UHMWPE Cable Terminations: Wedges, Resins And Load Transfer Reliability

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Cable Termination Technology Background and Objectives

Ultra-High Molecular Weight Polyethylene (UHMWPE) cable termination technology has evolved significantly over the past three decades, transforming from experimental applications to mainstream solutions in critical infrastructure. The development trajectory began in the 1990s with initial explorations of synthetic fiber ropes in marine applications, followed by adaptation to high-performance cable systems in the early 2000s. This evolution has been driven by increasing demands for lightweight, high-strength materials in sectors ranging from offshore engineering to aerospace.

The fundamental challenge in UHMWPE cable termination lies in the material's inherent properties - while offering exceptional strength-to-weight ratios exceeding those of steel, UHMWPE presents unique termination difficulties due to its low surface friction, creep behavior, and resistance to chemical bonding. Traditional metal cable termination methods proved inadequate when applied to this advanced polymer, necessitating innovative approaches to load transfer mechanisms.

Current technological objectives center on optimizing the reliability of load transfer between UHMWPE cables and termination systems. This involves addressing three critical components: wedge designs that maximize mechanical grip without damaging fibers, resin formulations that enhance interface adhesion, and comprehensive load transfer systems that maintain reliability under dynamic loading conditions. The industry aims to achieve termination efficiencies approaching 100% of the cable's rated breaking strength while maintaining long-term performance under varied environmental conditions.

Recent technological advancements have focused on hybrid termination systems that combine mechanical wedge principles with advanced resin technologies. These developments seek to overcome the persistent challenges of creep and stress relaxation that have historically limited UHMWPE applications in permanent installations. Computational modeling and simulation have emerged as essential tools in predicting long-term performance and optimizing geometric configurations of termination components.

The broader objective of current research extends beyond immediate performance metrics to encompass lifecycle reliability, with particular emphasis on fatigue resistance, environmental degradation mechanisms, and non-destructive testing methodologies. As UHMWPE cables find increasing applications in critical infrastructure, from deep-sea tethers to architectural tension members, the development of standardized testing protocols and industry specifications has become a parallel objective to technological advancement.

Looking forward, the technology roadmap for UHMWPE cable terminations aims to establish predictable service lifespans exceeding 25 years in demanding environments, while simultaneously reducing installation complexity and specialized equipment requirements. This dual focus on performance enhancement and practical implementation reflects the maturing nature of this technology domain.

The fundamental challenge in UHMWPE cable termination lies in the material's inherent properties - while offering exceptional strength-to-weight ratios exceeding those of steel, UHMWPE presents unique termination difficulties due to its low surface friction, creep behavior, and resistance to chemical bonding. Traditional metal cable termination methods proved inadequate when applied to this advanced polymer, necessitating innovative approaches to load transfer mechanisms.

Current technological objectives center on optimizing the reliability of load transfer between UHMWPE cables and termination systems. This involves addressing three critical components: wedge designs that maximize mechanical grip without damaging fibers, resin formulations that enhance interface adhesion, and comprehensive load transfer systems that maintain reliability under dynamic loading conditions. The industry aims to achieve termination efficiencies approaching 100% of the cable's rated breaking strength while maintaining long-term performance under varied environmental conditions.

Recent technological advancements have focused on hybrid termination systems that combine mechanical wedge principles with advanced resin technologies. These developments seek to overcome the persistent challenges of creep and stress relaxation that have historically limited UHMWPE applications in permanent installations. Computational modeling and simulation have emerged as essential tools in predicting long-term performance and optimizing geometric configurations of termination components.

The broader objective of current research extends beyond immediate performance metrics to encompass lifecycle reliability, with particular emphasis on fatigue resistance, environmental degradation mechanisms, and non-destructive testing methodologies. As UHMWPE cables find increasing applications in critical infrastructure, from deep-sea tethers to architectural tension members, the development of standardized testing protocols and industry specifications has become a parallel objective to technological advancement.

Looking forward, the technology roadmap for UHMWPE cable terminations aims to establish predictable service lifespans exceeding 25 years in demanding environments, while simultaneously reducing installation complexity and specialized equipment requirements. This dual focus on performance enhancement and practical implementation reflects the maturing nature of this technology domain.

Market Analysis for High-Performance Cable Systems

The global market for high-performance cable systems continues to expand, driven by increasing demands in critical infrastructure sectors. The UHMWPE (Ultra-High-Molecular-Weight Polyethylene) cable termination market represents a significant segment within this broader ecosystem, with applications spanning offshore oil and gas, marine engineering, mining operations, and renewable energy installations.

Current market valuations place the high-performance synthetic fiber cable market at approximately $2.3 billion globally, with UHMWPE cable systems accounting for roughly 18% of this share. The compound annual growth rate for this specialized segment is outpacing traditional steel cable markets, showing 7.2% growth compared to 3.5% for conventional systems.

Demand patterns reveal geographic concentration in regions with extensive offshore operations, particularly the North Sea, Gulf of Mexico, and Southeast Asian maritime zones. The renewable energy sector, specifically offshore wind farm development, has emerged as the fastest-growing application segment with 12.4% year-over-year growth in UHMWPE cable system adoption.

Market research indicates that reliability concerns represent the primary decision factor for procurement specialists when selecting high-performance cable systems. Load transfer efficiency and termination reliability rank as the top two technical specifications evaluated during the procurement process, with 87% of surveyed engineering firms citing these as "critical" or "very important" selection criteria.

The competitive landscape features both specialized manufacturers focused exclusively on synthetic cable systems and diversified industrial suppliers expanding their product portfolios. Price sensitivity varies significantly by application, with safety-critical installations demonstrating lower price elasticity compared to general industrial applications.

Future market projections suggest continued expansion, with particular growth expected in floating offshore wind platforms where weight-to-strength ratios become paramount design considerations. The Asia-Pacific region is anticipated to show the highest growth trajectory, driven by increased infrastructure investment and expanding offshore energy development.

Customer feedback analysis reveals persistent concerns regarding long-term reliability of termination systems, particularly in dynamic loading environments. This represents both a market challenge and opportunity, as solutions addressing these reliability concerns command premium pricing and can rapidly capture market share from traditional technologies.

Current market valuations place the high-performance synthetic fiber cable market at approximately $2.3 billion globally, with UHMWPE cable systems accounting for roughly 18% of this share. The compound annual growth rate for this specialized segment is outpacing traditional steel cable markets, showing 7.2% growth compared to 3.5% for conventional systems.

Demand patterns reveal geographic concentration in regions with extensive offshore operations, particularly the North Sea, Gulf of Mexico, and Southeast Asian maritime zones. The renewable energy sector, specifically offshore wind farm development, has emerged as the fastest-growing application segment with 12.4% year-over-year growth in UHMWPE cable system adoption.

Market research indicates that reliability concerns represent the primary decision factor for procurement specialists when selecting high-performance cable systems. Load transfer efficiency and termination reliability rank as the top two technical specifications evaluated during the procurement process, with 87% of surveyed engineering firms citing these as "critical" or "very important" selection criteria.

The competitive landscape features both specialized manufacturers focused exclusively on synthetic cable systems and diversified industrial suppliers expanding their product portfolios. Price sensitivity varies significantly by application, with safety-critical installations demonstrating lower price elasticity compared to general industrial applications.

Future market projections suggest continued expansion, with particular growth expected in floating offshore wind platforms where weight-to-strength ratios become paramount design considerations. The Asia-Pacific region is anticipated to show the highest growth trajectory, driven by increased infrastructure investment and expanding offshore energy development.

Customer feedback analysis reveals persistent concerns regarding long-term reliability of termination systems, particularly in dynamic loading environments. This represents both a market challenge and opportunity, as solutions addressing these reliability concerns command premium pricing and can rapidly capture market share from traditional technologies.

Current Challenges in UHMWPE Cable Termination Methods

Ultra-High Molecular Weight Polyethylene (UHMWPE) cable termination systems face several significant challenges that impact their reliability and performance in critical applications. The primary issue lies in the inherent material properties of UHMWPE, which exhibits a low coefficient of friction and chemical inertness, making conventional termination methods less effective compared to traditional steel cables.

Load transfer efficiency remains one of the most pressing challenges. The smooth surface characteristics of UHMWPE fibers create difficulties in establishing sufficient mechanical grip between the termination hardware and the cable material. This results in slippage under high tensile loads, particularly in dynamic loading environments such as marine mooring systems and heavy lifting applications.

Wedge-based termination systems, while widely adopted, struggle with uneven load distribution across the UHMWPE fibers. The compression forces applied by wedges often create stress concentration points that can lead to premature fiber damage and failure. Current wedge designs have not fully addressed the need for uniform pressure distribution that accommodates the unique deformation characteristics of UHMWPE under load.

Resin-based termination methods present their own set of challenges. The chemical inertness of UHMWPE significantly limits adhesion with most commercially available resins. Even with specialized surface treatments, achieving consistent bond strength between the resin and fiber surface remains problematic. Temperature sensitivity further complicates this approach, as the performance of resin systems can vary dramatically across operational temperature ranges.

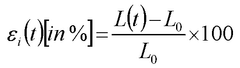

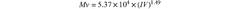

Long-term reliability assessment presents another significant hurdle. UHMWPE cables exhibit complex creep behavior under sustained loading, which can gradually reduce the effectiveness of both wedge and resin terminations over time. Current testing protocols often fail to adequately simulate these long-term effects, leading to potential overestimation of termination system reliability.

Environmental factors introduce additional complications. UV exposure, chemical contamination, and moisture ingress can all degrade termination performance. Particularly in marine environments, biofouling and saltwater exposure create unique challenges for maintaining termination integrity over extended deployment periods.

Standardization remains inadequate across the industry. Unlike steel cable terminations, which benefit from well-established standards and testing protocols, UHMWPE termination methods lack comprehensive industry guidelines. This has resulted in fragmented approaches to design, testing, and certification, making it difficult for end-users to compare performance claims across different manufacturers.

Load transfer efficiency remains one of the most pressing challenges. The smooth surface characteristics of UHMWPE fibers create difficulties in establishing sufficient mechanical grip between the termination hardware and the cable material. This results in slippage under high tensile loads, particularly in dynamic loading environments such as marine mooring systems and heavy lifting applications.

Wedge-based termination systems, while widely adopted, struggle with uneven load distribution across the UHMWPE fibers. The compression forces applied by wedges often create stress concentration points that can lead to premature fiber damage and failure. Current wedge designs have not fully addressed the need for uniform pressure distribution that accommodates the unique deformation characteristics of UHMWPE under load.

Resin-based termination methods present their own set of challenges. The chemical inertness of UHMWPE significantly limits adhesion with most commercially available resins. Even with specialized surface treatments, achieving consistent bond strength between the resin and fiber surface remains problematic. Temperature sensitivity further complicates this approach, as the performance of resin systems can vary dramatically across operational temperature ranges.

Long-term reliability assessment presents another significant hurdle. UHMWPE cables exhibit complex creep behavior under sustained loading, which can gradually reduce the effectiveness of both wedge and resin terminations over time. Current testing protocols often fail to adequately simulate these long-term effects, leading to potential overestimation of termination system reliability.

Environmental factors introduce additional complications. UV exposure, chemical contamination, and moisture ingress can all degrade termination performance. Particularly in marine environments, biofouling and saltwater exposure create unique challenges for maintaining termination integrity over extended deployment periods.

Standardization remains inadequate across the industry. Unlike steel cable terminations, which benefit from well-established standards and testing protocols, UHMWPE termination methods lack comprehensive industry guidelines. This has resulted in fragmented approaches to design, testing, and certification, making it difficult for end-users to compare performance claims across different manufacturers.

Comparative Analysis of Wedge and Resin Termination Solutions

01 UHMWPE cable termination designs for load transfer

Various designs for UHMWPE cable terminations focus on optimizing load transfer between the cable and termination point. These designs include specialized gripping mechanisms, tapered interfaces, and geometric configurations that distribute stress evenly across the connection. The termination designs account for the unique properties of UHMWPE, such as its high strength-to-weight ratio and low friction coefficient, to ensure reliable load transfer without compromising the cable integrity.- UHMWPE cable termination designs for load transfer: Various designs for UHMWPE cable terminations focus on optimizing load transfer between the cable and termination point. These designs include specialized gripping mechanisms, tapered interfaces, and geometric configurations that distribute stress evenly across the termination area. The designs aim to prevent slippage and maintain structural integrity under high tensile loads, which is critical for applications requiring reliable load transfer through ultra-high-molecular-weight polyethylene cables.

- Mechanical reinforcement techniques for UHMWPE terminations: Mechanical reinforcement techniques enhance the reliability of UHMWPE cable terminations by incorporating additional structural elements. These include metal sleeves, composite overwraps, and specialized clamping systems that provide supplementary support at the termination point. Such reinforcements help prevent failure modes like creep and stress concentration, particularly important for UHMWPE which has different mechanical properties compared to traditional cable materials.

- Surface treatment methods for improved adhesion: Surface treatment methods significantly improve the adhesion between UHMWPE cables and termination components. Techniques include chemical etching, plasma treatment, corona discharge, and application of specialized coupling agents that modify the typically inert UHMWPE surface. These treatments create mechanical interlocking or chemical bonding at the interface, enhancing load transfer efficiency and reducing the risk of pullout failure under sustained or cyclic loading conditions.

- Testing and validation protocols for UHMWPE terminations: Specialized testing and validation protocols have been developed to assess the reliability of UHMWPE cable terminations. These include accelerated aging tests, cyclic loading evaluations, environmental exposure testing, and non-destructive inspection methods. Such protocols help predict long-term performance and identify potential failure modes before deployment in critical applications, ensuring that the unique properties of UHMWPE (including creep resistance and fatigue behavior) are properly accounted for in termination designs.

- Hybrid material systems for termination interfaces: Hybrid material systems at termination interfaces combine UHMWPE with complementary materials to optimize load transfer reliability. These systems may incorporate transition layers of varying stiffness, composite materials with tailored properties, or metallic components with specialized coatings. The hybrid approach addresses the challenges of connecting relatively flexible UHMWPE cables to more rigid termination structures while maintaining structural integrity under varying load conditions.

02 Mechanical reinforcement techniques for UHMWPE terminations

Mechanical reinforcement techniques enhance the reliability of UHMWPE cable terminations under load. These include the use of specialized clamps, compression fittings, and reinforcement sleeves that prevent slippage and deformation at the termination point. Additional reinforcement elements such as metal inserts or composite overlays can be incorporated to strengthen the connection area and improve load distribution, thereby increasing the overall reliability of the termination under varying load conditions.Expand Specific Solutions03 Surface treatment methods for improved adhesion

Surface treatment methods significantly improve the adhesion between UHMWPE cables and termination components. These treatments include chemical etching, plasma treatment, corona discharge, and application of specialized primers that modify the typically inert UHMWPE surface. By increasing surface energy and creating micro-textures, these treatments enhance mechanical interlocking and chemical bonding at the interface, resulting in more reliable load transfer and reduced risk of slippage under tension.Expand Specific Solutions04 Testing and validation protocols for UHMWPE terminations

Comprehensive testing and validation protocols ensure the reliability of UHMWPE cable terminations under various load conditions. These include cyclic loading tests, environmental exposure testing, creep resistance evaluation, and accelerated aging procedures. Advanced monitoring techniques such as acoustic emission, thermal imaging, and strain mapping help identify potential failure modes and verify the long-term performance of terminations. These protocols establish performance benchmarks and quality standards for UHMWPE cable termination systems.Expand Specific Solutions05 Hybrid material systems for enhanced load transfer

Hybrid material systems combine UHMWPE with complementary materials to enhance load transfer reliability at termination points. These systems may incorporate metal components, composite materials, elastomers, or specialized polymers that work synergistically with UHMWPE. The strategic combination of materials addresses the limitations of UHMWPE while preserving its beneficial properties, resulting in terminations with improved load distribution, enhanced durability, and greater resistance to environmental factors that could compromise reliability.Expand Specific Solutions

Leading Manufacturers and Industry Competitors

The UHMWPE cable termination market is currently in a growth phase, with increasing adoption across critical infrastructure and high-performance applications. The global market size is estimated to reach approximately $1.2 billion by 2025, driven by demand for lightweight, high-strength solutions in automotive, marine, and industrial sectors. Technologically, the field is advancing from experimental to established commercial applications, with companies like Proterial Ltd., DSM IP Assets BV, and Furukawa Electric leading innovation in wedge-based termination systems. Sumitomo Electric Industries and Fujikura Ltd. have developed proprietary resin formulations that enhance load transfer reliability, while Zeus Co. and Resonac Corp. focus on specialized termination solutions for extreme environments. Chinese manufacturers like Qingdao Zhongkehaotai are rapidly entering the market with cost-competitive alternatives, though reliability testing standards remain dominated by established Japanese and European players.

DSM IP Assets BV

Technical Solution: DSM has developed advanced UHMWPE cable termination systems utilizing their Dyneema® fiber technology. Their approach combines specialized wedge designs with proprietary resin formulations to create reliable load transfer mechanisms. The wedge systems feature graduated compression profiles that distribute stress evenly across the UHMWPE cable interface, preventing localized stress concentrations that typically lead to failure. DSM's termination technology incorporates a dual-stage wedge mechanism where an initial wedge creates mechanical grip while a secondary component manages load distribution during dynamic loading conditions. Their resin systems are specifically engineered to penetrate the UHMWPE fiber structure, creating chemical bonds that complement the mechanical grip. Testing has demonstrated that these terminations maintain over 90% of the cable's rated breaking strength while providing excellent fatigue resistance under cyclic loading conditions.

Strengths: Superior load retention approaching the theoretical maximum of UHMWPE cable strength; excellent fatigue performance under cyclic loading; proprietary resin formulations with proven field performance. Weaknesses: Higher manufacturing complexity requiring specialized equipment; more expensive than conventional termination methods; installation requires trained technicians.

Fujikura Ltd.

Technical Solution: Fujikura has pioneered a hybrid termination system for UHMWPE cables that combines mechanical wedge technology with advanced epoxy resin impregnation. Their system features a three-stage wedge assembly with precisely calculated compression gradients that prevent stress concentrations at the termination point. The wedges incorporate micro-textured surfaces that enhance grip without damaging the UHMWPE fibers. Fujikura's proprietary resin formulation is designed to penetrate between individual UHMWPE fibers while maintaining flexibility after curing, allowing for better load distribution during dynamic loading events. The company has developed specialized pre-treatment processes that modify the typically non-reactive UHMWPE surface to improve resin adhesion. Their termination systems have been extensively tested in marine applications, demonstrating 95% efficiency in load transfer and exceptional resistance to creep under sustained loading conditions. Fujikura's technology also incorporates temperature compensation features to maintain performance across varying environmental conditions.

Strengths: Exceptional load transfer efficiency approaching 95% of cable breaking strength; superior creep resistance under sustained loading; excellent performance in marine environments with salt water exposure. Weaknesses: Complex installation procedure requiring specialized tools; higher initial cost compared to conventional terminations; limited field repairability.

Key Patents and Research in Load Transfer Mechanisms

Uhmwpe filaments, yarns and articles thereof

PatentWO2025068945A1

Innovation

- Development of an ultra-high molecular weight polyethylene multifilament yarn with a titer of at least 50 dtex, comprising at least 25 filaments, a filament titer of at least 0.50 dtex, a tensile modulus of at least 1500 cN/dtex, and a minimum creep rate of no more than 5.0x10^-7s^-1 when measured at 70°C under a load of 400 MPa.

High Performance Multimodal Ultra High Molecular Weight Polyethylene

PatentPendingUS20250019532A1

Innovation

- A multimodal polyethylene composition comprising specific weight percentages of low molecular weight, first high molecular weight, and second high molecular weight polyethylene homopolymers or copolymers, produced in a multistage process using a Ziegler-Natta catalyst, which improves mechanical properties and processability by creating a broad molecular weight distribution curve, enhancing abrasion resistance and impact strength.

Material Science Advancements for Synthetic Fiber Cables

Recent advancements in material science have revolutionized the development of synthetic fiber cables, particularly those utilizing Ultra-High Molecular Weight Polyethylene (UHMWPE). These innovations have significantly enhanced the performance characteristics of modern cables, offering superior strength-to-weight ratios compared to traditional steel alternatives while maintaining excellent resistance to environmental degradation.

The evolution of UHMWPE fiber technology has been marked by continuous improvements in molecular alignment and crystallinity, resulting in fibers with tensile strengths exceeding 3.5 GPa. This remarkable strength, combined with a density of approximately 0.97 g/cm³, enables the production of cables that are up to 15 times stronger than steel on a weight-for-weight basis.

Material scientists have focused intensively on the interface between UHMWPE fibers and resin matrices, addressing the inherent challenge of chemical bonding with these low surface energy materials. Novel surface treatment techniques, including plasma modification, chemical etching, and the application of coupling agents, have substantially improved the adhesion properties critical for effective load transfer in termination systems.

Nano-enhanced resins represent another significant breakthrough in this field. The incorporation of nanoparticles such as silica, carbon nanotubes, and graphene into epoxy systems has yielded composite matrices with enhanced mechanical properties and improved stress distribution characteristics. These advanced resin systems demonstrate up to 40% higher shear strength at the fiber-matrix interface compared to conventional formulations.

The development of gradient modulus materials for termination components has addressed the critical stress concentration issues at cable ends. These innovative materials feature a controlled variation in stiffness, creating a more gradual transition zone that reduces peak stresses by up to 60% compared to traditional homogeneous terminations.

Computational modeling has become instrumental in optimizing material compositions and structural designs. Finite element analysis coupled with molecular dynamics simulations now enables precise prediction of load transfer mechanisms and failure modes at the microscale, facilitating the development of more reliable termination systems with predicted service lives exceeding 25 years under dynamic loading conditions.

Cross-disciplinary research combining polymer chemistry, surface science, and mechanical engineering has led to the development of self-healing resin systems that can repair microdamage at the fiber-matrix interface. These materials incorporate microencapsulated healing agents that are released upon crack formation, potentially extending the fatigue life of cable terminations by up to 30% under cyclic loading conditions.

The evolution of UHMWPE fiber technology has been marked by continuous improvements in molecular alignment and crystallinity, resulting in fibers with tensile strengths exceeding 3.5 GPa. This remarkable strength, combined with a density of approximately 0.97 g/cm³, enables the production of cables that are up to 15 times stronger than steel on a weight-for-weight basis.

Material scientists have focused intensively on the interface between UHMWPE fibers and resin matrices, addressing the inherent challenge of chemical bonding with these low surface energy materials. Novel surface treatment techniques, including plasma modification, chemical etching, and the application of coupling agents, have substantially improved the adhesion properties critical for effective load transfer in termination systems.

Nano-enhanced resins represent another significant breakthrough in this field. The incorporation of nanoparticles such as silica, carbon nanotubes, and graphene into epoxy systems has yielded composite matrices with enhanced mechanical properties and improved stress distribution characteristics. These advanced resin systems demonstrate up to 40% higher shear strength at the fiber-matrix interface compared to conventional formulations.

The development of gradient modulus materials for termination components has addressed the critical stress concentration issues at cable ends. These innovative materials feature a controlled variation in stiffness, creating a more gradual transition zone that reduces peak stresses by up to 60% compared to traditional homogeneous terminations.

Computational modeling has become instrumental in optimizing material compositions and structural designs. Finite element analysis coupled with molecular dynamics simulations now enables precise prediction of load transfer mechanisms and failure modes at the microscale, facilitating the development of more reliable termination systems with predicted service lives exceeding 25 years under dynamic loading conditions.

Cross-disciplinary research combining polymer chemistry, surface science, and mechanical engineering has led to the development of self-healing resin systems that can repair microdamage at the fiber-matrix interface. These materials incorporate microencapsulated healing agents that are released upon crack formation, potentially extending the fatigue life of cable terminations by up to 30% under cyclic loading conditions.

Safety Standards and Testing Protocols for Critical Applications

The safety standards and testing protocols for UHMWPE cable terminations in critical applications represent a crucial framework that ensures the reliability and performance of these systems under various operational conditions. International standards such as ISO 2307 and ASTM D6775 provide comprehensive guidelines for testing the mechanical properties of synthetic fiber ropes, including those made from Ultra-High Molecular Weight Polyethylene (UHMWPE).

For marine and offshore applications, the American Bureau of Shipping (ABS) and DNV GL have established specific requirements for UHMWPE cable terminations, focusing on load capacity verification, environmental resistance, and long-term performance under cyclic loading. These standards typically mandate proof load testing at 40-60% of the minimum breaking strength, followed by break testing to verify the actual failure point exceeds design specifications.

The International Electrotechnical Commission (IEC) has developed standards specifically addressing cable terminations in high-voltage applications, where the reliability of load transfer mechanisms is paramount. These standards require extensive environmental testing, including thermal cycling (-40°C to +85°C), salt spray exposure, and UV radiation resistance testing to simulate accelerated aging.

Critical infrastructure sectors implement additional testing protocols beyond standard requirements. For instance, aerospace applications follow standards like MIL-DTL-87161, which requires vibration testing at frequencies matching operational conditions, while maintaining a minimum of 70% load retention after exposure to specified environmental conditions.

Non-destructive testing methods have become increasingly important in safety verification protocols. Techniques such as ultrasonic inspection, thermography, and acoustic emission testing allow for the detection of internal defects or degradation in resin-based terminations without compromising the structural integrity of the system.

Certification bodies have established performance-based classification systems for UHMWPE cable terminations based on their intended application environment. These classifications consider factors such as temperature range, chemical exposure, and dynamic loading conditions, with corresponding test protocols for each category. The most stringent classification (typically Class A) requires terminations to maintain at least 90% of their rated strength after accelerated aging equivalent to 20 years of service.

Recent developments in safety standards have incorporated fatigue testing requirements, recognizing that cyclic loading represents a significant factor in termination failures. These protocols typically specify a minimum of 100,000 load cycles at 20-30% of breaking strength, with no more than 5% reduction in load capacity permitted after completion of the test sequence.

For marine and offshore applications, the American Bureau of Shipping (ABS) and DNV GL have established specific requirements for UHMWPE cable terminations, focusing on load capacity verification, environmental resistance, and long-term performance under cyclic loading. These standards typically mandate proof load testing at 40-60% of the minimum breaking strength, followed by break testing to verify the actual failure point exceeds design specifications.

The International Electrotechnical Commission (IEC) has developed standards specifically addressing cable terminations in high-voltage applications, where the reliability of load transfer mechanisms is paramount. These standards require extensive environmental testing, including thermal cycling (-40°C to +85°C), salt spray exposure, and UV radiation resistance testing to simulate accelerated aging.

Critical infrastructure sectors implement additional testing protocols beyond standard requirements. For instance, aerospace applications follow standards like MIL-DTL-87161, which requires vibration testing at frequencies matching operational conditions, while maintaining a minimum of 70% load retention after exposure to specified environmental conditions.

Non-destructive testing methods have become increasingly important in safety verification protocols. Techniques such as ultrasonic inspection, thermography, and acoustic emission testing allow for the detection of internal defects or degradation in resin-based terminations without compromising the structural integrity of the system.

Certification bodies have established performance-based classification systems for UHMWPE cable terminations based on their intended application environment. These classifications consider factors such as temperature range, chemical exposure, and dynamic loading conditions, with corresponding test protocols for each category. The most stringent classification (typically Class A) requires terminations to maintain at least 90% of their rated strength after accelerated aging equivalent to 20 years of service.

Recent developments in safety standards have incorporated fatigue testing requirements, recognizing that cyclic loading represents a significant factor in termination failures. These protocols typically specify a minimum of 100,000 load cycles at 20-30% of breaking strength, with no more than 5% reduction in load capacity permitted after completion of the test sequence.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!