How UHMWPE Manages Long-Term Creep In Load-Bearing Ropes And Cables?

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Creep Resistance Background and Objectives

Ultra-High Molecular Weight Polyethylene (UHMWPE) has emerged as a revolutionary material in load-bearing applications over the past four decades. Initially developed in the 1950s, UHMWPE gained significant traction in the 1980s when its exceptional strength-to-weight ratio was recognized for marine and industrial applications. The evolution of this material represents a significant advancement in polymer science, particularly in addressing the persistent challenge of creep behavior under sustained loads.

Creep, the tendency of a solid material to deform permanently under mechanical stresses, has historically limited the application of polymeric materials in critical load-bearing scenarios. Traditional materials like steel and nylon ropes have dominated these applications despite their weight and maintenance disadvantages. The technological trajectory of UHMWPE has been focused on overcoming this inherent limitation while maintaining its advantageous properties.

Recent advancements in molecular engineering have enabled significant improvements in UHMWPE's creep resistance. The development of higher molecular weight variants, improved cross-linking techniques, and novel fiber drawing processes have collectively contributed to enhanced performance characteristics. These innovations have progressively expanded UHMWPE's application range from simple utility ropes to critical infrastructure components and safety-critical systems.

The global trend toward lightweight, high-performance materials has accelerated research in this domain. Particularly noteworthy is the shift from empirical development approaches to molecular-level design strategies informed by advanced computational modeling. This transition marks a paradigm shift in how polymer scientists approach the creep challenge in UHMWPE materials.

The primary objective of current research is to develop a comprehensive understanding of the molecular mechanisms governing long-term creep behavior in UHMWPE under various loading conditions. This includes investigating the relationship between molecular weight distribution, crystallinity, orientation, and long-term deformation characteristics. Additionally, researchers aim to establish reliable predictive models that can accurately forecast creep behavior over decades of service life.

Secondary objectives include developing standardized testing methodologies that can accelerate the evaluation of creep resistance, identifying optimal processing parameters for maximizing creep resistance, and exploring hybrid material systems that combine UHMWPE with complementary materials to achieve superior performance profiles. These efforts collectively seek to expand the application envelope of UHMWPE in increasingly demanding environments.

The ultimate goal is to enable UHMWPE ropes and cables to reliably replace traditional materials in critical applications where failure is not an option, while simultaneously reducing weight, maintenance requirements, and lifetime costs. This would represent a significant technological leap with implications across multiple industries including maritime, energy, construction, and aerospace sectors.

Creep, the tendency of a solid material to deform permanently under mechanical stresses, has historically limited the application of polymeric materials in critical load-bearing scenarios. Traditional materials like steel and nylon ropes have dominated these applications despite their weight and maintenance disadvantages. The technological trajectory of UHMWPE has been focused on overcoming this inherent limitation while maintaining its advantageous properties.

Recent advancements in molecular engineering have enabled significant improvements in UHMWPE's creep resistance. The development of higher molecular weight variants, improved cross-linking techniques, and novel fiber drawing processes have collectively contributed to enhanced performance characteristics. These innovations have progressively expanded UHMWPE's application range from simple utility ropes to critical infrastructure components and safety-critical systems.

The global trend toward lightweight, high-performance materials has accelerated research in this domain. Particularly noteworthy is the shift from empirical development approaches to molecular-level design strategies informed by advanced computational modeling. This transition marks a paradigm shift in how polymer scientists approach the creep challenge in UHMWPE materials.

The primary objective of current research is to develop a comprehensive understanding of the molecular mechanisms governing long-term creep behavior in UHMWPE under various loading conditions. This includes investigating the relationship between molecular weight distribution, crystallinity, orientation, and long-term deformation characteristics. Additionally, researchers aim to establish reliable predictive models that can accurately forecast creep behavior over decades of service life.

Secondary objectives include developing standardized testing methodologies that can accelerate the evaluation of creep resistance, identifying optimal processing parameters for maximizing creep resistance, and exploring hybrid material systems that combine UHMWPE with complementary materials to achieve superior performance profiles. These efforts collectively seek to expand the application envelope of UHMWPE in increasingly demanding environments.

The ultimate goal is to enable UHMWPE ropes and cables to reliably replace traditional materials in critical applications where failure is not an option, while simultaneously reducing weight, maintenance requirements, and lifetime costs. This would represent a significant technological leap with implications across multiple industries including maritime, energy, construction, and aerospace sectors.

Market Analysis for UHMWPE Load-Bearing Applications

The global market for UHMWPE (Ultra-High-Molecular-Weight Polyethylene) in load-bearing applications has experienced significant growth over the past decade, with a compound annual growth rate exceeding 11% between 2018 and 2023. This robust expansion is primarily driven by increasing demand across marine, industrial lifting, and offshore sectors where traditional materials like steel and nylon face limitations in performance and longevity.

The marine sector represents the largest market segment for UHMWPE ropes and cables, accounting for approximately 42% of total market share. This dominance stems from the material's superior strength-to-weight ratio, which enables vessels to operate with reduced deadweight while maintaining operational safety margins. Commercial shipping and offshore support vessels have increasingly adopted UHMWPE mooring systems to reduce handling complexity and extend service intervals.

Industrial lifting applications constitute the second-largest market segment at 28%, where UHMWPE's resistance to creep under sustained loading conditions provides critical advantages in construction, mining, and manufacturing environments. The material's ability to maintain dimensional stability under cyclic loading patterns has positioned it as a premium alternative to conventional steel wire ropes in safety-critical applications.

The offshore energy sector, particularly oil and gas exploration, represents a high-value niche market where UHMWPE's corrosion resistance and fatigue performance command premium pricing. This segment has shown the highest growth rate at 14.3% annually, driven by deepwater developments where traditional materials reach their performance limits. Wind energy installations are emerging as another significant growth driver, with floating offshore platforms requiring advanced mooring solutions.

Regional analysis reveals North America and Europe as mature markets with established adoption patterns, collectively accounting for 58% of global consumption. The Asia-Pacific region, however, demonstrates the highest growth potential, with China and South Korea leading manufacturing capacity expansion. Emerging economies in Southeast Asia show accelerating adoption rates as maritime infrastructure development intensifies.

Market forecasts indicate continued expansion through 2030, with particular growth in specialized applications requiring resistance to long-term creep deformation. The premium segment of this market, featuring advanced creep-resistant UHMWPE formulations, is projected to grow at twice the rate of standard products, reflecting industry recognition of lifecycle cost benefits despite higher initial investment.

Customer demand increasingly focuses on predictable performance characteristics and quantifiable service life estimates, driving manufacturers toward more sophisticated testing protocols and performance guarantees. This trend has elevated technical specifications and material science considerations as key differentiators in purchasing decisions, moving beyond simple price competition.

The marine sector represents the largest market segment for UHMWPE ropes and cables, accounting for approximately 42% of total market share. This dominance stems from the material's superior strength-to-weight ratio, which enables vessels to operate with reduced deadweight while maintaining operational safety margins. Commercial shipping and offshore support vessels have increasingly adopted UHMWPE mooring systems to reduce handling complexity and extend service intervals.

Industrial lifting applications constitute the second-largest market segment at 28%, where UHMWPE's resistance to creep under sustained loading conditions provides critical advantages in construction, mining, and manufacturing environments. The material's ability to maintain dimensional stability under cyclic loading patterns has positioned it as a premium alternative to conventional steel wire ropes in safety-critical applications.

The offshore energy sector, particularly oil and gas exploration, represents a high-value niche market where UHMWPE's corrosion resistance and fatigue performance command premium pricing. This segment has shown the highest growth rate at 14.3% annually, driven by deepwater developments where traditional materials reach their performance limits. Wind energy installations are emerging as another significant growth driver, with floating offshore platforms requiring advanced mooring solutions.

Regional analysis reveals North America and Europe as mature markets with established adoption patterns, collectively accounting for 58% of global consumption. The Asia-Pacific region, however, demonstrates the highest growth potential, with China and South Korea leading manufacturing capacity expansion. Emerging economies in Southeast Asia show accelerating adoption rates as maritime infrastructure development intensifies.

Market forecasts indicate continued expansion through 2030, with particular growth in specialized applications requiring resistance to long-term creep deformation. The premium segment of this market, featuring advanced creep-resistant UHMWPE formulations, is projected to grow at twice the rate of standard products, reflecting industry recognition of lifecycle cost benefits despite higher initial investment.

Customer demand increasingly focuses on predictable performance characteristics and quantifiable service life estimates, driving manufacturers toward more sophisticated testing protocols and performance guarantees. This trend has elevated technical specifications and material science considerations as key differentiators in purchasing decisions, moving beyond simple price competition.

Technical Challenges in UHMWPE Creep Management

Ultra-high-molecular-weight polyethylene (UHMWPE) faces significant technical challenges in managing long-term creep behavior when used in load-bearing ropes and cables. The viscoelastic nature of UHMWPE causes it to deform gradually under constant load, even when stresses remain well below the material's yield strength. This creep phenomenon represents one of the most critical limitations for applications requiring dimensional stability over extended periods.

The primary challenge stems from UHMWPE's semi-crystalline polymer structure, where amorphous regions between crystalline domains allow for molecular chain mobility. Under sustained loading, these polymer chains gradually realign and slip past one another, resulting in permanent deformation. This behavior is particularly problematic in high-tension applications such as mooring lines, lifting slings, and structural cables where dimensional stability directly impacts safety and performance.

Temperature dependency presents another significant hurdle in creep management. UHMWPE exhibits accelerated creep rates at elevated temperatures, with research indicating that creep rates can double with every 10°C increase above ambient conditions. This thermal sensitivity severely limits the material's application in environments with temperature fluctuations or consistently warm conditions.

Load history effects further complicate creep prediction and management. UHMWPE displays complex viscoelastic memory, where previous loading events influence subsequent creep behavior. This non-linear response makes accurate lifetime prediction models exceptionally difficult to develop, as the material's deformation cannot be characterized by simple mathematical relationships.

Manufacturing variability introduces additional challenges, as differences in molecular weight distribution, crystallinity percentage, and processing conditions significantly impact creep resistance. Even within the same grade of UHMWPE, batch-to-batch variations can lead to inconsistent creep performance, complicating quality control and reliability engineering.

Surface degradation mechanisms, including UV exposure and chemical interactions, can exacerbate creep behavior by disrupting the polymer structure at the molecular level. These environmental factors often work synergistically with mechanical stress to accelerate creep rates beyond what would be predicted in laboratory conditions.

Current testing methodologies present limitations in accurately predicting long-term creep behavior. Accelerated testing protocols frequently fail to capture the complex time-dependent mechanisms that occur over years or decades of service. This disconnect between laboratory testing and field performance creates significant uncertainty in lifetime predictions for critical applications.

The industry also faces challenges in developing standardized creep testing protocols specific to rope and cable applications, where loading conditions differ substantially from traditional tensile specimens. This lack of application-specific standards hampers material selection and design optimization efforts across the sector.

The primary challenge stems from UHMWPE's semi-crystalline polymer structure, where amorphous regions between crystalline domains allow for molecular chain mobility. Under sustained loading, these polymer chains gradually realign and slip past one another, resulting in permanent deformation. This behavior is particularly problematic in high-tension applications such as mooring lines, lifting slings, and structural cables where dimensional stability directly impacts safety and performance.

Temperature dependency presents another significant hurdle in creep management. UHMWPE exhibits accelerated creep rates at elevated temperatures, with research indicating that creep rates can double with every 10°C increase above ambient conditions. This thermal sensitivity severely limits the material's application in environments with temperature fluctuations or consistently warm conditions.

Load history effects further complicate creep prediction and management. UHMWPE displays complex viscoelastic memory, where previous loading events influence subsequent creep behavior. This non-linear response makes accurate lifetime prediction models exceptionally difficult to develop, as the material's deformation cannot be characterized by simple mathematical relationships.

Manufacturing variability introduces additional challenges, as differences in molecular weight distribution, crystallinity percentage, and processing conditions significantly impact creep resistance. Even within the same grade of UHMWPE, batch-to-batch variations can lead to inconsistent creep performance, complicating quality control and reliability engineering.

Surface degradation mechanisms, including UV exposure and chemical interactions, can exacerbate creep behavior by disrupting the polymer structure at the molecular level. These environmental factors often work synergistically with mechanical stress to accelerate creep rates beyond what would be predicted in laboratory conditions.

Current testing methodologies present limitations in accurately predicting long-term creep behavior. Accelerated testing protocols frequently fail to capture the complex time-dependent mechanisms that occur over years or decades of service. This disconnect between laboratory testing and field performance creates significant uncertainty in lifetime predictions for critical applications.

The industry also faces challenges in developing standardized creep testing protocols specific to rope and cable applications, where loading conditions differ substantially from traditional tensile specimens. This lack of application-specific standards hampers material selection and design optimization efforts across the sector.

Current Creep Mitigation Strategies and Solutions

01 Creep resistance improvement through crosslinking

Crosslinking techniques can significantly enhance the creep resistance of UHMWPE. Various methods including radiation, chemical, and thermal crosslinking create bonds between polymer chains, restricting their movement under sustained loads. This structural modification improves dimensional stability and reduces permanent deformation during long-term use. Crosslinked UHMWPE demonstrates superior performance in applications requiring resistance to creep deformation under constant stress.- Creep resistance improvement through cross-linking: Cross-linking techniques can significantly enhance the long-term creep resistance of UHMWPE. By forming chemical bonds between polymer chains, cross-linking restricts molecular mobility and increases dimensional stability under sustained loads. Various methods including radiation, chemical agents, and thermal treatments can be employed to achieve different degrees of cross-linking, resulting in improved mechanical properties and reduced permanent deformation over time.

- Reinforcement with fillers and additives: Incorporating specific fillers and additives into UHMWPE can substantially improve its creep resistance properties. Materials such as carbon fibers, glass fibers, carbon nanotubes, and mineral particles create composite structures that restrict polymer chain movement under load. Additionally, certain stabilizers and processing aids can enhance the material's long-term performance by improving crystallinity and reducing oxidative degradation that contributes to creep behavior.

- Processing techniques affecting creep behavior: Manufacturing and processing methods significantly impact the long-term creep properties of UHMWPE. Techniques such as compression molding, ram extrusion, and specialized cooling protocols can optimize the crystalline structure and molecular orientation of the polymer. Controlled processing parameters including temperature profiles, pressure cycles, and cooling rates are critical for developing UHMWPE products with enhanced resistance to dimensional changes under sustained loads.

- Testing and prediction methods for long-term creep: Advanced testing methodologies and predictive models have been developed to evaluate and forecast the long-term creep behavior of UHMWPE. Accelerated testing protocols, time-temperature superposition principles, and computational modeling techniques enable researchers to predict material performance over extended timeframes. These approaches help in understanding creep mechanisms and developing materials with improved long-term dimensional stability for critical applications.

- Application-specific UHMWPE formulations: Specialized UHMWPE formulations have been developed to address creep concerns in specific applications such as medical implants, industrial bearings, and high-performance fibers. These tailored materials incorporate specific molecular weight distributions, crystallinity levels, and additive packages designed to optimize creep resistance under the unique loading conditions, temperature profiles, and environmental factors encountered in each application domain.

02 Reinforcement with fillers and nanocomposites

Incorporating fillers and creating nanocomposites can enhance the creep resistance of UHMWPE. Materials such as carbon fibers, glass fibers, carbon nanotubes, and mineral particles are added to the polymer matrix to restrict chain mobility. These reinforcements create a more rigid structure that resists deformation under sustained loads. The type, concentration, and dispersion of these fillers significantly impact the long-term creep behavior of the resulting composite materials.Expand Specific Solutions03 Processing techniques affecting creep properties

Manufacturing and processing methods significantly influence the long-term creep behavior of UHMWPE. Techniques such as compression molding, ram extrusion, and specialized cooling protocols can optimize the crystallinity and molecular orientation of the polymer. These processing parameters directly affect the microstructure, which determines creep resistance. Advanced processing methods can produce UHMWPE with enhanced long-term dimensional stability under constant stress conditions.Expand Specific Solutions04 Testing and prediction methods for long-term creep

Various testing methodologies and predictive models have been developed to evaluate and forecast the long-term creep behavior of UHMWPE. Accelerated testing protocols, mathematical models, and computer simulations help predict how the material will perform over extended periods. These methods consider factors such as temperature, stress level, and environmental conditions to provide reliable estimates of creep deformation over the material's service life.Expand Specific Solutions05 Application-specific UHMWPE formulations

Specialized UHMWPE formulations have been developed for specific applications where creep resistance is critical. These include medical implants, industrial bearings, mining equipment, and high-performance fibers. Each application requires tailored properties to address specific loading conditions and environmental factors. The formulations may combine various enhancement techniques such as controlled molecular weight distribution, specific additives, and optimized processing to achieve the required long-term creep resistance for each application.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The UHMWPE load-bearing rope and cable market is currently in a growth phase, with increasing adoption across marine, industrial, and defense sectors. The global market size is estimated to exceed $1.5 billion, expanding at approximately 8-10% CAGR. Technologically, the field shows moderate maturity with ongoing innovation addressing creep challenges. Leading players include Hampiðjan hf. with advanced marine rope solutions, DSM/Toyobo partnerships offering high-performance fibers, and China Petroleum & Chemical Corp. developing specialized polymer formulations. Emerging competitors like Jiangsu Jonnyma and Shanghai Lianle Chemical are advancing material science capabilities, while established manufacturers such as W.L. Gore and JDR Cable Systems focus on specialized applications requiring superior creep resistance in critical environments.

Hampiðjan hf.

Technical Solution: Hampiðjan has developed the DynIce® technology specifically addressing UHMWPE creep in maritime and offshore applications. Their approach combines material science innovations with structural engineering to create high-performance ropes with minimal creep. The company employs a proprietary heat-setting process that exposes UHMWPE fibers to temperatures between 125-140°C under controlled tension, which increases crystallinity and improves molecular alignment. This treatment has been shown to reduce creep by approximately 60% compared to untreated fibers. Hampiðjan's DynIce® ropes feature a unique braided construction with specialized core-jacket integration that distributes loads evenly across fibers, minimizing localized stress concentrations that accelerate creep. Their manufacturing process includes a pre-stretching phase where ropes are subjected to cyclic loading at 30-40% of breaking strength, effectively "pre-creeping" the material to achieve dimensional stability. Testing has demonstrated that DynIce® ropes maintain over 95% of their original strength after 10,000 hours under sustained loading at 20% of breaking strength, with creep elongation limited to less than 2%. The company has also developed specialized termination methods that prevent stress concentration at connection points, a common failure mode in UHMWPE ropes under long-term loading.

Strengths: Exceptional performance in marine environments; comprehensive solution addressing both material properties and rope construction; extensive field-proven reliability in demanding offshore applications. Weaknesses: Higher initial cost compared to conventional materials; requires specialized handling and installation procedures; performance advantages diminish in high-temperature environments above 70°C.

Toyobo MC Corp.

Technical Solution: Toyobo MC has developed the IZANAS® UHMWPE fiber technology with specific innovations targeting creep reduction in load-bearing applications. Their approach combines advanced polymer chemistry with specialized processing techniques to enhance long-term dimensional stability. Toyobo's proprietary manufacturing process involves a multi-stage drawing technique that achieves molecular orientation exceeding 90%, creating highly aligned polymer chains that resist slippage under sustained loading. Their technology incorporates a thermal stabilization treatment at precisely controlled temperatures between 130-145°C, which optimizes crystallinity while preserving mechanical properties. Toyobo has pioneered a unique surface modification process that creates nano-scale roughness on fiber surfaces, increasing inter-fiber friction and mechanical interlocking within rope structures to distribute loads more effectively. Testing has shown their IZANAS® fibers exhibit approximately 40-50% less creep deformation under sustained loading compared to conventional UHMWPE. For critical applications, Toyobo has developed hybrid rope constructions that strategically combine their UHMWPE with complementary materials in engineered arrangements that leverage the strengths of each component. Their most advanced ropes incorporate a proprietary core-jacket design with differential pre-tensioning that compensates for the natural creep tendency of UHMWPE, maintaining dimensional stability even under variable loading conditions.

Strengths: Excellent balance of creep resistance and mechanical properties; innovative surface treatments enhance performance in rope constructions; comprehensive solution addressing both material properties and structural design. Weaknesses: Higher production costs compared to standard UHMWPE; specialized processing requirements limit manufacturing flexibility; performance advantages diminish at elevated temperatures above 80°C.

Key Patents and Research on UHMWPE Creep Resistance

Ultra-high molecular weight polyethylene (uhmwpe)/inorganic nanocomposite material and high performance fiber manufacturing method thereof

PatentInactiveEP2308922A1

Innovation

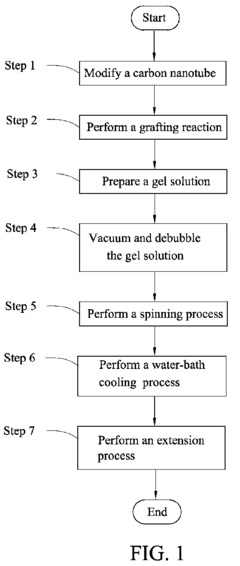

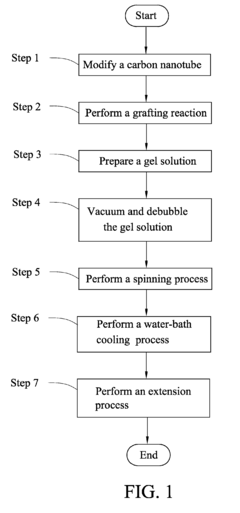

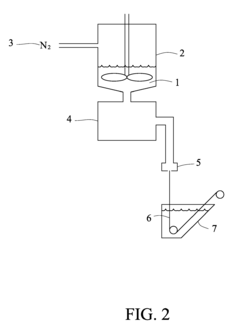

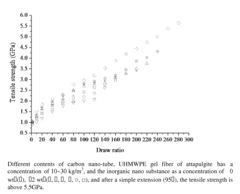

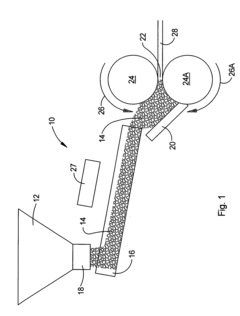

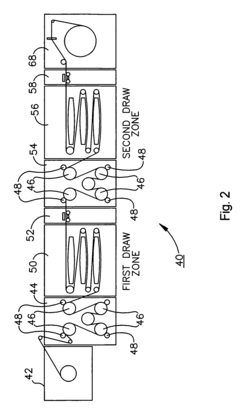

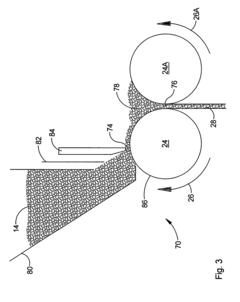

- A manufacturing process involving the uniform dispersion of inorganic nano substances like attapulgite, carbon nanotubes, sepiolite, and wollastonite into UHMWPE gel solutions, followed by specific processing steps including sudden air cooling and multi-stage temperature-changing drawing, to produce high-tenacity fibers with reduced crimp, light transmittance, and creep.

High modulus ultra high molecular weight polyethylene tape

PatentActiveUS8206810B1

Innovation

- A direct roll process that eliminates the compaction step and uses UHMWPE powder directly fed into heated calender rolls to produce a coherent, high-density sheet, which is then drawn to achieve a high tenacity and high modulus tape with an aspect ratio of 1600 to 2500 grams per denier, without the use of solvents and with simpler, less capital-intensive equipment.

Environmental Factors Affecting UHMWPE Longevity

The environmental conditions in which Ultra-High Molecular Weight Polyethylene (UHMWPE) ropes and cables operate significantly impact their long-term performance and creep resistance. Understanding these factors is crucial for predicting service life and ensuring safety in critical applications.

Temperature variations represent one of the most significant environmental challenges for UHMWPE materials. When exposed to elevated temperatures (typically above 50°C), UHMWPE exhibits accelerated creep behavior, as the increased thermal energy allows polymer chains to slide past one another more readily. Conversely, extremely low temperatures can cause embrittlement, potentially leading to microcracking that compromises the material's load-bearing capacity over time.

Ultraviolet (UV) radiation exposure presents another critical environmental factor affecting UHMWPE longevity. Extended exposure to sunlight causes photo-oxidation of the polymer chains, resulting in chain scission and cross-linking that alter the mechanical properties. This degradation manifests as reduced tensile strength and increased brittleness, which can exacerbate creep behavior under sustained loads.

Chemical exposure, particularly to hydrocarbons, strong acids, and oxidizing agents, can significantly impact UHMWPE performance. While UHMWPE generally exhibits excellent chemical resistance, certain substances can penetrate the material over time, causing swelling, plasticization, or chemical degradation that compromises its creep resistance properties.

Moisture and humidity levels influence UHMWPE performance in subtle but important ways. Although UHMWPE does not absorb significant amounts of water, moisture can affect the interface between fibers in rope constructions, potentially altering friction characteristics and load distribution. In marine environments, saltwater exposure introduces additional concerns regarding salt crystal formation and accelerated UV degradation.

Cyclic loading combined with environmental factors creates particularly challenging conditions. The synergistic effects of mechanical stress and environmental exposure can accelerate degradation beyond what would be expected from either factor alone. For instance, UHMWPE under tension in a high-temperature, UV-rich environment will experience more rapid creep than predicted by standard laboratory tests conducted under controlled conditions.

Abrasion and particulate contamination represent mechanical environmental factors that affect UHMWPE longevity. Sand, dust, and other abrasive particles can work their way between fibers, causing internal wear and creating stress concentration points that accelerate creep failure. This is particularly relevant in applications like mining, construction, and offshore operations.

Proper environmental protection strategies, including coatings, sheaths, and maintenance protocols, can significantly extend UHMWPE service life by mitigating these environmental factors. Advanced monitoring techniques that account for environmental exposure history are increasingly being employed to provide more accurate predictions of remaining service life in critical applications.

Temperature variations represent one of the most significant environmental challenges for UHMWPE materials. When exposed to elevated temperatures (typically above 50°C), UHMWPE exhibits accelerated creep behavior, as the increased thermal energy allows polymer chains to slide past one another more readily. Conversely, extremely low temperatures can cause embrittlement, potentially leading to microcracking that compromises the material's load-bearing capacity over time.

Ultraviolet (UV) radiation exposure presents another critical environmental factor affecting UHMWPE longevity. Extended exposure to sunlight causes photo-oxidation of the polymer chains, resulting in chain scission and cross-linking that alter the mechanical properties. This degradation manifests as reduced tensile strength and increased brittleness, which can exacerbate creep behavior under sustained loads.

Chemical exposure, particularly to hydrocarbons, strong acids, and oxidizing agents, can significantly impact UHMWPE performance. While UHMWPE generally exhibits excellent chemical resistance, certain substances can penetrate the material over time, causing swelling, plasticization, or chemical degradation that compromises its creep resistance properties.

Moisture and humidity levels influence UHMWPE performance in subtle but important ways. Although UHMWPE does not absorb significant amounts of water, moisture can affect the interface between fibers in rope constructions, potentially altering friction characteristics and load distribution. In marine environments, saltwater exposure introduces additional concerns regarding salt crystal formation and accelerated UV degradation.

Cyclic loading combined with environmental factors creates particularly challenging conditions. The synergistic effects of mechanical stress and environmental exposure can accelerate degradation beyond what would be expected from either factor alone. For instance, UHMWPE under tension in a high-temperature, UV-rich environment will experience more rapid creep than predicted by standard laboratory tests conducted under controlled conditions.

Abrasion and particulate contamination represent mechanical environmental factors that affect UHMWPE longevity. Sand, dust, and other abrasive particles can work their way between fibers, causing internal wear and creating stress concentration points that accelerate creep failure. This is particularly relevant in applications like mining, construction, and offshore operations.

Proper environmental protection strategies, including coatings, sheaths, and maintenance protocols, can significantly extend UHMWPE service life by mitigating these environmental factors. Advanced monitoring techniques that account for environmental exposure history are increasingly being employed to provide more accurate predictions of remaining service life in critical applications.

Testing Standards and Performance Certification

The standardization of testing protocols for UHMWPE ropes and cables is critical for ensuring consistent performance evaluation across the industry. ASTM D6611 and ISO 2307 serve as the primary international standards governing the testing of synthetic fiber ropes, including those made from UHMWPE. These standards outline specific methodologies for measuring tensile strength, elongation characteristics, and most importantly for UHMWPE applications, creep behavior under sustained loading conditions.

Creep testing for UHMWPE typically involves subjecting samples to constant loads at various percentages of their breaking strength (commonly 20%, 30%, and 50%) while monitoring deformation over extended periods. The ISO 18692 standard specifically addresses the performance requirements for HMPE fiber ropes in maritime applications, providing guidelines for accelerated creep testing protocols that can predict long-term behavior.

Certification bodies such as DNV GL and ABS have developed their own supplementary standards that incorporate more rigorous testing regimes for critical marine and offshore applications. These certifications often require cyclic loading tests that simulate real-world conditions, with some protocols mandating testing periods of up to 10,000 hours to accurately capture the long-term creep response of UHMWPE materials.

Temperature-dependent testing has emerged as a crucial component of performance certification, as UHMWPE exhibits significantly different creep behaviors across its operational temperature range. The OCIMF (Oil Companies International Marine Forum) guidelines recommend testing at multiple temperatures (typically -20°C, 23°C, and 70°C) to establish comprehensive performance envelopes for maritime applications.

Recent advancements in testing methodologies include the implementation of digital image correlation techniques to provide more precise measurements of strain distribution throughout rope structures. This approach has been incorporated into newer versions of testing standards, allowing for better understanding of how creep manifests in complex rope constructions with multiple load-bearing elements.

Certification programs increasingly require manufacturers to provide detailed documentation of creep performance under various environmental conditions, including exposure to UV radiation, saltwater immersion, and chemical contaminants. These comprehensive testing regimes help end-users select appropriate UHMWPE products for specific applications based on verified performance data rather than theoretical projections.

The development of standardized accelerated aging protocols represents a significant advancement in the certification landscape, allowing testing laboratories to simulate decades of service life within compressed timeframes. These protocols typically involve elevated temperature testing combined with cyclic loading to induce accelerated creep, with mathematical models then extrapolating results to predict performance over 20+ year service lifespans.

Creep testing for UHMWPE typically involves subjecting samples to constant loads at various percentages of their breaking strength (commonly 20%, 30%, and 50%) while monitoring deformation over extended periods. The ISO 18692 standard specifically addresses the performance requirements for HMPE fiber ropes in maritime applications, providing guidelines for accelerated creep testing protocols that can predict long-term behavior.

Certification bodies such as DNV GL and ABS have developed their own supplementary standards that incorporate more rigorous testing regimes for critical marine and offshore applications. These certifications often require cyclic loading tests that simulate real-world conditions, with some protocols mandating testing periods of up to 10,000 hours to accurately capture the long-term creep response of UHMWPE materials.

Temperature-dependent testing has emerged as a crucial component of performance certification, as UHMWPE exhibits significantly different creep behaviors across its operational temperature range. The OCIMF (Oil Companies International Marine Forum) guidelines recommend testing at multiple temperatures (typically -20°C, 23°C, and 70°C) to establish comprehensive performance envelopes for maritime applications.

Recent advancements in testing methodologies include the implementation of digital image correlation techniques to provide more precise measurements of strain distribution throughout rope structures. This approach has been incorporated into newer versions of testing standards, allowing for better understanding of how creep manifests in complex rope constructions with multiple load-bearing elements.

Certification programs increasingly require manufacturers to provide detailed documentation of creep performance under various environmental conditions, including exposure to UV radiation, saltwater immersion, and chemical contaminants. These comprehensive testing regimes help end-users select appropriate UHMWPE products for specific applications based on verified performance data rather than theoretical projections.

The development of standardized accelerated aging protocols represents a significant advancement in the certification landscape, allowing testing laboratories to simulate decades of service life within compressed timeframes. These protocols typically involve elevated temperature testing combined with cyclic loading to induce accelerated creep, with mathematical models then extrapolating results to predict performance over 20+ year service lifespans.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!