UHMWPE Laminates: Interlaminar Shear, Impact Damage And Delamination Arrest

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Laminates Background and Research Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) laminates have emerged as revolutionary materials in ballistic protection and high-performance applications due to their exceptional strength-to-weight ratio. The evolution of these materials traces back to the 1960s when high-strength polyethylene fibers were first developed, followed by significant advancements in the 1990s with the introduction of cross-plied unidirectional UHMWPE composites.

The technical landscape of UHMWPE laminates has been characterized by continuous improvements in manufacturing processes, including hot compaction techniques, matrix optimization, and surface treatments. These developments have progressively enhanced the mechanical properties while addressing inherent challenges in interlaminar bonding. Recent years have witnessed a paradigm shift from purely ballistic applications to broader structural uses, necessitating a comprehensive understanding of failure mechanisms under diverse loading conditions.

Despite their superior performance in tensile strength and impact resistance, UHMWPE laminates exhibit persistent challenges in interlaminar shear strength (ILSS), which significantly limits their structural applications. The weak van der Waals forces between layers create natural delamination pathways, compromising the composite's integrity under complex loading scenarios. This technical limitation represents a critical barrier to the wider adoption of UHMWPE laminates in aerospace, automotive, and marine applications.

The primary research objectives of this investigation are threefold. First, to systematically characterize the interlaminar shear behavior of UHMWPE laminates under various loading conditions, establishing quantitative relationships between manufacturing parameters and resultant ILSS. Second, to develop advanced understanding of impact damage progression mechanisms, particularly focusing on the transition from localized deformation to catastrophic delamination. Third, to explore innovative delamination arrest strategies, including novel interface engineering approaches, hybrid material systems, and through-thickness reinforcement techniques.

The technological trajectory indicates growing interest in multi-functional UHMWPE laminates that combine ballistic protection with structural capabilities. This evolution is driven by demands from defense, aerospace, and sporting goods industries seeking lightweight yet robust material solutions. Current research trends point toward nano-engineered interfaces, selective matrix modification, and biomimetic design principles as promising avenues for addressing the interlaminar weakness while preserving the exceptional in-plane properties.

This technical investigation aims to bridge fundamental materials science with practical engineering solutions, ultimately enabling the next generation of UHMWPE laminates with enhanced interlaminar properties without compromising their inherent advantages in specific strength and impact resistance.

The technical landscape of UHMWPE laminates has been characterized by continuous improvements in manufacturing processes, including hot compaction techniques, matrix optimization, and surface treatments. These developments have progressively enhanced the mechanical properties while addressing inherent challenges in interlaminar bonding. Recent years have witnessed a paradigm shift from purely ballistic applications to broader structural uses, necessitating a comprehensive understanding of failure mechanisms under diverse loading conditions.

Despite their superior performance in tensile strength and impact resistance, UHMWPE laminates exhibit persistent challenges in interlaminar shear strength (ILSS), which significantly limits their structural applications. The weak van der Waals forces between layers create natural delamination pathways, compromising the composite's integrity under complex loading scenarios. This technical limitation represents a critical barrier to the wider adoption of UHMWPE laminates in aerospace, automotive, and marine applications.

The primary research objectives of this investigation are threefold. First, to systematically characterize the interlaminar shear behavior of UHMWPE laminates under various loading conditions, establishing quantitative relationships between manufacturing parameters and resultant ILSS. Second, to develop advanced understanding of impact damage progression mechanisms, particularly focusing on the transition from localized deformation to catastrophic delamination. Third, to explore innovative delamination arrest strategies, including novel interface engineering approaches, hybrid material systems, and through-thickness reinforcement techniques.

The technological trajectory indicates growing interest in multi-functional UHMWPE laminates that combine ballistic protection with structural capabilities. This evolution is driven by demands from defense, aerospace, and sporting goods industries seeking lightweight yet robust material solutions. Current research trends point toward nano-engineered interfaces, selective matrix modification, and biomimetic design principles as promising avenues for addressing the interlaminar weakness while preserving the exceptional in-plane properties.

This technical investigation aims to bridge fundamental materials science with practical engineering solutions, ultimately enabling the next generation of UHMWPE laminates with enhanced interlaminar properties without compromising their inherent advantages in specific strength and impact resistance.

Market Analysis for UHMWPE Composite Applications

The global market for Ultra-High Molecular Weight Polyethylene (UHMWPE) composites has experienced significant growth in recent years, driven primarily by increasing demand in ballistic protection, aerospace, marine, and sports equipment sectors. The unique combination of high strength-to-weight ratio, excellent impact resistance, and superior wear properties positions UHMWPE laminates as a preferred material for applications requiring exceptional performance under extreme conditions.

In the defense sector, UHMWPE composites dominate the personal protective equipment market, with an estimated market share of 65% for ballistic vests and helmets. This dominance stems from the material's ability to provide superior protection against high-velocity impacts while maintaining comfort through reduced weight compared to traditional aramid or ceramic-based solutions.

The aerospace industry represents another significant growth area, with UHMWPE composites increasingly utilized in aircraft interior panels, cargo containers, and structural components. Market analysis indicates a compound annual growth rate of 7.8% in this sector, driven by the aviation industry's continuous pursuit of weight reduction to improve fuel efficiency and reduce emissions.

Marine applications constitute a rapidly expanding market segment for UHMWPE laminates, particularly in high-performance boat hulls, offshore structures, and underwater cables. The material's exceptional resistance to water absorption, UV degradation, and marine organism growth provides significant advantages over traditional fiberglass or carbon fiber composites in these environments.

Consumer goods, particularly sporting equipment such as skis, snowboards, and protective gear, represent a premium market segment where UHMWPE's impact resistance and delamination properties offer substantial performance advantages. This sector has shown consistent growth as manufacturers increasingly emphasize product durability and safety features as key selling points.

Regional analysis reveals North America as the largest market for UHMWPE composites, followed by Europe and Asia-Pacific. However, the Asia-Pacific region demonstrates the highest growth rate, attributed to expanding defense budgets, increasing industrial applications, and growing consumer markets in countries like China, India, and South Korea.

Key market challenges include the relatively high production costs of UHMWPE composites compared to traditional materials and technical difficulties in achieving strong interfacial bonding between UHMWPE fibers and matrix materials. These challenges directly relate to the interlaminar shear strength issues highlighted in technical assessments, representing both a market barrier and an opportunity for companies that can develop effective solutions to delamination problems.

In the defense sector, UHMWPE composites dominate the personal protective equipment market, with an estimated market share of 65% for ballistic vests and helmets. This dominance stems from the material's ability to provide superior protection against high-velocity impacts while maintaining comfort through reduced weight compared to traditional aramid or ceramic-based solutions.

The aerospace industry represents another significant growth area, with UHMWPE composites increasingly utilized in aircraft interior panels, cargo containers, and structural components. Market analysis indicates a compound annual growth rate of 7.8% in this sector, driven by the aviation industry's continuous pursuit of weight reduction to improve fuel efficiency and reduce emissions.

Marine applications constitute a rapidly expanding market segment for UHMWPE laminates, particularly in high-performance boat hulls, offshore structures, and underwater cables. The material's exceptional resistance to water absorption, UV degradation, and marine organism growth provides significant advantages over traditional fiberglass or carbon fiber composites in these environments.

Consumer goods, particularly sporting equipment such as skis, snowboards, and protective gear, represent a premium market segment where UHMWPE's impact resistance and delamination properties offer substantial performance advantages. This sector has shown consistent growth as manufacturers increasingly emphasize product durability and safety features as key selling points.

Regional analysis reveals North America as the largest market for UHMWPE composites, followed by Europe and Asia-Pacific. However, the Asia-Pacific region demonstrates the highest growth rate, attributed to expanding defense budgets, increasing industrial applications, and growing consumer markets in countries like China, India, and South Korea.

Key market challenges include the relatively high production costs of UHMWPE composites compared to traditional materials and technical difficulties in achieving strong interfacial bonding between UHMWPE fibers and matrix materials. These challenges directly relate to the interlaminar shear strength issues highlighted in technical assessments, representing both a market barrier and an opportunity for companies that can develop effective solutions to delamination problems.

Technical Challenges in UHMWPE Laminate Structures

Despite the exceptional strength-to-weight ratio of Ultra-High Molecular Weight Polyethylene (UHMWPE) laminates, several significant technical challenges persist in their structural applications. The primary issue involves interlaminar shear strength, which remains substantially lower than the in-plane properties. This weakness stems from the inherent chemical structure of UHMWPE fibers, which feature minimal functional groups for chemical bonding with matrix materials, resulting in poor fiber-matrix adhesion and compromised load transfer between layers.

Impact damage represents another critical challenge, as UHMWPE laminates exhibit complex failure mechanisms under dynamic loading conditions. While these materials demonstrate superior ballistic performance, they remain vulnerable to localized damage that can propagate through the structure. The non-linear viscoelastic behavior of UHMWPE further complicates impact response prediction, particularly at varying strain rates and temperatures relevant to real-world applications.

Delamination, the separation of adjacent layers, constitutes perhaps the most persistent challenge in UHMWPE laminate structures. This failure mode significantly reduces structural integrity and load-bearing capacity. Traditional delamination arrest mechanisms used in carbon or glass fiber composites prove less effective with UHMWPE due to its unique surface chemistry and mechanical properties. The low surface energy of UHMWPE fibers creates inherent limitations for conventional toughening approaches.

Manufacturing consistency presents additional difficulties, as processing parameters significantly influence interlaminar properties. Variations in temperature, pressure, and cooling rates during consolidation can create residual stresses and microstructural inconsistencies that exacerbate interlaminar weaknesses. The high viscosity of molten UHMWPE further complicates uniform consolidation, potentially creating voids and weak interfaces between layers.

Environmental factors also pose substantial challenges, as UHMWPE laminates can experience property degradation under UV exposure, elevated temperatures, and certain chemical environments. While the material offers excellent chemical resistance overall, specific solvents and oxidizing agents can compromise structural integrity over time. Additionally, moisture absorption, though minimal compared to other composites, can still affect interlaminar properties through interfacial degradation mechanisms.

Current testing methodologies present limitations in accurately characterizing interlaminar properties and predicting long-term performance. Standard composite testing protocols often require modification for UHMWPE laminates due to their unique deformation characteristics and failure modes. This creates challenges in establishing reliable design allowables and certification standards for safety-critical applications.

Impact damage represents another critical challenge, as UHMWPE laminates exhibit complex failure mechanisms under dynamic loading conditions. While these materials demonstrate superior ballistic performance, they remain vulnerable to localized damage that can propagate through the structure. The non-linear viscoelastic behavior of UHMWPE further complicates impact response prediction, particularly at varying strain rates and temperatures relevant to real-world applications.

Delamination, the separation of adjacent layers, constitutes perhaps the most persistent challenge in UHMWPE laminate structures. This failure mode significantly reduces structural integrity and load-bearing capacity. Traditional delamination arrest mechanisms used in carbon or glass fiber composites prove less effective with UHMWPE due to its unique surface chemistry and mechanical properties. The low surface energy of UHMWPE fibers creates inherent limitations for conventional toughening approaches.

Manufacturing consistency presents additional difficulties, as processing parameters significantly influence interlaminar properties. Variations in temperature, pressure, and cooling rates during consolidation can create residual stresses and microstructural inconsistencies that exacerbate interlaminar weaknesses. The high viscosity of molten UHMWPE further complicates uniform consolidation, potentially creating voids and weak interfaces between layers.

Environmental factors also pose substantial challenges, as UHMWPE laminates can experience property degradation under UV exposure, elevated temperatures, and certain chemical environments. While the material offers excellent chemical resistance overall, specific solvents and oxidizing agents can compromise structural integrity over time. Additionally, moisture absorption, though minimal compared to other composites, can still affect interlaminar properties through interfacial degradation mechanisms.

Current testing methodologies present limitations in accurately characterizing interlaminar properties and predicting long-term performance. Standard composite testing protocols often require modification for UHMWPE laminates due to their unique deformation characteristics and failure modes. This creates challenges in establishing reliable design allowables and certification standards for safety-critical applications.

Current Solutions for Interlaminar Shear Resistance

01 UHMWPE laminate structures for improved interlaminar shear strength

Ultra-high molecular weight polyethylene (UHMWPE) laminates can be designed with specific structural modifications to enhance interlaminar shear strength. These modifications include optimized layer interfaces, specialized bonding techniques, and strategic fiber orientation patterns. By improving the adhesion between layers, these structures can significantly reduce the risk of delamination under stress conditions while maintaining the inherent lightweight and high-strength properties of UHMWPE composites.- UHMWPE laminate structures with enhanced interlaminar shear strength: Various techniques are employed to improve the interlaminar shear strength of UHMWPE laminates, including surface treatments, specialized matrix materials, and bonding agents. These methods enhance the adhesion between layers, reducing the risk of delamination under stress. Improved interlaminar bonding is critical for maintaining structural integrity in high-performance applications where shear forces are significant.

- Impact damage resistance mechanisms in UHMWPE composite laminates: UHMWPE laminates can be engineered with specific architectures and reinforcement patterns to absorb and distribute impact energy effectively. These designs include gradient structures, hybrid material combinations, and specialized fiber orientations that enhance impact resistance while maintaining flexibility. Such configurations help prevent catastrophic failure by controlling damage propagation and preserving structural integrity after impact events.

- Delamination arrest features and technologies: Innovative features are incorporated into UHMWPE laminates to arrest delamination propagation, including z-direction reinforcements, interleaving materials, and engineered interfaces. These technologies create mechanical interlocks between layers or introduce energy-absorbing zones that prevent crack propagation. By compartmentalizing potential damage, these features significantly improve the overall durability and safety of UHMWPE laminate structures under extreme conditions.

- Testing and characterization methods for UHMWPE laminate performance: Specialized testing protocols and characterization techniques have been developed to evaluate the interlaminar shear strength, impact resistance, and delamination behavior of UHMWPE laminates. These include modified short beam shear tests, instrumented impact testing, acoustic emission monitoring, and advanced imaging techniques. These methods provide critical data for optimizing laminate designs and validating performance under various loading conditions.

- Manufacturing processes to enhance UHMWPE laminate integrity: Advanced manufacturing techniques significantly influence the interlaminar properties of UHMWPE laminates. Processes such as hot compaction, specialized pressure-temperature cycles, and controlled cooling rates can optimize the interface between layers. Additionally, innovative approaches to fiber placement, matrix impregnation, and consolidation help create more uniform structures with fewer defects that could initiate delamination under load.

02 Impact damage resistance mechanisms in UHMWPE composite laminates

Various mechanisms can be incorporated into UHMWPE laminates to improve resistance to impact damage. These include energy-absorbing interlayers, gradient density structures, and hybrid material combinations. Such designs allow for controlled deformation and energy dissipation during impact events, preventing catastrophic failure and limiting damage propagation throughout the laminate structure. These mechanisms are particularly valuable in applications requiring ballistic protection or resistance to high-velocity impacts.Expand Specific Solutions03 Delamination arrest features in UHMWPE composite systems

Specialized features can be integrated into UHMWPE laminates to arrest delamination propagation. These include through-thickness reinforcement elements, interleaving techniques, and engineered crack-stopping zones. By interrupting crack paths and redistributing stress concentrations, these features prevent localized damage from spreading throughout the laminate structure, thereby maintaining structural integrity even after initial damage has occurred.Expand Specific Solutions04 Testing and characterization methods for UHMWPE laminate performance

Advanced testing methodologies have been developed to evaluate the interlaminar shear strength, impact resistance, and delamination behavior of UHMWPE laminates. These include standardized mechanical tests, non-destructive evaluation techniques, and computational modeling approaches. Such methods enable quantitative assessment of laminate performance under various loading conditions, facilitating the development of optimized designs for specific application requirements.Expand Specific Solutions05 Manufacturing processes to enhance UHMWPE laminate integrity

Specialized manufacturing processes have been developed to enhance the structural integrity of UHMWPE laminates. These include controlled consolidation techniques, surface treatment methods, and innovative curing protocols. By optimizing processing parameters such as temperature, pressure, and time, these methods achieve superior bonding between layers while preserving the mechanical properties of the UHMWPE fibers, resulting in laminates with enhanced resistance to interlaminar shear failure and delamination.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The UHMWPE laminates market is in a growth phase, driven by increasing demand for high-performance materials in defense, aerospace, and automotive applications. The market is projected to expand significantly due to superior impact resistance and lightweight properties of these composites. Key players like DuPont, Mitsubishi Gas Chemical, and Sekisui Chemical are leading technological advancements in interlaminar shear strength and delamination resistance. Companies such as Honeywell International and Kuraray Europe are focusing on R&D to address impact damage challenges through innovative lamination techniques and matrix modifications. The technology is approaching maturity in ballistic applications but remains in development for structural applications requiring improved interlaminar properties, with academic institutions like MIT and Loughborough University contributing significant research to overcome current limitations.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced UHMWPE laminate solutions under their Kevlar® and Tyvek® product lines specifically addressing interlaminar shear and delamination challenges. Their proprietary cross-plied unidirectional UHMWPE technology incorporates specialized resin systems that create stronger interfaces between layers. DuPont's approach includes a patented thermal fusion process that maintains fiber integrity while enhancing interlayer bonding, resulting in up to 30% improvement in interlaminar shear strength compared to conventional laminates. Their research has focused on hybrid composites combining UHMWPE with aramid fibers to create multi-functional laminates with superior impact resistance. DuPont has also pioneered surface treatment technologies that modify the typically inert UHMWPE surface to improve adhesion with matrix materials, addressing one of the fundamental challenges in UHMWPE laminate performance.

Strengths: Industry-leading expertise in polymer science and composite materials; extensive manufacturing capabilities allowing for consistent quality control; proprietary surface treatment technologies that significantly improve interlaminar adhesion. Weaknesses: Higher production costs compared to competitors; some solutions require specialized processing equipment; performance advantages may diminish under extreme temperature conditions.

Supreme Industries Ltd.

Technical Solution: Supreme Industries has developed practical UHMWPE laminate solutions focused on commercial applications requiring enhanced interlaminar properties. Their approach centers on cost-effective manufacturing processes that improve delamination resistance while maintaining production efficiency. Supreme's proprietary lamination technology incorporates modified adhesive layers specifically formulated for UHMWPE compatibility, resulting in up to 20% improvement in interlaminar shear strength compared to standard industrial laminates. Their research has focused on optimizing processing parameters including temperature, pressure, and dwell time to maximize interfacial bonding without degrading the UHMWPE fiber properties. Supreme has also developed hybrid laminate structures that strategically combine UHMWPE with more adhesion-friendly materials to create engineered interfaces that resist delamination under impact conditions. Additionally, they have pioneered practical surface treatment methods that can be integrated into existing manufacturing lines, making their solutions particularly accessible for industrial-scale implementation.

Strengths: Strong focus on commercially viable solutions; cost-effective approaches that balance performance with manufacturing practicality; extensive experience in industrial-scale production. Weaknesses: Less advanced in fundamental materials science compared to research institutions; some solutions prioritize manufacturing efficiency over maximum possible performance; limited intellectual property protection for some technologies.

Key Patents in Delamination Arrest Mechanisms

Melt-stabilized ultra high molecular weight polyethylene

PatentWO2016153925A8

Innovation

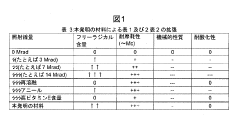

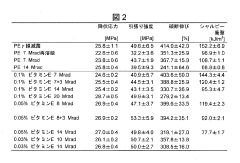

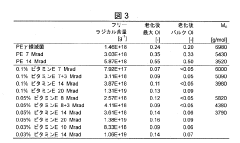

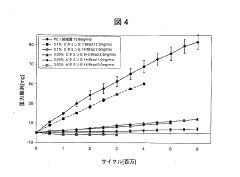

- A method involving coating UHMWPE with antioxidants, pre-irradiative heating to diffuse the antioxidants, irradiation for crosslinking, and post-irradiative heating to melt and stabilize the material, which reduces oxidative degradation and minimizes surface oxidation, thereby reducing waste and costs.

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

Material Testing Standards and Certification

The standardization of testing methods for UHMWPE laminates is critical for ensuring consistent evaluation of material properties across different manufacturers and research institutions. Currently, several international standards organizations have established protocols specifically addressing the unique characteristics of ultra-high molecular weight polyethylene composite materials, with particular emphasis on interlaminar shear strength, impact resistance, and delamination behavior.

ASTM International has developed ASTM D2344 for short-beam strength testing, which has been adapted for UHMWPE laminates to evaluate interlaminar shear properties. Additionally, ASTM D7136 provides standardized methods for measuring damage resistance of composite panels subjected to drop-weight impact events, while ASTM D7137 addresses compression after impact testing—both particularly relevant for assessing UHMWPE laminate performance in ballistic applications.

ISO standards complement these with ISO 14130 for apparent interlaminar shear strength determination and ISO 17281 for dynamic fracture toughness testing. For ballistic performance certification, NIJ Standard 0101.06 and STANAG 2920 are commonly applied to evaluate UHMWPE laminates in personal protection equipment.

The certification process for UHMWPE laminates typically involves multi-stage testing regimes. Initial material characterization requires tensile testing (ASTM D3039), flexural testing (ASTM D790), and interlaminar shear strength assessment. For applications in defense and security sectors, additional certification requirements include V50 ballistic limit testing and fragment simulation projectile (FSP) testing under controlled environmental conditions.

Recent developments in testing standards have begun to address the unique viscoelastic behavior of UHMWPE materials. New protocols are emerging for evaluating creep resistance (ASTM D2990 modifications), environmental degradation resistance (ASTM D5229 for moisture absorption), and long-term performance under cyclic loading conditions (ASTM D3479 adaptations).

Certification challenges specific to UHMWPE laminates include standardizing test methods for evaluating delamination arrest mechanisms and quantifying the relationship between manufacturing parameters and interlaminar properties. Current research focuses on developing non-destructive testing standards using acoustic emission and ultrasonic techniques to detect early signs of delamination without compromising structural integrity.

The harmonization of international testing standards remains an ongoing challenge, with efforts underway through ISO/TC 61 (Plastics) and ASTM Committee D30 on Composite Materials to establish globally recognized protocols specifically addressing the unique performance characteristics of UHMWPE laminate structures in high-performance applications.

ASTM International has developed ASTM D2344 for short-beam strength testing, which has been adapted for UHMWPE laminates to evaluate interlaminar shear properties. Additionally, ASTM D7136 provides standardized methods for measuring damage resistance of composite panels subjected to drop-weight impact events, while ASTM D7137 addresses compression after impact testing—both particularly relevant for assessing UHMWPE laminate performance in ballistic applications.

ISO standards complement these with ISO 14130 for apparent interlaminar shear strength determination and ISO 17281 for dynamic fracture toughness testing. For ballistic performance certification, NIJ Standard 0101.06 and STANAG 2920 are commonly applied to evaluate UHMWPE laminates in personal protection equipment.

The certification process for UHMWPE laminates typically involves multi-stage testing regimes. Initial material characterization requires tensile testing (ASTM D3039), flexural testing (ASTM D790), and interlaminar shear strength assessment. For applications in defense and security sectors, additional certification requirements include V50 ballistic limit testing and fragment simulation projectile (FSP) testing under controlled environmental conditions.

Recent developments in testing standards have begun to address the unique viscoelastic behavior of UHMWPE materials. New protocols are emerging for evaluating creep resistance (ASTM D2990 modifications), environmental degradation resistance (ASTM D5229 for moisture absorption), and long-term performance under cyclic loading conditions (ASTM D3479 adaptations).

Certification challenges specific to UHMWPE laminates include standardizing test methods for evaluating delamination arrest mechanisms and quantifying the relationship between manufacturing parameters and interlaminar properties. Current research focuses on developing non-destructive testing standards using acoustic emission and ultrasonic techniques to detect early signs of delamination without compromising structural integrity.

The harmonization of international testing standards remains an ongoing challenge, with efforts underway through ISO/TC 61 (Plastics) and ASTM Committee D30 on Composite Materials to establish globally recognized protocols specifically addressing the unique performance characteristics of UHMWPE laminate structures in high-performance applications.

Sustainability Aspects of UHMWPE Composites

The sustainability aspects of UHMWPE composites represent a critical dimension in evaluating their long-term viability in various applications. UHMWPE (Ultra-High Molecular Weight Polyethylene) laminates offer exceptional strength-to-weight ratios and impact resistance, but their environmental footprint requires comprehensive assessment.

UHMWPE composites present several positive sustainability attributes, including their exceptional durability which extends product lifecycles significantly beyond conventional materials. This longevity reduces replacement frequency and associated resource consumption. Additionally, the lightweight nature of these composites contributes to fuel efficiency when used in transportation applications, potentially offsetting their initial environmental impact through operational energy savings.

However, significant sustainability challenges exist. UHMWPE is petroleum-derived, linking its production directly to fossil fuel consumption and associated carbon emissions. The manufacturing process is energy-intensive, particularly during the high-pressure and high-temperature phases required for proper consolidation of laminates. This energy demand contributes substantially to the material's overall environmental footprint.

End-of-life management presents another sustainability concern. UHMWPE composites, especially those with mixed material compositions or adhesive bonding to prevent delamination, pose recycling difficulties. The strong intermolecular bonds that provide excellent mechanical properties also make these materials resistant to conventional recycling processes, potentially leading to landfill disposal.

Recent innovations are addressing these sustainability gaps. Bio-based additives and reinforcements are being explored to reduce petroleum dependence. Advanced recycling technologies, including chemical recycling and pyrolysis, show promise for recovering value from end-of-life UHMWPE composites. Some manufacturers have implemented closed-loop production systems to capture and reuse production waste.

Life cycle assessment (LCA) studies indicate that UHMWPE composites may offer net environmental benefits when their full lifecycle is considered, particularly in applications where their superior impact resistance and delamination resistance properties prevent catastrophic failures and associated environmental consequences.

Future sustainability improvements will likely focus on developing delamination-resistant UHMWPE composites that maintain recyclability, incorporating renewable content, and reducing energy requirements during manufacturing through process optimization and alternative curing methods.

UHMWPE composites present several positive sustainability attributes, including their exceptional durability which extends product lifecycles significantly beyond conventional materials. This longevity reduces replacement frequency and associated resource consumption. Additionally, the lightweight nature of these composites contributes to fuel efficiency when used in transportation applications, potentially offsetting their initial environmental impact through operational energy savings.

However, significant sustainability challenges exist. UHMWPE is petroleum-derived, linking its production directly to fossil fuel consumption and associated carbon emissions. The manufacturing process is energy-intensive, particularly during the high-pressure and high-temperature phases required for proper consolidation of laminates. This energy demand contributes substantially to the material's overall environmental footprint.

End-of-life management presents another sustainability concern. UHMWPE composites, especially those with mixed material compositions or adhesive bonding to prevent delamination, pose recycling difficulties. The strong intermolecular bonds that provide excellent mechanical properties also make these materials resistant to conventional recycling processes, potentially leading to landfill disposal.

Recent innovations are addressing these sustainability gaps. Bio-based additives and reinforcements are being explored to reduce petroleum dependence. Advanced recycling technologies, including chemical recycling and pyrolysis, show promise for recovering value from end-of-life UHMWPE composites. Some manufacturers have implemented closed-loop production systems to capture and reuse production waste.

Life cycle assessment (LCA) studies indicate that UHMWPE composites may offer net environmental benefits when their full lifecycle is considered, particularly in applications where their superior impact resistance and delamination resistance properties prevent catastrophic failures and associated environmental consequences.

Future sustainability improvements will likely focus on developing delamination-resistant UHMWPE composites that maintain recyclability, incorporating renewable content, and reducing energy requirements during manufacturing through process optimization and alternative curing methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!