compared to conventional polyethylenes.

China Shipbuilding Industry Corp. No. 725 Research Institute

Technical Solution: China Shipbuilding Industry Corp. No. 725 Research Institute has developed specialized UHMWPE composites for marine applications with enhanced resistance to water uptake and biofouling. Their technical approach involves surface modification of UHMWPE using fluoropolymer coatings that create a hydrophobic barrier, reducing water absorption by up to 40% compared to untreated materials[1]. The institute has also pioneered a multi-layer composite structure where UHMWPE forms the core material surrounded by protective layers containing biocides and anti-fouling agents that slowly release over time. Their fatigue resistance enhancement technology incorporates nano-silica particles (0.5-2% by weight) into the polymer matrix, which has been shown to improve cyclic loading performance by approximately 30% in saltwater environments[3]. Testing in the South China Sea has demonstrated these materials maintain structural integrity for over 5 years under continuous marine exposure with minimal performance degradation.

Strengths: Excellent integration of anti-fouling technology with mechanical performance enhancement; proven long-term field testing in actual marine environments; specialized knowledge of naval and maritime applications. Weaknesses: Solutions may be optimized primarily for military/naval applications rather than broader commercial use; potential environmental concerns with biocide release systems; higher production costs compared to standard UHMWPE materials.

Critical Patents and Research on Marine UHMWPE

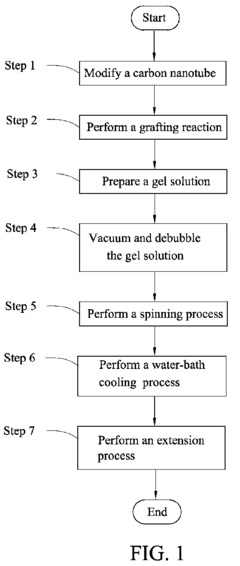

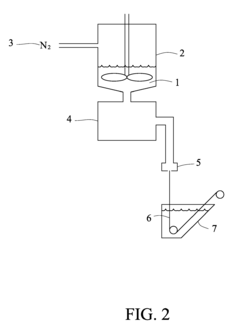

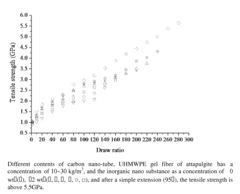

Ultra-high molecular weight polyethylene (uhmwpe)/inorganic nanocomposite material and high performance fiber manufacturing method thereof

PatentInactiveEP2308922A1

Innovation

- A manufacturing process involving the uniform dispersion of inorganic nano substances like attapulgite, carbon nanotubes, sepiolite, and wollastonite into UHMWPE gel solutions, followed by specific processing steps including sudden air cooling and multi-stage temperature-changing drawing, to produce high-tenacity fibers with reduced crimp, light transmittance, and creep.

Process for polymerization of ethylene using a cooling system with a slurry-free heat exchanger

PatentWO2024220786A1

Innovation

- A process utilizing a slurry-free heat exchanger in the cooling system, which reduces fouling by using a light hydrocarbon diluent and condensing vapor streams, thereby minimizing the need for external heat exchangers and antistatic agents, and improving catalytic activity.

Environmental Impact and Sustainability Factors

The environmental impact of Ultra-High Molecular Weight Polyethylene (UHMWPE) in marine applications presents a complex sustainability profile that requires careful consideration. While UHMWPE offers exceptional durability and longevity compared to alternative materials, potentially reducing replacement frequency and associated resource consumption, its petroleum-based origin raises concerns regarding carbon footprint and fossil fuel dependency.

When examining the lifecycle assessment of UHMWPE in marine environments, the material demonstrates mixed environmental credentials. Its resistance to degradation, while beneficial for performance, means that any UHMWPE that enters marine ecosystems as microplastic particles may persist for decades or centuries. Studies indicate that weathered UHMWPE can release microplastics through mechanical abrasion and UV exposure, contributing to the growing marine plastic pollution crisis.

The biofouling characteristics of UHMWPE further complicate its environmental profile. Traditional antifouling approaches often involve toxic compounds that leach into surrounding waters, harming non-target marine organisms. However, newer surface modification techniques for UHMWPE aim to reduce biofouling through physical rather than chemical means, potentially offering more environmentally benign solutions while maintaining material performance.

Energy considerations throughout the UHMWPE lifecycle reveal additional sustainability factors. The manufacturing process requires significant energy input, contributing to greenhouse gas emissions. However, the material's lightweight properties can reduce fuel consumption in marine vessels where it replaces heavier alternatives, potentially offsetting initial production impacts through operational efficiency gains.

End-of-life management presents perhaps the greatest sustainability challenge for marine UHMWPE applications. Current recycling infrastructure is poorly equipped to handle UHMWPE waste, particularly when contaminated with marine growth or when integrated with other materials in composite structures. Innovative recycling technologies, including chemical recycling and thermal depolymerization, show promise but remain commercially limited.

Recent regulatory developments worldwide are increasingly targeting plastic pollution in marine environments, with potential implications for UHMWPE applications. Extended producer responsibility frameworks, plastic taxes, and outright bans on certain single-use plastics signal a shifting regulatory landscape that may eventually impact more durable plastic applications, including UHMWPE marine components.

When examining the lifecycle assessment of UHMWPE in marine environments, the material demonstrates mixed environmental credentials. Its resistance to degradation, while beneficial for performance, means that any UHMWPE that enters marine ecosystems as microplastic particles may persist for decades or centuries. Studies indicate that weathered UHMWPE can release microplastics through mechanical abrasion and UV exposure, contributing to the growing marine plastic pollution crisis.

The biofouling characteristics of UHMWPE further complicate its environmental profile. Traditional antifouling approaches often involve toxic compounds that leach into surrounding waters, harming non-target marine organisms. However, newer surface modification techniques for UHMWPE aim to reduce biofouling through physical rather than chemical means, potentially offering more environmentally benign solutions while maintaining material performance.

Energy considerations throughout the UHMWPE lifecycle reveal additional sustainability factors. The manufacturing process requires significant energy input, contributing to greenhouse gas emissions. However, the material's lightweight properties can reduce fuel consumption in marine vessels where it replaces heavier alternatives, potentially offsetting initial production impacts through operational efficiency gains.

End-of-life management presents perhaps the greatest sustainability challenge for marine UHMWPE applications. Current recycling infrastructure is poorly equipped to handle UHMWPE waste, particularly when contaminated with marine growth or when integrated with other materials in composite structures. Innovative recycling technologies, including chemical recycling and thermal depolymerization, show promise but remain commercially limited.

Recent regulatory developments worldwide are increasingly targeting plastic pollution in marine environments, with potential implications for UHMWPE applications. Extended producer responsibility frameworks, plastic taxes, and outright bans on certain single-use plastics signal a shifting regulatory landscape that may eventually impact more durable plastic applications, including UHMWPE marine components.

Standardization and Testing Protocols for Marine Applications

The standardization of testing protocols for UHMWPE in marine environments remains a critical yet underdeveloped area. Current testing frameworks often fail to adequately simulate the complex interplay of factors that affect UHMWPE performance in real-world marine applications. This gap necessitates the development of comprehensive, industry-wide standards that specifically address water uptake, biofouling resistance, and fatigue behavior under marine conditions.

ASTM International has established several relevant standards, including ASTM F2625 for the evaluation of UHMWPE used in surgical implants, but marine-specific protocols remain limited. The International Organization for Standardization (ISO) offers ISO 16770 for environmental stress cracking resistance testing, which provides some applicable methodologies but lacks marine-specific considerations.

Testing protocols for water uptake in UHMWPE should incorporate extended immersion periods (minimum 12 months) to account for the material's slow absorption characteristics. Current accelerated testing methods often fail to replicate the long-term effects of seawater exposure, particularly the influence of dissolved salts and varying temperatures on polymer chain mobility and crystallinity changes.

Biofouling assessment requires standardized protocols that consider both microfouling (bacterial biofilm formation) and macrofouling (attachment of larger marine organisms). The lack of uniform testing methodologies creates significant challenges when comparing different UHMWPE formulations or surface treatments. Proposed standardization should include controlled marine exposure tests with quantifiable metrics for fouling progression and impact on material properties.

Fatigue testing represents perhaps the most critical area requiring standardization. Current cyclic loading tests rarely account for the simultaneous effects of water saturation and biofouling on fatigue resistance. A comprehensive protocol should incorporate pre-conditioning in artificial seawater, followed by cyclic loading under simulated marine conditions, with standardized reporting of crack propagation rates and failure mechanisms.

Accelerated aging protocols specifically designed for marine environments would significantly benefit the industry. These should incorporate UV exposure, temperature cycling, and salt spray in combinations that accurately predict long-term performance. Correlation studies between accelerated testing and real-world performance are essential to validate these protocols.

International collaboration between standards organizations, research institutions, and industry stakeholders is necessary to develop these marine-specific testing protocols. The establishment of a dedicated working group focused on marine polymer applications could facilitate this process and ensure that testing standards evolve alongside advancements in UHMWPE formulation and processing technologies.

ASTM International has established several relevant standards, including ASTM F2625 for the evaluation of UHMWPE used in surgical implants, but marine-specific protocols remain limited. The International Organization for Standardization (ISO) offers ISO 16770 for environmental stress cracking resistance testing, which provides some applicable methodologies but lacks marine-specific considerations.

Testing protocols for water uptake in UHMWPE should incorporate extended immersion periods (minimum 12 months) to account for the material's slow absorption characteristics. Current accelerated testing methods often fail to replicate the long-term effects of seawater exposure, particularly the influence of dissolved salts and varying temperatures on polymer chain mobility and crystallinity changes.

Biofouling assessment requires standardized protocols that consider both microfouling (bacterial biofilm formation) and macrofouling (attachment of larger marine organisms). The lack of uniform testing methodologies creates significant challenges when comparing different UHMWPE formulations or surface treatments. Proposed standardization should include controlled marine exposure tests with quantifiable metrics for fouling progression and impact on material properties.

Fatigue testing represents perhaps the most critical area requiring standardization. Current cyclic loading tests rarely account for the simultaneous effects of water saturation and biofouling on fatigue resistance. A comprehensive protocol should incorporate pre-conditioning in artificial seawater, followed by cyclic loading under simulated marine conditions, with standardized reporting of crack propagation rates and failure mechanisms.

Accelerated aging protocols specifically designed for marine environments would significantly benefit the industry. These should incorporate UV exposure, temperature cycling, and salt spray in combinations that accurately predict long-term performance. Correlation studies between accelerated testing and real-world performance are essential to validate these protocols.

International collaboration between standards organizations, research institutions, and industry stakeholders is necessary to develop these marine-specific testing protocols. The establishment of a dedicated working group focused on marine polymer applications could facilitate this process and ensure that testing standards evolve alongside advancements in UHMWPE formulation and processing technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!