UHMWPE Melt Processing Windows: Gel-Spun Precursors, Orientation And Property Scatter

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Processing Evolution and Objectives

Ultra-high molecular weight polyethylene (UHMWPE) processing has undergone significant evolution since its commercial introduction in the 1950s. Initially, conventional processing techniques such as compression molding and ram extrusion were the primary methods employed, severely limiting product forms and applications due to the extremely high molecular weight and resultant high melt viscosity of the polymer. These early processing constraints restricted UHMWPE to simple shapes and relatively low-performance applications.

The breakthrough came in the 1970s with the development of gel-spinning technology by DSM (now Dyneema) and Allied Signal (now Honeywell), revolutionizing UHMWPE processing. This technique involves dissolving UHMWPE in a solvent at elevated temperatures, followed by extrusion and subsequent solvent extraction, enabling the production of high-strength fibers with exceptional mechanical properties. The 1980s and 1990s witnessed further refinements in gel-spinning processes, particularly in controlling molecular orientation during processing.

Recent decades have seen increasing focus on understanding and expanding the melt processing window of UHMWPE. Researchers have explored various approaches including the use of disentangled UHMWPE, processing aids, and controlled molecular architecture to enhance processability while maintaining the exceptional mechanical properties that make UHMWPE valuable. The development of multi-stage drawing processes has further improved fiber properties by optimizing molecular orientation.

The current technical landscape is characterized by efforts to balance the inherent trade-off between processability and final mechanical properties. Gel-spinning remains the dominant method for producing high-performance UHMWPE fibers, but innovations in reactor technology and catalyst systems have enabled the synthesis of UHMWPE grades with improved processability characteristics.

The primary objective in UHMWPE processing research is to expand the melt processing window while maintaining or enhancing the exceptional mechanical properties that make this polymer valuable. Specifically, researchers aim to develop processing techniques that can accommodate the extremely high molecular weight (typically 3-6 million g/mol) while achieving uniform molecular orientation critical for optimal mechanical performance.

Additional objectives include reducing property scatter in final products, which remains a significant challenge in UHMWPE processing. The relationship between gel-spun precursor characteristics, processing parameters, and final property consistency represents a critical area for investigation. Furthermore, there is growing interest in developing more environmentally sustainable processing methods that reduce or eliminate solvent usage while maintaining the high-performance characteristics of UHMWPE products.

The breakthrough came in the 1970s with the development of gel-spinning technology by DSM (now Dyneema) and Allied Signal (now Honeywell), revolutionizing UHMWPE processing. This technique involves dissolving UHMWPE in a solvent at elevated temperatures, followed by extrusion and subsequent solvent extraction, enabling the production of high-strength fibers with exceptional mechanical properties. The 1980s and 1990s witnessed further refinements in gel-spinning processes, particularly in controlling molecular orientation during processing.

Recent decades have seen increasing focus on understanding and expanding the melt processing window of UHMWPE. Researchers have explored various approaches including the use of disentangled UHMWPE, processing aids, and controlled molecular architecture to enhance processability while maintaining the exceptional mechanical properties that make UHMWPE valuable. The development of multi-stage drawing processes has further improved fiber properties by optimizing molecular orientation.

The current technical landscape is characterized by efforts to balance the inherent trade-off between processability and final mechanical properties. Gel-spinning remains the dominant method for producing high-performance UHMWPE fibers, but innovations in reactor technology and catalyst systems have enabled the synthesis of UHMWPE grades with improved processability characteristics.

The primary objective in UHMWPE processing research is to expand the melt processing window while maintaining or enhancing the exceptional mechanical properties that make this polymer valuable. Specifically, researchers aim to develop processing techniques that can accommodate the extremely high molecular weight (typically 3-6 million g/mol) while achieving uniform molecular orientation critical for optimal mechanical performance.

Additional objectives include reducing property scatter in final products, which remains a significant challenge in UHMWPE processing. The relationship between gel-spun precursor characteristics, processing parameters, and final property consistency represents a critical area for investigation. Furthermore, there is growing interest in developing more environmentally sustainable processing methods that reduce or eliminate solvent usage while maintaining the high-performance characteristics of UHMWPE products.

Market Analysis for High-Performance Fiber Applications

The high-performance fiber market has experienced significant growth over the past decade, driven by increasing demand across multiple industries including aerospace, defense, automotive, and sporting goods. Ultra-high molecular weight polyethylene (UHMWPE) fibers represent a critical segment within this market due to their exceptional strength-to-weight ratio, chemical resistance, and durability characteristics.

The global high-performance fiber market was valued at approximately 11.6 billion USD in 2022 and is projected to reach 23.5 billion USD by 2030, growing at a compound annual growth rate (CAGR) of 9.2%. Within this broader market, UHMWPE fibers specifically account for roughly 15% of market share, with consistent growth outpacing the overall sector average.

Key application segments for UHMWPE fibers include ballistic protection (body armor, vehicle armor), maritime applications (ropes, nets, cables), medical devices, and high-performance sporting goods. The ballistic protection segment currently dominates consumption, representing approximately 40% of UHMWPE fiber applications, followed by maritime applications at 25%.

Regional analysis indicates that North America and Europe currently lead consumption of UHMWPE fibers, collectively accounting for 65% of global demand. However, the Asia-Pacific region, particularly China, Japan, and South Korea, demonstrates the fastest growth trajectory with annual increases exceeding 12%.

Market drivers supporting continued expansion include increasing military and defense spending globally, growing awareness of personal protection equipment requirements, and the ongoing replacement of traditional materials with lightweight alternatives in transportation applications. The push toward sustainability also benefits UHMWPE fibers, as their durability translates to longer product lifecycles.

Pricing trends reveal moderate but consistent increases, with premium-grade gel-spun UHMWPE fibers commanding 30-40% higher prices than standard grades due to superior orientation and mechanical properties. This price premium underscores the market value of optimized processing windows that yield consistent fiber properties.

Customer requirements increasingly emphasize property consistency across production batches, with major end-users implementing stringent quality control specifications. This trend directly relates to the technical challenges of controlling gel-spinning precursors and orientation parameters during UHMWPE processing.

Market forecasts suggest that applications requiring precisely engineered property profiles will drive future growth, with particular emphasis on reducing property scatter through improved processing techniques. This market dynamic creates significant commercial incentive for research focused on expanding UHMWPE melt processing windows and orientation control methodologies.

The global high-performance fiber market was valued at approximately 11.6 billion USD in 2022 and is projected to reach 23.5 billion USD by 2030, growing at a compound annual growth rate (CAGR) of 9.2%. Within this broader market, UHMWPE fibers specifically account for roughly 15% of market share, with consistent growth outpacing the overall sector average.

Key application segments for UHMWPE fibers include ballistic protection (body armor, vehicle armor), maritime applications (ropes, nets, cables), medical devices, and high-performance sporting goods. The ballistic protection segment currently dominates consumption, representing approximately 40% of UHMWPE fiber applications, followed by maritime applications at 25%.

Regional analysis indicates that North America and Europe currently lead consumption of UHMWPE fibers, collectively accounting for 65% of global demand. However, the Asia-Pacific region, particularly China, Japan, and South Korea, demonstrates the fastest growth trajectory with annual increases exceeding 12%.

Market drivers supporting continued expansion include increasing military and defense spending globally, growing awareness of personal protection equipment requirements, and the ongoing replacement of traditional materials with lightweight alternatives in transportation applications. The push toward sustainability also benefits UHMWPE fibers, as their durability translates to longer product lifecycles.

Pricing trends reveal moderate but consistent increases, with premium-grade gel-spun UHMWPE fibers commanding 30-40% higher prices than standard grades due to superior orientation and mechanical properties. This price premium underscores the market value of optimized processing windows that yield consistent fiber properties.

Customer requirements increasingly emphasize property consistency across production batches, with major end-users implementing stringent quality control specifications. This trend directly relates to the technical challenges of controlling gel-spinning precursors and orientation parameters during UHMWPE processing.

Market forecasts suggest that applications requiring precisely engineered property profiles will drive future growth, with particular emphasis on reducing property scatter through improved processing techniques. This market dynamic creates significant commercial incentive for research focused on expanding UHMWPE melt processing windows and orientation control methodologies.

Technical Challenges in UHMWPE Melt Processing

Ultra-high molecular weight polyethylene (UHMWPE) presents significant processing challenges due to its extremely high molecular weight and corresponding high melt viscosity. The conventional melt processing techniques that work effectively for standard polyethylene grades become inadequate when applied to UHMWPE, creating a narrow processing window that severely limits manufacturing capabilities.

The primary challenge in UHMWPE melt processing stems from its inherently high viscosity, which can exceed 10^6 Pa·s at processing temperatures. This high viscosity results from extensive chain entanglements due to the polymer's extremely long chains, typically having molecular weights above 3.5 million g/mol. These entanglements create substantial resistance to flow, making conventional extrusion and injection molding processes nearly impossible without significant modification.

Temperature management represents another critical challenge. UHMWPE requires processing temperatures between 160-220°C to achieve sufficient flow properties. However, this temperature range sits dangerously close to the polymer's degradation threshold. The narrow thermal processing window creates a delicate balance between achieving adequate flow and avoiding thermal degradation, which can compromise the material's exceptional mechanical properties.

Shear-induced degradation further complicates processing efforts. The high shear forces necessary to process UHMWPE can cause chain scission, reducing molecular weight and consequently diminishing the very properties that make UHMWPE valuable. This creates a paradoxical situation where the processing required to shape the material can destroy its desirable characteristics.

Gel formation presents yet another significant obstacle. Partially melted particles or regions of higher molecular weight can create gel structures within the polymer melt, leading to inconsistencies in the final product. These gels contribute to property scatter and can create weak points in the material structure, particularly problematic for high-performance applications.

The orientation of polymer chains during processing critically affects final material properties. Achieving consistent orientation throughout the material volume remains challenging due to flow irregularities caused by the high viscosity. This orientation variability directly contributes to property scatter in the finished products, creating inconsistencies in tensile strength, impact resistance, and wear performance.

Recent research has focused on developing specialized processing aids and techniques to expand the processing window. Modified die designs, novel extruder configurations, and the incorporation of processing aids have shown promise in improving processability without sacrificing mechanical properties. However, these solutions often introduce additional complexity and cost to the manufacturing process.

The primary challenge in UHMWPE melt processing stems from its inherently high viscosity, which can exceed 10^6 Pa·s at processing temperatures. This high viscosity results from extensive chain entanglements due to the polymer's extremely long chains, typically having molecular weights above 3.5 million g/mol. These entanglements create substantial resistance to flow, making conventional extrusion and injection molding processes nearly impossible without significant modification.

Temperature management represents another critical challenge. UHMWPE requires processing temperatures between 160-220°C to achieve sufficient flow properties. However, this temperature range sits dangerously close to the polymer's degradation threshold. The narrow thermal processing window creates a delicate balance between achieving adequate flow and avoiding thermal degradation, which can compromise the material's exceptional mechanical properties.

Shear-induced degradation further complicates processing efforts. The high shear forces necessary to process UHMWPE can cause chain scission, reducing molecular weight and consequently diminishing the very properties that make UHMWPE valuable. This creates a paradoxical situation where the processing required to shape the material can destroy its desirable characteristics.

Gel formation presents yet another significant obstacle. Partially melted particles or regions of higher molecular weight can create gel structures within the polymer melt, leading to inconsistencies in the final product. These gels contribute to property scatter and can create weak points in the material structure, particularly problematic for high-performance applications.

The orientation of polymer chains during processing critically affects final material properties. Achieving consistent orientation throughout the material volume remains challenging due to flow irregularities caused by the high viscosity. This orientation variability directly contributes to property scatter in the finished products, creating inconsistencies in tensile strength, impact resistance, and wear performance.

Recent research has focused on developing specialized processing aids and techniques to expand the processing window. Modified die designs, novel extruder configurations, and the incorporation of processing aids have shown promise in improving processability without sacrificing mechanical properties. However, these solutions often introduce additional complexity and cost to the manufacturing process.

Current Methodologies for UHMWPE Orientation Control

01 Melt processing parameters for UHMWPE

Specific processing parameters are critical for successful melt processing of UHMWPE. These include temperature windows, pressure conditions, and processing speeds that allow for proper flow while preventing degradation. The high molecular weight of UHMWPE presents challenges during processing, requiring careful control of these parameters to achieve desired material properties while maintaining the polymer's structural integrity.- Melt processing parameters for UHMWPE: Specific processing parameters are critical for successful melt processing of UHMWPE. These include temperature windows, pressure conditions, and processing rates that allow for proper flow while preventing degradation. The high molecular weight of UHMWPE presents challenges during processing, requiring careful control of these parameters to maintain material integrity and achieve desired properties in the final product.

- Orientation techniques for UHMWPE fibers and films: Various techniques can be employed to achieve molecular orientation in UHMWPE, including drawing, compression molding, and extrusion processes. Controlled orientation significantly enhances mechanical properties such as tensile strength and modulus. The degree of orientation can be manipulated through processing conditions like draw ratio, temperature, and strain rate, resulting in highly anisotropic properties beneficial for specific applications.

- Additives and modifiers for improved UHMWPE processing: Incorporating specific additives and modifiers can enhance the processability of UHMWPE. These include processing aids, compatibilizers, plasticizers, and nucleating agents that improve flow characteristics and reduce processing temperatures. Such additives can widen the processing window, reduce property scatter, and enable more consistent production of UHMWPE products while maintaining the material's desirable mechanical properties.

- Property scatter reduction methods in UHMWPE processing: Various methods have been developed to reduce property scatter in UHMWPE products, including controlled cooling rates, uniform pressure distribution during molding, and homogeneous mixing techniques. Consistent processing conditions and raw material quality control are essential for minimizing variations in mechanical properties. Advanced monitoring and control systems can be implemented to ensure reproducibility and reliability in UHMWPE processing.

- Novel processing technologies for UHMWPE: Innovative processing technologies have been developed to overcome the challenges associated with UHMWPE melt processing. These include solid-state processing, ram extrusion, compression molding with specific pressure profiles, and specialized twin-screw extrusion techniques. These methods enable better control over molecular weight distribution, crystallinity, and orientation, resulting in UHMWPE products with enhanced performance characteristics and more consistent properties.

02 Orientation techniques for UHMWPE fibers and films

Various techniques can be employed to achieve molecular orientation in UHMWPE, including drawing, stretching, and specialized extrusion methods. Orientation significantly enhances mechanical properties such as tensile strength and modulus by aligning polymer chains in the direction of applied force. The degree of orientation can be controlled through processing conditions and has a direct impact on the final performance characteristics of UHMWPE products.Expand Specific Solutions03 Property scatter reduction methods

Reducing property scatter in UHMWPE involves standardizing raw materials, optimizing processing conditions, and implementing quality control measures. Consistent molecular weight distribution, uniform particle morphology, and controlled processing parameters help minimize variations in mechanical and physical properties. Advanced characterization techniques are employed to identify sources of variability and develop strategies to enhance batch-to-batch consistency.Expand Specific Solutions04 Additives and modifiers for improved processability

Various additives and modifiers can be incorporated into UHMWPE to enhance its processability while maintaining desirable properties. These include processing aids, compatibilizers, plasticizers, and nucleating agents that facilitate melt flow, reduce processing temperatures, and improve homogeneity. The careful selection and concentration of these additives can significantly widen the processing window while minimizing negative impacts on mechanical properties.Expand Specific Solutions05 Novel processing technologies for UHMWPE

Innovative processing technologies have been developed to overcome the challenges associated with UHMWPE melt processing. These include ram extrusion, compression molding with sintering, solid-state processing, and specialized twin-screw extrusion techniques. These methods address the high viscosity and limited flowability of UHMWPE, enabling the production of complex shapes and profiles while maintaining the polymer's exceptional mechanical properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions

# UHMWPE Melt Processing Windows: Competitive Landscape Analysis

The ultra-high molecular weight polyethylene (UHMWPE) melt processing industry is in a growth phase, with the global market expected to reach $3.5 billion by 2027, driven by demand in medical, defense, and industrial applications. The technology landscape shows varying maturity levels across different processing methods. Leading players include DSM IP Assets BV, which has pioneered gel-spinning technology for high-performance fibers, and Sinopec subsidiaries that have developed significant expertise in polymer processing. Research institutions like South China University of Technology and Qilu University are advancing fundamental understanding of orientation mechanisms. Japanese corporations (Tokyo Electron, FUJIFILM) and Western companies (Oerlikon Textile, Daramic) are competing through specialized equipment and process innovations, creating a fragmented but innovation-driven competitive environment focused on overcoming the inherent processing challenges of UHMWPE.

The ultra-high molecular weight polyethylene (UHMWPE) melt processing industry is in a growth phase, with the global market expected to reach $3.5 billion by 2027, driven by demand in medical, defense, and industrial applications. The technology landscape shows varying maturity levels across different processing methods. Leading players include DSM IP Assets BV, which has pioneered gel-spinning technology for high-performance fibers, and Sinopec subsidiaries that have developed significant expertise in polymer processing. Research institutions like South China University of Technology and Qilu University are advancing fundamental understanding of orientation mechanisms. Japanese corporations (Tokyo Electron, FUJIFILM) and Western companies (Oerlikon Textile, Daramic) are competing through specialized equipment and process innovations, creating a fragmented but innovation-driven competitive environment focused on overcoming the inherent processing challenges of UHMWPE.

DSM IP Assets BV

Technical Solution: DSM has developed advanced gel-spinning technology for UHMWPE fiber production that addresses the challenges of melt processing windows. Their approach involves dissolving UHMWPE in a solvent to create a gel, followed by controlled extrusion and drawing processes. DSM's technology carefully manages the critical parameters of molecular weight, temperature profiles, and drawing ratios to optimize fiber properties. They've implemented precise thermal control systems that maintain temperatures within the narrow processing window required for successful gel-spinning. Their process includes specialized spinneret designs that facilitate uniform gel formation and subsequent fiber orientation. DSM has also developed proprietary additives that enhance processability without compromising the mechanical properties of the final fibers.

Strengths: Superior control over molecular orientation resulting in exceptional strength-to-weight ratios; ability to process ultra-high molecular weight polymers that are typically difficult to melt process. Weaknesses: Complex multi-stage process requiring precise solvent handling and recovery systems; higher production costs compared to conventional melt spinning techniques.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive approach to UHMWPE melt processing that focuses on reactor design and catalyst systems to produce polymers with controlled molecular weight distribution specifically tailored for gel-spinning. Their technology incorporates a two-stage polymerization process that yields UHMWPE with balanced processability and performance characteristics. Sinopec's method includes specialized disentanglement techniques that temporarily reduce melt viscosity during processing without compromising the molecular weight that provides strength in the final product. They've implemented a controlled cooling system that manages crystallization kinetics to optimize orientation development during the drawing phase. Additionally, Sinopec has developed proprietary stabilizers that prevent degradation during the high-temperature processing required for UHMWPE melt extrusion.

Strengths: Vertically integrated approach from polymer synthesis to fiber production allows for customized molecular structures specifically designed for gel-spinning; large-scale production capabilities with consistent quality control. Weaknesses: Process requires significant energy input for the high-temperature melt processing stages; challenging to rapidly adjust processing parameters for different product specifications.

Critical Patents in Gel-Spinning Process Optimization

A process for preparing a disentangled uhmwpe product

PatentWO2015140681A1

Innovation

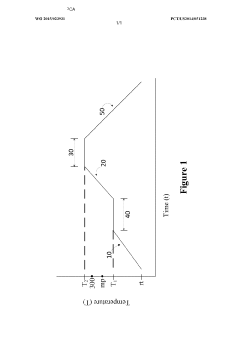

- A process involving a positive mold preheated in a compression molding machine, where disentangled UHMWPE is compacted below its melt temperature with stepwise pressure and temperature variations to achieve a density of at least 1 g/cc, followed by cooling and stretching to enhance crystallinity and mechanical properties.

Method for making ultra high molecular weight polyethylene

PatentWO2015023931A2

Innovation

- Applying radial pressure during heat treatment, specifically by constraining the UHMWPE in a sleeve that allows thermal expansion to apply pressure radially while keeping the longitudinal axis unconstrained, prevents cavitation damage, enabling subsequent heat processing above the melting temperature without degrading mechanical properties.

Material Characterization Techniques for UHMWPE Fibers

The characterization of Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers requires sophisticated analytical techniques to understand their unique structural and mechanical properties. These techniques are essential for evaluating the relationship between processing conditions, molecular orientation, and the resulting fiber properties within the melt processing window.

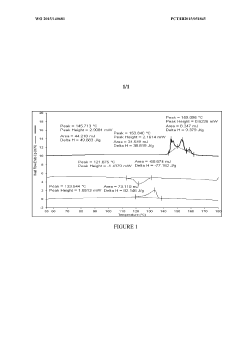

Differential Scanning Calorimetry (DSC) serves as a primary tool for analyzing the thermal behavior of UHMWPE fibers, providing critical insights into crystallinity, melting points, and thermal transitions. This technique helps researchers understand how gel-spinning parameters affect the crystalline structure, which directly influences fiber performance. DSC measurements can reveal the presence of multiple melting peaks, indicating different crystal populations formed during processing.

X-ray diffraction techniques, including Wide-Angle X-ray Scattering (WAXS) and Small-Angle X-ray Scattering (SAXS), are invaluable for quantifying molecular orientation and crystalline morphology. WAXS provides information about crystal structure and orientation factors, while SAXS reveals details about lamellar spacing and long-range order. These measurements are particularly important for correlating processing conditions with the development of oriented structures in gel-spun UHMWPE.

Rheological characterization using dynamic mechanical analysis and melt rheometry offers insights into the viscoelastic properties of UHMWPE during processing. These techniques help define the processing window by measuring parameters such as complex viscosity, storage modulus, and loss modulus as functions of temperature and shear rate. Understanding these properties is crucial for optimizing gel-spinning conditions and predicting processability.

Microscopy techniques, including Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM), provide direct visualization of fiber morphology and internal structure. SEM reveals surface features and defects, while TEM can show the nanoscale organization of crystalline and amorphous regions. Atomic Force Microscopy (AFM) offers additional information about surface topography and mechanical properties at the nanoscale.

Spectroscopic methods such as Fourier Transform Infrared Spectroscopy (FTIR) and Raman spectroscopy enable the analysis of chemical composition, conformational changes, and orientation at the molecular level. These techniques can detect subtle changes in chain conformation and packing that occur during processing and drawing, providing insights into structure-property relationships.

Mechanical testing protocols, including tensile testing, creep testing, and dynamic mechanical analysis, are essential for evaluating the performance characteristics of UHMWPE fibers. These tests quantify properties such as tensile strength, modulus, elongation at break, and viscoelastic response, allowing researchers to correlate processing conditions with final fiber performance and property scatter.

Differential Scanning Calorimetry (DSC) serves as a primary tool for analyzing the thermal behavior of UHMWPE fibers, providing critical insights into crystallinity, melting points, and thermal transitions. This technique helps researchers understand how gel-spinning parameters affect the crystalline structure, which directly influences fiber performance. DSC measurements can reveal the presence of multiple melting peaks, indicating different crystal populations formed during processing.

X-ray diffraction techniques, including Wide-Angle X-ray Scattering (WAXS) and Small-Angle X-ray Scattering (SAXS), are invaluable for quantifying molecular orientation and crystalline morphology. WAXS provides information about crystal structure and orientation factors, while SAXS reveals details about lamellar spacing and long-range order. These measurements are particularly important for correlating processing conditions with the development of oriented structures in gel-spun UHMWPE.

Rheological characterization using dynamic mechanical analysis and melt rheometry offers insights into the viscoelastic properties of UHMWPE during processing. These techniques help define the processing window by measuring parameters such as complex viscosity, storage modulus, and loss modulus as functions of temperature and shear rate. Understanding these properties is crucial for optimizing gel-spinning conditions and predicting processability.

Microscopy techniques, including Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM), provide direct visualization of fiber morphology and internal structure. SEM reveals surface features and defects, while TEM can show the nanoscale organization of crystalline and amorphous regions. Atomic Force Microscopy (AFM) offers additional information about surface topography and mechanical properties at the nanoscale.

Spectroscopic methods such as Fourier Transform Infrared Spectroscopy (FTIR) and Raman spectroscopy enable the analysis of chemical composition, conformational changes, and orientation at the molecular level. These techniques can detect subtle changes in chain conformation and packing that occur during processing and drawing, providing insights into structure-property relationships.

Mechanical testing protocols, including tensile testing, creep testing, and dynamic mechanical analysis, are essential for evaluating the performance characteristics of UHMWPE fibers. These tests quantify properties such as tensile strength, modulus, elongation at break, and viscoelastic response, allowing researchers to correlate processing conditions with final fiber performance and property scatter.

Sustainability Aspects of UHMWPE Production Processes

The production of Ultra-High Molecular Weight Polyethylene (UHMWPE) presents significant sustainability challenges and opportunities that warrant careful examination. Traditional manufacturing processes for UHMWPE, particularly those involving gel-spinning for high-performance fibers, are characterized by substantial energy consumption and solvent usage, raising environmental concerns.

Energy efficiency represents a critical sustainability factor in UHMWPE production. The gel-spinning process requires multiple thermal cycles—from initial polymerization to dissolution, extrusion, and subsequent heat treatments for orientation. Each thermal stage contributes to the carbon footprint of the final product. Recent innovations have focused on optimizing processing windows to reduce energy requirements while maintaining the exceptional mechanical properties that make UHMWPE valuable.

Solvent recovery systems have emerged as an essential component in sustainable UHMWPE production. Conventional gel-spinning relies heavily on hydrocarbon solvents like decalin or paraffin oil, which pose environmental hazards if released. Closed-loop solvent recovery technologies now achieve recapture rates exceeding 95%, significantly reducing both environmental impact and production costs.

Water consumption presents another sustainability challenge, particularly in cooling systems for extrusion and during fiber washing stages. Advanced water recycling systems and air-cooling alternatives are being implemented to address this concern, with some manufacturers reporting water usage reductions of up to 40% compared to previous generation processes.

Raw material efficiency has improved through precise control of the melt processing window. By optimizing temperature profiles and extrusion parameters, manufacturers have reduced material waste during production. This optimization has dual benefits: conserving petroleum-based resources while minimizing waste management requirements.

Life cycle assessment (LCA) studies indicate that despite energy-intensive production, UHMWPE products often demonstrate favorable sustainability profiles over their complete life cycle due to exceptional durability. Applications in medical implants, protective equipment, and industrial components typically show extended service lives compared to alternatives, offsetting initial production impacts.

Emerging bio-based catalysts and environmentally friendly processing aids represent promising directions for further sustainability improvements. Research into catalysts derived from renewable resources has shown potential for reducing the environmental footprint of polymerization while maintaining the ultra-high molecular weight necessary for premium performance properties.

Energy efficiency represents a critical sustainability factor in UHMWPE production. The gel-spinning process requires multiple thermal cycles—from initial polymerization to dissolution, extrusion, and subsequent heat treatments for orientation. Each thermal stage contributes to the carbon footprint of the final product. Recent innovations have focused on optimizing processing windows to reduce energy requirements while maintaining the exceptional mechanical properties that make UHMWPE valuable.

Solvent recovery systems have emerged as an essential component in sustainable UHMWPE production. Conventional gel-spinning relies heavily on hydrocarbon solvents like decalin or paraffin oil, which pose environmental hazards if released. Closed-loop solvent recovery technologies now achieve recapture rates exceeding 95%, significantly reducing both environmental impact and production costs.

Water consumption presents another sustainability challenge, particularly in cooling systems for extrusion and during fiber washing stages. Advanced water recycling systems and air-cooling alternatives are being implemented to address this concern, with some manufacturers reporting water usage reductions of up to 40% compared to previous generation processes.

Raw material efficiency has improved through precise control of the melt processing window. By optimizing temperature profiles and extrusion parameters, manufacturers have reduced material waste during production. This optimization has dual benefits: conserving petroleum-based resources while minimizing waste management requirements.

Life cycle assessment (LCA) studies indicate that despite energy-intensive production, UHMWPE products often demonstrate favorable sustainability profiles over their complete life cycle due to exceptional durability. Applications in medical implants, protective equipment, and industrial components typically show extended service lives compared to alternatives, offsetting initial production impacts.

Emerging bio-based catalysts and environmentally friendly processing aids represent promising directions for further sustainability improvements. Research into catalysts derived from renewable resources has shown potential for reducing the environmental footprint of polymerization while maintaining the ultra-high molecular weight necessary for premium performance properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!