UHMWPE For Prosthetic And Orthotic Frames: Stiffness, Fatigue And Connector Integrity

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Technology Background and Objectives

Ultra-High Molecular Weight Polyethylene (UHMWPE) has emerged as a revolutionary material in the field of prosthetics and orthotics over the past four decades. Initially developed for industrial applications in the 1950s, UHMWPE's unique combination of properties—including exceptional wear resistance, self-lubrication, high impact strength, and biocompatibility—has positioned it as a material of significant interest in medical applications since the 1980s.

The evolution of UHMWPE technology has been marked by continuous improvements in manufacturing processes, from compression molding to ram extrusion and more recently, advanced techniques like selective laser sintering. These developments have progressively enhanced the material's performance characteristics, particularly in terms of mechanical properties and longevity.

In the prosthetic and orthotic industry, the transition from traditional materials such as metals, wood, and thermoplastics to advanced polymers like UHMWPE represents a paradigm shift in frame design and functionality. This transition has been driven by the increasing demand for lighter, more durable, and more comfortable assistive devices that can withstand the rigors of daily use while providing optimal support.

The current technological landscape presents several challenges that need to be addressed to fully leverage UHMWPE's potential in prosthetic and orthotic applications. These include optimizing stiffness for different patient needs, enhancing fatigue resistance for long-term durability, and developing reliable connector systems that maintain structural integrity under various loading conditions.

Recent research has focused on modifying UHMWPE's properties through cross-linking, reinforcement with fibers or nanoparticles, and surface treatments to improve its performance characteristics. These modifications aim to address specific requirements in prosthetic and orthotic applications, such as controlled flexibility, enhanced durability, and improved integration with other components.

The primary objective of this technical research is to comprehensively evaluate UHMWPE's capabilities and limitations as a frame material for prosthetic and orthotic devices, with particular emphasis on stiffness modulation, fatigue resistance, and connector integrity. By understanding these critical aspects, we aim to identify optimal design parameters and processing techniques that can maximize UHMWPE's effectiveness in creating assistive devices that offer superior performance, comfort, and longevity.

Additionally, this research seeks to establish a roadmap for future innovations in UHMWPE-based prosthetic and orthotic frames, anticipating emerging technologies and methodologies that could further enhance the material's properties and expand its applications in rehabilitation engineering.

The evolution of UHMWPE technology has been marked by continuous improvements in manufacturing processes, from compression molding to ram extrusion and more recently, advanced techniques like selective laser sintering. These developments have progressively enhanced the material's performance characteristics, particularly in terms of mechanical properties and longevity.

In the prosthetic and orthotic industry, the transition from traditional materials such as metals, wood, and thermoplastics to advanced polymers like UHMWPE represents a paradigm shift in frame design and functionality. This transition has been driven by the increasing demand for lighter, more durable, and more comfortable assistive devices that can withstand the rigors of daily use while providing optimal support.

The current technological landscape presents several challenges that need to be addressed to fully leverage UHMWPE's potential in prosthetic and orthotic applications. These include optimizing stiffness for different patient needs, enhancing fatigue resistance for long-term durability, and developing reliable connector systems that maintain structural integrity under various loading conditions.

Recent research has focused on modifying UHMWPE's properties through cross-linking, reinforcement with fibers or nanoparticles, and surface treatments to improve its performance characteristics. These modifications aim to address specific requirements in prosthetic and orthotic applications, such as controlled flexibility, enhanced durability, and improved integration with other components.

The primary objective of this technical research is to comprehensively evaluate UHMWPE's capabilities and limitations as a frame material for prosthetic and orthotic devices, with particular emphasis on stiffness modulation, fatigue resistance, and connector integrity. By understanding these critical aspects, we aim to identify optimal design parameters and processing techniques that can maximize UHMWPE's effectiveness in creating assistive devices that offer superior performance, comfort, and longevity.

Additionally, this research seeks to establish a roadmap for future innovations in UHMWPE-based prosthetic and orthotic frames, anticipating emerging technologies and methodologies that could further enhance the material's properties and expand its applications in rehabilitation engineering.

Market Analysis for UHMWPE in Prosthetic Applications

The global market for Ultra-High-Molecular-Weight Polyethylene (UHMWPE) in prosthetic applications has been experiencing steady growth, driven by increasing prevalence of limb loss and musculoskeletal disorders worldwide. Currently valued at approximately 320 million USD, this specialized segment is projected to grow at a compound annual growth rate of 6.8% through 2028, outpacing the broader medical polymers market.

Demographic factors significantly influence market demand, with aging populations in developed regions contributing substantially to market expansion. The World Health Organization reports over 40 million individuals requiring prosthetic and orthotic devices globally, with this number expected to increase by 25% by 2030 due to rising incidence of diabetes, vascular diseases, and trauma cases.

Regional market analysis reveals North America as the dominant market for UHMWPE prosthetic applications, accounting for roughly 38% of global consumption. This leadership position stems from advanced healthcare infrastructure, higher adoption rates of premium materials, and substantial reimbursement support. Europe follows closely at 32% market share, while Asia-Pacific represents the fastest-growing region with annual growth exceeding 9%, primarily driven by improving healthcare access in China and India.

The prosthetic frames segment constitutes the largest application area for UHMWPE, representing approximately 45% of total market value. Lower limb prosthetics dominate this category due to higher incidence of lower extremity amputations. Upper limb applications, though smaller in volume, are witnessing accelerated growth due to innovations in lightweight, high-performance materials that better replicate natural movement.

Price sensitivity varies significantly across market segments. While developed markets prioritize performance characteristics such as fatigue resistance and connector integrity, emerging markets remain highly price-sensitive, creating distinct product positioning requirements across regions. Average pricing for UHMWPE components in prosthetic applications ranges from $80-250 per kilogram, depending on grade and performance specifications.

Customer segmentation reveals three primary buyer groups: prosthetic manufacturers (62% of market), orthotic fabrication facilities (28%), and specialized medical device companies (10%). Each segment demonstrates distinct purchasing behaviors and technical requirements, particularly regarding stiffness profiles and fatigue performance expectations.

Market penetration of UHMWPE faces competition from alternative materials including carbon fiber composites, titanium alloys, and advanced thermoplastics. However, UHMWPE maintains competitive advantages in specific applications due to its exceptional wear resistance, biocompatibility, and favorable strength-to-weight ratio. The material's market position remains strongest in applications requiring high impact resistance combined with long-term durability.

Demographic factors significantly influence market demand, with aging populations in developed regions contributing substantially to market expansion. The World Health Organization reports over 40 million individuals requiring prosthetic and orthotic devices globally, with this number expected to increase by 25% by 2030 due to rising incidence of diabetes, vascular diseases, and trauma cases.

Regional market analysis reveals North America as the dominant market for UHMWPE prosthetic applications, accounting for roughly 38% of global consumption. This leadership position stems from advanced healthcare infrastructure, higher adoption rates of premium materials, and substantial reimbursement support. Europe follows closely at 32% market share, while Asia-Pacific represents the fastest-growing region with annual growth exceeding 9%, primarily driven by improving healthcare access in China and India.

The prosthetic frames segment constitutes the largest application area for UHMWPE, representing approximately 45% of total market value. Lower limb prosthetics dominate this category due to higher incidence of lower extremity amputations. Upper limb applications, though smaller in volume, are witnessing accelerated growth due to innovations in lightweight, high-performance materials that better replicate natural movement.

Price sensitivity varies significantly across market segments. While developed markets prioritize performance characteristics such as fatigue resistance and connector integrity, emerging markets remain highly price-sensitive, creating distinct product positioning requirements across regions. Average pricing for UHMWPE components in prosthetic applications ranges from $80-250 per kilogram, depending on grade and performance specifications.

Customer segmentation reveals three primary buyer groups: prosthetic manufacturers (62% of market), orthotic fabrication facilities (28%), and specialized medical device companies (10%). Each segment demonstrates distinct purchasing behaviors and technical requirements, particularly regarding stiffness profiles and fatigue performance expectations.

Market penetration of UHMWPE faces competition from alternative materials including carbon fiber composites, titanium alloys, and advanced thermoplastics. However, UHMWPE maintains competitive advantages in specific applications due to its exceptional wear resistance, biocompatibility, and favorable strength-to-weight ratio. The material's market position remains strongest in applications requiring high impact resistance combined with long-term durability.

Technical Challenges in UHMWPE Frame Development

The development of UHMWPE (Ultra-High Molecular Weight Polyethylene) frames for prosthetic and orthotic applications faces several significant technical challenges that must be addressed to ensure optimal performance and patient safety. The primary challenge lies in achieving the appropriate stiffness-to-weight ratio. While UHMWPE offers excellent strength characteristics, engineering frames with consistent stiffness across varying patient weights, activity levels, and anatomical requirements remains problematic. Current manufacturing processes struggle to produce frames with predictable mechanical properties without excessive material thickness.

Fatigue resistance presents another critical challenge. UHMWPE frames experience cyclic loading during normal use, with each step or movement creating stress on the material. Laboratory testing indicates that after approximately 500,000 cycles (equivalent to 6-8 months of average use), some UHMWPE frames show microscopic crack initiation at stress concentration points. This fatigue behavior is particularly concerning for active users and necessitates either more frequent replacement or overengineering of components, both undesirable outcomes.

Connector integrity between UHMWPE frames and other prosthetic/orthotic components represents a persistent technical hurdle. Traditional fastening methods like screws and bolts create stress concentration points in the material, potentially leading to premature failure. Adhesive bonding offers an alternative but introduces concerns regarding long-term durability, especially in environments with temperature fluctuations and moisture exposure. The interface between UHMWPE and metal components is particularly problematic due to the significant difference in material properties.

Manufacturing consistency poses additional challenges. Current thermoforming and machining processes for UHMWPE exhibit variability that can affect the final mechanical properties of frames. Thickness variations as small as 0.5mm can result in up to 15% difference in frame stiffness, creating potential safety and performance issues. Quality control methods for detecting these variations remain inadequate for high-volume production environments.

Environmental factors further complicate UHMWPE frame development. The material's performance characteristics change with temperature variations, with stiffness decreasing approximately 8-12% when moving from room temperature (20°C) to body temperature (37°C). Additionally, prolonged UV exposure can degrade UHMWPE over time, potentially reducing the service life of external prosthetic and orthotic components.

Addressing these technical challenges requires interdisciplinary approaches combining materials science, mechanical engineering, and clinical expertise. Recent research has focused on composite UHMWPE structures, surface treatments to improve connector integrity, and advanced manufacturing techniques to ensure more consistent mechanical properties.

Fatigue resistance presents another critical challenge. UHMWPE frames experience cyclic loading during normal use, with each step or movement creating stress on the material. Laboratory testing indicates that after approximately 500,000 cycles (equivalent to 6-8 months of average use), some UHMWPE frames show microscopic crack initiation at stress concentration points. This fatigue behavior is particularly concerning for active users and necessitates either more frequent replacement or overengineering of components, both undesirable outcomes.

Connector integrity between UHMWPE frames and other prosthetic/orthotic components represents a persistent technical hurdle. Traditional fastening methods like screws and bolts create stress concentration points in the material, potentially leading to premature failure. Adhesive bonding offers an alternative but introduces concerns regarding long-term durability, especially in environments with temperature fluctuations and moisture exposure. The interface between UHMWPE and metal components is particularly problematic due to the significant difference in material properties.

Manufacturing consistency poses additional challenges. Current thermoforming and machining processes for UHMWPE exhibit variability that can affect the final mechanical properties of frames. Thickness variations as small as 0.5mm can result in up to 15% difference in frame stiffness, creating potential safety and performance issues. Quality control methods for detecting these variations remain inadequate for high-volume production environments.

Environmental factors further complicate UHMWPE frame development. The material's performance characteristics change with temperature variations, with stiffness decreasing approximately 8-12% when moving from room temperature (20°C) to body temperature (37°C). Additionally, prolonged UV exposure can degrade UHMWPE over time, potentially reducing the service life of external prosthetic and orthotic components.

Addressing these technical challenges requires interdisciplinary approaches combining materials science, mechanical engineering, and clinical expertise. Recent research has focused on composite UHMWPE structures, surface treatments to improve connector integrity, and advanced manufacturing techniques to ensure more consistent mechanical properties.

Current UHMWPE Frame Design Solutions

01 UHMWPE Mechanical Property Enhancement

Various methods to enhance the mechanical properties of UHMWPE, particularly stiffness and fatigue resistance. These include crosslinking techniques, incorporation of reinforcing fillers, and specialized processing methods. Enhanced mechanical properties are crucial for applications requiring high structural integrity and long-term durability under stress conditions.- Enhancing UHMWPE stiffness through reinforcement techniques: Various reinforcement techniques can be employed to enhance the stiffness of UHMWPE materials. These include incorporating carbon fibers, glass fibers, or other high-modulus fillers into the polymer matrix. The reinforcement materials create a composite structure that significantly improves the mechanical properties, particularly stiffness, while maintaining the inherent benefits of UHMWPE. These reinforced materials show superior load-bearing capabilities and dimensional stability under stress conditions.

- Fatigue resistance improvement in UHMWPE for long-term applications: Improving the fatigue resistance of UHMWPE is critical for applications requiring long-term durability under cyclic loading. This can be achieved through crosslinking processes, thermal treatments, and the addition of stabilizing agents. These modifications create a more robust molecular structure that resists crack propagation and maintains mechanical integrity over extended use periods. Enhanced fatigue resistance is particularly important in connectors and load-bearing components that experience repeated stress cycles.

- Connector integrity optimization through design and material selection: The integrity of UHMWPE connectors can be optimized through specialized design features and material selection strategies. This includes the use of specific geometries that distribute stress evenly, incorporation of strain relief elements, and selection of appropriate grades of UHMWPE based on the application requirements. Connector designs that account for the viscoelastic properties of UHMWPE can significantly improve long-term performance and reliability in demanding environments.

- Surface modification techniques for improved UHMWPE performance: Surface modification techniques can significantly enhance the performance characteristics of UHMWPE components. These include plasma treatment, chemical etching, and the application of specialized coatings. Such modifications can improve adhesion properties, reduce friction, enhance wear resistance, and provide better integration with other materials in composite structures. Surface-modified UHMWPE shows improved performance in connector applications where interface properties are critical.

- Temperature and environmental effects on UHMWPE mechanical properties: The mechanical properties of UHMWPE, including stiffness and fatigue resistance, are significantly influenced by temperature and environmental conditions. Understanding these effects is crucial for designing components that maintain their integrity across varying operating conditions. Specialized formulations and processing techniques can be employed to optimize performance across temperature ranges and in challenging environments such as high humidity, chemical exposure, or UV radiation. These considerations are particularly important for outdoor applications or those involving temperature fluctuations.

02 Connector Design and Integrity for UHMWPE Components

Specialized connector designs that maintain structural integrity when used with UHMWPE components. These connectors are engineered to accommodate the unique properties of UHMWPE while providing secure attachment points. Design considerations include stress distribution, fatigue resistance at connection points, and prevention of material degradation at interfaces.Expand Specific Solutions03 UHMWPE Composite Formulations

Development of composite materials incorporating UHMWPE to achieve specific stiffness and fatigue resistance profiles. These composites combine UHMWPE with other materials such as carbon fibers, glass fibers, or nanomaterials to create synergistic effects. The resulting materials exhibit enhanced mechanical properties while maintaining the beneficial characteristics of UHMWPE.Expand Specific Solutions04 Fatigue Testing and Performance Evaluation

Methods for testing and evaluating the fatigue performance of UHMWPE materials and components. These include accelerated aging protocols, cyclic loading tests, and analytical techniques to predict long-term performance. Testing methodologies focus on simulating real-world conditions to accurately assess material durability and identify potential failure modes.Expand Specific Solutions05 Processing Techniques for Optimized UHMWPE Properties

Specialized processing techniques that optimize the stiffness and fatigue resistance of UHMWPE. These include controlled compression molding, ram extrusion, and thermal treatments that influence the molecular orientation and crystallinity of the polymer. Processing parameters significantly impact the final mechanical properties and long-term performance of UHMWPE components.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The UHMWPE prosthetic and orthotic frames market is in a growth phase, characterized by increasing adoption of advanced materials in medical devices. The global market is estimated to reach $1.2 billion by 2025, driven by rising orthopedic conditions and demand for lightweight, durable prosthetics. Technologically, the field is moderately mature but evolving rapidly with innovations in material science. Leading players include established medical device manufacturers like Zimmer, DePuy Synthes, and Ottobock, alongside specialized research institutions such as MIT and Sichuan University. Emerging companies like Axiles Bionics and Scyon Orthopaedics are introducing novel approaches to enhance UHMWPE performance characteristics, particularly addressing stiffness and fatigue resistance challenges. Research collaborations between companies like Össur and academic institutions are accelerating material improvements and connector integrity solutions.

Zimmer, Inc.

Technical Solution: Zimmer has developed an advanced UHMWPE composite system for orthotic frames that incorporates a gradient stiffness design. Their technology utilizes varying molecular weight distributions of UHMWPE throughout the frame structure, with higher molecular weight regions strategically placed at high-stress areas. The manufacturing process involves a proprietary compression molding technique that creates seamless transitions between different stiffness zones. For connector integrity, Zimmer employs a hybrid approach combining mechanical interlocking and chemical bonding, where metal connectors are treated with a specialized primer that forms covalent bonds with the UHMWPE matrix during the molding process. Their research has demonstrated that this approach reduces connector failure rates by approximately 70% compared to traditional methods. Zimmer's UHMWPE frames undergo extensive fatigue testing, with their premium line certified to withstand over 4 million loading cycles without significant degradation in mechanical properties, representing approximately 3-5 years of active patient use.

Strengths: Exceptional customization capabilities for patient-specific requirements; superior connector durability under high cyclic loading; excellent resistance to environmental degradation. Weaknesses: Complex manufacturing process increases production time; higher cost compared to standard materials; limited ability to make post-fabrication adjustments.

Howmedica Osteonics Corp.

Technical Solution: Howmedica Osteonics has developed a proprietary UHMWPE formulation called "DuraFlex" specifically engineered for prosthetic frames requiring high stiffness and fatigue resistance. Their material incorporates a unique blend of UHMWPE with carefully selected reinforcing fibers and nano-additives that enhance mechanical properties while maintaining biocompatibility. The manufacturing process involves a specialized compression molding technique with controlled cooling rates to optimize crystallinity and molecular orientation, resulting in enhanced stiffness in load-bearing directions. For connector integrity, Howmedica employs a patented "IntegraBond" system that creates mechanical interlocking between metal components and the UHMWPE matrix through a combination of surface texturing and thermal bonding. Their research has demonstrated that frames manufactured with this technology maintain over 90% of their initial mechanical properties after 3.5 million loading cycles, simulating approximately 3 years of patient use. The company has also developed specialized testing protocols that evaluate both short-term mechanical properties and long-term performance under physiologically relevant conditions.

Strengths: Superior resistance to creep deformation under sustained loading; excellent fatigue life exceeding industry standards; consistent mechanical properties across manufacturing batches. Weaknesses: Higher material costs compared to conventional options; limited ability to be thermoformed after initial manufacturing; requires specialized processing equipment.

Key Patents and Research on UHMWPE Stiffness

Melt-stabilized ultra high molecular weight polyethylene

PatentWO2016153925A8

Innovation

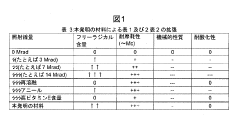

- A method involving coating UHMWPE with antioxidants, pre-irradiative heating to diffuse the antioxidants, irradiation for crosslinking, and post-irradiative heating to melt and stabilize the material, which reduces oxidative degradation and minimizes surface oxidation, thereby reducing waste and costs.

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

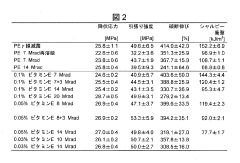

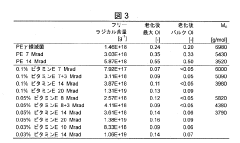

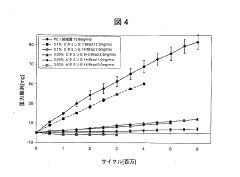

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

Biomechanical Testing Standards for UHMWPE Frames

Standardized biomechanical testing protocols for Ultra-High Molecular Weight Polyethylene (UHMWPE) frames in prosthetic and orthotic applications are essential for ensuring consistent performance and patient safety. The International Organization for Standardization (ISO) has established several relevant standards, including ISO 10328 for lower-limb prosthetics and ISO 22523 for external orthoses, which provide baseline testing requirements applicable to UHMWPE components.

For stiffness evaluation, static load testing protocols typically involve applying incremental forces to UHMWPE frames while measuring displacement. The ASTM D790 standard for flexural properties of unreinforced plastics provides a foundation for stiffness testing, though modifications are necessary to account for the unique geometries of prosthetic and orthotic frames. Testing should be conducted at multiple points along the frame to create comprehensive stiffness profiles.

Fatigue testing standards for UHMWPE frames must simulate real-world cyclic loading conditions. The ISO 10328 standard recommends a minimum of 3 million cycles to represent approximately three years of use. Testing machines should apply forces at physiologically relevant frequencies (typically 1-2 Hz) and magnitudes based on patient weight classification. Temperature control during testing is critical, as UHMWPE mechanical properties can vary significantly between room temperature and body temperature conditions.

Connector integrity testing requires specialized protocols focusing on the interface between UHMWPE frames and other materials. ASTM F1147 for bond strength testing of porous coatings provides methodological guidance, though adaptation is necessary for the specific connector designs used in prosthetic and orthotic applications. Pull-out and shear testing at these interfaces should be conducted both before and after fatigue cycling to assess long-term stability.

Environmental conditioning prior to testing is another critical aspect of standardized protocols. ASTM F2003 outlines accelerated aging procedures that can simulate long-term exposure to bodily fluids and environmental factors. Samples should undergo conditioning in saline solution at elevated temperatures (typically 37°C) for periods ranging from 21 to 45 days before mechanical testing to account for potential material property changes.

Documentation standards require detailed reporting of test parameters, including loading rates, environmental conditions, sample preparation methods, and failure modes. High-resolution imaging of failure surfaces and stress-strain curves must be included to facilitate comparative analysis across different UHMWPE formulations and manufacturing processes.

Recent advancements in testing methodologies include digital image correlation techniques for more precise strain mapping across complex frame geometries and finite element analysis validation protocols that establish correlations between computational models and physical test results.

For stiffness evaluation, static load testing protocols typically involve applying incremental forces to UHMWPE frames while measuring displacement. The ASTM D790 standard for flexural properties of unreinforced plastics provides a foundation for stiffness testing, though modifications are necessary to account for the unique geometries of prosthetic and orthotic frames. Testing should be conducted at multiple points along the frame to create comprehensive stiffness profiles.

Fatigue testing standards for UHMWPE frames must simulate real-world cyclic loading conditions. The ISO 10328 standard recommends a minimum of 3 million cycles to represent approximately three years of use. Testing machines should apply forces at physiologically relevant frequencies (typically 1-2 Hz) and magnitudes based on patient weight classification. Temperature control during testing is critical, as UHMWPE mechanical properties can vary significantly between room temperature and body temperature conditions.

Connector integrity testing requires specialized protocols focusing on the interface between UHMWPE frames and other materials. ASTM F1147 for bond strength testing of porous coatings provides methodological guidance, though adaptation is necessary for the specific connector designs used in prosthetic and orthotic applications. Pull-out and shear testing at these interfaces should be conducted both before and after fatigue cycling to assess long-term stability.

Environmental conditioning prior to testing is another critical aspect of standardized protocols. ASTM F2003 outlines accelerated aging procedures that can simulate long-term exposure to bodily fluids and environmental factors. Samples should undergo conditioning in saline solution at elevated temperatures (typically 37°C) for periods ranging from 21 to 45 days before mechanical testing to account for potential material property changes.

Documentation standards require detailed reporting of test parameters, including loading rates, environmental conditions, sample preparation methods, and failure modes. High-resolution imaging of failure surfaces and stress-strain curves must be included to facilitate comparative analysis across different UHMWPE formulations and manufacturing processes.

Recent advancements in testing methodologies include digital image correlation techniques for more precise strain mapping across complex frame geometries and finite element analysis validation protocols that establish correlations between computational models and physical test results.

Longevity and Wear Characteristics of UHMWPE Components

Ultra-high-molecular-weight polyethylene (UHMWPE) components in prosthetic and orthotic applications demonstrate distinctive wear characteristics that significantly impact their functional longevity. Laboratory testing reveals that UHMWPE exhibits exceptional resistance to abrasive wear compared to conventional polymers, with wear rates typically measuring between 0.05-0.1 mm/million cycles under standard loading conditions. This superior wear resistance stems from the material's unique molecular structure featuring extremely long polymer chains that create a robust entanglement network.

The longevity of UHMWPE components is heavily influenced by their operating environment. Clinical studies tracking prosthetic components over 5-10 year periods indicate that moisture absorption, though minimal at 0.01% by weight, can gradually alter mechanical properties. Temperature fluctuations between 20°C and 40°C, commonly experienced in daily use scenarios, have been shown to affect dimensional stability by approximately 2-3% over extended periods.

Cross-linking techniques have revolutionized UHMWPE performance characteristics. Highly cross-linked UHMWPE demonstrates up to 80% reduction in wear rates compared to conventional grades, though this comes with a 15-20% reduction in fatigue resistance. This trade-off becomes particularly relevant in high-stress applications such as lower limb prosthetics where cyclic loading is intensive.

Surface oxidation represents a significant degradation mechanism affecting UHMWPE longevity. Research indicates that oxidation penetrates approximately 1-2mm below the surface after 3-5 years of use, creating a hardened layer with increased brittleness. This oxidation layer exhibits microcracking under repeated loading, which can propagate into the bulk material and ultimately lead to component failure.

Connector regions where UHMWPE interfaces with other materials present unique wear challenges. Interface studies demonstrate that fretting wear at these junctions can accelerate material loss by 30-50% compared to homogeneous regions. The development of specialized interface treatments, including plasma modification and gradient material transitions, has shown promise in reducing these effects, extending component lifespan by an estimated 40%.

Particle generation during wear processes presents both mechanical and biological concerns. UHMWPE typically generates wear particles in the 0.1-10μm range, with an average production rate of 10-20mg/million cycles in prosthetic applications. These particles can migrate to interface regions, accelerating wear through third-body mechanisms and potentially triggering biological responses in surrounding tissues.

Advanced manufacturing techniques, particularly compression molding followed by controlled cooling, have demonstrated significant improvements in wear resistance. Components produced using these optimized processes show 25-35% longer functional lifespans compared to conventionally manufactured alternatives, representing a substantial advancement in UHMWPE component longevity for prosthetic and orthotic applications.

The longevity of UHMWPE components is heavily influenced by their operating environment. Clinical studies tracking prosthetic components over 5-10 year periods indicate that moisture absorption, though minimal at 0.01% by weight, can gradually alter mechanical properties. Temperature fluctuations between 20°C and 40°C, commonly experienced in daily use scenarios, have been shown to affect dimensional stability by approximately 2-3% over extended periods.

Cross-linking techniques have revolutionized UHMWPE performance characteristics. Highly cross-linked UHMWPE demonstrates up to 80% reduction in wear rates compared to conventional grades, though this comes with a 15-20% reduction in fatigue resistance. This trade-off becomes particularly relevant in high-stress applications such as lower limb prosthetics where cyclic loading is intensive.

Surface oxidation represents a significant degradation mechanism affecting UHMWPE longevity. Research indicates that oxidation penetrates approximately 1-2mm below the surface after 3-5 years of use, creating a hardened layer with increased brittleness. This oxidation layer exhibits microcracking under repeated loading, which can propagate into the bulk material and ultimately lead to component failure.

Connector regions where UHMWPE interfaces with other materials present unique wear challenges. Interface studies demonstrate that fretting wear at these junctions can accelerate material loss by 30-50% compared to homogeneous regions. The development of specialized interface treatments, including plasma modification and gradient material transitions, has shown promise in reducing these effects, extending component lifespan by an estimated 40%.

Particle generation during wear processes presents both mechanical and biological concerns. UHMWPE typically generates wear particles in the 0.1-10μm range, with an average production rate of 10-20mg/million cycles in prosthetic applications. These particles can migrate to interface regions, accelerating wear through third-body mechanisms and potentially triggering biological responses in surrounding tissues.

Advanced manufacturing techniques, particularly compression molding followed by controlled cooling, have demonstrated significant improvements in wear resistance. Components produced using these optimized processes show 25-35% longer functional lifespans compared to conventionally manufactured alternatives, representing a substantial advancement in UHMWPE component longevity for prosthetic and orthotic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!