UHMWPE Ropes And Slings: UV Aging, Abrasion Mechanisms And Safety Factors

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Rope Technology Background and Objectives

Ultra-High Molecular Weight Polyethylene (UHMWPE) ropes and slings represent a significant advancement in lifting and rigging technology, emerging in the 1990s as a revolutionary alternative to traditional steel wire ropes. The evolution of UHMWPE fiber technology began in the 1950s with the development of high-performance polymers, but it wasn't until the 1980s that commercial production of UHMWPE fibers under brand names like Dyneema and Spectra became viable.

The technological trajectory of UHMWPE ropes has been characterized by continuous improvements in molecular weight, fiber alignment techniques, and coating technologies. Initially developed for marine applications due to their exceptional strength-to-weight ratio and buoyancy, these synthetic ropes have progressively expanded into critical sectors including offshore operations, heavy lifting, defense, and aerospace industries.

Recent technological developments have focused on enhancing the performance characteristics of UHMWPE ropes under extreme environmental conditions. Particularly noteworthy is the industry's growing concern regarding UV degradation mechanisms, which can significantly compromise rope integrity over time. Research indicates that prolonged exposure to ultraviolet radiation can initiate photo-oxidative processes within the polymer structure, leading to chain scission and subsequent mechanical property deterioration.

Concurrently, abrasion resistance has emerged as a critical performance parameter, especially in applications involving repeated contact with rough surfaces or cyclic loading conditions. The microscopic mechanisms of abrasion in UHMWPE fibers involve surface fibrillation, thermal degradation at contact points, and progressive fiber failure that can propagate through the rope structure.

The primary technological objective in this field is to develop comprehensive understanding of the degradation pathways—particularly UV aging and abrasion mechanisms—and their combined effects on rope performance. This understanding must translate into reliable safety factors that account for these degradation processes across diverse operational environments.

Secondary objectives include the development of accelerated testing protocols that accurately predict long-term performance, advanced coating technologies that enhance UV and abrasion resistance without compromising flexibility, and non-destructive evaluation methods for in-service condition monitoring. The industry also aims to establish standardized safety guidelines that specifically address the unique characteristics of UHMWPE materials.

The technological evolution continues toward smart rope systems incorporating embedded sensors for real-time monitoring, environmentally sustainable manufacturing processes, and hybrid designs that optimize performance across multiple parameters. These advancements collectively aim to expand the application envelope of UHMWPE ropes while ensuring operational safety in increasingly demanding environments.

The technological trajectory of UHMWPE ropes has been characterized by continuous improvements in molecular weight, fiber alignment techniques, and coating technologies. Initially developed for marine applications due to their exceptional strength-to-weight ratio and buoyancy, these synthetic ropes have progressively expanded into critical sectors including offshore operations, heavy lifting, defense, and aerospace industries.

Recent technological developments have focused on enhancing the performance characteristics of UHMWPE ropes under extreme environmental conditions. Particularly noteworthy is the industry's growing concern regarding UV degradation mechanisms, which can significantly compromise rope integrity over time. Research indicates that prolonged exposure to ultraviolet radiation can initiate photo-oxidative processes within the polymer structure, leading to chain scission and subsequent mechanical property deterioration.

Concurrently, abrasion resistance has emerged as a critical performance parameter, especially in applications involving repeated contact with rough surfaces or cyclic loading conditions. The microscopic mechanisms of abrasion in UHMWPE fibers involve surface fibrillation, thermal degradation at contact points, and progressive fiber failure that can propagate through the rope structure.

The primary technological objective in this field is to develop comprehensive understanding of the degradation pathways—particularly UV aging and abrasion mechanisms—and their combined effects on rope performance. This understanding must translate into reliable safety factors that account for these degradation processes across diverse operational environments.

Secondary objectives include the development of accelerated testing protocols that accurately predict long-term performance, advanced coating technologies that enhance UV and abrasion resistance without compromising flexibility, and non-destructive evaluation methods for in-service condition monitoring. The industry also aims to establish standardized safety guidelines that specifically address the unique characteristics of UHMWPE materials.

The technological evolution continues toward smart rope systems incorporating embedded sensors for real-time monitoring, environmentally sustainable manufacturing processes, and hybrid designs that optimize performance across multiple parameters. These advancements collectively aim to expand the application envelope of UHMWPE ropes while ensuring operational safety in increasingly demanding environments.

Market Analysis for High-Performance Synthetic Ropes

The global market for high-performance synthetic ropes has experienced significant growth over the past decade, driven by increasing demand across multiple industries including maritime, oil and gas, construction, and recreational sectors. UHMWPE (Ultra-High-Molecular-Weight Polyethylene) ropes have emerged as a dominant player in this market due to their exceptional strength-to-weight ratio, chemical resistance, and durability compared to traditional materials.

Current market valuations place the high-performance synthetic rope sector at approximately $1.8 billion globally, with UHMWPE products representing about 35% of this market. Industry analysts project a compound annual growth rate of 6.7% through 2028, outpacing traditional steel wire rope markets which are growing at only 3.2% annually.

The offshore energy sector remains the largest consumer of UHMWPE ropes, accounting for roughly 42% of total market volume. This dominance stems from the material's superior performance in deep-sea applications where weight reduction and corrosion resistance provide significant operational advantages. The maritime shipping industry follows at 28% market share, with construction and recreational climbing sectors representing 15% and 8% respectively.

Regional analysis reveals North America and Europe as mature markets with stable growth rates of 4-5% annually, while Asia-Pacific demonstrates more aggressive expansion at 9.3%, particularly driven by China's rapid infrastructure development and growing maritime activities. Middle Eastern markets show increasing adoption rates as the region diversifies beyond traditional petroleum industries.

Key market drivers include the ongoing replacement of steel wire ropes with lighter synthetic alternatives, stringent safety regulations in industrial applications, and growing awareness of total cost of ownership benefits despite higher initial investment costs for UHMWPE products. The weight reduction advantage alone typically translates to 15-20% operational cost savings in maritime applications.

Market challenges primarily center around UV degradation concerns, which can reduce rope lifespan by 30-40% in high-exposure environments without proper treatment. Additionally, abrasion resistance limitations compared to steel alternatives remain a technical hurdle, particularly in applications involving rough surfaces or edges.

Pricing trends show gradual stabilization after significant fluctuations during 2020-2022 due to supply chain disruptions. Premium UHMWPE ropes command price premiums of 2.5-3.5 times comparable polyester products, though this gap has narrowed by approximately 8% over the past three years as manufacturing efficiencies improve and competition intensifies.

Customer segmentation reveals increasing sophistication in purchasing decisions, with safety certification and documented performance testing now ranking as the primary selection criteria for 78% of industrial buyers, surpassing price considerations for the first time in market history.

Current market valuations place the high-performance synthetic rope sector at approximately $1.8 billion globally, with UHMWPE products representing about 35% of this market. Industry analysts project a compound annual growth rate of 6.7% through 2028, outpacing traditional steel wire rope markets which are growing at only 3.2% annually.

The offshore energy sector remains the largest consumer of UHMWPE ropes, accounting for roughly 42% of total market volume. This dominance stems from the material's superior performance in deep-sea applications where weight reduction and corrosion resistance provide significant operational advantages. The maritime shipping industry follows at 28% market share, with construction and recreational climbing sectors representing 15% and 8% respectively.

Regional analysis reveals North America and Europe as mature markets with stable growth rates of 4-5% annually, while Asia-Pacific demonstrates more aggressive expansion at 9.3%, particularly driven by China's rapid infrastructure development and growing maritime activities. Middle Eastern markets show increasing adoption rates as the region diversifies beyond traditional petroleum industries.

Key market drivers include the ongoing replacement of steel wire ropes with lighter synthetic alternatives, stringent safety regulations in industrial applications, and growing awareness of total cost of ownership benefits despite higher initial investment costs for UHMWPE products. The weight reduction advantage alone typically translates to 15-20% operational cost savings in maritime applications.

Market challenges primarily center around UV degradation concerns, which can reduce rope lifespan by 30-40% in high-exposure environments without proper treatment. Additionally, abrasion resistance limitations compared to steel alternatives remain a technical hurdle, particularly in applications involving rough surfaces or edges.

Pricing trends show gradual stabilization after significant fluctuations during 2020-2022 due to supply chain disruptions. Premium UHMWPE ropes command price premiums of 2.5-3.5 times comparable polyester products, though this gap has narrowed by approximately 8% over the past three years as manufacturing efficiencies improve and competition intensifies.

Customer segmentation reveals increasing sophistication in purchasing decisions, with safety certification and documented performance testing now ranking as the primary selection criteria for 78% of industrial buyers, surpassing price considerations for the first time in market history.

Current Challenges in UHMWPE Rope Durability

Ultra-High Molecular Weight Polyethylene (UHMWPE) ropes and slings have revolutionized various industries due to their exceptional strength-to-weight ratio, making them superior alternatives to traditional steel cables in many applications. However, despite their advantages, these materials face significant durability challenges that limit their service life and reliability in critical applications.

UV degradation represents one of the most pressing challenges for UHMWPE ropes. When exposed to sunlight, the polymer chains undergo photodegradation, leading to chain scission and oxidation. This process significantly reduces the mechanical properties of the material, with studies indicating strength losses of up to 30% after prolonged UV exposure in marine and high-altitude environments. The degradation mechanism is particularly problematic because it occurs progressively from the outer layers inward, making visual inspection unreliable for determining the actual structural integrity.

Abrasion resistance presents another major durability concern. While UHMWPE fibers exhibit good abrasion resistance compared to many synthetic fibers, they still suffer from mechanical wear when subjected to cyclic loading against rough surfaces. The abrasion mechanisms involve both surface fibrillation and internal fiber fatigue, which can lead to catastrophic failure without adequate warning signs. Industry testing has revealed that abrasion damage can reduce rope strength by up to 50% before visible signs become apparent.

Creep behavior under sustained loading conditions further complicates the durability equation. UHMWPE materials exhibit viscoelastic properties that result in permanent deformation over time, even at loads well below their breaking strength. This characteristic necessitates higher safety factors in applications where dimensional stability is critical, such as in lifting operations and mooring systems.

The interaction between different degradation mechanisms creates complex failure modes that are difficult to predict. For instance, UV-degraded outer fibers have reduced abrasion resistance, accelerating the overall deterioration rate when both factors are present. Similarly, moisture absorption, though minimal compared to other synthetic fibers, can exacerbate both UV degradation and mechanical wear through hydrolysis reactions and reduced interfacial friction between fibers.

Current safety factor recommendations vary widely across industries, ranging from 5:1 for general lifting applications to 12:1 for critical human safety scenarios. However, these factors often fail to account for the cumulative and synergistic effects of multiple degradation mechanisms, potentially leading to premature failures in complex real-world environments.

The lack of standardized non-destructive testing methods for in-service inspection represents a significant gap in ensuring ongoing safety. While technologies such as acoustic emission testing and spectroscopic analysis show promise, they remain largely confined to laboratory settings rather than field applications where they are most needed.

UV degradation represents one of the most pressing challenges for UHMWPE ropes. When exposed to sunlight, the polymer chains undergo photodegradation, leading to chain scission and oxidation. This process significantly reduces the mechanical properties of the material, with studies indicating strength losses of up to 30% after prolonged UV exposure in marine and high-altitude environments. The degradation mechanism is particularly problematic because it occurs progressively from the outer layers inward, making visual inspection unreliable for determining the actual structural integrity.

Abrasion resistance presents another major durability concern. While UHMWPE fibers exhibit good abrasion resistance compared to many synthetic fibers, they still suffer from mechanical wear when subjected to cyclic loading against rough surfaces. The abrasion mechanisms involve both surface fibrillation and internal fiber fatigue, which can lead to catastrophic failure without adequate warning signs. Industry testing has revealed that abrasion damage can reduce rope strength by up to 50% before visible signs become apparent.

Creep behavior under sustained loading conditions further complicates the durability equation. UHMWPE materials exhibit viscoelastic properties that result in permanent deformation over time, even at loads well below their breaking strength. This characteristic necessitates higher safety factors in applications where dimensional stability is critical, such as in lifting operations and mooring systems.

The interaction between different degradation mechanisms creates complex failure modes that are difficult to predict. For instance, UV-degraded outer fibers have reduced abrasion resistance, accelerating the overall deterioration rate when both factors are present. Similarly, moisture absorption, though minimal compared to other synthetic fibers, can exacerbate both UV degradation and mechanical wear through hydrolysis reactions and reduced interfacial friction between fibers.

Current safety factor recommendations vary widely across industries, ranging from 5:1 for general lifting applications to 12:1 for critical human safety scenarios. However, these factors often fail to account for the cumulative and synergistic effects of multiple degradation mechanisms, potentially leading to premature failures in complex real-world environments.

The lack of standardized non-destructive testing methods for in-service inspection represents a significant gap in ensuring ongoing safety. While technologies such as acoustic emission testing and spectroscopic analysis show promise, they remain largely confined to laboratory settings rather than field applications where they are most needed.

Current UV Protection and Abrasion Resistance Solutions

01 UV aging mechanisms and protection methods for UHMWPE ropes

Ultra-high-molecular-weight polyethylene (UHMWPE) ropes are susceptible to degradation when exposed to ultraviolet radiation. UV exposure can break down the polymer chains, leading to reduced tensile strength and compromised structural integrity. Various protection methods have been developed, including UV stabilizers, protective coatings, and additives that absorb or reflect UV radiation. These methods help extend the service life of UHMWPE ropes in outdoor applications where sun exposure is unavoidable.- UV aging mechanisms and protection methods for UHMWPE ropes: Ultra-high-molecular-weight polyethylene (UHMWPE) ropes are susceptible to degradation when exposed to ultraviolet radiation, which breaks down polymer chains and reduces tensile strength over time. Various protection methods have been developed, including UV stabilizers, protective coatings, and specialized additives that absorb or reflect UV radiation. These protection methods can significantly extend the service life of UHMWPE ropes in outdoor applications by preventing photodegradation of the polymer structure.

- Abrasion resistance mechanisms and improvements for UHMWPE slings: UHMWPE slings face significant abrasion challenges in industrial applications. The abrasion mechanisms include surface wear from friction against rough surfaces, internal fiber-to-fiber abrasion, and particle intrusion causing accelerated wear. Improvements to abrasion resistance include specialized coatings, fiber surface treatments, optimized weaving patterns, and composite structures that incorporate sacrificial outer layers. These innovations help distribute load forces more evenly and protect the core strength members from premature wear.

- Safety factors and load rating methodologies for UHMWPE lifting systems: Safety factors for UHMWPE ropes and slings are critical for preventing catastrophic failures during lifting operations. These factors account for dynamic loading, environmental degradation, and material fatigue. Industry standards typically recommend safety factors between 5:1 and 12:1 depending on the application risk level. Load rating methodologies incorporate accelerated aging tests, cyclic loading simulations, and statistical analysis of failure modes to establish working load limits that maintain adequate margins of safety throughout the expected service life.

- Composite structures and hybrid designs for enhanced UHMWPE rope performance: Advanced UHMWPE rope designs incorporate composite structures and hybrid materials to overcome inherent limitations of pure UHMWPE. These designs include core-jacket configurations where different materials provide complementary properties, fiber blends that combine UHMWPE with aramid or polyester, and specialized braiding patterns that optimize strength-to-weight ratios. Some designs incorporate sacrificial outer layers to indicate wear before critical strength loss occurs, while others use nano-additives to enhance specific performance characteristics like heat resistance or UV stability.

- Testing protocols and condition monitoring for UHMWPE sling integrity: Comprehensive testing protocols have been developed to assess and monitor the condition of UHMWPE slings throughout their service life. These include non-destructive testing methods such as visual inspection enhanced by specialized imaging techniques, tensile strength verification, and analysis of fiber degradation markers. Advanced monitoring systems incorporate embedded sensors that track cumulative UV exposure, load history, and abrasion damage. Retirement criteria based on these monitoring systems help prevent accidents by removing damaged slings from service before they reach critical degradation levels.

02 Abrasion resistance mechanisms and improvements for UHMWPE slings

UHMWPE slings face significant abrasion challenges in industrial applications. The abrasion mechanisms include surface wear from friction against rough surfaces, internal fiber-to-fiber abrasion, and particle intrusion. Improvements to abrasion resistance include specialized coatings, fiber treatments, and optimized weaving patterns. Some solutions incorporate sacrificial outer layers that protect the load-bearing core fibers. Advanced manufacturing techniques can also align fibers to minimize internal abrasion and maximize load distribution, significantly extending the operational lifespan of the slings.Expand Specific Solutions03 Safety factors and load rating methodologies for UHMWPE lifting systems

Safety factors for UHMWPE ropes and slings are critical for preventing catastrophic failures during lifting operations. These factors account for various uncertainties including material variability, environmental conditions, dynamic loading, and aging effects. Standard methodologies for determining appropriate safety factors include accelerated aging tests, cyclic loading evaluations, and statistical analysis of failure modes. Industry standards typically recommend safety factors between 5:1 and 7:1 for critical lifting applications, with higher factors applied when environmental degradation is expected or when human safety is directly at risk.Expand Specific Solutions04 Comparative performance of UHMWPE versus traditional materials in lifting applications

UHMWPE ropes and slings offer significant advantages over traditional materials like steel wire, nylon, and polyester in many lifting applications. These advantages include superior strength-to-weight ratios (up to 15 times stronger than steel at equal weight), excellent chemical resistance, and minimal water absorption. However, UHMWPE has limitations including lower heat resistance, susceptibility to UV degradation, and creep behavior under sustained loads. Performance comparisons show that UHMWPE excels in applications requiring lightweight, high-strength solutions, while traditional materials may be preferred where heat resistance or budget constraints are primary concerns.Expand Specific Solutions05 Inspection protocols and end-of-life indicators for UHMWPE lifting equipment

Proper inspection of UHMWPE ropes and slings is essential for safe operation. Inspection protocols include visual examination for signs of abrasion, cuts, heat damage, and UV degradation. Advanced inspection methods utilize technologies such as ultrasonic testing, thermography, and fiber optic sensing to detect internal damage not visible to the naked eye. End-of-life indicators include specific levels of visible fiber damage, reduction in diameter, changes in flexibility, and discoloration patterns. Regular inspection schedules based on usage intensity and environmental exposure help prevent failures by identifying deterioration before it reaches critical levels.Expand Specific Solutions

Leading Manufacturers and Industry Competition

The UHMWPE ropes and slings market is in a growth phase, with increasing adoption across marine, industrial, and safety applications due to superior strength-to-weight ratio compared to traditional materials. The market is projected to expand significantly as industries prioritize lightweight, high-performance rigging solutions. Technologically, the sector is advancing from early maturity toward innovation phases, with leading players like DSM IP Assets BV and W.L. Gore & Associates developing enhanced UV resistance and abrasion mitigation technologies. Tokyo Rope MFG and Pfeifer Isofer AG are advancing safety factor improvements, while research institutions like Tongji University and Donghua University contribute fundamental aging mechanism studies. The competitive landscape features established materials science corporations alongside specialized rope manufacturers addressing critical performance challenges.

DSM IP Assets BV

Technical Solution: DSM has developed proprietary Dyneema® UHMWPE fiber technology with advanced UV stabilization systems that incorporate specialized additives to prevent chain scission during prolonged UV exposure. Their technical approach includes a multi-layer protection system where primary stabilizers intercept UV radiation before it damages the polymer backbone, while secondary antioxidants prevent propagation of oxidative degradation. DSM's research has demonstrated that their treated UHMWPE ropes retain up to 80% of tensile strength after 2000 hours of accelerated UV testing, compared to 40-50% retention in untreated fibers. For abrasion resistance, DSM employs surface modification techniques including plasma treatment and specialized coatings that create a sacrificial outer layer while maintaining core strength. Their safety factor methodology incorporates real-world testing with dynamic load modeling that accounts for both gradual UV degradation and cyclic abrasion patterns.

Strengths: Industry-leading UV stabilization technology with documented performance; comprehensive testing protocols that exceed industry standards; global research capabilities allowing rapid innovation. Weaknesses: Premium pricing structure limits adoption in cost-sensitive applications; some coating technologies may add weight and reduce flexibility in certain applications.

W. L. Gore & Associates, Inc.

Technical Solution: Gore has developed a proprietary UHMWPE composite technology that incorporates fluoropolymer elements to enhance UV resistance and abrasion performance. Their approach involves creating a co-extruded fiber structure where UHMWPE forms the strength-bearing core while specialized fluoropolymers provide environmental protection. Gore's research has demonstrated that this hybrid structure maintains mechanical properties after UV exposure significantly better than conventional UHMWPE, with testing showing less than 15% strength degradation after 3000 hours of accelerated weathering. For abrasion resistance, Gore employs a micro-textured surface technology that reduces friction at contact points while distributing forces across a larger area. Their safety factor methodology is particularly advanced, incorporating probabilistic modeling that accounts for statistical variations in both material properties and environmental conditions. Gore has also pioneered non-destructive testing methods that can assess UV degradation in-situ, allowing for more precise lifetime predictions and maintenance scheduling.

Strengths: Unique composite material approach that addresses multiple degradation mechanisms simultaneously; advanced testing capabilities including proprietary accelerated aging protocols; strong intellectual property position. Weaknesses: Higher manufacturing complexity leads to increased production costs; composite structure may have different handling characteristics than pure UHMWPE, requiring user adaptation.

Key Research on UHMWPE Degradation Mechanisms

Ultra-high molecular weight polyethylene

PatentActiveEP2526131A1

Innovation

- A novel UHMW-PE is produced using a blend of metallocene-type catalysts, specifically a bimetallic catalyst system comprising Hafnium (Hf) and Chromium (Cr) residues, which are present as ionic compounds or complexes, and are co-localized within a refractory support material, allowing for enhanced abrasion and Charpy impact resistance while maintaining medium density and sufficient average grain size.

Method and apparatus for manufacturing ultra-high molecular weight polyethylene structures incorporating graphene

PatentWO2024088841A1

Innovation

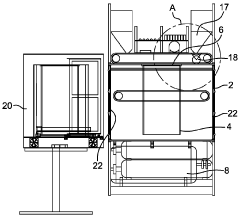

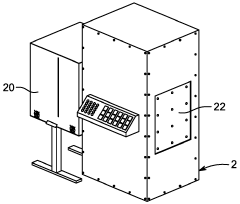

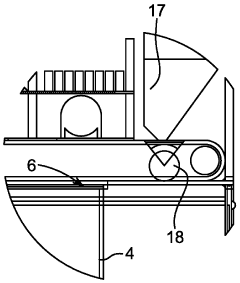

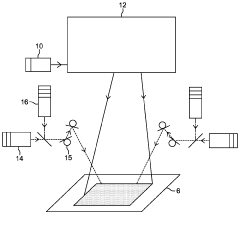

- A method and apparatus for manufacturing UHMWPE structures incorporating graphene using a modified SLS 3D printing process, involving a build chamber with a vertically moveable platform, pre-heating, reduced pressure, and inert gas, with unfocussed IR and focussed UV lasers to sinter and form graphene within the UHMWPE powder layers, and a heated roller to ensure adhesion and reduce porosity.

Safety Standards and Certification Requirements

The safety standards and certification requirements for UHMWPE ropes and slings are governed by multiple international and regional regulatory bodies, each establishing specific protocols to ensure operational safety across various industries. The International Organization for Standardization (ISO) has developed ISO 2307 and ISO 10325, which specifically address the determination of certain physical and mechanical properties of fiber ropes, including UHMWPE materials. These standards outline testing methodologies for tensile strength, elongation characteristics, and cyclic loading performance.

In the United States, the American National Standards Institute (ANSI) works in conjunction with the Web Sling and Tie Down Association (WSTDA) to establish ANSI/WSTDA-RS-1, which provides comprehensive guidelines for the manufacturing, testing, and use of synthetic fiber ropes in lifting applications. Additionally, the Cordage Institute has published CI 1500, which specifically addresses the performance requirements of high-performance synthetic fiber ropes.

The European Committee for Standardization (CEN) has established EN 1492 for textile slings, with specific sections addressing the safety requirements for flat woven webbing slings and roundslings made from man-made fibers, including UHMWPE. These standards mandate regular inspection protocols, clear marking requirements, and specific safety factors that must be applied when calculating working load limits.

For maritime applications, the International Maritime Organization (IMO) has developed guidelines through MSC.1/Circ.1554, which addresses the use of fiber ropes in mooring operations, including those manufactured from UHMWPE materials. These guidelines emphasize the importance of UV resistance testing and abrasion resistance evaluation in marine environments.

Certification processes typically involve third-party testing by accredited laboratories that verify compliance with these standards. Manufacturers must submit samples for destructive testing to determine breaking strength, elongation characteristics, and resistance to environmental factors. Certification documentation must include detailed information about the manufacturing process, material composition, and performance characteristics under various loading conditions.

Safety factors for UHMWPE ropes and slings typically range from 5:1 to 12:1 depending on the application, with higher safety factors required for critical lifting operations or environments with significant UV exposure or abrasion risks. These safety factors are established based on extensive testing of material degradation patterns under various environmental conditions, particularly focusing on the cumulative effects of UV radiation and mechanical abrasion on tensile strength retention.

Regular recertification requirements vary by industry and application, but generally mandate inspection and potential replacement after significant environmental exposure or at specified time intervals, typically ranging from 6 months to 2 years depending on usage intensity and environmental conditions.

In the United States, the American National Standards Institute (ANSI) works in conjunction with the Web Sling and Tie Down Association (WSTDA) to establish ANSI/WSTDA-RS-1, which provides comprehensive guidelines for the manufacturing, testing, and use of synthetic fiber ropes in lifting applications. Additionally, the Cordage Institute has published CI 1500, which specifically addresses the performance requirements of high-performance synthetic fiber ropes.

The European Committee for Standardization (CEN) has established EN 1492 for textile slings, with specific sections addressing the safety requirements for flat woven webbing slings and roundslings made from man-made fibers, including UHMWPE. These standards mandate regular inspection protocols, clear marking requirements, and specific safety factors that must be applied when calculating working load limits.

For maritime applications, the International Maritime Organization (IMO) has developed guidelines through MSC.1/Circ.1554, which addresses the use of fiber ropes in mooring operations, including those manufactured from UHMWPE materials. These guidelines emphasize the importance of UV resistance testing and abrasion resistance evaluation in marine environments.

Certification processes typically involve third-party testing by accredited laboratories that verify compliance with these standards. Manufacturers must submit samples for destructive testing to determine breaking strength, elongation characteristics, and resistance to environmental factors. Certification documentation must include detailed information about the manufacturing process, material composition, and performance characteristics under various loading conditions.

Safety factors for UHMWPE ropes and slings typically range from 5:1 to 12:1 depending on the application, with higher safety factors required for critical lifting operations or environments with significant UV exposure or abrasion risks. These safety factors are established based on extensive testing of material degradation patterns under various environmental conditions, particularly focusing on the cumulative effects of UV radiation and mechanical abrasion on tensile strength retention.

Regular recertification requirements vary by industry and application, but generally mandate inspection and potential replacement after significant environmental exposure or at specified time intervals, typically ranging from 6 months to 2 years depending on usage intensity and environmental conditions.

Environmental Impact and Sustainability Considerations

The environmental impact of UHMWPE (Ultra-High-Molecular-Weight Polyethylene) ropes and slings extends throughout their entire lifecycle, from production to disposal. During manufacturing, UHMWPE production consumes significant energy but generates fewer toxic emissions compared to traditional steel cable manufacturing. The polymer-based production process typically requires less water and produces fewer hazardous byproducts than metal processing, representing a comparative environmental advantage.

In operational use, UHMWPE ropes offer substantial sustainability benefits. Their lightweight nature (approximately one-eighth the weight of steel wire ropes of equivalent strength) significantly reduces transportation-related carbon emissions. This weight reduction translates to fuel savings in marine applications and reduced energy requirements in lifting operations, contributing to overall operational carbon footprint reduction.

The extended service life of properly maintained UHMWPE ropes further enhances their sustainability profile. When protected from excessive UV exposure and abrasion, these ropes can outlast conventional alternatives, reducing replacement frequency and associated resource consumption. However, this advantage is contingent upon proper implementation of UV protection measures and abrasion management protocols discussed in previous sections.

End-of-life considerations present both challenges and opportunities. UHMWPE is not biodegradable, potentially contributing to microplastic pollution when improperly disposed of. The material's high durability, while beneficial during use, becomes problematic in waste streams. Current recycling technologies for UHMWPE ropes remain limited due to contamination issues and the presence of coatings and treatments that complicate processing.

Emerging circular economy initiatives are beginning to address these challenges through mechanical recycling processes that convert retired UHMWPE ropes into lower-grade plastic products. Chemical recycling technologies that break down the polymer chains for reuse in new products show promise but remain in developmental stages. Some manufacturers have implemented take-back programs to ensure proper disposal and potential recycling of end-of-life products.

The carbon footprint comparison between UHMWPE and traditional steel alternatives reveals a complex picture. While UHMWPE production may have higher initial energy requirements, the total lifecycle emissions are often lower due to transportation efficiencies, extended service life, and operational energy savings. Life Cycle Assessment (LCA) studies indicate that UHMWPE ropes can achieve 30-40% lower overall environmental impact compared to steel alternatives in many applications, particularly in marine and offshore contexts.

In operational use, UHMWPE ropes offer substantial sustainability benefits. Their lightweight nature (approximately one-eighth the weight of steel wire ropes of equivalent strength) significantly reduces transportation-related carbon emissions. This weight reduction translates to fuel savings in marine applications and reduced energy requirements in lifting operations, contributing to overall operational carbon footprint reduction.

The extended service life of properly maintained UHMWPE ropes further enhances their sustainability profile. When protected from excessive UV exposure and abrasion, these ropes can outlast conventional alternatives, reducing replacement frequency and associated resource consumption. However, this advantage is contingent upon proper implementation of UV protection measures and abrasion management protocols discussed in previous sections.

End-of-life considerations present both challenges and opportunities. UHMWPE is not biodegradable, potentially contributing to microplastic pollution when improperly disposed of. The material's high durability, while beneficial during use, becomes problematic in waste streams. Current recycling technologies for UHMWPE ropes remain limited due to contamination issues and the presence of coatings and treatments that complicate processing.

Emerging circular economy initiatives are beginning to address these challenges through mechanical recycling processes that convert retired UHMWPE ropes into lower-grade plastic products. Chemical recycling technologies that break down the polymer chains for reuse in new products show promise but remain in developmental stages. Some manufacturers have implemented take-back programs to ensure proper disposal and potential recycling of end-of-life products.

The carbon footprint comparison between UHMWPE and traditional steel alternatives reveals a complex picture. While UHMWPE production may have higher initial energy requirements, the total lifecycle emissions are often lower due to transportation efficiencies, extended service life, and operational energy savings. Life Cycle Assessment (LCA) studies indicate that UHMWPE ropes can achieve 30-40% lower overall environmental impact compared to steel alternatives in many applications, particularly in marine and offshore contexts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!