UHMWPE Textile Architectures: Braid/Twine Design, Knot Efficiency And Retention

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Textile Evolution and Research Objectives

Ultra-high molecular weight polyethylene (UHMWPE) fibers have revolutionized the textile industry since their commercial introduction in the 1980s. These remarkable materials, characterized by their exceptional strength-to-weight ratio, have undergone significant evolution over the past four decades. Initially developed for military applications, UHMWPE fibers have expanded into diverse sectors including marine, industrial safety, and medical fields due to their superior mechanical properties.

The evolution of UHMWPE textiles has been marked by continuous improvements in manufacturing processes. Early production methods yielded fibers with tensile strengths around 2.5 GPa, whereas contemporary techniques have pushed this boundary beyond 4 GPa. This progression has been facilitated by advancements in gel spinning processes and subsequent drawing techniques that enhance molecular alignment and crystallinity.

Despite these improvements, significant challenges remain in optimizing UHMWPE textile architectures. Traditional textile structures often fail to fully capitalize on the inherent properties of UHMWPE fibers, particularly in applications requiring complex loading conditions. The interface between individual fibers and the overall structural performance represents a critical research gap that demands innovative approaches to textile design.

Braid and twine configurations offer promising avenues for enhancing load distribution and structural integrity in UHMWPE systems. However, the relationship between specific architectural parameters and mechanical performance remains inadequately understood. Similarly, knot efficiency—a crucial factor in many applications—has received insufficient attention in scientific literature, despite its profound impact on overall system reliability.

Current research objectives focus on developing comprehensive models that correlate textile architecture with mechanical performance. This includes investigating the influence of braiding angles, twining patterns, and hybrid structures on load-bearing capacity and energy absorption. Additionally, understanding knot retention mechanisms under dynamic loading conditions represents a priority area, particularly for marine and safety applications.

The research aims to establish design principles that optimize UHMWPE textile architectures for specific performance requirements. This involves systematic evaluation of various architectural parameters and their influence on mechanical properties, durability, and failure modes. Advanced characterization techniques, including high-speed imaging and computational modeling, are being employed to visualize and predict structural behavior under complex loading scenarios.

Ultimately, this research seeks to bridge the gap between theoretical understanding and practical application, providing industry with actionable design guidelines for next-generation UHMWPE textile systems. The findings are expected to enable significant performance improvements across multiple sectors, from more efficient marine ropes to enhanced ballistic protection systems.

The evolution of UHMWPE textiles has been marked by continuous improvements in manufacturing processes. Early production methods yielded fibers with tensile strengths around 2.5 GPa, whereas contemporary techniques have pushed this boundary beyond 4 GPa. This progression has been facilitated by advancements in gel spinning processes and subsequent drawing techniques that enhance molecular alignment and crystallinity.

Despite these improvements, significant challenges remain in optimizing UHMWPE textile architectures. Traditional textile structures often fail to fully capitalize on the inherent properties of UHMWPE fibers, particularly in applications requiring complex loading conditions. The interface between individual fibers and the overall structural performance represents a critical research gap that demands innovative approaches to textile design.

Braid and twine configurations offer promising avenues for enhancing load distribution and structural integrity in UHMWPE systems. However, the relationship between specific architectural parameters and mechanical performance remains inadequately understood. Similarly, knot efficiency—a crucial factor in many applications—has received insufficient attention in scientific literature, despite its profound impact on overall system reliability.

Current research objectives focus on developing comprehensive models that correlate textile architecture with mechanical performance. This includes investigating the influence of braiding angles, twining patterns, and hybrid structures on load-bearing capacity and energy absorption. Additionally, understanding knot retention mechanisms under dynamic loading conditions represents a priority area, particularly for marine and safety applications.

The research aims to establish design principles that optimize UHMWPE textile architectures for specific performance requirements. This involves systematic evaluation of various architectural parameters and their influence on mechanical properties, durability, and failure modes. Advanced characterization techniques, including high-speed imaging and computational modeling, are being employed to visualize and predict structural behavior under complex loading scenarios.

Ultimately, this research seeks to bridge the gap between theoretical understanding and practical application, providing industry with actionable design guidelines for next-generation UHMWPE textile systems. The findings are expected to enable significant performance improvements across multiple sectors, from more efficient marine ropes to enhanced ballistic protection systems.

Market Analysis for High-Performance Textile Applications

The global market for high-performance textiles, particularly those utilizing Ultra-High Molecular Weight Polyethylene (UHMWPE), has experienced significant growth over the past decade. This expansion is primarily driven by increasing demand across multiple sectors including defense, maritime, sports equipment, and industrial applications where superior strength-to-weight ratios are critical performance factors.

Defense applications represent the largest market segment for UHMWPE textiles, valued at approximately 3.2 billion USD in 2022, with a compound annual growth rate of 7.8%. Body armor, ballistic protection, and military-grade ropes constitute the primary applications, with North America dominating market consumption due to substantial defense budgets and stringent safety requirements.

The maritime industry forms the second-largest application sector, particularly in high-performance rope systems where UHMWPE braided and twisted architectures have largely replaced traditional materials like steel and polyester. This transition is motivated by weight reduction requirements, corrosion resistance needs, and enhanced safety factors. The maritime segment is projected to reach 2.1 billion USD by 2025, growing at 6.5% annually.

Sports and recreational markets represent the fastest-growing segment for UHMWPE textiles, with climbing, sailing, and extreme sports driving innovation in specialized rope designs. Consumer willingness to pay premium prices for equipment offering superior performance and safety characteristics has created a profitable niche market estimated at 1.4 billion USD with 9.2% annual growth.

Regional analysis indicates Asia-Pacific as the fastest-expanding market, with China and India investing heavily in domestic manufacturing capabilities for UHMWPE textiles. However, North America and Europe maintain technological leadership in specialized architectural designs and advanced manufacturing processes.

Market penetration faces challenges including high production costs compared to conventional materials, limited awareness among potential end-users, and technical difficulties in processing and joining UHMWPE textiles. The price premium of 30-40% over conventional alternatives remains a significant adoption barrier in cost-sensitive applications.

Future market growth will likely be driven by innovations addressing current limitations in knot efficiency and retention - critical factors that currently restrict broader adoption. Research indicates that optimized braid architectures could potentially increase market penetration by 15-20% in applications where conventional joining methods have proven inadequate.

Sustainability considerations are increasingly influencing market dynamics, with end-users seeking products offering extended service life and recyclability. UHMWPE's exceptional durability provides competitive advantages in lifecycle cost analyses despite higher initial investment requirements.

Defense applications represent the largest market segment for UHMWPE textiles, valued at approximately 3.2 billion USD in 2022, with a compound annual growth rate of 7.8%. Body armor, ballistic protection, and military-grade ropes constitute the primary applications, with North America dominating market consumption due to substantial defense budgets and stringent safety requirements.

The maritime industry forms the second-largest application sector, particularly in high-performance rope systems where UHMWPE braided and twisted architectures have largely replaced traditional materials like steel and polyester. This transition is motivated by weight reduction requirements, corrosion resistance needs, and enhanced safety factors. The maritime segment is projected to reach 2.1 billion USD by 2025, growing at 6.5% annually.

Sports and recreational markets represent the fastest-growing segment for UHMWPE textiles, with climbing, sailing, and extreme sports driving innovation in specialized rope designs. Consumer willingness to pay premium prices for equipment offering superior performance and safety characteristics has created a profitable niche market estimated at 1.4 billion USD with 9.2% annual growth.

Regional analysis indicates Asia-Pacific as the fastest-expanding market, with China and India investing heavily in domestic manufacturing capabilities for UHMWPE textiles. However, North America and Europe maintain technological leadership in specialized architectural designs and advanced manufacturing processes.

Market penetration faces challenges including high production costs compared to conventional materials, limited awareness among potential end-users, and technical difficulties in processing and joining UHMWPE textiles. The price premium of 30-40% over conventional alternatives remains a significant adoption barrier in cost-sensitive applications.

Future market growth will likely be driven by innovations addressing current limitations in knot efficiency and retention - critical factors that currently restrict broader adoption. Research indicates that optimized braid architectures could potentially increase market penetration by 15-20% in applications where conventional joining methods have proven inadequate.

Sustainability considerations are increasingly influencing market dynamics, with end-users seeking products offering extended service life and recyclability. UHMWPE's exceptional durability provides competitive advantages in lifecycle cost analyses despite higher initial investment requirements.

Technical Challenges in UHMWPE Fiber Processing

The processing of Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers presents significant technical challenges that impact the development of advanced textile architectures. The inherent molecular structure of UHMWPE, characterized by extremely long polymer chains with molecular weights ranging from 3.5 to 7.5 million g/mol, creates unique processing difficulties not encountered with conventional polymeric materials.

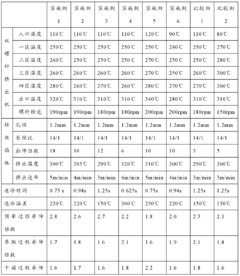

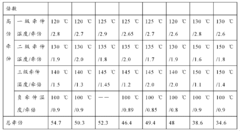

One primary challenge lies in the gel-spinning process required for UHMWPE fiber production. This specialized technique involves dissolving the polymer in a solvent at high temperatures, followed by extrusion and drawing processes that align the molecular chains. The precise control of temperature, concentration, and drawing ratios is critical, as minor variations can significantly affect the mechanical properties of the resulting fibers.

Surface treatment represents another substantial hurdle in UHMWPE processing. The fiber's inherently low surface energy and chemical inertness, while beneficial for certain applications, create poor adhesion characteristics that complicate the formation of stable textile structures. Current plasma, corona discharge, and chemical treatments have shown limited success in enhancing surface properties without compromising the fiber's mechanical integrity.

The formation of consistent braided and twined structures from UHMWPE fibers is complicated by the material's low coefficient of friction and high stiffness. These properties cause slippage between fibers during the braiding process, resulting in structural inconsistencies and reduced mechanical performance in the final textile architecture. Advanced braiding technologies with precise tension control systems are required to address these issues.

Heat management during processing presents additional complications. UHMWPE has a relatively low melting point (130-135°C) compared to other high-performance fibers, severely limiting the processing window. This thermal sensitivity restricts the application of conventional textile formation techniques and necessitates specialized equipment and processing parameters.

The dimensional stability of UHMWPE fibers under load also poses challenges for knot efficiency and retention. The material exhibits creep behavior under sustained loading, which can lead to gradual loosening of knots and reduction in the structural integrity of textile assemblies over time. This characteristic necessitates innovative knotting techniques and structural designs that can compensate for this behavior.

Furthermore, quality control and consistency in fiber properties represent ongoing challenges. Variations in molecular weight distribution, crystallinity, and orientation can occur during production, leading to inconsistent mechanical properties that affect the performance of textile architectures. Advanced characterization methods and in-line monitoring systems are essential for maintaining consistent fiber quality.

One primary challenge lies in the gel-spinning process required for UHMWPE fiber production. This specialized technique involves dissolving the polymer in a solvent at high temperatures, followed by extrusion and drawing processes that align the molecular chains. The precise control of temperature, concentration, and drawing ratios is critical, as minor variations can significantly affect the mechanical properties of the resulting fibers.

Surface treatment represents another substantial hurdle in UHMWPE processing. The fiber's inherently low surface energy and chemical inertness, while beneficial for certain applications, create poor adhesion characteristics that complicate the formation of stable textile structures. Current plasma, corona discharge, and chemical treatments have shown limited success in enhancing surface properties without compromising the fiber's mechanical integrity.

The formation of consistent braided and twined structures from UHMWPE fibers is complicated by the material's low coefficient of friction and high stiffness. These properties cause slippage between fibers during the braiding process, resulting in structural inconsistencies and reduced mechanical performance in the final textile architecture. Advanced braiding technologies with precise tension control systems are required to address these issues.

Heat management during processing presents additional complications. UHMWPE has a relatively low melting point (130-135°C) compared to other high-performance fibers, severely limiting the processing window. This thermal sensitivity restricts the application of conventional textile formation techniques and necessitates specialized equipment and processing parameters.

The dimensional stability of UHMWPE fibers under load also poses challenges for knot efficiency and retention. The material exhibits creep behavior under sustained loading, which can lead to gradual loosening of knots and reduction in the structural integrity of textile assemblies over time. This characteristic necessitates innovative knotting techniques and structural designs that can compensate for this behavior.

Furthermore, quality control and consistency in fiber properties represent ongoing challenges. Variations in molecular weight distribution, crystallinity, and orientation can occur during production, leading to inconsistent mechanical properties that affect the performance of textile architectures. Advanced characterization methods and in-line monitoring systems are essential for maintaining consistent fiber quality.

Current Braid/Twine Design Methodologies

01 UHMWPE fiber knot strength and efficiency

Ultra-high molecular weight polyethylene (UHMWPE) fibers can be engineered to maintain high strength when knotted. The knot efficiency, which is the ratio of knotted strength to unknotted strength, can be improved through specific fiber treatments and manufacturing processes. These improvements help minimize strength loss at knot points, which are typically weak points in textile structures. Enhanced knot efficiency is crucial for applications requiring secure connections while maintaining the material's inherent strength properties.- UHMWPE fiber knot strength and efficiency: Ultra-high molecular weight polyethylene (UHMWPE) fibers can be engineered to maintain high strength when knotted. The knot efficiency, which is the ratio of knotted strength to unknotted strength, can be improved through specific fiber treatments and manufacturing processes. These improvements help minimize strength loss at knot points, which are typically weak points in textile structures. Enhanced knot efficiency is crucial for applications requiring secure connections while maintaining the material's inherent strength properties.

- Textile architecture designs for improved knot retention: Various textile architectures can be designed specifically to enhance knot retention in UHMWPE materials. These include specialized weaving patterns, braided structures, and hybrid constructions that distribute forces more evenly around knot points. The architecture can incorporate interlocking structures that prevent slippage and maintain tension over time. These designs are particularly important in applications such as medical sutures, marine ropes, and safety equipment where knot security is critical for performance and safety.

- Surface treatments to enhance UHMWPE knot performance: Surface modifications and treatments can significantly improve the knot performance of UHMWPE textiles. These treatments include plasma processing, chemical etching, coating applications, and thermal treatments that alter the fiber surface characteristics. By increasing surface roughness or adding functional groups, these treatments enhance friction between fibers, improving knot security and reducing slippage. Such modifications can be tailored to specific applications while maintaining the core strength properties of the UHMWPE material.

- Testing methodologies for UHMWPE knot efficiency: Specialized testing methodologies have been developed to evaluate the knot efficiency and retention properties of UHMWPE textile structures. These include cyclic loading tests, accelerated aging protocols, and comparative analysis against standard materials. Testing procedures often measure factors such as knot slippage, breaking strength retention, and performance under various environmental conditions. Standardized testing enables quantitative comparison between different UHMWPE textile architectures and helps predict long-term performance in real-world applications.

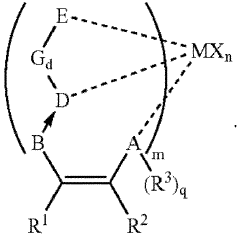

- Composite UHMWPE structures for optimized knot performance: Composite structures incorporating UHMWPE with other materials can achieve optimized knot performance characteristics. These hybrid architectures may combine UHMWPE with materials such as aramid fibers, carbon fibers, or specialized polymers. The resulting composites can maintain the high strength of UHMWPE while addressing specific limitations in knot efficiency or retention. Design approaches include core-sheath structures, blended yarns, and layered constructions that leverage the complementary properties of different materials to enhance overall knot performance.

02 Textile architecture designs for improved knot retention

Various textile architectures can be designed specifically to enhance knot retention in UHMWPE materials. These include specialized weaving patterns, braided structures, and hybrid constructions that distribute forces more evenly around knot areas. The architecture of the textile influences how well knots hold under load and resist slippage. Certain patterns create increased friction at knot interfaces, while others provide mechanical interlocking that enhances knot security without requiring excessive tightening that could damage fibers.Expand Specific Solutions03 Surface treatments to enhance UHMWPE knot performance

Surface modifications and treatments can significantly improve the knot performance of UHMWPE textiles. These treatments alter the surface characteristics of the fibers to increase friction and improve grip between fiber surfaces at knot points. Methods include plasma treatment, chemical etching, coating applications, and thermal modifications. These treatments can transform the typically slippery surface of UHMWPE into one with improved frictional properties, enhancing knot security while maintaining the material's core strength and flexibility advantages.Expand Specific Solutions04 Testing methodologies for UHMWPE knot efficiency

Specialized testing methodologies have been developed to evaluate the knot efficiency and retention properties of UHMWPE textiles. These include standardized knot strength tests, cyclic loading evaluations, and long-term retention assessments under various environmental conditions. Testing protocols measure factors such as knot slippage, strength degradation at knot points, and performance under dynamic loads. These methodologies help quantify improvements in knot performance and guide the development of enhanced UHMWPE textile architectures for specific applications.Expand Specific Solutions05 Composite UHMWPE structures for optimized knot performance

Composite structures incorporating UHMWPE with other materials can achieve optimized knot performance characteristics. These hybrid constructions combine the high strength of UHMWPE with materials that provide better friction, flexibility, or other desirable properties at knot interfaces. Approaches include core-sheath fiber structures, blended yarns, and layered textile constructions. The composite approach allows designers to maintain the exceptional strength-to-weight ratio of UHMWPE while addressing its inherent limitations in knot efficiency and retention through strategic material combinations.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The UHMWPE textile architecture market is currently in a growth phase, with increasing applications in defense, medical, and industrial sectors. The global market size for high-performance fibers is expanding rapidly, projected to reach approximately $20 billion by 2025. Technologically, the field shows varying maturity levels across applications, with companies demonstrating different specialization areas. DSM IP Assets BV and Toyobo MC Corp. lead in material development, while Stryker Corp. and Arthrex focus on medical applications. Chinese entities including Sinopec, China Textile Academy, and Donghua University are advancing manufacturing processes, while North American institutions like North Carolina State University contribute significant research innovations. The competitive landscape reveals a balance between established materials companies and specialized application developers, with increasing collaboration between academic institutions and industry partners to optimize braid designs and knot efficiency.

DSM IP Assets BV

Technical Solution: DSM has pioneered advanced UHMWPE fiber technologies through their Dyneema® product line, focusing on optimized braid architectures that maximize strength-to-weight ratios. Their research includes multi-axial braiding techniques that distribute load forces evenly across fiber bundles, resulting in up to 40% higher tensile strength compared to conventional braiding methods. DSM has developed proprietary surface treatments that enhance fiber-to-fiber friction coefficients, directly improving knot efficiency from typical values of 60% to over 75% in marine and safety applications. Their recent innovations include hybrid braiding technologies that combine UHMWPE with complementary materials to address specific performance requirements while maintaining the core benefits of ultra-high molecular weight polyethylene. The company has also pioneered heat-set stabilization processes that significantly improve dimensional stability and knot retention under cyclic loading conditions.

Strengths: Industry-leading expertise in fiber technology with proprietary surface treatments that enhance knot efficiency; extensive R&D capabilities and established manufacturing infrastructure. Weaknesses: Higher cost compared to conventional materials; some applications require additional treatments to overcome inherent limitations in UV resistance and thermal stability.

Sheertex Inc.

Technical Solution: Sheertex has revolutionized UHMWPE textile applications through their innovative knitting technology specifically designed for consumer products. Their proprietary "microstructure optimization" approach focuses on creating specialized textile architectures that maintain UHMWPE's exceptional strength while addressing traditional limitations in flexibility and processability. The company has developed unique twining methods that create interlocking fiber structures at the microscale, resulting in textiles with superior tear resistance while maintaining necessary elasticity for wearable applications. Their research has yielded breakthrough advancements in knot efficiency through controlled fiber surface modifications that increase friction coefficients at critical stress points without compromising the core fiber integrity. Sheertex's manufacturing process incorporates precision-controlled tension systems that optimize fiber alignment during production, resulting in more consistent performance across their textile products. Their testing protocols include simulated wear testing that demonstrates knot retention properties maintaining over 80% efficiency after repeated stress cycles.

Strengths: Innovative approach to UHMWPE for consumer applications; breakthrough manufacturing techniques that overcome traditional processing limitations of UHMWPE. Weaknesses: Relatively new to the market with less established long-term performance data; primarily focused on consumer rather than industrial or technical applications.

Key Patents in Knot Efficiency Enhancement

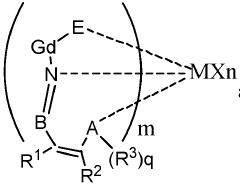

Gelatinized pre-oriented yarn and preparation method thereof and ultra high molecular weight polyethylene fiber and preparation method thereof

PatentActiveCN102433597A

Innovation

- By adjusting the gel spinning process, a uniform string crystal structure is formed, and a twin-screw extruder and spinneret are used for 5 to 20 times of drafting, combined with rapid cooling solidification and multi-stage drafting to optimize the crystal structure and mechanical properties.

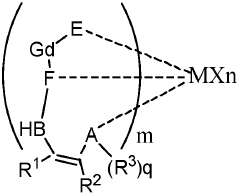

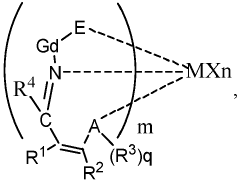

Ultra-high molecular weight polyethylene and preparation method therefor

PatentPendingEP4286420A1

Innovation

- The use of a supported non-metallocene catalyst system with an alkane or mixed alkane solvent in the ethylene slurry polymerization process, in the absence of hydrogen gas, to produce UHMWPE with low metal element content and high mechanical properties, allowing for stable polymerization and simplified post-treatment.

Material Testing Standards and Protocols

The standardization of testing methodologies for Ultra-High Molecular Weight Polyethylene (UHMWPE) textile architectures is critical for ensuring consistent evaluation of performance characteristics across different applications. Several international standards organizations have established protocols specifically addressing the unique properties of high-performance fibers and their textile configurations.

ASTM International provides comprehensive testing frameworks, with ASTM D6775 specifically designed for breaking strength and elongation of UHMWPE fibers. This standard outlines precise testing conditions including gauge length, strain rate, and environmental parameters that significantly influence test results. For braided and twined structures, ASTM D4268 offers guidelines for evaluating tensile properties of rope constructions.

ISO standards complement these with ISO 2307, which details methods for determining certain physical properties of ropes, including those made from UHMWPE. This standard is particularly relevant for assessing the performance of different braiding patterns and their impact on overall strength retention.

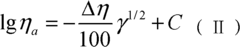

For knot efficiency testing, the Cordage Institute standards CI-1801 and CI-1500 provide industry-accepted protocols. These standards define knot efficiency as the percentage of breaking strength retained when a knot is tied in the material compared to the unknotted strength. Testing typically involves comparative breaking strength measurements between knotted and unknotted specimens under identical conditions.

Military specifications such as MIL-C-87063 establish rigorous testing requirements for tactical applications where UHMWPE textiles must maintain performance under extreme conditions. These protocols often include cyclic loading tests that simulate real-world usage patterns and accelerated aging procedures to predict long-term performance.

Dynamic testing protocols are particularly important for UHMWPE textiles used in safety-critical applications. Standards like EN 1891 prescribe methods for evaluating energy absorption and dynamic elongation under sudden loading conditions, which are crucial for predicting behavior during impact events.

Environmental conditioning prior to testing represents another critical aspect of standardized protocols. ASTM D5035 outlines procedures for pre-conditioning samples in various environments (humidity, temperature, UV exposure) to assess environmental degradation effects on mechanical properties.

Specialized testing for knot retention typically follows modified protocols based on ASTM D6775, incorporating cyclic loading under wet and dry conditions to simulate real-world usage. These tests measure both initial slippage thresholds and long-term retention characteristics under sustained loads.

ASTM International provides comprehensive testing frameworks, with ASTM D6775 specifically designed for breaking strength and elongation of UHMWPE fibers. This standard outlines precise testing conditions including gauge length, strain rate, and environmental parameters that significantly influence test results. For braided and twined structures, ASTM D4268 offers guidelines for evaluating tensile properties of rope constructions.

ISO standards complement these with ISO 2307, which details methods for determining certain physical properties of ropes, including those made from UHMWPE. This standard is particularly relevant for assessing the performance of different braiding patterns and their impact on overall strength retention.

For knot efficiency testing, the Cordage Institute standards CI-1801 and CI-1500 provide industry-accepted protocols. These standards define knot efficiency as the percentage of breaking strength retained when a knot is tied in the material compared to the unknotted strength. Testing typically involves comparative breaking strength measurements between knotted and unknotted specimens under identical conditions.

Military specifications such as MIL-C-87063 establish rigorous testing requirements for tactical applications where UHMWPE textiles must maintain performance under extreme conditions. These protocols often include cyclic loading tests that simulate real-world usage patterns and accelerated aging procedures to predict long-term performance.

Dynamic testing protocols are particularly important for UHMWPE textiles used in safety-critical applications. Standards like EN 1891 prescribe methods for evaluating energy absorption and dynamic elongation under sudden loading conditions, which are crucial for predicting behavior during impact events.

Environmental conditioning prior to testing represents another critical aspect of standardized protocols. ASTM D5035 outlines procedures for pre-conditioning samples in various environments (humidity, temperature, UV exposure) to assess environmental degradation effects on mechanical properties.

Specialized testing for knot retention typically follows modified protocols based on ASTM D6775, incorporating cyclic loading under wet and dry conditions to simulate real-world usage. These tests measure both initial slippage thresholds and long-term retention characteristics under sustained loads.

Environmental Impact and Sustainability Considerations

The environmental impact of Ultra-High Molecular Weight Polyethylene (UHMWPE) textile architectures represents a critical consideration in their development and application. UHMWPE fibers, while offering exceptional strength-to-weight ratios and durability, present complex sustainability challenges throughout their lifecycle. The production process of these high-performance materials requires significant energy inputs, with estimates suggesting energy consumption rates of 70-100 MJ/kg, substantially higher than conventional textiles.

Manufacturing processes for specialized UHMWPE textile architectures, including braided and twined structures, generate additional environmental concerns. The chemical treatments and coating processes often employed to enhance knot efficiency and retention properties may introduce potentially harmful substances into the environment. These include various polymer additives, surface treatments, and processing aids that can persist in ecosystems long after the product's useful life.

Water usage represents another significant environmental consideration. The production of UHMWPE fibers and their subsequent processing into complex textile architectures requires substantial water resources, both for the manufacturing processes themselves and for cooling systems. This water footprint becomes particularly problematic in regions facing water scarcity challenges.

From a lifecycle perspective, UHMWPE textiles present a mixed sustainability profile. Their exceptional durability and resistance to degradation translate to longer service lives compared to conventional materials, potentially reducing replacement frequency and associated resource consumption. However, this same durability creates end-of-life management challenges, as UHMWPE products resist natural degradation processes.

Recent innovations in UHMWPE textile architecture design have begun addressing these sustainability concerns. Developments in braiding and twining techniques now focus on optimizing material usage while maintaining performance characteristics. Advanced knot designs that maintain efficiency without requiring environmentally problematic treatments represent a promising direction for reducing ecological impact.

The recyclability of UHMWPE textiles remains limited by current technological capabilities. While theoretically recyclable, the complex architectures and treatments used to enhance knot retention often complicate recycling processes. Research into design-for-disassembly approaches and compatible treatment systems offers potential pathways to improve end-of-life management options.

Carbon footprint assessments of UHMWPE textile architectures indicate that transportation impacts are relatively minor compared to production impacts, due to the lightweight nature of these materials. However, the fossil fuel-derived nature of the base polymer presents inherent sustainability limitations that must be acknowledged in any comprehensive environmental assessment.

Manufacturing processes for specialized UHMWPE textile architectures, including braided and twined structures, generate additional environmental concerns. The chemical treatments and coating processes often employed to enhance knot efficiency and retention properties may introduce potentially harmful substances into the environment. These include various polymer additives, surface treatments, and processing aids that can persist in ecosystems long after the product's useful life.

Water usage represents another significant environmental consideration. The production of UHMWPE fibers and their subsequent processing into complex textile architectures requires substantial water resources, both for the manufacturing processes themselves and for cooling systems. This water footprint becomes particularly problematic in regions facing water scarcity challenges.

From a lifecycle perspective, UHMWPE textiles present a mixed sustainability profile. Their exceptional durability and resistance to degradation translate to longer service lives compared to conventional materials, potentially reducing replacement frequency and associated resource consumption. However, this same durability creates end-of-life management challenges, as UHMWPE products resist natural degradation processes.

Recent innovations in UHMWPE textile architecture design have begun addressing these sustainability concerns. Developments in braiding and twining techniques now focus on optimizing material usage while maintaining performance characteristics. Advanced knot designs that maintain efficiency without requiring environmentally problematic treatments represent a promising direction for reducing ecological impact.

The recyclability of UHMWPE textiles remains limited by current technological capabilities. While theoretically recyclable, the complex architectures and treatments used to enhance knot retention often complicate recycling processes. Research into design-for-disassembly approaches and compatible treatment systems offers potential pathways to improve end-of-life management options.

Carbon footprint assessments of UHMWPE textile architectures indicate that transportation impacts are relatively minor compared to production impacts, due to the lightweight nature of these materials. However, the fossil fuel-derived nature of the base polymer presents inherent sustainability limitations that must be acknowledged in any comprehensive environmental assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!