UHMWPE Thermal Management: Heat Build-Up, Softening Onset And Dimensional Stability

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Thermal Properties Background and Objectives

Ultra-High Molecular Weight Polyethylene (UHMWPE) has emerged as a critical engineering material across various industries due to its exceptional mechanical properties, including high abrasion resistance, impact strength, and chemical stability. The thermal behavior of UHMWPE, however, presents significant challenges that limit its application scope and performance reliability in demanding environments.

The thermal properties of UHMWPE have been studied since its commercial introduction in the 1950s. Initially developed as a specialized form of high-density polyethylene, UHMWPE's molecular weight exceeding 3.1 million g/mol creates a unique microstructure that influences its thermal response. Historical development shows progressive improvements in processing techniques to overcome the inherent challenges posed by its high melt viscosity and thermal sensitivity.

Heat management in UHMWPE represents a critical technical challenge due to the material's relatively low melting point (130-135°C) compared to other engineering polymers. When subjected to mechanical stress, friction-induced heat build-up can occur rapidly, leading to softening and potential failure. This thermal vulnerability becomes particularly problematic in high-load bearing applications where mechanical stress is continuous.

The dimensional stability of UHMWPE under thermal fluctuations presents another significant concern. The material exhibits a relatively high coefficient of thermal expansion (approximately 200×10^-6/K), which can lead to dimensional changes during temperature variations. This property necessitates careful design considerations in precision applications where tight tolerances must be maintained across varying thermal conditions.

Recent technological advancements have focused on enhancing UHMWPE's thermal performance through various modification strategies. Cross-linking techniques, initially developed for improving wear resistance in orthopedic implants, have demonstrated potential for enhancing thermal stability. Additionally, the incorporation of nanofillers and the development of composite structures have shown promise in mitigating heat build-up and improving dimensional stability.

The primary objective of this technical investigation is to comprehensively analyze the thermal behavior of UHMWPE, with specific focus on heat build-up mechanisms, softening onset parameters, and dimensional stability factors. By understanding these fundamental aspects, we aim to identify potential pathways for enhancing UHMWPE's thermal performance without compromising its desirable mechanical properties.

Furthermore, this research seeks to establish quantitative relationships between processing conditions, molecular structure, and thermal response characteristics. Such correlations would enable more precise prediction of thermal behavior in various application environments and facilitate the development of application-specific UHMWPE formulations with optimized thermal management capabilities.

The thermal properties of UHMWPE have been studied since its commercial introduction in the 1950s. Initially developed as a specialized form of high-density polyethylene, UHMWPE's molecular weight exceeding 3.1 million g/mol creates a unique microstructure that influences its thermal response. Historical development shows progressive improvements in processing techniques to overcome the inherent challenges posed by its high melt viscosity and thermal sensitivity.

Heat management in UHMWPE represents a critical technical challenge due to the material's relatively low melting point (130-135°C) compared to other engineering polymers. When subjected to mechanical stress, friction-induced heat build-up can occur rapidly, leading to softening and potential failure. This thermal vulnerability becomes particularly problematic in high-load bearing applications where mechanical stress is continuous.

The dimensional stability of UHMWPE under thermal fluctuations presents another significant concern. The material exhibits a relatively high coefficient of thermal expansion (approximately 200×10^-6/K), which can lead to dimensional changes during temperature variations. This property necessitates careful design considerations in precision applications where tight tolerances must be maintained across varying thermal conditions.

Recent technological advancements have focused on enhancing UHMWPE's thermal performance through various modification strategies. Cross-linking techniques, initially developed for improving wear resistance in orthopedic implants, have demonstrated potential for enhancing thermal stability. Additionally, the incorporation of nanofillers and the development of composite structures have shown promise in mitigating heat build-up and improving dimensional stability.

The primary objective of this technical investigation is to comprehensively analyze the thermal behavior of UHMWPE, with specific focus on heat build-up mechanisms, softening onset parameters, and dimensional stability factors. By understanding these fundamental aspects, we aim to identify potential pathways for enhancing UHMWPE's thermal performance without compromising its desirable mechanical properties.

Furthermore, this research seeks to establish quantitative relationships between processing conditions, molecular structure, and thermal response characteristics. Such correlations would enable more precise prediction of thermal behavior in various application environments and facilitate the development of application-specific UHMWPE formulations with optimized thermal management capabilities.

Market Demand Analysis for Thermally Stable UHMWPE

The global market for Ultra-High Molecular Weight Polyethylene (UHMWPE) with enhanced thermal stability is experiencing significant growth, driven primarily by increasing applications in aerospace, defense, industrial machinery, and medical devices. Current market valuations indicate that the thermally stable UHMWPE segment represents approximately 30% of the overall UHMWPE market, with annual growth rates consistently outpacing traditional variants.

Industries requiring high-performance materials are increasingly demanding UHMWPE solutions that maintain dimensional stability and mechanical properties under thermal stress. The aerospace sector, in particular, has shown strong demand growth as manufacturers seek lightweight yet durable materials capable of withstanding extreme temperature fluctuations without compromising structural integrity. This demand is further amplified by the industry's push toward fuel efficiency and reduced emissions through weight reduction.

The medical device industry represents another significant market driver, with thermally stable UHMWPE being essential for implantable devices and surgical instruments that must withstand sterilization processes. The aging global population and increasing prevalence of orthopedic procedures have created sustained demand growth in this sector, with particular emphasis on materials that resist deformation during thermal cycling.

Industrial applications, especially in mining, material handling, and heavy machinery, constitute a substantial market segment where thermal management capabilities directly correlate with equipment longevity and operational efficiency. End-users in these sectors report willingness to pay premium prices for UHMWPE variants that demonstrate superior heat dissipation and dimensional stability under load.

Market research indicates regional variations in demand patterns, with North America and Europe leading in adoption for high-specification applications, while Asia-Pacific markets show the fastest growth rates, particularly in manufacturing and industrial applications. This geographic distribution reflects both technological maturity and industrial development patterns across regions.

Consumer preference analysis reveals that purchasing decisions increasingly prioritize total lifecycle cost over initial acquisition expense, favoring thermally stable UHMWPE despite higher upfront costs. This trend is particularly pronounced in applications where material failure results in significant operational disruptions or safety concerns.

Market forecasts suggest continued expansion of demand for thermally stable UHMWPE, with particular growth expected in renewable energy applications, advanced transportation systems, and next-generation medical devices. The market is also witnessing increased interest from sectors traditionally reliant on metal components, as engineers seek lightweight alternatives with comparable thermal performance characteristics.

Industries requiring high-performance materials are increasingly demanding UHMWPE solutions that maintain dimensional stability and mechanical properties under thermal stress. The aerospace sector, in particular, has shown strong demand growth as manufacturers seek lightweight yet durable materials capable of withstanding extreme temperature fluctuations without compromising structural integrity. This demand is further amplified by the industry's push toward fuel efficiency and reduced emissions through weight reduction.

The medical device industry represents another significant market driver, with thermally stable UHMWPE being essential for implantable devices and surgical instruments that must withstand sterilization processes. The aging global population and increasing prevalence of orthopedic procedures have created sustained demand growth in this sector, with particular emphasis on materials that resist deformation during thermal cycling.

Industrial applications, especially in mining, material handling, and heavy machinery, constitute a substantial market segment where thermal management capabilities directly correlate with equipment longevity and operational efficiency. End-users in these sectors report willingness to pay premium prices for UHMWPE variants that demonstrate superior heat dissipation and dimensional stability under load.

Market research indicates regional variations in demand patterns, with North America and Europe leading in adoption for high-specification applications, while Asia-Pacific markets show the fastest growth rates, particularly in manufacturing and industrial applications. This geographic distribution reflects both technological maturity and industrial development patterns across regions.

Consumer preference analysis reveals that purchasing decisions increasingly prioritize total lifecycle cost over initial acquisition expense, favoring thermally stable UHMWPE despite higher upfront costs. This trend is particularly pronounced in applications where material failure results in significant operational disruptions or safety concerns.

Market forecasts suggest continued expansion of demand for thermally stable UHMWPE, with particular growth expected in renewable energy applications, advanced transportation systems, and next-generation medical devices. The market is also witnessing increased interest from sectors traditionally reliant on metal components, as engineers seek lightweight alternatives with comparable thermal performance characteristics.

Current Thermal Management Challenges in UHMWPE

Ultra-high-molecular-weight polyethylene (UHMWPE) faces significant thermal management challenges that limit its applications in high-performance environments. The primary issue stems from its inherently low thermal conductivity (approximately 0.4-0.5 W/m·K), which causes heat accumulation during processing and operational use. This heat build-up creates a cascade of problematic effects that engineers and materials scientists must address.

When UHMWPE experiences elevated temperatures, particularly approaching its melting point of 130-135°C, the material undergoes substantial changes in mechanical properties. The polymer chains gain mobility, leading to decreased stiffness and strength. This softening onset occurs progressively, with noticeable effects beginning around 80-90°C, well below the actual melting temperature.

Dimensional stability represents another critical challenge. UHMWPE exhibits a relatively high coefficient of thermal expansion (approximately 200×10^-6/K), causing significant dimensional changes with temperature fluctuations. In precision applications such as bearings, gears, or medical implants, these dimensional variations can lead to component failure, reduced performance, or compromised functionality.

The heat dissipation inefficiency in UHMWPE creates localized hot spots during processing operations like extrusion, compression molding, and ram extrusion. These thermal gradients induce internal stresses that manifest as warping, shrinkage, and other dimensional inconsistencies in finished products. The challenge intensifies with increasing part thickness, as heat transfer becomes progressively more difficult through the material's cross-section.

Current manufacturing processes attempt to mitigate these issues through extended cooling cycles, which significantly reduces production efficiency and increases manufacturing costs. The slow cooling requirement stems from UHMWPE's semicrystalline nature, where improper cooling rates lead to inconsistent crystallinity, affecting both dimensional stability and mechanical properties.

In dynamic applications involving friction, such as bearings or wear surfaces, the poor thermal conductivity creates a self-reinforcing problem: friction generates heat that cannot dissipate effectively, accelerating material softening and potentially leading to catastrophic failure. This limitation restricts UHMWPE's use in high-load, high-speed applications despite its excellent wear resistance.

The industry currently employs several approaches to address these challenges, including the incorporation of thermally conductive fillers, modified processing techniques, and design adaptations that account for thermal expansion. However, these solutions often compromise other desirable properties of UHMWPE, such as its chemical resistance, biocompatibility, or mechanical strength, creating a complex engineering trade-off that requires careful optimization for specific applications.

When UHMWPE experiences elevated temperatures, particularly approaching its melting point of 130-135°C, the material undergoes substantial changes in mechanical properties. The polymer chains gain mobility, leading to decreased stiffness and strength. This softening onset occurs progressively, with noticeable effects beginning around 80-90°C, well below the actual melting temperature.

Dimensional stability represents another critical challenge. UHMWPE exhibits a relatively high coefficient of thermal expansion (approximately 200×10^-6/K), causing significant dimensional changes with temperature fluctuations. In precision applications such as bearings, gears, or medical implants, these dimensional variations can lead to component failure, reduced performance, or compromised functionality.

The heat dissipation inefficiency in UHMWPE creates localized hot spots during processing operations like extrusion, compression molding, and ram extrusion. These thermal gradients induce internal stresses that manifest as warping, shrinkage, and other dimensional inconsistencies in finished products. The challenge intensifies with increasing part thickness, as heat transfer becomes progressively more difficult through the material's cross-section.

Current manufacturing processes attempt to mitigate these issues through extended cooling cycles, which significantly reduces production efficiency and increases manufacturing costs. The slow cooling requirement stems from UHMWPE's semicrystalline nature, where improper cooling rates lead to inconsistent crystallinity, affecting both dimensional stability and mechanical properties.

In dynamic applications involving friction, such as bearings or wear surfaces, the poor thermal conductivity creates a self-reinforcing problem: friction generates heat that cannot dissipate effectively, accelerating material softening and potentially leading to catastrophic failure. This limitation restricts UHMWPE's use in high-load, high-speed applications despite its excellent wear resistance.

The industry currently employs several approaches to address these challenges, including the incorporation of thermally conductive fillers, modified processing techniques, and design adaptations that account for thermal expansion. However, these solutions often compromise other desirable properties of UHMWPE, such as its chemical resistance, biocompatibility, or mechanical strength, creating a complex engineering trade-off that requires careful optimization for specific applications.

Existing Heat Dissipation Solutions for UHMWPE

01 Thermal properties and heat management in UHMWPE

UHMWPE materials exhibit specific thermal behaviors including heat build-up characteristics and softening onset temperatures. Various formulations and processing techniques have been developed to manage heat generation during use and manufacturing. These approaches include incorporating thermal stabilizers, optimizing crystallinity, and using specific cooling methods to control heat dissipation and prevent premature softening, which is critical for applications where thermal stability is required.- Thermal stability and heat management in UHMWPE: Ultra-high-molecular-weight polyethylene (UHMWPE) can be formulated with additives to improve its thermal stability and manage heat build-up during processing and application. These formulations help control the softening onset temperature and prevent dimensional changes when exposed to heat. Various stabilizers, heat dissipation agents, and processing aids can be incorporated to enhance the material's resistance to thermal degradation and maintain structural integrity at elevated temperatures.

- Cross-linking techniques for dimensional stability: Cross-linking methods can significantly improve the dimensional stability of UHMWPE when subjected to heat. Radiation-induced cross-linking, chemical cross-linking agents, and thermal treatment processes create a more stable polymer network that resists deformation and maintains dimensional integrity even at temperatures approaching the softening point. These techniques are particularly important for applications requiring precise dimensional tolerances under varying thermal conditions.

- Reinforcement materials for heat resistance: Incorporating reinforcement materials such as carbon fibers, glass fibers, ceramic particles, or mineral fillers into UHMWPE composites can enhance heat resistance and dimensional stability. These reinforcements create a more thermally stable matrix that reduces heat build-up, increases the softening onset temperature, and minimizes thermal expansion. The resulting composites maintain their structural integrity and dimensional stability even under conditions of thermal stress.

- Processing techniques to control thermal properties: Specialized processing techniques such as compression molding, ram extrusion, and controlled cooling protocols can significantly influence the thermal behavior of UHMWPE. These methods help manage internal stresses, crystallinity, and molecular orientation, which directly affect heat build-up characteristics, softening onset temperature, and dimensional stability. Optimized processing parameters can produce UHMWPE components with enhanced resistance to thermal deformation and improved dimensional stability under heat load.

- Nanocomposite formulations for thermal performance: Incorporating nanomaterials such as nanoclays, graphene, carbon nanotubes, or metal oxide nanoparticles into UHMWPE can create nanocomposites with superior thermal properties. These nanofillers enhance heat dissipation, increase the softening onset temperature, and improve dimensional stability by restricting polymer chain mobility and creating efficient thermal conduction pathways. The resulting nanocomposites exhibit reduced heat build-up and maintain dimensional integrity at higher temperatures compared to conventional UHMWPE.

02 Dimensional stability enhancement techniques

Maintaining dimensional stability in UHMWPE components is achieved through various methods including crosslinking, reinforcement with fillers, and specialized processing techniques. These approaches help minimize creep, thermal expansion, and deformation under load or temperature fluctuations. Specific additives and processing parameters can significantly improve the material's ability to maintain its dimensions in challenging environments, which is particularly important for precision components and structural applications.Expand Specific Solutions03 Composite formulations for improved thermal performance

UHMWPE composites incorporating specific fillers such as carbon fibers, ceramic particles, or mineral additives demonstrate enhanced thermal stability and reduced heat build-up. These composite formulations modify the thermal conductivity and heat capacity of the base polymer, allowing for better heat distribution and dissipation. The strategic selection of fillers and their concentration can be tailored to specific application requirements where thermal management is critical.Expand Specific Solutions04 Processing methods affecting thermal and dimensional properties

Various processing techniques including compression molding, ram extrusion, and specialized cooling protocols significantly impact the thermal behavior and dimensional stability of UHMWPE products. The processing history affects crystallinity, molecular orientation, and internal stress distribution, which in turn influence softening onset temperatures and dimensional response to thermal loads. Optimized processing parameters can be established to achieve the desired balance between processability and thermal-dimensional stability.Expand Specific Solutions05 Additives for controlling softening onset and thermal stability

Specific additives including antioxidants, nucleating agents, and thermal stabilizers can be incorporated into UHMWPE formulations to control softening onset temperatures and improve overall thermal stability. These additives work by interrupting degradation mechanisms, enhancing crystallization behavior, or forming protective networks within the polymer matrix. The strategic selection and concentration of these additives can be tailored to specific application requirements where resistance to thermal deformation is critical.Expand Specific Solutions

Leading UHMWPE Manufacturers and Research Institutions

The UHMWPE thermal management market is currently in a growth phase, with increasing applications across automotive, electronics, and medical sectors. The global market size is estimated to exceed $1.5 billion, driven by demand for high-performance polymers with superior thermal properties. While the technology is established, innovations in thermal stability and dimensional control represent key competitive frontiers. Leading players include Valeo Thermal Systems focusing on automotive applications, Contemporary Amperex Technology developing battery-related solutions, and Zeus specializing in precision polymer extrusions. Research institutions like South China University of Technology and Shanghai Jiao Tong University are advancing fundamental understanding of UHMWPE thermal behavior, while industrial giants such as GE, Panasonic, and Microsoft are exploring specialized applications requiring enhanced thermal management capabilities.

South China University of Technology

Technical Solution: South China University of Technology has developed an innovative approach to UHMWPE thermal management through their research on nanocomposite structures. Their technology incorporates graphene nanoplatelets and boron nitride particles in a carefully controlled distribution throughout the UHMWPE matrix, creating a three-dimensional thermal conduction network. This structure has demonstrated a thermal conductivity improvement of up to 45% compared to standard UHMWPE while maintaining over 90% of the original mechanical properties. The university's research team has pioneered a specialized processing technique that aligns these nanomaterials along preferred heat dissipation pathways, addressing directional heat flow requirements in complex applications. Their solution also includes a gradient crystallinity control method that enhances dimensional stability near the softening onset temperature (approximately 135°C), reducing deformation by up to 60% compared to conventional UHMWPE under similar thermal loads. Additionally, they've developed a surface modification technique that improves thermal radiation efficiency, allowing components to dissipate heat more effectively to the surrounding environment.

Strengths: Exceptional thermal conductivity improvement through advanced nanocomposite structure; maintains excellent mechanical properties; solution can be tailored for specific directional heat flow requirements. Weaknesses: Laboratory-scale technology may face challenges in industrial-scale implementation; higher material cost due to nanomaterial incorporation; requires specialized processing equipment for optimal results.

Hutchinson SA

Technical Solution: Hutchinson SA has developed a sophisticated thermal management system for UHMWPE components used in demanding industrial applications. Their technology combines material science innovations with structural design optimizations to address heat build-up challenges. Hutchinson's approach incorporates a network of thermally conductive carbon nanotubes (CNTs) strategically distributed throughout the UHMWPE matrix, creating efficient heat dissipation pathways while preserving the material's mechanical properties. Their manufacturing process includes a proprietary thermal annealing step that enhances crystallinity in specific regions, improving dimensional stability at elevated temperatures. The company has also developed specialized surface treatments that modify the thermal emissivity of UHMWPE components, allowing for more efficient radiative heat transfer. Hutchinson's solution includes integrated thermal monitoring capabilities through embedded microsensors that provide real-time temperature data, enabling predictive maintenance and preventing catastrophic thermal failures in critical applications.

Strengths: Carbon nanotube network provides exceptional thermal conductivity improvement without significant weight increase; integrated monitoring capabilities allow for proactive thermal management; solution maintains UHMWPE's chemical resistance properties. Weaknesses: Higher production costs due to advanced materials and processing requirements; CNT integration requires precise manufacturing controls; technology is primarily focused on industrial applications rather than consumer products.

Key Thermal Stabilization Technologies for UHMWPE

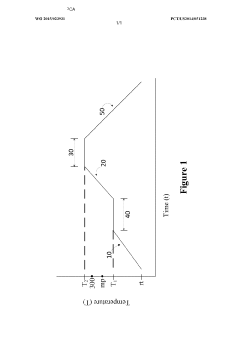

Method for making ultra high molecular weight polyethylene

PatentWO2015023931A2

Innovation

- Applying radial pressure during heat treatment, specifically by constraining the UHMWPE in a sleeve that allows thermal expansion to apply pressure radially while keeping the longitudinal axis unconstrained, prevents cavitation damage, enabling subsequent heat processing above the melting temperature without degrading mechanical properties.

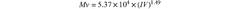

High Performance Multimodal Ultra High Molecular Weight Polyethylene

PatentPendingUS20250019532A1

Innovation

- A multimodal polyethylene composition comprising specific weight percentages of low molecular weight, first high molecular weight, and second high molecular weight polyethylene homopolymers or copolymers, produced in a multistage process using a Ziegler-Natta catalyst, which improves mechanical properties and processability by creating a broad molecular weight distribution curve, enhancing abrasion resistance and impact strength.

Material Testing Standards for UHMWPE Thermal Properties

The standardization of testing methods for UHMWPE thermal properties is essential for ensuring consistent evaluation and comparison across different material formulations and manufacturing processes. ASTM International and ISO have developed several key standards specifically addressing the thermal characterization of polymers, with some directly applicable to UHMWPE.

ASTM D3418 and ISO 11357 provide standardized procedures for determining melting and crystallization temperatures using Differential Scanning Calorimetry (DSC). These standards are particularly relevant for UHMWPE as they enable precise measurement of the material's phase transitions, which typically occur between 125-138°C depending on molecular weight and processing history.

For thermal conductivity assessment, ASTM C177 (guarded hot plate method) and ASTM D5930 (transient plane source method) offer reliable protocols. These standards are crucial for UHMWPE applications where heat dissipation is critical, such as in bearing surfaces or high-friction environments where heat build-up can lead to dimensional instability.

Thermal expansion characteristics, which directly impact dimensional stability under varying temperature conditions, are standardized through ASTM E831 and ISO 11359. These test methods employ thermomechanical analysis (TMA) to measure the coefficient of linear thermal expansion (CLTE), a parameter particularly important for UHMWPE components in precision engineering applications.

Dynamic Mechanical Analysis (DMA) standards, including ASTM D4065 and ISO 6721, provide frameworks for evaluating viscoelastic properties as functions of temperature. These tests are invaluable for determining the softening onset temperature and modulus retention at elevated temperatures, which directly correlate with UHMWPE's performance under thermal stress.

Heat deflection temperature (HDT) and Vicat softening point measurements follow ASTM D648 and ISO 75 protocols, offering standardized approaches to determine critical temperatures at which UHMWPE components begin to deform under specified loads.

For accelerated aging studies that simulate long-term thermal exposure effects, ASTM F2003 specifically addresses the thermal aging of UHMWPE used in medical applications, while ASTM D3045 provides guidelines for thermal-oxidative stability assessment.

Recent developments in standardization have focused on specialized tests for UHMWPE in demanding applications, including methods to evaluate thermal fatigue resistance and thermally-induced oxidation. These emerging standards recognize the unique challenges posed by UHMWPE's combination of high molecular weight, crystallinity, and thermal response characteristics.

ASTM D3418 and ISO 11357 provide standardized procedures for determining melting and crystallization temperatures using Differential Scanning Calorimetry (DSC). These standards are particularly relevant for UHMWPE as they enable precise measurement of the material's phase transitions, which typically occur between 125-138°C depending on molecular weight and processing history.

For thermal conductivity assessment, ASTM C177 (guarded hot plate method) and ASTM D5930 (transient plane source method) offer reliable protocols. These standards are crucial for UHMWPE applications where heat dissipation is critical, such as in bearing surfaces or high-friction environments where heat build-up can lead to dimensional instability.

Thermal expansion characteristics, which directly impact dimensional stability under varying temperature conditions, are standardized through ASTM E831 and ISO 11359. These test methods employ thermomechanical analysis (TMA) to measure the coefficient of linear thermal expansion (CLTE), a parameter particularly important for UHMWPE components in precision engineering applications.

Dynamic Mechanical Analysis (DMA) standards, including ASTM D4065 and ISO 6721, provide frameworks for evaluating viscoelastic properties as functions of temperature. These tests are invaluable for determining the softening onset temperature and modulus retention at elevated temperatures, which directly correlate with UHMWPE's performance under thermal stress.

Heat deflection temperature (HDT) and Vicat softening point measurements follow ASTM D648 and ISO 75 protocols, offering standardized approaches to determine critical temperatures at which UHMWPE components begin to deform under specified loads.

For accelerated aging studies that simulate long-term thermal exposure effects, ASTM F2003 specifically addresses the thermal aging of UHMWPE used in medical applications, while ASTM D3045 provides guidelines for thermal-oxidative stability assessment.

Recent developments in standardization have focused on specialized tests for UHMWPE in demanding applications, including methods to evaluate thermal fatigue resistance and thermally-induced oxidation. These emerging standards recognize the unique challenges posed by UHMWPE's combination of high molecular weight, crystallinity, and thermal response characteristics.

Environmental Impact of UHMWPE Thermal Additives

The environmental implications of thermal additives used in Ultra-High Molecular Weight Polyethylene (UHMWPE) merit careful consideration as these compounds increasingly find applications across various industries. Traditional thermal management additives for UHMWPE, such as metal-based compounds and certain halogenated flame retardants, pose significant environmental concerns throughout their lifecycle.

Metal-based thermal additives, while effective at managing heat build-up in UHMWPE, can leach into ecosystems during product use and disposal phases. Studies indicate that zinc, copper, and aluminum compounds commonly used as thermal conductivity enhancers may accumulate in aquatic environments, potentially disrupting ecological balances and affecting biodiversity. The extraction processes for these metals also contribute to habitat destruction and energy-intensive mining operations.

Halogenated compounds, historically employed to improve flame resistance and thermal stability in UHMWPE, present persistent environmental hazards. These substances demonstrate remarkable environmental persistence, with degradation half-lives often exceeding decades. Bioaccumulation in wildlife and potential endocrine-disrupting properties have prompted regulatory restrictions in many jurisdictions, including the European Union's RoHS directive.

Recent innovations in eco-friendly thermal additives represent promising alternatives. Naturally derived minerals like modified clays and bio-based carbon additives demonstrate comparable thermal management capabilities while significantly reducing environmental footprint. Life cycle assessments reveal that these sustainable alternatives can reduce carbon emissions by 30-45% compared to conventional metal-based additives.

Recycling challenges present another environmental dimension of UHMWPE thermal additives. Certain additives can complicate recycling processes by degrading during reprocessing or contaminating recycling streams. Advanced sorting technologies utilizing near-infrared spectroscopy show promise in identifying and segregating differently formulated UHMWPE materials, potentially improving recycling rates.

Water consumption and pollution associated with manufacturing UHMWPE thermal additives also warrant attention. Production processes for conventional additives typically require 3-5 gallons of water per pound of additive produced, with wastewater often containing trace metals and processing chemicals. Closed-loop manufacturing systems and water recycling technologies are gradually being implemented by industry leaders to address these concerns.

Regulatory frameworks governing UHMWPE additives continue to evolve globally, with increasing emphasis on lifecycle environmental impact. The EU's REACH regulations and similar initiatives in North America and Asia are driving manufacturers toward greener formulations that maintain thermal performance while minimizing ecological harm. This regulatory landscape is accelerating research into biodegradable and renewable-sourced thermal management solutions for next-generation UHMWPE applications.

Metal-based thermal additives, while effective at managing heat build-up in UHMWPE, can leach into ecosystems during product use and disposal phases. Studies indicate that zinc, copper, and aluminum compounds commonly used as thermal conductivity enhancers may accumulate in aquatic environments, potentially disrupting ecological balances and affecting biodiversity. The extraction processes for these metals also contribute to habitat destruction and energy-intensive mining operations.

Halogenated compounds, historically employed to improve flame resistance and thermal stability in UHMWPE, present persistent environmental hazards. These substances demonstrate remarkable environmental persistence, with degradation half-lives often exceeding decades. Bioaccumulation in wildlife and potential endocrine-disrupting properties have prompted regulatory restrictions in many jurisdictions, including the European Union's RoHS directive.

Recent innovations in eco-friendly thermal additives represent promising alternatives. Naturally derived minerals like modified clays and bio-based carbon additives demonstrate comparable thermal management capabilities while significantly reducing environmental footprint. Life cycle assessments reveal that these sustainable alternatives can reduce carbon emissions by 30-45% compared to conventional metal-based additives.

Recycling challenges present another environmental dimension of UHMWPE thermal additives. Certain additives can complicate recycling processes by degrading during reprocessing or contaminating recycling streams. Advanced sorting technologies utilizing near-infrared spectroscopy show promise in identifying and segregating differently formulated UHMWPE materials, potentially improving recycling rates.

Water consumption and pollution associated with manufacturing UHMWPE thermal additives also warrant attention. Production processes for conventional additives typically require 3-5 gallons of water per pound of additive produced, with wastewater often containing trace metals and processing chemicals. Closed-loop manufacturing systems and water recycling technologies are gradually being implemented by industry leaders to address these concerns.

Regulatory frameworks governing UHMWPE additives continue to evolve globally, with increasing emphasis on lifecycle environmental impact. The EU's REACH regulations and similar initiatives in North America and Asia are driving manufacturers toward greener formulations that maintain thermal performance while minimizing ecological harm. This regulatory landscape is accelerating research into biodegradable and renewable-sourced thermal management solutions for next-generation UHMWPE applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!