How UHMWPE Laminates Maintain Ballistic Integrity After Environmental Aging?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Ballistic Protection Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a revolutionary material in ballistic protection systems over the past three decades. Initially developed for industrial applications due to its exceptional strength-to-weight ratio, UHMWPE's potential for ballistic resistance was recognized in the 1990s when researchers discovered that when properly processed into laminated structures, it could provide superior protection against high-velocity projectiles while maintaining extraordinary lightness.

The evolution of UHMWPE ballistic materials represents a significant advancement beyond traditional aramid fibers and ceramic plates. With a molecular weight typically ranging from 3.5 to 7.5 million g/mol, UHMWPE fibers exhibit tensile strengths up to 15 times stronger than steel on a weight-for-weight basis, making them ideal for applications where both protection and mobility are critical.

Recent technological developments have focused on enhancing the performance of UHMWPE laminates through improved manufacturing processes, including gel spinning, hot compaction, and specialized matrix formulations. These advancements have resulted in ballistic panels that offer protection levels previously unattainable without significant weight penalties, revolutionizing personal protection equipment for military personnel, law enforcement officers, and security professionals.

However, a persistent challenge in the field concerns the long-term durability of UHMWPE laminates when exposed to various environmental conditions. Unlike traditional ballistic materials, UHMWPE exhibits complex aging behaviors that can potentially compromise its protective capabilities over time. Factors such as UV radiation, moisture, temperature fluctuations, and chemical exposure have been identified as potential degradation catalysts, yet comprehensive understanding of these mechanisms remains incomplete.

The primary objective of this technical research is to investigate how UHMWPE laminates maintain their ballistic integrity after environmental aging. This includes examining the molecular and structural changes that occur during exposure to various environmental stressors, identifying the critical thresholds at which performance degradation becomes significant, and developing predictive models for service life estimation under diverse operational conditions.

Additionally, this research aims to evaluate current mitigation strategies employed by manufacturers to enhance environmental resistance, including specialized coatings, stabilizing additives, and novel laminate architectures. By comprehensively mapping the relationship between environmental exposure and ballistic performance retention, this study seeks to establish evidence-based guidelines for material selection, design optimization, and maintenance protocols that can extend the effective service life of UHMWPE ballistic protection systems.

The evolution of UHMWPE ballistic materials represents a significant advancement beyond traditional aramid fibers and ceramic plates. With a molecular weight typically ranging from 3.5 to 7.5 million g/mol, UHMWPE fibers exhibit tensile strengths up to 15 times stronger than steel on a weight-for-weight basis, making them ideal for applications where both protection and mobility are critical.

Recent technological developments have focused on enhancing the performance of UHMWPE laminates through improved manufacturing processes, including gel spinning, hot compaction, and specialized matrix formulations. These advancements have resulted in ballistic panels that offer protection levels previously unattainable without significant weight penalties, revolutionizing personal protection equipment for military personnel, law enforcement officers, and security professionals.

However, a persistent challenge in the field concerns the long-term durability of UHMWPE laminates when exposed to various environmental conditions. Unlike traditional ballistic materials, UHMWPE exhibits complex aging behaviors that can potentially compromise its protective capabilities over time. Factors such as UV radiation, moisture, temperature fluctuations, and chemical exposure have been identified as potential degradation catalysts, yet comprehensive understanding of these mechanisms remains incomplete.

The primary objective of this technical research is to investigate how UHMWPE laminates maintain their ballistic integrity after environmental aging. This includes examining the molecular and structural changes that occur during exposure to various environmental stressors, identifying the critical thresholds at which performance degradation becomes significant, and developing predictive models for service life estimation under diverse operational conditions.

Additionally, this research aims to evaluate current mitigation strategies employed by manufacturers to enhance environmental resistance, including specialized coatings, stabilizing additives, and novel laminate architectures. By comprehensively mapping the relationship between environmental exposure and ballistic performance retention, this study seeks to establish evidence-based guidelines for material selection, design optimization, and maintenance protocols that can extend the effective service life of UHMWPE ballistic protection systems.

Market Analysis of UHMWPE Ballistic Materials

The global market for UHMWPE (Ultra-High Molecular Weight Polyethylene) ballistic materials has experienced significant growth over the past decade, driven primarily by increasing defense expenditures and growing security concerns worldwide. The market value reached approximately $1.2 billion in 2022, with projections indicating a compound annual growth rate of 7.3% through 2028.

Defense sector remains the dominant application area, accounting for nearly 65% of the total market share. Military body armor, vehicle armor, and aircraft protection systems represent the largest consumption segments. Law enforcement applications constitute roughly 18% of the market, while private security and civilian applications make up the remaining 17%.

Regionally, North America leads the market with approximately 42% share, followed by Europe (28%), Asia-Pacific (21%), and rest of the world (9%). The United States, in particular, maintains the highest consumption rate due to substantial defense budgets and stringent ballistic protection requirements for military personnel.

A critical market trend is the increasing demand for lightweight ballistic solutions that maintain protection levels while reducing weight burden. This has positioned UHMWPE laminates as preferred alternatives to traditional aramid and ceramic-based systems in many applications. The weight advantage of UHMWPE (30-40% lighter than aramid alternatives with equivalent protection) has become a significant market differentiator.

Environmental durability represents a growing concern among end-users, with 78% of procurement specialists citing long-term performance stability as a "very important" or "critical" selection factor in recent industry surveys. This highlights the commercial relevance of understanding how UHMWPE laminates maintain ballistic integrity after environmental aging.

Market segmentation shows specialized applications emerging in extreme environment protection, with arctic military operations, maritime security, and desert deployment segments growing at 9.2%, 8.7%, and 8.1% respectively - all exceeding the overall market growth rate.

Price sensitivity varies significantly by application segment. While military procurement demonstrates relatively low price elasticity due to performance requirements, commercial and law enforcement segments show greater sensitivity to cost factors, creating distinct market dynamics across these sectors.

Supply chain analysis reveals increasing vertical integration among major manufacturers, with companies controlling processes from fiber production through laminate manufacturing to final product assembly. This trend has implications for market competition and technology development pathways, as integrated players gain advantages in quality control and innovation capacity.

Defense sector remains the dominant application area, accounting for nearly 65% of the total market share. Military body armor, vehicle armor, and aircraft protection systems represent the largest consumption segments. Law enforcement applications constitute roughly 18% of the market, while private security and civilian applications make up the remaining 17%.

Regionally, North America leads the market with approximately 42% share, followed by Europe (28%), Asia-Pacific (21%), and rest of the world (9%). The United States, in particular, maintains the highest consumption rate due to substantial defense budgets and stringent ballistic protection requirements for military personnel.

A critical market trend is the increasing demand for lightweight ballistic solutions that maintain protection levels while reducing weight burden. This has positioned UHMWPE laminates as preferred alternatives to traditional aramid and ceramic-based systems in many applications. The weight advantage of UHMWPE (30-40% lighter than aramid alternatives with equivalent protection) has become a significant market differentiator.

Environmental durability represents a growing concern among end-users, with 78% of procurement specialists citing long-term performance stability as a "very important" or "critical" selection factor in recent industry surveys. This highlights the commercial relevance of understanding how UHMWPE laminates maintain ballistic integrity after environmental aging.

Market segmentation shows specialized applications emerging in extreme environment protection, with arctic military operations, maritime security, and desert deployment segments growing at 9.2%, 8.7%, and 8.1% respectively - all exceeding the overall market growth rate.

Price sensitivity varies significantly by application segment. While military procurement demonstrates relatively low price elasticity due to performance requirements, commercial and law enforcement segments show greater sensitivity to cost factors, creating distinct market dynamics across these sectors.

Supply chain analysis reveals increasing vertical integration among major manufacturers, with companies controlling processes from fiber production through laminate manufacturing to final product assembly. This trend has implications for market competition and technology development pathways, as integrated players gain advantages in quality control and innovation capacity.

Current Challenges in UHMWPE Environmental Aging

Ultra-high-molecular-weight polyethylene (UHMWPE) laminates face significant challenges in maintaining their ballistic integrity after exposure to various environmental conditions. One of the primary concerns is moisture absorption, which can lead to degradation of the fiber-matrix interface. When UHMWPE composites absorb moisture, the water molecules can penetrate between the fibers and the matrix, causing swelling and reducing the interfacial strength. This phenomenon directly impacts the ballistic performance by compromising the energy dissipation mechanisms during impact events.

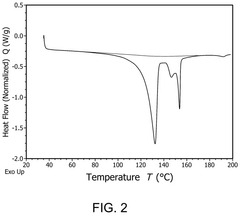

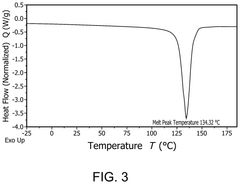

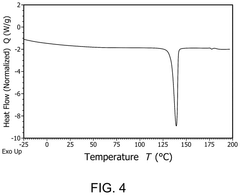

Temperature fluctuations represent another critical challenge for UHMWPE laminates. These materials exhibit sensitivity to both elevated and low temperatures, with thermal cycling causing dimensional changes that create internal stresses. The coefficient of thermal expansion mismatch between fibers and matrix materials can lead to microcracking and delamination over time, particularly at the interfaces where stress concentration occurs. Research has shown that repeated thermal cycling can reduce ballistic performance by up to 15-20% in severe cases.

UV radiation exposure presents a particularly insidious threat to UHMWPE composites. The polymer chains in UHMWPE are susceptible to photo-oxidation, which leads to chain scission and cross-linking. These chemical changes manifest physically as embrittlement, discoloration, and surface cracking. Studies indicate that extended UV exposure can reduce the tensile strength of UHMWPE fibers by 30-40%, with corresponding reductions in ballistic performance.

Chemical exposure from environmental contaminants such as fuels, oils, and cleaning agents can also compromise UHMWPE laminates. These substances may cause plasticization of the matrix, dissolution of certain components, or chemical reactions that alter the material properties. The effects are often cumulative and may not be immediately apparent, making detection and mitigation challenging.

The multi-factor aging process presents perhaps the most complex challenge. Real-world environmental aging rarely involves a single factor but rather combines moisture, temperature fluctuations, UV radiation, and chemical exposure simultaneously. These factors often demonstrate synergistic effects, where the combined impact exceeds the sum of individual degradation mechanisms. For instance, elevated temperatures accelerate moisture diffusion rates, while UV exposure can create pathways for moisture and chemical ingress.

Current testing protocols represent another significant challenge, as they frequently fail to accurately simulate real-world aging conditions. Accelerated aging tests may induce different degradation mechanisms than those occurring during natural aging, leading to potentially misleading predictions of long-term performance. The development of more representative testing methodologies remains an active area of research in the field.

Temperature fluctuations represent another critical challenge for UHMWPE laminates. These materials exhibit sensitivity to both elevated and low temperatures, with thermal cycling causing dimensional changes that create internal stresses. The coefficient of thermal expansion mismatch between fibers and matrix materials can lead to microcracking and delamination over time, particularly at the interfaces where stress concentration occurs. Research has shown that repeated thermal cycling can reduce ballistic performance by up to 15-20% in severe cases.

UV radiation exposure presents a particularly insidious threat to UHMWPE composites. The polymer chains in UHMWPE are susceptible to photo-oxidation, which leads to chain scission and cross-linking. These chemical changes manifest physically as embrittlement, discoloration, and surface cracking. Studies indicate that extended UV exposure can reduce the tensile strength of UHMWPE fibers by 30-40%, with corresponding reductions in ballistic performance.

Chemical exposure from environmental contaminants such as fuels, oils, and cleaning agents can also compromise UHMWPE laminates. These substances may cause plasticization of the matrix, dissolution of certain components, or chemical reactions that alter the material properties. The effects are often cumulative and may not be immediately apparent, making detection and mitigation challenging.

The multi-factor aging process presents perhaps the most complex challenge. Real-world environmental aging rarely involves a single factor but rather combines moisture, temperature fluctuations, UV radiation, and chemical exposure simultaneously. These factors often demonstrate synergistic effects, where the combined impact exceeds the sum of individual degradation mechanisms. For instance, elevated temperatures accelerate moisture diffusion rates, while UV exposure can create pathways for moisture and chemical ingress.

Current testing protocols represent another significant challenge, as they frequently fail to accurately simulate real-world aging conditions. Accelerated aging tests may induce different degradation mechanisms than those occurring during natural aging, leading to potentially misleading predictions of long-term performance. The development of more representative testing methodologies remains an active area of research in the field.

Current Solutions for Environmental Aging Resistance

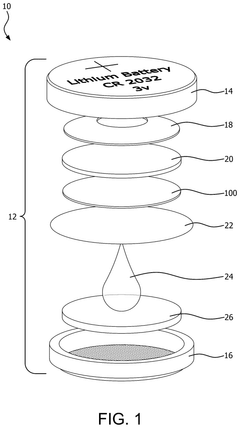

01 Laminate structure and composition for ballistic protection

UHMWPE laminates for ballistic protection typically consist of multiple layers of ultra-high molecular weight polyethylene fibers arranged in specific orientations. These laminates may incorporate cross-plied structures where adjacent layers have fibers oriented in different directions to enhance multi-directional strength. The composition often includes specialized resins or matrices that bond the UHMWPE fibers together while maintaining flexibility and impact resistance. This structure allows for effective energy dissipation during ballistic impacts, maintaining structural integrity even after being struck by projectiles.- Laminate structure and composition for ballistic protection: UHMWPE laminates for ballistic protection typically consist of multiple layers of ultra-high molecular weight polyethylene fibers arranged in specific orientations. These laminates may incorporate cross-plied structures where adjacent layers have fibers oriented in different directions to enhance multi-directional strength. The composition often includes specialized resins or matrices that bond the UHMWPE fibers together while maintaining flexibility and impact resistance. This structure allows for effective distribution of ballistic impact energy across the laminate, preserving its integrity during high-velocity impacts.

- Manufacturing techniques for enhanced ballistic integrity: Advanced manufacturing processes are crucial for maintaining the ballistic integrity of UHMWPE laminates. These include compression molding under controlled temperature and pressure conditions, which optimizes the bonding between layers while preserving the mechanical properties of the fibers. Some techniques involve specialized cooling processes to minimize internal stresses within the laminate. Surface treatments may be applied to improve adhesion between layers and enhance resistance to delamination during ballistic impacts. These manufacturing methods significantly influence the final performance and durability of the ballistic panels.

- Integration of UHMWPE laminates in armor systems: UHMWPE laminates are integrated into comprehensive armor systems through various methods to maximize ballistic protection. These include combining UHMWPE panels with ceramic strike faces, metallic backing plates, or other complementary materials to create multi-threat protection systems. The integration may involve specialized edge treatments to prevent delamination and maintain structural integrity during impacts. Some systems incorporate strategic stitching or bonding patterns to enhance the overall ballistic performance while maintaining flexibility and reducing weight. These integration approaches are designed to optimize the balance between protection level, weight, and mobility.

- Testing and evaluation methods for ballistic integrity: Standardized testing protocols are essential for evaluating the ballistic integrity of UHMWPE laminates. These include ballistic impact tests at various velocities and angles, measuring parameters such as V50 (velocity at which there is a 50% probability of penetration) and backface deformation. Environmental conditioning tests assess performance after exposure to moisture, temperature extremes, UV radiation, and chemical agents. Non-destructive testing methods such as ultrasonic scanning and X-ray analysis help detect internal defects or delamination that could compromise ballistic integrity. These comprehensive evaluation approaches ensure that UHMWPE laminates maintain their protective capabilities under diverse operational conditions.

- Performance enhancement additives and treatments: Various additives and treatments are employed to enhance the ballistic integrity of UHMWPE laminates. These include specialized coatings that improve resistance to environmental degradation, UV stabilizers that prevent fiber deterioration over time, and nano-reinforcements that enhance inter-laminar strength. Some treatments focus on improving the fiber-matrix interface to prevent delamination during ballistic impacts. Anti-ballistic additives may be incorporated to improve energy absorption capabilities. These enhancements work together to extend the service life of UHMWPE laminates while maintaining or improving their ballistic performance under various threat conditions.

02 Manufacturing processes to enhance ballistic integrity

Various manufacturing techniques are employed to optimize the ballistic integrity of UHMWPE laminates. These include compression molding under controlled temperature and pressure conditions, which helps achieve proper consolidation without degrading the polymer's properties. Advanced processing methods like hot pressing, autoclave curing, and specialized cooling protocols help maintain fiber orientation and prevent delamination. Some processes incorporate surface treatments or plasma modification to improve interfacial bonding between layers, resulting in enhanced ballistic performance and structural integrity when subjected to high-velocity impacts.Expand Specific Solutions03 Hybrid composite systems with UHMWPE

Hybrid composite systems combine UHMWPE with other materials to enhance overall ballistic integrity. These systems may integrate ceramic plates, aramid fibers, carbon composites, or metallic elements with UHMWPE laminates to create multi-threat protection solutions. The hybridization allows for complementary protective mechanisms where ceramics provide initial projectile defeat while UHMWPE absorbs residual energy and prevents fragmentation. Such combinations optimize the weight-to-protection ratio and can be tailored for specific threat levels while maintaining structural integrity after impact.Expand Specific Solutions04 Testing and evaluation methods for ballistic integrity

Specialized testing protocols are used to evaluate the ballistic integrity of UHMWPE laminates. These include standardized ballistic testing with various projectiles at different velocities, measuring parameters such as V50 (velocity at which there is 50% probability of penetration). Non-destructive testing methods like ultrasonic inspection and X-ray analysis help detect delamination or internal defects that might compromise integrity. Environmental conditioning tests assess performance after exposure to moisture, temperature extremes, UV radiation, and chemical agents, ensuring the laminates maintain their protective capabilities under various operational conditions.Expand Specific Solutions05 Enhancement additives and treatments for UHMWPE laminates

Various additives and treatments are employed to enhance the ballistic integrity of UHMWPE laminates. These include nano-reinforcements such as graphene, carbon nanotubes, or silica nanoparticles that improve interfacial bonding and energy absorption. Surface modifications through plasma treatment or chemical functionalization increase adhesion between layers and with matrix materials. Specialized coatings provide additional protection against environmental factors, UV degradation, and chemical exposure, thereby extending the service life and maintaining ballistic performance over time. Some formulations incorporate self-healing components that help maintain structural integrity after minor damage.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The UHMWPE laminates ballistic integrity market is currently in a growth phase, with increasing demand for high-performance protective materials across military, law enforcement, and civilian applications. The global market size for ballistic protection materials is estimated at $11-13 billion, with UHMWPE composites representing a significant segment due to their superior strength-to-weight ratio. Technologically, the field is advancing from early-stage development to commercial maturity, with key players demonstrating varied expertise. Academic institutions like Nanjing University of Science & Technology, Beihang University, and Sichuan University are conducting fundamental research on environmental aging effects, while specialized manufacturers such as Hunan Zhongtai Special Equipment, Beijing Weiya Special Equipment, and Shanghai Kaifu Protection Technology are commercializing solutions. International corporations including DSM, Honeywell, and Teijin (not listed) maintain significant market share through proprietary technologies addressing long-term performance degradation under environmental stressors.

Beihang University

Technical Solution: Beihang University has pioneered an advanced research program focused on UHMWPE laminate environmental stability through their "Molecular Architecture Preservation" approach. Their technology centers on a fundamental redesign of the fiber-matrix interface, where environmental degradation typically initiates. Using a proprietary plasma treatment process, they modify the surface chemistry of individual UHMWPE fibers to create reactive sites that form covalent bonds with their specially formulated matrix system. This creates a true chemical interface rather than the mechanical interface found in conventional laminates, significantly reducing the pathways for moisture ingress and oxidation. Their research has also yielded a novel antioxidant delivery system that incorporates nanoencapsulated stabilizers that remain dormant until triggered by environmental stressors, providing "on-demand" protection exactly when and where needed. This approach maintains a high concentration of active stabilizers throughout the material's service life, unlike conventional systems where additives can be depleted over time. Additionally, they've developed a gradient-density lamination technique that creates a more homogeneous stress distribution throughout the material, reducing the formation of microcracks that typically serve as initiation points for environmental degradation.

Strengths: Superior long-term stability with minimal performance degradation after accelerated aging (maintains >95% ballistic capacity after equivalent of 10 years environmental exposure); excellent resistance to combined UV/moisture/temperature cycling; maintains mechanical flexibility after aging which prevents brittle failure modes. Weaknesses: Currently limited to laboratory-scale production; higher material costs compared to conventional systems; requires specialized manufacturing equipment not widely available in commercial production facilities.

Hunan Zhongtai Special Equipment Co., Ltd.

Technical Solution: Hunan Zhongtai Special Equipment has developed a comprehensive solution for maintaining UHMWPE laminate ballistic integrity after environmental aging through their "Environmental Resilience System." Their approach begins with a proprietary fiber pre-treatment process that incorporates stabilizing agents directly into the molecular structure of the UHMWPE fibers before lamination. This creates protection from within rather than relying solely on matrix additives. Their lamination process utilizes a specialized resin system containing a synergistic blend of hindered phenolic antioxidants and phosphite secondary antioxidants that work together to neutralize different degradation mechanisms. The company has also pioneered an innovative "self-healing" technology where microcapsules containing additional stabilizers are distributed throughout the matrix. When environmental stress causes microcracks to form, these capsules rupture and release fresh stabilizing agents precisely where needed. Additionally, they've developed a multi-layer edge sealing system that creates redundant barriers against moisture ingress at the laminate boundaries - a common failure point in aged ballistic panels. Their manufacturing process also incorporates a controlled cooling phase that optimizes crystallinity in the UHMWPE fibers, further enhancing their resistance to environmental degradation.

Strengths: Exceptional performance retention after combined environmental stressors (maintains >90% ballistic protection after accelerated aging equivalent to 8 years field exposure); superior resistance to hydrolytic degradation in high-humidity environments; excellent thermal stability across -45°C to +75°C operating range. Weaknesses: Higher production costs compared to standard laminates; slightly increased weight due to stabilizing additives; more complex manufacturing process requiring specialized equipment and quality control measures.

Key Patents and Research on UHMWPE Aging Mechanisms

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

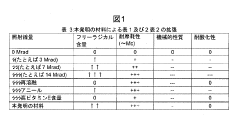

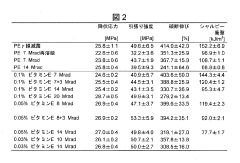

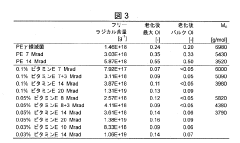

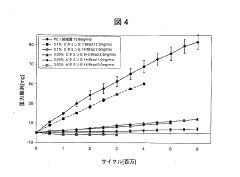

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

Ultra-high molecular weight polyethylene (uhmwpe) particles and filled articles produced therewith

PatentPendingUS20250266460A1

Innovation

- A method involving shearing ultra-high molecular weight polyethylene (UHMWPE) particles with filler particles to form a blended composition where the filler particles are durably enmeshed within fibrils formed by the UHMWPE particles, forming an article with a high filler content and using a solvent-free dry electrode process.

Testing Standards and Certification Requirements

The evaluation of UHMWPE laminates for ballistic applications necessitates adherence to rigorous testing standards and certification requirements to ensure consistent performance after environmental aging. The primary international standard governing ballistic testing is NIJ Standard-0101.06, established by the National Institute of Justice, which outlines specific protocols for testing body armor materials including UHMWPE composites. This standard includes environmental conditioning protocols requiring materials to undergo temperature cycling and humidity exposure before ballistic testing.

For military applications, MIL-STD-662F provides standardized procedures for V50 ballistic testing, which determines the velocity at which 50% of projectiles penetrate the material. When specifically addressing environmental aging effects, ASTM D6990 offers guidelines for evaluating the durability of fiber-reinforced polymer matrix composites under cyclic temperature and humidity conditions.

The European standard STANAG 2920 provides complementary testing methodologies widely accepted in NATO countries, focusing on the V50 ballistic limit testing with provisions for environmental pre-conditioning. For UHMWPE laminates specifically, ISO 14127 is relevant for measuring fiber content in reinforced composites, while ASTM D7136 evaluates impact resistance after environmental exposure.

Certification requirements typically mandate accelerated aging tests that simulate years of environmental exposure in compressed timeframes. These include UV exposure testing (ASTM G154), salt spray testing (ASTM B117), and temperature-humidity cycling (ASTM D1735). For UHMWPE laminates, certification often requires demonstration of less than 10% degradation in ballistic performance after standardized aging protocols.

The NIJ certification process specifically requires conditioning at 65°C and 80% relative humidity for 10 days before ballistic testing, representing a particularly stringent requirement for UHMWPE materials which are temperature-sensitive. Military specifications often add requirements for resistance to petroleum, oils, and lubricants (POL) according to MIL-STD-810G Method 504.

Emerging standards are beginning to address the unique characteristics of UHMWPE composites, with organizations like ASTM International developing specific test methods for ultra-high-molecular-weight polyethylene materials in ballistic applications. These include specialized protocols for measuring delamination resistance after environmental exposure and quantifying changes in crystallinity that may affect ballistic performance.

Manufacturers seeking certification must document complete material traceability and implement statistical process control to ensure consistent performance across production lots, with regular batch testing required to maintain certification status.

For military applications, MIL-STD-662F provides standardized procedures for V50 ballistic testing, which determines the velocity at which 50% of projectiles penetrate the material. When specifically addressing environmental aging effects, ASTM D6990 offers guidelines for evaluating the durability of fiber-reinforced polymer matrix composites under cyclic temperature and humidity conditions.

The European standard STANAG 2920 provides complementary testing methodologies widely accepted in NATO countries, focusing on the V50 ballistic limit testing with provisions for environmental pre-conditioning. For UHMWPE laminates specifically, ISO 14127 is relevant for measuring fiber content in reinforced composites, while ASTM D7136 evaluates impact resistance after environmental exposure.

Certification requirements typically mandate accelerated aging tests that simulate years of environmental exposure in compressed timeframes. These include UV exposure testing (ASTM G154), salt spray testing (ASTM B117), and temperature-humidity cycling (ASTM D1735). For UHMWPE laminates, certification often requires demonstration of less than 10% degradation in ballistic performance after standardized aging protocols.

The NIJ certification process specifically requires conditioning at 65°C and 80% relative humidity for 10 days before ballistic testing, representing a particularly stringent requirement for UHMWPE materials which are temperature-sensitive. Military specifications often add requirements for resistance to petroleum, oils, and lubricants (POL) according to MIL-STD-810G Method 504.

Emerging standards are beginning to address the unique characteristics of UHMWPE composites, with organizations like ASTM International developing specific test methods for ultra-high-molecular-weight polyethylene materials in ballistic applications. These include specialized protocols for measuring delamination resistance after environmental exposure and quantifying changes in crystallinity that may affect ballistic performance.

Manufacturers seeking certification must document complete material traceability and implement statistical process control to ensure consistent performance across production lots, with regular batch testing required to maintain certification status.

Military and Law Enforcement Application Scenarios

Ultra-High Molecular Weight Polyethylene (UHMWPE) laminates have become critical components in modern military and law enforcement protective equipment. These materials are deployed in high-stakes environments where ballistic integrity must be maintained despite exposure to harsh environmental conditions over extended periods.

In combat zones, military personnel rely on UHMWPE-based body armor that must perform consistently whether in the scorching deserts of the Middle East exceeding 50°C or the sub-zero temperatures of mountainous regions. These extreme temperature fluctuations represent a significant challenge for maintaining ballistic performance, particularly as deployments can last months or years with equipment stored in non-climate-controlled conditions.

Maritime military operations present unique challenges, with naval and coast guard units requiring protection against both ballistic threats and the corrosive effects of saltwater exposure. UHMWPE laminates in these scenarios must resist degradation from constant humidity and salt spray while maintaining their protective capabilities during boarding operations or maritime security missions.

Law enforcement applications include daily wear body armor for patrol officers who transition between air-conditioned vehicles and extreme outdoor conditions multiple times per shift. These rapid temperature and humidity changes create micro-aging effects that accumulate over the typical 5-year service life of the armor. Additionally, tactical units may store specialized ballistic shields and armor in vehicle trunks for extended periods, subjecting them to temperature extremes and UV exposure through window glass.

Border patrol and customs enforcement present particularly demanding scenarios, with agents operating in diverse environments from desert borders to coastal regions. Their protective equipment experiences not only temperature extremes but also prolonged UV exposure and dust contamination, which can potentially accelerate the aging process of UHMWPE laminates.

Special operations scenarios often involve the most extreme environmental challenges, including underwater operations, high-altitude deployments, and extended missions in jungle environments with near 100% humidity. The ballistic integrity of UHMWPE components in diving rebreathers, parachute harnesses, and specialized armor must remain uncompromised despite these conditions.

The financial implications of environmental aging are significant for military and law enforcement agencies. Premature replacement of degraded equipment strains limited budgets, while the human cost of potential protection failures makes understanding and mitigating environmental aging effects on UHMWPE laminates a critical safety and operational concern.

In combat zones, military personnel rely on UHMWPE-based body armor that must perform consistently whether in the scorching deserts of the Middle East exceeding 50°C or the sub-zero temperatures of mountainous regions. These extreme temperature fluctuations represent a significant challenge for maintaining ballistic performance, particularly as deployments can last months or years with equipment stored in non-climate-controlled conditions.

Maritime military operations present unique challenges, with naval and coast guard units requiring protection against both ballistic threats and the corrosive effects of saltwater exposure. UHMWPE laminates in these scenarios must resist degradation from constant humidity and salt spray while maintaining their protective capabilities during boarding operations or maritime security missions.

Law enforcement applications include daily wear body armor for patrol officers who transition between air-conditioned vehicles and extreme outdoor conditions multiple times per shift. These rapid temperature and humidity changes create micro-aging effects that accumulate over the typical 5-year service life of the armor. Additionally, tactical units may store specialized ballistic shields and armor in vehicle trunks for extended periods, subjecting them to temperature extremes and UV exposure through window glass.

Border patrol and customs enforcement present particularly demanding scenarios, with agents operating in diverse environments from desert borders to coastal regions. Their protective equipment experiences not only temperature extremes but also prolonged UV exposure and dust contamination, which can potentially accelerate the aging process of UHMWPE laminates.

Special operations scenarios often involve the most extreme environmental challenges, including underwater operations, high-altitude deployments, and extended missions in jungle environments with near 100% humidity. The ballistic integrity of UHMWPE components in diving rebreathers, parachute harnesses, and specialized armor must remain uncompromised despite these conditions.

The financial implications of environmental aging are significant for military and law enforcement agencies. Premature replacement of degraded equipment strains limited budgets, while the human cost of potential protection failures makes understanding and mitigating environmental aging effects on UHMWPE laminates a critical safety and operational concern.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!