UHMWPE Surface Activation: Plasma, Corona And Grafting For Bond Integrity

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Surface Activation Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a critical engineering material across various industries due to its exceptional mechanical properties, including high impact strength, excellent abrasion resistance, and low friction coefficient. The development of UHMWPE dates back to the 1950s, with significant advancements occurring in the 1970s and 1980s that expanded its applications from industrial components to medical implants and ballistic protection.

Despite its remarkable physical properties, UHMWPE presents significant challenges in bonding and adhesion processes due to its inherently low surface energy, chemical inertness, and non-polar nature. These characteristics, while beneficial for many applications, create substantial obstacles when integration with other materials is required. The evolution of surface activation technologies for UHMWPE has therefore become a crucial area of research and development over the past three decades.

The technical progression in this field has followed three main pathways: plasma treatment, corona discharge, and chemical grafting methods. Plasma treatment technologies have evolved from simple oxygen plasma systems to sophisticated atmospheric pressure plasma jets with precise control parameters. Corona discharge techniques have transitioned from basic industrial applications to more refined processes with controlled atmospheric conditions. Chemical grafting approaches have advanced from conventional peroxide-based methods to innovative radiation-induced grafting techniques.

The primary objective of UHMWPE surface activation research is to develop reliable, scalable, and cost-effective methods that can create strong and durable bonds without compromising the bulk properties of the material. This includes achieving consistent surface modification across complex geometries, ensuring long-term stability of the activated surface, and developing processes compatible with existing manufacturing workflows.

Additional technical goals include reducing the environmental impact of surface activation processes, minimizing processing time and energy requirements, and creating activation methods that can be tailored to specific end-use applications. The ideal solution would provide a balance between bond strength, processing efficiency, and preservation of UHMWPE's valuable inherent properties.

Recent technological trends indicate a growing interest in hybrid approaches that combine multiple activation methods, as well as the development of environmentally friendly alternatives to traditional chemical treatments. The integration of real-time monitoring and quality control systems into activation processes represents another important direction, aimed at ensuring consistent results in industrial settings.

Despite its remarkable physical properties, UHMWPE presents significant challenges in bonding and adhesion processes due to its inherently low surface energy, chemical inertness, and non-polar nature. These characteristics, while beneficial for many applications, create substantial obstacles when integration with other materials is required. The evolution of surface activation technologies for UHMWPE has therefore become a crucial area of research and development over the past three decades.

The technical progression in this field has followed three main pathways: plasma treatment, corona discharge, and chemical grafting methods. Plasma treatment technologies have evolved from simple oxygen plasma systems to sophisticated atmospheric pressure plasma jets with precise control parameters. Corona discharge techniques have transitioned from basic industrial applications to more refined processes with controlled atmospheric conditions. Chemical grafting approaches have advanced from conventional peroxide-based methods to innovative radiation-induced grafting techniques.

The primary objective of UHMWPE surface activation research is to develop reliable, scalable, and cost-effective methods that can create strong and durable bonds without compromising the bulk properties of the material. This includes achieving consistent surface modification across complex geometries, ensuring long-term stability of the activated surface, and developing processes compatible with existing manufacturing workflows.

Additional technical goals include reducing the environmental impact of surface activation processes, minimizing processing time and energy requirements, and creating activation methods that can be tailored to specific end-use applications. The ideal solution would provide a balance between bond strength, processing efficiency, and preservation of UHMWPE's valuable inherent properties.

Recent technological trends indicate a growing interest in hybrid approaches that combine multiple activation methods, as well as the development of environmentally friendly alternatives to traditional chemical treatments. The integration of real-time monitoring and quality control systems into activation processes represents another important direction, aimed at ensuring consistent results in industrial settings.

Market Analysis for Modified UHMWPE Applications

The global market for modified Ultra-High Molecular Weight Polyethylene (UHMWPE) has experienced significant growth in recent years, driven by increasing demand across multiple industries. The market size for modified UHMWPE reached approximately $2.1 billion in 2022 and is projected to grow at a CAGR of 9.7% through 2030, reflecting the expanding applications of this versatile material.

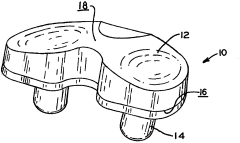

Healthcare and medical devices represent the largest application segment, accounting for nearly 38% of the modified UHMWPE market. Surface-activated UHMWPE has revolutionized orthopedic implants, particularly in joint replacement components where enhanced bonding with bone cement and biological tissues is critical. The aging global population and rising prevalence of orthopedic conditions continue to drive demand in this sector.

The automotive and transportation industry constitutes the second-largest market segment at 24%, where lightweight, high-strength materials with superior bonding capabilities are increasingly sought after to improve fuel efficiency and meet stringent emissions standards. Surface-activated UHMWPE composites are gaining traction in structural components where adhesion to other materials is essential.

Industrial applications, including chemical processing equipment, mining equipment, and material handling systems, represent approximately 19% of the market. The superior chemical resistance and improved bondability of surface-activated UHMWPE make it ideal for linings, seals, and components in harsh chemical environments.

Regionally, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (27%). The Asia-Pacific region is expected to witness the fastest growth rate of 11.3% annually, driven by rapid industrialization, increasing healthcare infrastructure, and growing automotive production in countries like China and India.

Market dynamics are increasingly influenced by sustainability concerns, with manufacturers developing eco-friendly surface activation methods that reduce environmental impact while maintaining performance characteristics. Plasma treatment methods using atmospheric pressure plasma are gaining preference over traditional corona treatments due to their lower energy consumption and reduced environmental footprint.

Customer preferences are evolving toward customized surface activation solutions tailored to specific bonding requirements. This trend is particularly evident in high-performance applications where precise control over surface properties is critical for product performance and longevity.

The competitive landscape features both specialized material science companies focusing exclusively on UHMWPE modifications and larger chemical conglomerates with diversified product portfolios. Recent market consolidation through mergers and acquisitions indicates the strategic importance of surface activation technologies in the broader advanced materials sector.

Healthcare and medical devices represent the largest application segment, accounting for nearly 38% of the modified UHMWPE market. Surface-activated UHMWPE has revolutionized orthopedic implants, particularly in joint replacement components where enhanced bonding with bone cement and biological tissues is critical. The aging global population and rising prevalence of orthopedic conditions continue to drive demand in this sector.

The automotive and transportation industry constitutes the second-largest market segment at 24%, where lightweight, high-strength materials with superior bonding capabilities are increasingly sought after to improve fuel efficiency and meet stringent emissions standards. Surface-activated UHMWPE composites are gaining traction in structural components where adhesion to other materials is essential.

Industrial applications, including chemical processing equipment, mining equipment, and material handling systems, represent approximately 19% of the market. The superior chemical resistance and improved bondability of surface-activated UHMWPE make it ideal for linings, seals, and components in harsh chemical environments.

Regionally, North America leads the market with a 35% share, followed by Europe (28%) and Asia-Pacific (27%). The Asia-Pacific region is expected to witness the fastest growth rate of 11.3% annually, driven by rapid industrialization, increasing healthcare infrastructure, and growing automotive production in countries like China and India.

Market dynamics are increasingly influenced by sustainability concerns, with manufacturers developing eco-friendly surface activation methods that reduce environmental impact while maintaining performance characteristics. Plasma treatment methods using atmospheric pressure plasma are gaining preference over traditional corona treatments due to their lower energy consumption and reduced environmental footprint.

Customer preferences are evolving toward customized surface activation solutions tailored to specific bonding requirements. This trend is particularly evident in high-performance applications where precise control over surface properties is critical for product performance and longevity.

The competitive landscape features both specialized material science companies focusing exclusively on UHMWPE modifications and larger chemical conglomerates with diversified product portfolios. Recent market consolidation through mergers and acquisitions indicates the strategic importance of surface activation technologies in the broader advanced materials sector.

Current Challenges in UHMWPE Surface Activation

Ultra-high-molecular-weight polyethylene (UHMWPE) presents significant bonding challenges due to its inherently low surface energy and chemical inertness. The material's high crystallinity, molecular weight, and non-polar nature create a hydrophobic surface that resists adhesion to other materials. This characteristic, while beneficial for certain applications, becomes problematic when UHMWPE needs to be bonded in composite structures or multi-material assemblies.

Current plasma treatment methods face efficiency limitations when applied to UHMWPE. The material's resistance to surface modification requires higher energy inputs and longer treatment times compared to conventional polymers. Additionally, the depth of surface activation remains shallow, typically affecting only the top few nanometers, which can be insufficient for applications requiring robust bonding under mechanical stress.

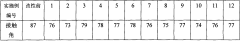

Corona discharge treatments, while more accessible and economical than plasma systems, struggle with uniformity issues when treating complex UHMWPE geometries. The corona effect tends to concentrate on edges and protrusions, leaving recessed areas inadequately activated. This non-uniform treatment creates inconsistent bonding surfaces that compromise overall structural integrity in final applications.

Grafting techniques face challenges related to process complexity and scalability. Chemical grafting methods often require hazardous solvents and precise reaction conditions that are difficult to maintain in industrial settings. The reaction kinetics between grafting agents and the UHMWPE surface remain poorly understood, leading to unpredictable results and batch-to-batch variations in surface properties.

The durability of activated surfaces represents another significant challenge. Surface modifications achieved through current activation methods often demonstrate poor temporal stability, with hydrophobic recovery occurring within hours to days after treatment. This aging effect necessitates tight process integration between activation and bonding steps, limiting manufacturing flexibility and increasing production complexity.

Environmental and regulatory concerns further complicate UHMWPE surface activation. Many traditional chemical treatments involve environmentally harmful substances that face increasing regulatory restrictions. Meanwhile, energy-intensive physical methods contribute to higher carbon footprints, creating tension between performance requirements and sustainability goals.

Quantification and quality control of surface activation remain problematic. Current analytical techniques provide limited real-time feedback on activation effectiveness, making process optimization largely empirical. The lack of standardized testing protocols specific to UHMWPE surface activation further complicates comparative assessment of different treatment methods and establishment of reliable quality control parameters.

Current plasma treatment methods face efficiency limitations when applied to UHMWPE. The material's resistance to surface modification requires higher energy inputs and longer treatment times compared to conventional polymers. Additionally, the depth of surface activation remains shallow, typically affecting only the top few nanometers, which can be insufficient for applications requiring robust bonding under mechanical stress.

Corona discharge treatments, while more accessible and economical than plasma systems, struggle with uniformity issues when treating complex UHMWPE geometries. The corona effect tends to concentrate on edges and protrusions, leaving recessed areas inadequately activated. This non-uniform treatment creates inconsistent bonding surfaces that compromise overall structural integrity in final applications.

Grafting techniques face challenges related to process complexity and scalability. Chemical grafting methods often require hazardous solvents and precise reaction conditions that are difficult to maintain in industrial settings. The reaction kinetics between grafting agents and the UHMWPE surface remain poorly understood, leading to unpredictable results and batch-to-batch variations in surface properties.

The durability of activated surfaces represents another significant challenge. Surface modifications achieved through current activation methods often demonstrate poor temporal stability, with hydrophobic recovery occurring within hours to days after treatment. This aging effect necessitates tight process integration between activation and bonding steps, limiting manufacturing flexibility and increasing production complexity.

Environmental and regulatory concerns further complicate UHMWPE surface activation. Many traditional chemical treatments involve environmentally harmful substances that face increasing regulatory restrictions. Meanwhile, energy-intensive physical methods contribute to higher carbon footprints, creating tension between performance requirements and sustainability goals.

Quantification and quality control of surface activation remain problematic. Current analytical techniques provide limited real-time feedback on activation effectiveness, making process optimization largely empirical. The lack of standardized testing protocols specific to UHMWPE surface activation further complicates comparative assessment of different treatment methods and establishment of reliable quality control parameters.

Comparative Analysis of Plasma, Corona and Grafting Methods

01 Surface treatment methods for UHMWPE bonding

Various surface treatment techniques can be applied to UHMWPE to improve bond integrity. These include plasma treatment, corona discharge, chemical etching, and surface oxidation processes that modify the typically inert UHMWPE surface to create functional groups capable of forming stronger bonds with adhesives or other materials. These treatments increase surface energy and wettability, which are critical factors for achieving strong adhesive bonds with this otherwise difficult-to-bond polymer.- Surface treatment methods for improving UHMWPE bond integrity: Various surface treatment methods can be applied to UHMWPE to enhance its bond integrity with other materials. These treatments modify the surface properties of UHMWPE, which is inherently difficult to bond due to its low surface energy and chemical inertness. Techniques include plasma treatment, corona discharge, chemical etching, and surface oxidation processes that create functional groups on the polymer surface, thereby improving adhesion capabilities and bond strength with adhesives or other materials.

- Composite structures incorporating UHMWPE with enhanced bonding: Specialized composite structures can be designed to maximize the bond integrity of UHMWPE components. These composites often involve strategic layering of materials, incorporation of intermediate bonding layers, or the use of mechanical interlocking features to enhance the connection between UHMWPE and other materials. Such composite structures are particularly valuable in applications requiring high strength-to-weight ratios while maintaining strong interfacial bonding, such as in ballistic protection, medical implants, and industrial components.

- Chemical modification of UHMWPE for improved adhesion: Chemical modification techniques can be employed to alter the molecular structure of UHMWPE, enhancing its bonding capabilities. These methods include grafting functional groups onto the polymer chains, crosslinking treatments, and the incorporation of compatibilizing agents. By introducing reactive sites or increasing the chemical compatibility with adhesives or other materials, these modifications significantly improve the bond integrity of UHMWPE without compromising its desirable mechanical properties such as wear resistance and impact strength.

- Thermal bonding techniques for UHMWPE: Specialized thermal bonding techniques have been developed to address the challenges of joining UHMWPE components. These methods include controlled heat fusion processes, ultrasonic welding adapted for high-molecular-weight polymers, and thermal compression bonding under specific pressure and temperature conditions. These techniques carefully manage the thermal profile to achieve molecular entanglement at interfaces without degrading the polymer's unique properties, resulting in strong, durable bonds between UHMWPE components or between UHMWPE and compatible materials.

- Adhesive systems specifically formulated for UHMWPE: Specialized adhesive systems have been developed to overcome the bonding challenges presented by UHMWPE's low surface energy. These adhesive formulations often incorporate specific primers, surface activators, or multi-component systems designed to interact effectively with the non-polar UHMWPE surface. Some advanced adhesives include nanoparticle reinforcements or polymer blends that enhance the mechanical interlocking and chemical interaction with UHMWPE, resulting in significantly improved bond strength and durability in demanding applications.

02 Adhesive formulations for UHMWPE bonding

Specialized adhesive formulations have been developed specifically for bonding UHMWPE. These include modified epoxy resins, polyurethane-based adhesives, and silane coupling agents that can form strong chemical bonds with treated UHMWPE surfaces. Some formulations incorporate reactive components that can penetrate the polymer surface or create mechanical interlocking at the molecular level, enhancing bond strength and durability under mechanical stress and environmental exposure.Expand Specific Solutions03 Thermal bonding techniques for UHMWPE

Thermal bonding methods provide effective solutions for joining UHMWPE components. These techniques include heat fusion, ultrasonic welding, and laser welding processes that temporarily melt the polymer interface to create strong molecular entanglements upon cooling. Controlled heating parameters and pressure application during the bonding process are critical to prevent material degradation while achieving optimal molecular diffusion across the bond interface, resulting in high-integrity joints.Expand Specific Solutions04 Composite structures with UHMWPE

Innovative composite structures incorporate UHMWPE with other materials to leverage its exceptional properties while addressing bonding challenges. These include fiber-reinforced composites, multi-layer laminates, and hybrid structures that use intermediate bonding layers or mechanical interlocking features. Such designs often employ specialized interface materials that are compatible with both UHMWPE and the secondary material, creating strong bonds through mechanical anchoring or chemical compatibility at the interface.Expand Specific Solutions05 Testing and evaluation of UHMWPE bond integrity

Various methods have been developed to assess and ensure the integrity of UHMWPE bonds. These include mechanical testing protocols such as peel strength, shear strength, and tensile testing, as well as accelerated aging tests to evaluate long-term durability. Advanced analytical techniques like scanning electron microscopy, infrared spectroscopy, and X-ray photoelectron spectroscopy are employed to characterize the bond interface at the molecular level, providing insights into bonding mechanisms and failure modes.Expand Specific Solutions

Key Industry Players in Polymer Surface Modification

The UHMWPE surface activation market is currently in a growth phase, with increasing applications across medical, automotive, and industrial sectors. The global market size for surface treatment technologies is expanding at approximately 5-7% annually, driven by demand for enhanced bonding solutions. Technologically, plasma treatment represents the most mature approach, with companies like Shanghai Lianle Chemical and Fraunhofer-Gesellschaft leading innovations. Corona discharge methods are gaining traction through advancements by Saint-Gobain Performance Plastics and tesa SE. Meanwhile, grafting techniques are emerging as promising alternatives, with significant research contributions from Donghua University and Zhejiang University. The competitive landscape shows a mix of specialized material manufacturers, research institutions, and end-users like AUDI AG and Zimmer Inc., indicating a diversifying ecosystem with increasing cross-industry applications.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed advanced plasma activation techniques specifically for UHMWPE surface modification. Their approach utilizes low-pressure plasma treatments with various gas compositions (oxygen, nitrogen, argon) to create tailored surface functionalities. The process involves precise control of plasma parameters including power density (typically 0.1-2.0 W/cm²), exposure time (30-300 seconds), and gas flow rates to optimize surface energy without compromising the bulk properties of UHMWPE. Their research demonstrates significant improvements in bond strength, with adhesion increases of up to 300% compared to untreated surfaces. Fraunhofer has also pioneered atmospheric pressure plasma systems that allow for continuous in-line processing of UHMWPE components, making the technology more accessible for industrial applications. Their plasma activation chambers incorporate specialized electrode configurations that ensure uniform treatment across complex geometries, addressing one of the key challenges in UHMWPE surface modification.

Strengths: Exceptional control over surface chemistry with customizable functional groups; scalable from laboratory to industrial production; non-destructive to bulk material properties. Weaknesses: Higher equipment costs compared to corona treatments; requires more precise process control parameters; some configurations may have limited penetration depth for complex geometries.

Ningbo Institute of Industrial Technology

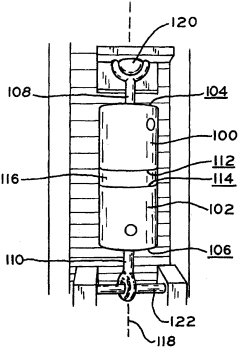

Technical Solution: Ningbo Institute has developed an innovative atmospheric pressure plasma jet (APPJ) system specifically optimized for UHMWPE surface activation. Their technology utilizes a helium-oxygen gas mixture (typically 98:2 ratio) delivered through a specialized nozzle design that creates a stable plasma plume at atmospheric conditions. The system operates at relatively low power (100-300W) while achieving high activation efficiency through precise control of the plasma-surface interaction zone. Their research demonstrates that this approach creates oxygen-containing functional groups (primarily -OH, -COOH, and C=O) at densities of 3-7 μmol/cm² without causing thermal damage to the substrate. The institute has also developed a robotic control system that enables precise treatment of complex 3D UHMWPE components with consistent results. Their studies show that treated surfaces maintain enhanced adhesion properties for extended periods (>6 months) when stored in controlled environments. Additionally, they've pioneered a post-treatment stabilization process using specialized coupling agents that further enhances bond durability, particularly in humid conditions. The technology has been successfully applied to UHMWPE components for automotive and medical applications.

Strengths: Atmospheric pressure operation eliminates need for vacuum systems; highly adaptable to complex geometries; energy-efficient process with minimal thermal impact. Weaknesses: Treatment uniformity can be challenging on large surfaces; requires precise control of standoff distance; gas consumption (particularly helium) adds to operational costs.

Critical Patents and Research in UHMWPE Activation

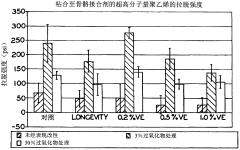

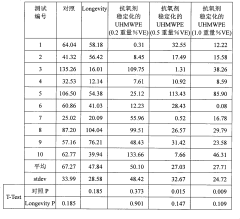

Surface modification of ultrahigh molecular weight polyethylene

PatentInactiveCN102405252A

Innovation

- By using hydrogen peroxide aqueous solution to treat the surface of UHMWPE components, chemical bonds are formed to bond with the PMMA bone cement to improve the bonding strength, and can be combined with antioxidant-stabilized UHMWPE to enhance the bonding effect.

Method for improving surface bonding strength of high molecular weight polyethylene (UHMWPE) fibre

PatentInactiveCN101988266A

Innovation

- The UHMWPE fiber surface is swollen and treated with a compatible solvent to form a transition layer to improve the wetting performance and bonding strength of the fiber surface. The specific steps include swelling at 60 to 135°C for 5 to 60 minutes to form a loose structure, and then Use 0.01 to 5% phase solvent at 70 to 100°C for 1 to 30 minutes to form a sub-grained region in which heterogeneous phases coexist, enhancing the wettability and reactivity of the resin.

Environmental Impact of Surface Activation Processes

The surface activation processes employed for UHMWPE bonding carry significant environmental implications that warrant careful consideration in industrial applications. Plasma treatment systems, while effective for surface modification, consume substantial electrical energy and often utilize greenhouse gases such as methane, oxygen, or argon as process gases. Modern plasma systems have improved energy efficiency, but their carbon footprint remains a concern, particularly in large-scale manufacturing operations where continuous processing is required.

Corona discharge treatments present a somewhat lower environmental impact profile compared to plasma systems. They operate at atmospheric pressure, eliminating the need for vacuum pumps and reducing energy consumption. However, corona processes generate ozone as a byproduct, which is a potent air pollutant and potential health hazard requiring proper ventilation and mitigation systems in production environments.

Chemical grafting methods introduce additional environmental considerations due to their reliance on potentially hazardous chemical reagents. Many grafting processes utilize organic solvents, initiators, and monomers that may pose risks to aquatic ecosystems if improperly disposed of. The production, transportation, and disposal of these chemicals contribute to the overall environmental footprint of grafting-based activation approaches.

Waste management represents a critical environmental challenge across all surface activation technologies. Plasma and corona treatments generate minimal direct waste but may produce volatile organic compounds (VOCs) during processing. Chemical grafting generates liquid waste streams containing unreacted reagents and byproducts that require specialized treatment before disposal.

Recent sustainability initiatives have focused on developing greener alternatives for UHMWPE surface activation. These include water-based chemical treatments, biodegradable grafting agents, and energy-efficient plasma systems utilizing renewable electricity sources. Life cycle assessment (LCA) studies indicate that optimizing process parameters can significantly reduce environmental impacts while maintaining bond integrity performance.

Regulatory frameworks governing environmental aspects of surface activation are becoming increasingly stringent worldwide. Manufacturers implementing UHMWPE activation processes must navigate complex compliance requirements related to air emissions, chemical handling, and waste disposal. This regulatory landscape is driving innovation toward more environmentally benign activation technologies that maintain technical performance while reducing ecological footprint.

The selection of appropriate surface activation technology should therefore include comprehensive environmental impact assessment alongside technical performance criteria, particularly for high-volume applications where cumulative effects become significant.

Corona discharge treatments present a somewhat lower environmental impact profile compared to plasma systems. They operate at atmospheric pressure, eliminating the need for vacuum pumps and reducing energy consumption. However, corona processes generate ozone as a byproduct, which is a potent air pollutant and potential health hazard requiring proper ventilation and mitigation systems in production environments.

Chemical grafting methods introduce additional environmental considerations due to their reliance on potentially hazardous chemical reagents. Many grafting processes utilize organic solvents, initiators, and monomers that may pose risks to aquatic ecosystems if improperly disposed of. The production, transportation, and disposal of these chemicals contribute to the overall environmental footprint of grafting-based activation approaches.

Waste management represents a critical environmental challenge across all surface activation technologies. Plasma and corona treatments generate minimal direct waste but may produce volatile organic compounds (VOCs) during processing. Chemical grafting generates liquid waste streams containing unreacted reagents and byproducts that require specialized treatment before disposal.

Recent sustainability initiatives have focused on developing greener alternatives for UHMWPE surface activation. These include water-based chemical treatments, biodegradable grafting agents, and energy-efficient plasma systems utilizing renewable electricity sources. Life cycle assessment (LCA) studies indicate that optimizing process parameters can significantly reduce environmental impacts while maintaining bond integrity performance.

Regulatory frameworks governing environmental aspects of surface activation are becoming increasingly stringent worldwide. Manufacturers implementing UHMWPE activation processes must navigate complex compliance requirements related to air emissions, chemical handling, and waste disposal. This regulatory landscape is driving innovation toward more environmentally benign activation technologies that maintain technical performance while reducing ecological footprint.

The selection of appropriate surface activation technology should therefore include comprehensive environmental impact assessment alongside technical performance criteria, particularly for high-volume applications where cumulative effects become significant.

Industrial Scale-up and Manufacturing Considerations

Scaling up UHMWPE surface activation technologies from laboratory to industrial production presents significant challenges that require careful consideration of equipment design, process parameters, and quality control systems. For plasma treatment, industrial implementation necessitates large-scale vacuum chambers or atmospheric plasma systems capable of treating high volumes of UHMWPE components continuously. These systems must maintain uniform plasma distribution across large surface areas while managing heat generation to prevent polymer degradation.

Corona discharge systems offer advantages for industrial scale-up due to their relatively simple design and ability to operate at atmospheric pressure. However, manufacturers must address electrode configuration optimization to ensure consistent treatment across varying product geometries. The integration of corona treatment into existing production lines requires precise control of treatment speed, discharge intensity, and electrode-to-substrate distance to maintain bond integrity specifications.

For grafting processes, the transition to industrial scale demands sophisticated chemical handling systems, precise temperature control, and effective waste management protocols. Batch-to-batch consistency becomes particularly challenging when scaling up grafting reactions, necessitating robust in-line monitoring systems to verify surface modification parameters in real-time.

Energy consumption represents a significant consideration for all activation methods at industrial scale. Plasma systems typically require substantial power inputs, while corona treatments offer more energy-efficient alternatives for certain applications. Manufacturers must conduct comprehensive cost-benefit analyses that account for equipment investment, operational expenses, and maintenance requirements when selecting appropriate activation technologies.

Quality assurance protocols must evolve to accommodate high-volume production, incorporating automated inspection systems capable of detecting surface activation inconsistencies. Non-destructive testing methods such as contact angle measurement stations, FTIR spectroscopy, or XPS sampling can be strategically positioned within production lines to provide continuous feedback on treatment effectiveness.

Workplace safety considerations become increasingly important at industrial scale, particularly for plasma and corona systems that generate ozone, UV radiation, and electrical hazards. Engineering controls, including proper ventilation systems, shielding, and automated safety interlocks, must be implemented to protect production personnel.

The development of specialized fixtures and handling systems represents another critical aspect of industrial implementation, as UHMWPE components must maintain precise positioning during activation processes to ensure uniform treatment. These systems must accommodate the dimensional variability inherent in polymer manufacturing while preventing contamination of activated surfaces prior to bonding operations.

Corona discharge systems offer advantages for industrial scale-up due to their relatively simple design and ability to operate at atmospheric pressure. However, manufacturers must address electrode configuration optimization to ensure consistent treatment across varying product geometries. The integration of corona treatment into existing production lines requires precise control of treatment speed, discharge intensity, and electrode-to-substrate distance to maintain bond integrity specifications.

For grafting processes, the transition to industrial scale demands sophisticated chemical handling systems, precise temperature control, and effective waste management protocols. Batch-to-batch consistency becomes particularly challenging when scaling up grafting reactions, necessitating robust in-line monitoring systems to verify surface modification parameters in real-time.

Energy consumption represents a significant consideration for all activation methods at industrial scale. Plasma systems typically require substantial power inputs, while corona treatments offer more energy-efficient alternatives for certain applications. Manufacturers must conduct comprehensive cost-benefit analyses that account for equipment investment, operational expenses, and maintenance requirements when selecting appropriate activation technologies.

Quality assurance protocols must evolve to accommodate high-volume production, incorporating automated inspection systems capable of detecting surface activation inconsistencies. Non-destructive testing methods such as contact angle measurement stations, FTIR spectroscopy, or XPS sampling can be strategically positioned within production lines to provide continuous feedback on treatment effectiveness.

Workplace safety considerations become increasingly important at industrial scale, particularly for plasma and corona systems that generate ozone, UV radiation, and electrical hazards. Engineering controls, including proper ventilation systems, shielding, and automated safety interlocks, must be implemented to protect production personnel.

The development of specialized fixtures and handling systems represents another critical aspect of industrial implementation, as UHMWPE components must maintain precise positioning during activation processes to ensure uniform treatment. These systems must accommodate the dimensional variability inherent in polymer manufacturing while preventing contamination of activated surfaces prior to bonding operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!