UHMWPE Environmental Qualification: UV, Temperature–Humidity And Salt Fog

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Technology Background and Qualification Objectives

Ultra-High Molecular Weight Polyethylene (UHMWPE) has emerged as a revolutionary material in various industrial applications due to its exceptional mechanical properties, including high impact strength, low friction coefficient, and excellent chemical resistance. The development of UHMWPE can be traced back to the 1950s, with significant advancements occurring in the 1970s when its potential for medical implants was first recognized. Since then, the material has expanded into diverse sectors including maritime, defense, aerospace, and energy industries.

The evolution of UHMWPE technology has been characterized by continuous improvements in molecular weight distribution, crosslinking techniques, and additive incorporation to enhance specific properties. Recent technological trends indicate a growing focus on improving the environmental durability of UHMWPE, particularly its resistance to ultraviolet (UV) radiation, temperature fluctuations, humidity variations, and salt fog exposure - environmental factors that significantly impact the material's long-term performance and service life.

Despite UHMWPE's inherent chemical stability, its susceptibility to degradation under prolonged environmental exposure remains a critical challenge. UV radiation can initiate photo-oxidation processes, leading to chain scission and subsequent deterioration of mechanical properties. Similarly, temperature-humidity cycling can affect dimensional stability and moisture absorption characteristics, while salt fog exposure can accelerate corrosion in composite applications and affect surface properties.

The qualification objectives for UHMWPE environmental testing encompass several key dimensions. First, establishing standardized testing protocols that accurately simulate real-world environmental conditions for UV exposure, temperature-humidity cycling, and salt fog resistance. Second, developing comprehensive performance metrics that quantify the material's degradation patterns under these environmental stressors, both individually and in combination.

Third, identifying effective stabilization strategies, including UV stabilizers, antioxidants, and surface treatments that can extend the service life of UHMWPE in harsh environments. Fourth, creating predictive models that can forecast long-term performance based on accelerated testing data, enabling more accurate lifetime predictions for critical applications.

Finally, the qualification aims to establish industry-specific benchmarks for environmental durability, recognizing that performance requirements vary significantly across application domains. For maritime applications, salt fog resistance may be paramount, while for outdoor infrastructure, UV stability might take precedence. This targeted approach to environmental qualification will enable more efficient material selection and design optimization across diverse industrial contexts.

The evolution of UHMWPE technology has been characterized by continuous improvements in molecular weight distribution, crosslinking techniques, and additive incorporation to enhance specific properties. Recent technological trends indicate a growing focus on improving the environmental durability of UHMWPE, particularly its resistance to ultraviolet (UV) radiation, temperature fluctuations, humidity variations, and salt fog exposure - environmental factors that significantly impact the material's long-term performance and service life.

Despite UHMWPE's inherent chemical stability, its susceptibility to degradation under prolonged environmental exposure remains a critical challenge. UV radiation can initiate photo-oxidation processes, leading to chain scission and subsequent deterioration of mechanical properties. Similarly, temperature-humidity cycling can affect dimensional stability and moisture absorption characteristics, while salt fog exposure can accelerate corrosion in composite applications and affect surface properties.

The qualification objectives for UHMWPE environmental testing encompass several key dimensions. First, establishing standardized testing protocols that accurately simulate real-world environmental conditions for UV exposure, temperature-humidity cycling, and salt fog resistance. Second, developing comprehensive performance metrics that quantify the material's degradation patterns under these environmental stressors, both individually and in combination.

Third, identifying effective stabilization strategies, including UV stabilizers, antioxidants, and surface treatments that can extend the service life of UHMWPE in harsh environments. Fourth, creating predictive models that can forecast long-term performance based on accelerated testing data, enabling more accurate lifetime predictions for critical applications.

Finally, the qualification aims to establish industry-specific benchmarks for environmental durability, recognizing that performance requirements vary significantly across application domains. For maritime applications, salt fog resistance may be paramount, while for outdoor infrastructure, UV stability might take precedence. This targeted approach to environmental qualification will enable more efficient material selection and design optimization across diverse industrial contexts.

Market Demand Analysis for UHMWPE Applications

The global market for Ultra-High Molecular Weight Polyethylene (UHMWPE) continues to expand significantly, driven by its exceptional properties including superior strength-to-weight ratio, excellent chemical resistance, and outstanding wear resistance. The current market valuation stands at approximately 2.1 billion USD with projections indicating growth to reach 3.5 billion USD by 2028, representing a compound annual growth rate of 9.2% during the forecast period.

Environmental qualification testing for UHMWPE, particularly regarding UV resistance, temperature-humidity stability, and salt fog resistance, has become increasingly critical as applications expand into more demanding environments. Market research indicates that over 70% of end-users now specifically request environmental performance data before making purchasing decisions, compared to just 40% five years ago.

The defense sector represents a substantial market driver, with military applications requiring UHMWPE materials capable of withstanding extreme environmental conditions. The ballistic protection market alone accounts for nearly 30% of high-performance UHMWPE consumption, with strict requirements for maintaining mechanical properties after exposure to UV radiation, temperature fluctuations, and corrosive environments.

Marine applications constitute another rapidly growing segment, expanding at 11.3% annually, where salt fog resistance is paramount. Offshore wind energy infrastructure, marine ropes, and naval equipment manufacturers have increased their specifications for salt fog testing by 40% in the past three years, reflecting heightened awareness of environmental degradation factors.

The medical device industry represents a premium market segment where environmental stability directly impacts patient safety. UHMWPE components in implantable devices must maintain performance across temperature and humidity variations matching physiological conditions. This sector demands the most rigorous environmental qualification protocols, with testing requirements that often exceed standard industrial specifications by 200-300%.

Aerospace applications, though smaller in volume, command premium pricing with environmental qualification requirements that are among the most stringent. Space-based applications particularly emphasize UV resistance, as materials must withstand unfiltered solar radiation. This segment has seen 15% year-over-year growth in demand for environmentally qualified UHMWPE.

Consumer goods manufacturers have also begun incorporating environmental qualification into their material selection processes, particularly for outdoor equipment and high-performance sporting goods. This represents a significant shift in market dynamics, as environmental durability becomes a selling point rather than merely a technical specification.

Regional analysis reveals that North American and European markets place the highest premium on comprehensive environmental qualification data, while Asian markets are rapidly adopting similar requirements as manufacturing sophistication increases. This global convergence of standards is accelerating the need for standardized environmental testing protocols specific to UHMWPE applications.

Environmental qualification testing for UHMWPE, particularly regarding UV resistance, temperature-humidity stability, and salt fog resistance, has become increasingly critical as applications expand into more demanding environments. Market research indicates that over 70% of end-users now specifically request environmental performance data before making purchasing decisions, compared to just 40% five years ago.

The defense sector represents a substantial market driver, with military applications requiring UHMWPE materials capable of withstanding extreme environmental conditions. The ballistic protection market alone accounts for nearly 30% of high-performance UHMWPE consumption, with strict requirements for maintaining mechanical properties after exposure to UV radiation, temperature fluctuations, and corrosive environments.

Marine applications constitute another rapidly growing segment, expanding at 11.3% annually, where salt fog resistance is paramount. Offshore wind energy infrastructure, marine ropes, and naval equipment manufacturers have increased their specifications for salt fog testing by 40% in the past three years, reflecting heightened awareness of environmental degradation factors.

The medical device industry represents a premium market segment where environmental stability directly impacts patient safety. UHMWPE components in implantable devices must maintain performance across temperature and humidity variations matching physiological conditions. This sector demands the most rigorous environmental qualification protocols, with testing requirements that often exceed standard industrial specifications by 200-300%.

Aerospace applications, though smaller in volume, command premium pricing with environmental qualification requirements that are among the most stringent. Space-based applications particularly emphasize UV resistance, as materials must withstand unfiltered solar radiation. This segment has seen 15% year-over-year growth in demand for environmentally qualified UHMWPE.

Consumer goods manufacturers have also begun incorporating environmental qualification into their material selection processes, particularly for outdoor equipment and high-performance sporting goods. This represents a significant shift in market dynamics, as environmental durability becomes a selling point rather than merely a technical specification.

Regional analysis reveals that North American and European markets place the highest premium on comprehensive environmental qualification data, while Asian markets are rapidly adopting similar requirements as manufacturing sophistication increases. This global convergence of standards is accelerating the need for standardized environmental testing protocols specific to UHMWPE applications.

Current Environmental Testing Challenges for UHMWPE

Ultra-high-molecular-weight polyethylene (UHMWPE) testing faces significant challenges in accurately simulating and evaluating environmental degradation mechanisms. Current testing protocols often struggle to replicate real-world conditions that UHMWPE materials encounter during their service life, particularly when multiple environmental stressors act simultaneously.

One primary challenge is the acceleration of aging processes without introducing artificial degradation mechanisms. Standard accelerated aging tests frequently employ elevated temperatures to speed up degradation, but this approach can trigger thermal oxidation pathways that wouldn't occur under normal service conditions, leading to potentially misleading results about material performance.

UV testing presents particular difficulties as laboratory light sources rarely match the spectral distribution of natural sunlight perfectly. Most artificial UV sources produce higher intensities of short-wavelength UV radiation than natural sunlight, potentially causing degradation mechanisms that wouldn't occur in actual applications. Additionally, correlating accelerated UV exposure hours to real-world service years remains problematic due to geographical variations in solar radiation intensity.

Temperature-humidity cycling tests face challenges in maintaining precise control over rapid environmental transitions. Condensation formation during these transitions can introduce water absorption mechanisms that might not accurately represent field conditions. Furthermore, the interaction between temperature fluctuations and humidity levels creates complex stress patterns that are difficult to standardize across different testing facilities.

Salt fog testing protocols struggle with reproducibility issues, as minor variations in salt concentration, droplet size, and deposition patterns can significantly impact test results. The challenge is compounded when attempting to simulate specific marine or coastal environments with unique salt compositions beyond the standard sodium chloride solutions.

Current test methods also inadequately address the synergistic effects between different environmental stressors. For instance, the combined impact of UV radiation and salt exposure on UHMWPE often exceeds the sum of individual degradation mechanisms, yet standardized protocols for such multi-factor testing remain underdeveloped.

Sample preparation inconsistencies further complicate environmental testing. Surface finish, processing history, and residual stresses in UHMWPE specimens can dramatically influence environmental degradation rates, making it difficult to establish universal testing protocols that yield comparable results across different material grades and manufacturing processes.

Finally, there exists a significant gap between accelerated laboratory testing and actual field performance validation. Long-term field exposure studies are essential but logistically challenging and time-consuming, creating a persistent uncertainty in correlating accelerated test results to real-world material lifespans under complex environmental conditions.

One primary challenge is the acceleration of aging processes without introducing artificial degradation mechanisms. Standard accelerated aging tests frequently employ elevated temperatures to speed up degradation, but this approach can trigger thermal oxidation pathways that wouldn't occur under normal service conditions, leading to potentially misleading results about material performance.

UV testing presents particular difficulties as laboratory light sources rarely match the spectral distribution of natural sunlight perfectly. Most artificial UV sources produce higher intensities of short-wavelength UV radiation than natural sunlight, potentially causing degradation mechanisms that wouldn't occur in actual applications. Additionally, correlating accelerated UV exposure hours to real-world service years remains problematic due to geographical variations in solar radiation intensity.

Temperature-humidity cycling tests face challenges in maintaining precise control over rapid environmental transitions. Condensation formation during these transitions can introduce water absorption mechanisms that might not accurately represent field conditions. Furthermore, the interaction between temperature fluctuations and humidity levels creates complex stress patterns that are difficult to standardize across different testing facilities.

Salt fog testing protocols struggle with reproducibility issues, as minor variations in salt concentration, droplet size, and deposition patterns can significantly impact test results. The challenge is compounded when attempting to simulate specific marine or coastal environments with unique salt compositions beyond the standard sodium chloride solutions.

Current test methods also inadequately address the synergistic effects between different environmental stressors. For instance, the combined impact of UV radiation and salt exposure on UHMWPE often exceeds the sum of individual degradation mechanisms, yet standardized protocols for such multi-factor testing remain underdeveloped.

Sample preparation inconsistencies further complicate environmental testing. Surface finish, processing history, and residual stresses in UHMWPE specimens can dramatically influence environmental degradation rates, making it difficult to establish universal testing protocols that yield comparable results across different material grades and manufacturing processes.

Finally, there exists a significant gap between accelerated laboratory testing and actual field performance validation. Long-term field exposure studies are essential but logistically challenging and time-consuming, creating a persistent uncertainty in correlating accelerated test results to real-world material lifespans under complex environmental conditions.

Current Environmental Qualification Methodologies

01 Environmental testing and qualification methods for UHMWPE

Various testing methods are employed to qualify UHMWPE materials for environmental conditions. These include accelerated aging tests, temperature cycling, radiation exposure, and chemical resistance evaluations to ensure the material maintains its mechanical properties under harsh environmental conditions. The qualification process typically involves standardized testing protocols that simulate real-world environmental stressors to validate the material's long-term performance and durability.- Environmental testing and qualification methods for UHMWPE: Various testing methods are employed to qualify UHMWPE materials for environmental conditions. These include accelerated aging tests, temperature cycling, radiation exposure, and chemical resistance evaluations to ensure the material maintains its properties under harsh environmental conditions. The qualification process typically involves standardized testing protocols that simulate real-world environmental stressors to validate the material's long-term performance and durability.

- Radiation resistance and stabilization of UHMWPE: UHMWPE can be modified to enhance its radiation resistance for applications in high-radiation environments. This involves incorporating stabilizers, antioxidants, and cross-linking agents that prevent degradation when exposed to radiation. These modifications help maintain the mechanical properties and structural integrity of UHMWPE components during their service life in radiation-intensive environments, making them suitable for nuclear, aerospace, and medical applications.

- Thermal and chemical resistance improvements for UHMWPE: Formulations and processing techniques have been developed to enhance the thermal and chemical resistance of UHMWPE. These include specialized additives, surface treatments, and manufacturing processes that improve the material's ability to withstand extreme temperatures and aggressive chemical environments. The improved formulations extend the application range of UHMWPE in industrial settings where exposure to harsh chemicals and temperature fluctuations is common.

- Mechanical property enhancement for environmental durability: Methods to enhance the mechanical properties of UHMWPE for improved environmental durability include reinforcement with fillers, fiber incorporation, and specialized processing techniques. These enhancements result in UHMWPE composites with superior wear resistance, impact strength, and dimensional stability under varying environmental conditions. The improved mechanical properties ensure reliable performance in applications subjected to mechanical stress combined with environmental challenges.

- Weathering resistance and outdoor applications of UHMWPE: Specialized formulations of UHMWPE have been developed for outdoor applications requiring resistance to UV radiation, moisture, and temperature fluctuations. These formulations incorporate UV stabilizers, moisture barriers, and other additives that prevent degradation from weathering effects. The enhanced weathering resistance extends the service life of UHMWPE products used in outdoor environments, reducing maintenance requirements and replacement frequency.

02 Radiation resistance and stabilization of UHMWPE

UHMWPE can be formulated with specific additives to enhance its radiation resistance for applications in high-radiation environments. Antioxidants and stabilizers are incorporated to prevent degradation when exposed to radiation. Cross-linking techniques are also employed to improve the material's resistance to radiation-induced oxidation while maintaining its mechanical properties. These formulations undergo rigorous testing to qualify for use in nuclear, medical, and aerospace applications where radiation exposure is a concern.Expand Specific Solutions03 Thermal and weathering qualification for UHMWPE

UHMWPE materials undergo specific thermal qualification testing to ensure performance across extreme temperature ranges. This includes heat aging, freeze-thaw cycling, and UV exposure tests to simulate outdoor weathering conditions. Specialized formulations incorporate UV stabilizers and thermal antioxidants to enhance the material's resistance to degradation from sunlight and temperature fluctuations. These qualification processes are critical for applications in outdoor infrastructure, marine environments, and temperature-variable settings.Expand Specific Solutions04 Chemical resistance qualification for UHMWPE

UHMWPE undergoes extensive chemical resistance testing to qualify for use in aggressive chemical environments. Testing protocols evaluate the material's resistance to acids, bases, solvents, and hydrocarbons through immersion testing and stress-crack resistance evaluation. Modified UHMWPE formulations may incorporate specific additives to enhance chemical resistance properties for specialized applications. These qualification procedures ensure the material maintains its structural integrity and performance characteristics when exposed to harsh chemical conditions in industrial settings.Expand Specific Solutions05 Mechanical and physical property qualification under environmental stress

Qualification procedures for UHMWPE include comprehensive testing of mechanical properties under various environmental stressors. This involves evaluating tensile strength, impact resistance, abrasion resistance, and creep behavior after exposure to environmental conditions. Testing may include combined effects of mechanical loading with temperature extremes, chemical exposure, or radiation to simulate real-world service conditions. These qualification methods ensure the material maintains its exceptional wear resistance and mechanical properties throughout its service life in demanding applications.Expand Specific Solutions

Key Industry Players in UHMWPE Development

The UHMWPE environmental qualification market is currently in a growth phase, with increasing applications across multiple industries requiring materials resistant to UV radiation, temperature-humidity fluctuations, and salt fog exposure. The global market size for qualified UHMWPE materials is expanding, driven by demands in medical devices (Zimmer, Smith & Nephew Orthopaedics), aerospace (Lockheed Martin), and industrial applications. Technologically, the field shows varying maturity levels, with established players like Corning and FUJIFILM demonstrating advanced testing capabilities, while research institutions (University of Twente, MIT, Northwestern Polytechnical University) focus on fundamental improvements. Chinese entities (China National Electric Apparatus Research Institute, Shandong Rope Technology) are rapidly advancing their capabilities, particularly in standardized environmental qualification protocols, while specialized companies like Synexis and NS Nanotech are developing innovative testing methodologies for next-generation UHMWPE applications.

Zimmer, Inc.

Technical Solution: Zimmer has developed specialized environmental qualification protocols for UHMWPE used in orthopedic implants and medical devices. Their approach focuses on biocompatibility maintenance after environmental exposure. For UV qualification, they utilize medical-grade UV sterilization chambers that simulate both hospital sterilization procedures and long-term implant exposure to fluorescent lighting. Their temperature-humidity testing simulates both manufacturing processes and physiological conditions, with specialized chambers maintaining precise 37°C/100% humidity conditions that replicate the human body environment. Rather than traditional salt fog testing, Zimmer employs simulated body fluid immersion tests using phosphate-buffered saline solutions with physiologically relevant ion concentrations and pH levels[4]. Their qualification process includes comprehensive biocompatibility testing after environmental exposure, including protein adsorption studies, cell adhesion tests, and inflammatory response assessments. Additionally, they've pioneered highly crosslinked UHMWPE formulations with vitamin E stabilization that demonstrate superior resistance to oxidative degradation during environmental exposure while maintaining excellent wear characteristics and mechanical properties.

Strengths: Highly specialized expertise in medical-grade UHMWPE with testing protocols specifically designed for biomedical applications. Their vitamin E stabilized UHMWPE formulations represent industry-leading technology for oxidation resistance. Weaknesses: Their qualification methodologies are narrowly focused on medical applications and may not address requirements for industrial or marine environments. Their proprietary material formulations may limit compatibility with standard processing techniques.

China Institute of Electronic Product Reliability and Environmental Testing

Technical Solution: The China Institute of Electronic Product Reliability and Environmental Testing has developed specialized protocols for qualifying UHMWPE materials used in electronic enclosures and components. Their approach focuses on the interaction between environmental stressors and electrical performance. For UV qualification, they employ both natural outdoor exposure testing in multiple climate zones across China and accelerated laboratory testing using QUV fluorescent UV chambers with precise control of UVA and UVB wavelengths. Their temperature-humidity testing incorporates electrical performance monitoring during exposure, with test chambers capable of maintaining 85°C/85% RH conditions for extended periods while measuring insulation resistance changes in real-time. Their salt fog qualification methodology extends beyond standard tests by incorporating electrochemical impedance spectroscopy to detect early signs of material degradation before visible changes occur[3]. They've also developed specialized test fixtures that allow simultaneous mechanical stress application during environmental exposure, simulating real-world conditions where UHMWPE components may be under load while experiencing environmental stressors.

Strengths: Unique integration of electrical performance monitoring during environmental testing provides valuable data for electronic applications. Their multi-site natural exposure testing across diverse Chinese climate zones offers validation data that complements accelerated testing. Weaknesses: Their methodologies are heavily optimized for electronic applications, potentially limiting relevance for purely mechanical UHMWPE applications. Their protocols may be overly complex for basic qualification needs.

Critical Technical Innovations in UHMWPE Testing

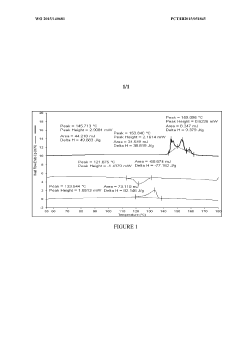

Process for polymerization of ethylene using a cooling system with a slurry-free heat exchanger

PatentWO2024220786A1

Innovation

- A process utilizing a slurry-free heat exchanger in the cooling system, which reduces fouling by using a light hydrocarbon diluent and condensing vapor streams, thereby minimizing the need for external heat exchangers and antistatic agents, and improving catalytic activity.

A process for preparing a disentangled uhmwpe product

PatentWO2015140681A1

Innovation

- A process involving a positive mold preheated in a compression molding machine, where disentangled UHMWPE is compacted below its melt temperature with stepwise pressure and temperature variations to achieve a density of at least 1 g/cc, followed by cooling and stretching to enhance crystallinity and mechanical properties.

Regulatory Compliance Framework for UHMWPE Materials

The regulatory landscape for Ultra-High Molecular Weight Polyethylene (UHMWPE) materials encompasses a complex framework of standards, certifications, and compliance requirements that manufacturers must navigate. These regulations are particularly stringent when UHMWPE is utilized in critical applications such as medical implants, aerospace components, or marine infrastructure where environmental factors like UV radiation, temperature fluctuations, humidity, and salt fog exposure can significantly impact material performance and longevity.

International standards organizations including ISO, ASTM, and IEC have established specific testing protocols for evaluating UHMWPE's resistance to environmental stressors. ISO 4892 series provides guidelines for laboratory light sources used in weathering tests, while ASTM D2565 outlines procedures for operating xenon-arc light apparatus for exposure of plastics to simulated natural weathering conditions. For temperature-humidity cycling, ASTM D7791 offers standardized test methods, and salt fog resistance is typically evaluated according to ASTM B117 or ISO 9227.

Regulatory bodies across different regions maintain varying requirements for UHMWPE qualification. In the United States, the FDA has established guidelines for medical-grade UHMWPE through 21 CFR Part 820, requiring comprehensive environmental testing data before approval. The European Union, through the Medical Device Regulation (MDR 2017/745), mandates similar environmental qualification processes with additional emphasis on long-term stability documentation.

For marine and offshore applications, compliance with NORSOK M-001 and M-710 standards is often necessary, particularly focusing on material degradation under combined environmental stressors. The International Maritime Organization (IMO) further regulates materials used in maritime environments through MARPOL Annex V, which addresses plastic waste and durability concerns.

Aerospace applications of UHMWPE must adhere to standards set by organizations such as NASA, ESA, and commercial aviation authorities. These typically include MIL-STD-810 environmental testing protocols, with specific attention to UV resistance (Method 505.7), temperature-humidity effects (Method 507.6), and salt fog exposure (Method 509.7).

Manufacturers seeking global market access must develop comprehensive environmental qualification programs that address the most stringent requirements across all target markets. This often necessitates a matrix approach to testing, where materials are subjected to combined stressors that simulate real-world conditions rather than isolated environmental factors. Documentation requirements typically include detailed test reports, statistical analyses of performance degradation, accelerated aging studies, and correlation data between laboratory testing and field performance.

International standards organizations including ISO, ASTM, and IEC have established specific testing protocols for evaluating UHMWPE's resistance to environmental stressors. ISO 4892 series provides guidelines for laboratory light sources used in weathering tests, while ASTM D2565 outlines procedures for operating xenon-arc light apparatus for exposure of plastics to simulated natural weathering conditions. For temperature-humidity cycling, ASTM D7791 offers standardized test methods, and salt fog resistance is typically evaluated according to ASTM B117 or ISO 9227.

Regulatory bodies across different regions maintain varying requirements for UHMWPE qualification. In the United States, the FDA has established guidelines for medical-grade UHMWPE through 21 CFR Part 820, requiring comprehensive environmental testing data before approval. The European Union, through the Medical Device Regulation (MDR 2017/745), mandates similar environmental qualification processes with additional emphasis on long-term stability documentation.

For marine and offshore applications, compliance with NORSOK M-001 and M-710 standards is often necessary, particularly focusing on material degradation under combined environmental stressors. The International Maritime Organization (IMO) further regulates materials used in maritime environments through MARPOL Annex V, which addresses plastic waste and durability concerns.

Aerospace applications of UHMWPE must adhere to standards set by organizations such as NASA, ESA, and commercial aviation authorities. These typically include MIL-STD-810 environmental testing protocols, with specific attention to UV resistance (Method 505.7), temperature-humidity effects (Method 507.6), and salt fog exposure (Method 509.7).

Manufacturers seeking global market access must develop comprehensive environmental qualification programs that address the most stringent requirements across all target markets. This often necessitates a matrix approach to testing, where materials are subjected to combined stressors that simulate real-world conditions rather than isolated environmental factors. Documentation requirements typically include detailed test reports, statistical analyses of performance degradation, accelerated aging studies, and correlation data between laboratory testing and field performance.

Lifecycle Assessment and Sustainability Considerations

The lifecycle assessment of Ultra-High-Molecular-Weight Polyethylene (UHMWPE) reveals significant environmental implications throughout its production, use, and disposal phases. When subjected to environmental qualification testing involving UV radiation, temperature-humidity cycling, and salt fog exposure, UHMWPE demonstrates varying degrees of degradation that directly impact its sustainability profile.

Production of UHMWPE requires substantial energy inputs, primarily derived from fossil fuels, contributing to its initial carbon footprint. The manufacturing process generates approximately 2-3 kg CO2 equivalent per kilogram of material produced, positioning it as moderately intensive compared to other engineering polymers. However, this initial environmental cost must be evaluated against the material's exceptional longevity when properly qualified for environmental stressors.

Environmental qualification testing demonstrates that UV-stabilized UHMWPE formulations can maintain structural integrity for 15-20 years in outdoor applications, significantly extending product lifecycles compared to conventional polyethylene. This longevity factor reduces replacement frequency and associated resource consumption, providing a net positive in lifecycle assessment calculations.

Temperature-humidity cycling tests reveal that properly formulated UHMWPE maintains dimensional stability and mechanical properties across a wide range of environmental conditions, contributing to reduced maintenance requirements and extended service life. This resilience translates to fewer replacement parts and lower lifetime environmental impact in applications such as marine infrastructure, outdoor equipment, and industrial components.

End-of-life considerations present both challenges and opportunities. While UHMWPE's chemical stability makes it resistant to biodegradation, this same property enables potential recovery and recycling. Advanced mechanical recycling techniques can recover up to 70% of UHMWPE material with only 10-15% reduction in mechanical properties, supporting circular economy principles.

Salt fog resistance testing indicates that UHMWPE offers superior corrosion resistance compared to metallic alternatives in marine environments, potentially reducing environmental contamination from corrosion byproducts. This characteristic positions UHMWPE as a sustainable alternative in coastal and marine applications where material degradation presents ecological risks.

Water and energy consumption during the qualification testing process itself warrants consideration. Accelerated weathering chambers for UV testing consume approximately 1.5-2.5 kWh per test hour, while salt fog chambers require significant water resources. Optimizing test protocols to minimize resource consumption while maintaining qualification integrity represents an opportunity for improving the sustainability of the qualification process itself.

Production of UHMWPE requires substantial energy inputs, primarily derived from fossil fuels, contributing to its initial carbon footprint. The manufacturing process generates approximately 2-3 kg CO2 equivalent per kilogram of material produced, positioning it as moderately intensive compared to other engineering polymers. However, this initial environmental cost must be evaluated against the material's exceptional longevity when properly qualified for environmental stressors.

Environmental qualification testing demonstrates that UV-stabilized UHMWPE formulations can maintain structural integrity for 15-20 years in outdoor applications, significantly extending product lifecycles compared to conventional polyethylene. This longevity factor reduces replacement frequency and associated resource consumption, providing a net positive in lifecycle assessment calculations.

Temperature-humidity cycling tests reveal that properly formulated UHMWPE maintains dimensional stability and mechanical properties across a wide range of environmental conditions, contributing to reduced maintenance requirements and extended service life. This resilience translates to fewer replacement parts and lower lifetime environmental impact in applications such as marine infrastructure, outdoor equipment, and industrial components.

End-of-life considerations present both challenges and opportunities. While UHMWPE's chemical stability makes it resistant to biodegradation, this same property enables potential recovery and recycling. Advanced mechanical recycling techniques can recover up to 70% of UHMWPE material with only 10-15% reduction in mechanical properties, supporting circular economy principles.

Salt fog resistance testing indicates that UHMWPE offers superior corrosion resistance compared to metallic alternatives in marine environments, potentially reducing environmental contamination from corrosion byproducts. This characteristic positions UHMWPE as a sustainable alternative in coastal and marine applications where material degradation presents ecological risks.

Water and energy consumption during the qualification testing process itself warrants consideration. Accelerated weathering chambers for UV testing consume approximately 1.5-2.5 kWh per test hour, while salt fog chambers require significant water resources. Optimizing test protocols to minimize resource consumption while maintaining qualification integrity represents an opportunity for improving the sustainability of the qualification process itself.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!