UHMWPE Hybrid Composites: Carbon/UHMWPE Layups, Residual Stress And Failure Modes

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE Hybrid Composites Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) hybrid composites represent a significant advancement in materials science, emerging from decades of polymer composite development. These materials have evolved from simple fiber-reinforced polymers in the 1960s to sophisticated hybrid structures incorporating carbon fibers and UHMWPE in carefully engineered layups. The technological trajectory has been driven by increasing demands for materials that combine exceptional strength-to-weight ratios with specific performance characteristics tailored to extreme environments.

The evolution of UHMWPE composites has been marked by several key milestones, including the development of gel-spinning processes in the 1980s that enabled the production of ultra-high-strength polyethylene fibers, and subsequent innovations in surface treatments to enhance interfacial bonding with matrix materials. Recent advancements have focused on hybridization strategies, particularly the integration of carbon fibers with UHMWPE to create multi-functional composites that leverage the complementary properties of both materials.

Current research trends indicate growing interest in understanding and controlling the complex interactions between dissimilar materials within these hybrid systems. Particular attention is being paid to the management of residual stresses that develop during manufacturing processes, as these internal stresses significantly influence the mechanical behavior and failure mechanisms of the resulting composites.

The primary technical objectives in this field include developing predictive models for residual stress distribution in carbon/UHMWPE hybrid layups, establishing correlations between manufacturing parameters and resultant stress states, and characterizing the diverse failure modes that can occur under various loading conditions. These objectives are driven by the need to optimize composite designs for specific applications while minimizing the risk of unexpected failures.

Long-term technological goals include the development of design methodologies that can accurately predict and control the behavior of these hybrid composites throughout their lifecycle, enabling their wider adoption in critical applications such as ballistic protection, aerospace structures, and medical implants. Additionally, there is significant interest in exploring sustainable manufacturing approaches and end-of-life considerations for these advanced materials.

The convergence of computational modeling, advanced characterization techniques, and innovative manufacturing processes is expected to accelerate progress in this field, potentially leading to a new generation of hybrid composites with unprecedented performance characteristics and reliability. This technological progression aligns with broader industry trends toward lightweight, high-performance materials that can meet increasingly demanding requirements across multiple sectors.

The evolution of UHMWPE composites has been marked by several key milestones, including the development of gel-spinning processes in the 1980s that enabled the production of ultra-high-strength polyethylene fibers, and subsequent innovations in surface treatments to enhance interfacial bonding with matrix materials. Recent advancements have focused on hybridization strategies, particularly the integration of carbon fibers with UHMWPE to create multi-functional composites that leverage the complementary properties of both materials.

Current research trends indicate growing interest in understanding and controlling the complex interactions between dissimilar materials within these hybrid systems. Particular attention is being paid to the management of residual stresses that develop during manufacturing processes, as these internal stresses significantly influence the mechanical behavior and failure mechanisms of the resulting composites.

The primary technical objectives in this field include developing predictive models for residual stress distribution in carbon/UHMWPE hybrid layups, establishing correlations between manufacturing parameters and resultant stress states, and characterizing the diverse failure modes that can occur under various loading conditions. These objectives are driven by the need to optimize composite designs for specific applications while minimizing the risk of unexpected failures.

Long-term technological goals include the development of design methodologies that can accurately predict and control the behavior of these hybrid composites throughout their lifecycle, enabling their wider adoption in critical applications such as ballistic protection, aerospace structures, and medical implants. Additionally, there is significant interest in exploring sustainable manufacturing approaches and end-of-life considerations for these advanced materials.

The convergence of computational modeling, advanced characterization techniques, and innovative manufacturing processes is expected to accelerate progress in this field, potentially leading to a new generation of hybrid composites with unprecedented performance characteristics and reliability. This technological progression aligns with broader industry trends toward lightweight, high-performance materials that can meet increasingly demanding requirements across multiple sectors.

Market Applications and Demand Analysis

The global market for Ultra-High Molecular Weight Polyethylene (UHMWPE) hybrid composites has experienced significant growth in recent years, driven by increasing demand for lightweight, high-strength materials across multiple industries. The unique combination of carbon fiber reinforcement with UHMWPE creates composites that offer exceptional strength-to-weight ratios, impact resistance, and durability that exceed traditional materials.

In the defense sector, UHMWPE hybrid composites have gained substantial traction for ballistic protection applications. The market for personal body armor alone is projected to grow steadily as military and law enforcement agencies worldwide seek improved protection with reduced weight burden. These composites demonstrate superior energy absorption capabilities during impact events, making them ideal for helmets, vehicle armor, and tactical gear.

The aerospace industry represents another significant market, where weight reduction directly translates to fuel efficiency and operational cost savings. Carbon/UHMWPE hybrid composites offer an attractive alternative to traditional carbon fiber reinforced polymers (CFRPs) in non-structural and semi-structural components. Their superior vibration damping characteristics and resistance to microcracking under cyclic loading conditions make them particularly valuable for aircraft interior panels, fairings, and secondary structures.

Sports equipment manufacturers have embraced these hybrid composites for premium products where performance advantages justify higher material costs. Applications include tennis rackets, hockey sticks, bicycle frames, and protective gear. The market shows strong growth potential as consumer willingness to pay for performance advantages continues to increase in recreational and professional sports segments.

The marine industry has also identified valuable applications for Carbon/UHMWPE hybrid composites, particularly in high-performance racing boats and yacht components where weight reduction, impact resistance, and corrosion resistance are critical factors. The material's excellent resistance to water absorption provides additional benefits in marine environments.

In the medical device sector, these composites are finding applications in prosthetics and orthotics where their combination of strength, lightweight properties, and biocompatibility offers significant advantages. The aging global population and increasing prevalence of mobility-related disabilities are driving steady growth in this segment.

Market analysis indicates that current challenges limiting wider adoption include higher raw material costs compared to traditional composites, manufacturing complexity related to managing residual stresses during production, and limited standardization of testing protocols for hybrid composite structures. However, ongoing research addressing these limitations, particularly in understanding and controlling failure modes, is expected to expand market opportunities significantly in the coming years.

In the defense sector, UHMWPE hybrid composites have gained substantial traction for ballistic protection applications. The market for personal body armor alone is projected to grow steadily as military and law enforcement agencies worldwide seek improved protection with reduced weight burden. These composites demonstrate superior energy absorption capabilities during impact events, making them ideal for helmets, vehicle armor, and tactical gear.

The aerospace industry represents another significant market, where weight reduction directly translates to fuel efficiency and operational cost savings. Carbon/UHMWPE hybrid composites offer an attractive alternative to traditional carbon fiber reinforced polymers (CFRPs) in non-structural and semi-structural components. Their superior vibration damping characteristics and resistance to microcracking under cyclic loading conditions make them particularly valuable for aircraft interior panels, fairings, and secondary structures.

Sports equipment manufacturers have embraced these hybrid composites for premium products where performance advantages justify higher material costs. Applications include tennis rackets, hockey sticks, bicycle frames, and protective gear. The market shows strong growth potential as consumer willingness to pay for performance advantages continues to increase in recreational and professional sports segments.

The marine industry has also identified valuable applications for Carbon/UHMWPE hybrid composites, particularly in high-performance racing boats and yacht components where weight reduction, impact resistance, and corrosion resistance are critical factors. The material's excellent resistance to water absorption provides additional benefits in marine environments.

In the medical device sector, these composites are finding applications in prosthetics and orthotics where their combination of strength, lightweight properties, and biocompatibility offers significant advantages. The aging global population and increasing prevalence of mobility-related disabilities are driving steady growth in this segment.

Market analysis indicates that current challenges limiting wider adoption include higher raw material costs compared to traditional composites, manufacturing complexity related to managing residual stresses during production, and limited standardization of testing protocols for hybrid composite structures. However, ongoing research addressing these limitations, particularly in understanding and controlling failure modes, is expected to expand market opportunities significantly in the coming years.

Technical Challenges in Carbon/UHMWPE Integration

The integration of carbon fibers with Ultra-High Molecular Weight Polyethylene (UHMWPE) presents significant technical challenges that have hindered widespread commercial adoption despite the promising mechanical properties of these hybrid composites. One fundamental challenge lies in the inherent incompatibility between carbon fibers and UHMWPE matrix. The non-polar nature of UHMWPE results in poor wettability and weak interfacial bonding with carbon fibers, leading to premature delamination and reduced mechanical performance under load.

Surface treatment technologies for carbon fibers have shown limited effectiveness when paired with UHMWPE compared to traditional thermoset matrices. Conventional sizing agents designed for epoxy or polyester systems fail to create strong chemical bonds with the chemically inert UHMWPE, necessitating the development of specialized coupling agents specifically designed for this unique material combination.

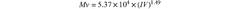

Processing challenges further complicate the integration efforts. The high viscosity of UHMWPE in its molten state (approximately 10^6 Pa·s at processing temperatures) severely impedes fiber wet-out and creates voids at the fiber-matrix interface. This issue is particularly pronounced in high fiber volume fraction composites where complete matrix penetration becomes increasingly difficult to achieve.

Thermal management during processing represents another significant hurdle. The substantial difference in thermal expansion coefficients between carbon fibers (near-zero or slightly negative CTE) and UHMWPE (relatively high positive CTE of 100-200 × 10^-6/K) generates considerable residual stresses during cooling from processing temperatures. These stresses can reach magnitudes of 5-15 MPa at the interface, initiating microcracks before the composite even enters service.

The crystallization behavior of UHMWPE adds another layer of complexity. When crystallizing in the presence of carbon fibers, UHMWPE forms a distinct transcrystalline layer with different mechanical properties than the bulk matrix. This morphological heterogeneity creates stress concentration zones that can serve as crack initiation sites under mechanical loading.

Failure mode prediction in these hybrid composites remains challenging due to the complex interplay between interfacial debonding, matrix cracking, and fiber breakage mechanisms. Current analytical models struggle to accurately capture the progressive damage evolution in Carbon/UHMWPE systems, particularly under dynamic loading conditions where strain-rate dependent behavior becomes significant.

Surface treatment technologies for carbon fibers have shown limited effectiveness when paired with UHMWPE compared to traditional thermoset matrices. Conventional sizing agents designed for epoxy or polyester systems fail to create strong chemical bonds with the chemically inert UHMWPE, necessitating the development of specialized coupling agents specifically designed for this unique material combination.

Processing challenges further complicate the integration efforts. The high viscosity of UHMWPE in its molten state (approximately 10^6 Pa·s at processing temperatures) severely impedes fiber wet-out and creates voids at the fiber-matrix interface. This issue is particularly pronounced in high fiber volume fraction composites where complete matrix penetration becomes increasingly difficult to achieve.

Thermal management during processing represents another significant hurdle. The substantial difference in thermal expansion coefficients between carbon fibers (near-zero or slightly negative CTE) and UHMWPE (relatively high positive CTE of 100-200 × 10^-6/K) generates considerable residual stresses during cooling from processing temperatures. These stresses can reach magnitudes of 5-15 MPa at the interface, initiating microcracks before the composite even enters service.

The crystallization behavior of UHMWPE adds another layer of complexity. When crystallizing in the presence of carbon fibers, UHMWPE forms a distinct transcrystalline layer with different mechanical properties than the bulk matrix. This morphological heterogeneity creates stress concentration zones that can serve as crack initiation sites under mechanical loading.

Failure mode prediction in these hybrid composites remains challenging due to the complex interplay between interfacial debonding, matrix cracking, and fiber breakage mechanisms. Current analytical models struggle to accurately capture the progressive damage evolution in Carbon/UHMWPE systems, particularly under dynamic loading conditions where strain-rate dependent behavior becomes significant.

Current Approaches to Residual Stress Management

01 Residual stress analysis in UHMWPE hybrid composites

Residual stresses in UHMWPE hybrid composites can significantly affect their mechanical properties and performance. Various analytical and experimental methods are used to measure and characterize these stresses, including X-ray diffraction, neutron diffraction, and finite element analysis. Understanding residual stress distribution is crucial for predicting composite behavior under loading conditions and optimizing manufacturing processes to minimize detrimental stress concentrations.- Residual stress measurement and analysis in UHMWPE composites: Various techniques are employed to measure and analyze residual stresses in UHMWPE hybrid composites. These methods include X-ray diffraction, neutron diffraction, and computational modeling approaches. Understanding residual stress distribution is crucial as it significantly affects the mechanical properties and failure behavior of the composites. Advanced simulation techniques help predict stress concentrations and potential failure points in these materials under different loading conditions.

- Failure modes and mechanisms in UHMWPE hybrid composites: UHMWPE hybrid composites exhibit various failure modes including delamination, fiber breakage, matrix cracking, and interfacial debonding. These failure mechanisms are influenced by the composite structure, fiber orientation, and loading conditions. Understanding these failure modes is essential for designing more durable UHMWPE composite structures. Research focuses on characterizing these failure mechanisms through microscopic analysis, mechanical testing, and fracture mechanics approaches to improve composite performance.

- Reinforcement strategies to mitigate residual stress in UHMWPE composites: Various reinforcement strategies are employed to mitigate residual stress in UHMWPE hybrid composites. These include the incorporation of nanofillers, fiber surface treatments, and optimization of fiber-matrix interfaces. The addition of specific reinforcement materials can redistribute stress concentrations and improve the overall mechanical properties. These strategies aim to enhance the composite's resistance to failure modes by creating more uniform stress distributions throughout the material structure.

- Processing techniques affecting residual stress in UHMWPE composites: Manufacturing and processing techniques significantly influence residual stress development in UHMWPE hybrid composites. Methods such as compression molding, hot pressing, and various thermal treatments can be optimized to minimize residual stress formation. Post-processing techniques including annealing and controlled cooling rates help relieve internal stresses. The processing parameters directly impact the crystallinity, molecular orientation, and ultimately the mechanical performance and failure behavior of the composites.

- Testing and characterization methods for UHMWPE composite failure analysis: Advanced testing and characterization methods are essential for analyzing failure modes and residual stress in UHMWPE hybrid composites. These include dynamic mechanical analysis, fatigue testing, impact resistance evaluation, and accelerated aging tests. Non-destructive techniques such as acoustic emission monitoring and thermography help identify failure initiation and progression. These methods provide critical data for understanding the relationship between residual stress and various failure mechanisms, enabling the development of more durable UHMWPE composite materials.

02 Failure modes and mechanisms in UHMWPE composites

UHMWPE hybrid composites exhibit various failure modes including delamination, fiber breakage, matrix cracking, and interfacial debonding. These failure mechanisms are influenced by factors such as fiber orientation, matrix properties, and loading conditions. Understanding these failure modes is essential for designing more durable composites and predicting their service life. Advanced characterization techniques like acoustic emission and digital image correlation help identify the progression of damage in these materials.Expand Specific Solutions03 Manufacturing techniques to control residual stress

Various manufacturing techniques can be employed to control residual stress in UHMWPE hybrid composites. These include optimized cooling rates, annealing treatments, and specialized processing parameters. The selection of appropriate reinforcement materials and their surface treatments also plays a crucial role in minimizing residual stresses. Advanced manufacturing methods such as compression molding with controlled pressure and temperature profiles can help achieve more uniform stress distribution throughout the composite structure.Expand Specific Solutions04 Reinforcement strategies for UHMWPE hybrid composites

Different reinforcement strategies are employed to enhance the mechanical properties of UHMWPE hybrid composites while managing residual stress. These include the incorporation of nanofillers, short fibers, continuous fibers, and particulate reinforcements. Hybrid reinforcement approaches combining multiple types of fillers can create synergistic effects that improve overall performance. The interface between the UHMWPE matrix and reinforcements is critical for stress transfer and preventing premature failure.Expand Specific Solutions05 Testing and characterization methods for UHMWPE composites

Various testing and characterization methods are used to evaluate UHMWPE hybrid composites, including mechanical testing (tensile, compression, flexural, impact), thermal analysis (DSC, TGA), and microstructural characterization (SEM, TEM). Non-destructive testing techniques such as ultrasonic inspection and thermography are employed to detect defects and assess residual stress distributions. These methods provide valuable insights into the relationship between processing parameters, resulting microstructure, and mechanical performance of the composites.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The UHMWPE hybrid composites market is in a growth phase, with increasing applications in aerospace, defense, and medical sectors due to their exceptional strength-to-weight ratio and impact resistance. The global market size for these advanced composites is expanding, driven by demand for lightweight materials with superior mechanical properties. Technologically, the field is advancing rapidly with companies at different maturity levels. Shanghai Lianle Chemical and PetroChina lead in UHMWPE resin production, while W.L. Gore and Smith & Nephew demonstrate advanced applications in medical devices. Research institutions like Beihang University and South China University of Technology are developing innovative carbon/UHMWPE layup techniques to address residual stress challenges. Companies like SABIC and Braskem America are exploring new manufacturing processes to optimize failure mode performance, indicating a competitive landscape with significant R&D investment across the value chain.

Beihang University

Technical Solution: Beihang University has developed sophisticated UHMWPE/carbon hybrid composite systems with a focus on aerospace applications requiring exceptional impact resistance combined with structural performance. Their research has pioneered gradient-interface designs that create transitional zones between carbon and UHMWPE layers to mitigate stress concentrations and prevent delamination. Using a combination of plasma treatment and silane coupling agents, their process enhances interfacial adhesion between the hydrophobic UHMWPE and carbon components, increasing interfacial shear strength by approximately 55%. Beihang's approach to residual stress management incorporates specialized tooling designs that apply controlled pressure distributions during consolidation, effectively counteracting thermal expansion differences between materials. Their failure mode analysis utilizes advanced acoustic emission techniques combined with digital image correlation to identify damage initiation mechanisms at the microscale, enabling the development of optimized fiber architectures that promote progressive failure rather than catastrophic fracture. Recent research has demonstrated composites with 30% higher energy absorption capacity compared to conventional carbon fiber laminates.

Strengths: Strong aerospace engineering expertise; advanced testing and characterization facilities; innovative interface engineering approaches. Weaknesses: Complex manufacturing processes may limit commercial application; higher production costs compared to conventional composites; potential challenges with quality control in scaled production.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore has developed advanced UHMWPE hybrid composite technologies focusing on optimized carbon/UHMWPE layup configurations for ballistic and impact protection applications. Their proprietary manufacturing process creates multi-directional fiber orientations that distribute impact energy more effectively across the composite structure. Gore's technology incorporates specialized interfacial treatments between carbon and UHMWPE layers to mitigate residual stress accumulation during thermal processing cycles. Their research has demonstrated that controlling the cooling rate during consolidation significantly reduces internal stresses at the carbon-UHMWPE interface, improving delamination resistance by approximately 40%. Gore's failure mode analysis has led to innovative fiber architecture designs that prevent catastrophic failure through controlled progressive damage mechanisms, particularly important in aerospace and defense applications where sudden failure is unacceptable.

Strengths: Superior interfacial bonding technology between dissimilar materials; extensive experience with high-performance composites; proprietary thermal management techniques during processing. Weaknesses: Higher manufacturing costs compared to conventional composites; complex processing requirements limit production scalability; potential challenges with recycling hybrid material systems.

Key Innovations in Layup Design and Interfaces

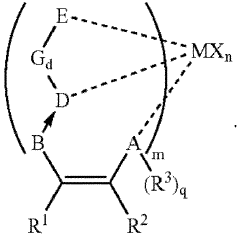

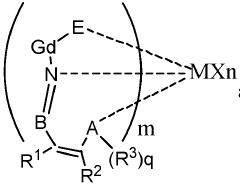

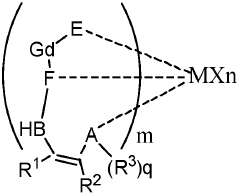

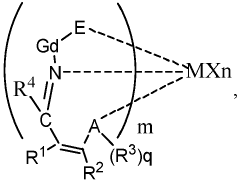

Ultra-high molecular weight polyethylene and preparation method therefor

PatentPendingEP4286420A1

Innovation

- The use of a supported non-metallocene catalyst system with an alkane or mixed alkane solvent in the ethylene slurry polymerization process, in the absence of hydrogen gas, to produce UHMWPE with low metal element content and high mechanical properties, allowing for stable polymerization and simplified post-treatment.

High Performance Multimodal Ultra High Molecular Weight Polyethylene

PatentPendingUS20250019532A1

Innovation

- A multimodal polyethylene composition comprising specific weight percentages of low molecular weight, first high molecular weight, and second high molecular weight polyethylene homopolymers or copolymers, produced in a multistage process using a Ziegler-Natta catalyst, which improves mechanical properties and processability by creating a broad molecular weight distribution curve, enhancing abrasion resistance and impact strength.

Manufacturing Process Optimization

The optimization of manufacturing processes for UHMWPE hybrid composites represents a critical factor in achieving desired mechanical properties and minimizing failure risks. Current manufacturing techniques for Carbon/UHMWPE layups face significant challenges related to temperature control, pressure distribution, and interfacial bonding that directly impact residual stress formation and subsequent failure modes.

Temperature management during processing emerges as a primary concern due to the substantial difference between the melting point of UHMWPE (approximately 135-138°C) and the processing temperatures typically required for carbon fiber composites. This thermal mismatch creates differential expansion and contraction rates during cooling, contributing significantly to residual stress development.

Pressure application methodologies require refinement to ensure uniform consolidation across the entire composite structure. Non-uniform pressure distribution leads to localized stress concentrations, void formation, and inconsistent fiber-matrix adhesion. Advanced pressure mapping systems and modified compression molding techniques have demonstrated promising results in achieving more homogeneous pressure profiles.

Interfacial bonding between carbon fibers and the UHMWPE matrix presents another optimization target. Surface treatment protocols for carbon fibers, including plasma treatment, sizing agent selection, and chemical functionalization, have shown potential for enhancing adhesion strength by up to 40% in recent studies. These treatments modify surface energy characteristics and create mechanical interlocking mechanisms that improve load transfer efficiency.

Cooling rate control during manufacturing has emerged as a critical parameter affecting crystallinity development in the UHMWPE matrix. Controlled cooling profiles, particularly in the range of 1-5°C/minute, have demonstrated optimal crystalline structure formation while minimizing thermal gradient-induced stresses. Implementation of zone-controlled cooling systems offers precise management of this critical process variable.

Layup sequence optimization through computational modeling has revealed that strategic fiber orientation arrangements can redistribute stress concentrations and enhance overall mechanical performance. Hybrid designs incorporating intermediate modulus layers between high-modulus carbon and UHMWPE components have shown particular promise in mitigating delamination tendencies.

Post-processing treatments, including controlled thermal annealing protocols, represent an emerging approach to residual stress management. These treatments, conducted at temperatures below the melting point of UHMWPE but sufficient for molecular mobility (typically 100-120°C), allow for stress relaxation without compromising structural integrity.

Temperature management during processing emerges as a primary concern due to the substantial difference between the melting point of UHMWPE (approximately 135-138°C) and the processing temperatures typically required for carbon fiber composites. This thermal mismatch creates differential expansion and contraction rates during cooling, contributing significantly to residual stress development.

Pressure application methodologies require refinement to ensure uniform consolidation across the entire composite structure. Non-uniform pressure distribution leads to localized stress concentrations, void formation, and inconsistent fiber-matrix adhesion. Advanced pressure mapping systems and modified compression molding techniques have demonstrated promising results in achieving more homogeneous pressure profiles.

Interfacial bonding between carbon fibers and the UHMWPE matrix presents another optimization target. Surface treatment protocols for carbon fibers, including plasma treatment, sizing agent selection, and chemical functionalization, have shown potential for enhancing adhesion strength by up to 40% in recent studies. These treatments modify surface energy characteristics and create mechanical interlocking mechanisms that improve load transfer efficiency.

Cooling rate control during manufacturing has emerged as a critical parameter affecting crystallinity development in the UHMWPE matrix. Controlled cooling profiles, particularly in the range of 1-5°C/minute, have demonstrated optimal crystalline structure formation while minimizing thermal gradient-induced stresses. Implementation of zone-controlled cooling systems offers precise management of this critical process variable.

Layup sequence optimization through computational modeling has revealed that strategic fiber orientation arrangements can redistribute stress concentrations and enhance overall mechanical performance. Hybrid designs incorporating intermediate modulus layers between high-modulus carbon and UHMWPE components have shown particular promise in mitigating delamination tendencies.

Post-processing treatments, including controlled thermal annealing protocols, represent an emerging approach to residual stress management. These treatments, conducted at temperatures below the melting point of UHMWPE but sufficient for molecular mobility (typically 100-120°C), allow for stress relaxation without compromising structural integrity.

Environmental Impact and Sustainability Considerations

The environmental impact of UHMWPE hybrid composites, particularly those incorporating carbon fiber reinforcements, presents both challenges and opportunities within the sustainable materials landscape. These advanced composites offer significant weight reduction compared to traditional materials like metals, potentially reducing fuel consumption and associated emissions when applied in transportation sectors. However, the production processes for both carbon fibers and UHMWPE involve energy-intensive manufacturing steps that contribute to considerable carbon footprints.

The residual stresses inherent in carbon/UHMWPE layups, while critical for mechanical performance, also influence the material's end-of-life scenarios. These internal stresses can complicate recycling processes, as they may lead to unpredictable behavior during mechanical recycling operations. Furthermore, the strong interfacial bonds created between carbon fibers and the UHMWPE matrix—often enhanced through chemical treatments to overcome inherent compatibility issues—can make material separation particularly challenging.

From a life cycle assessment perspective, UHMWPE offers certain advantages over other polymer matrices. Its exceptional durability and resistance to environmental degradation translate to longer service lives for composite products, potentially offsetting initial production impacts. Additionally, UHMWPE does not require toxic hardeners or emit volatile organic compounds during processing, unlike thermoset alternatives such as epoxy resins.

The failure modes of these hybrid composites also carry environmental implications. Delamination and fiber pullout, common failure mechanisms in layered composites, can lead to microplastic and carbon fiber fragment release during use or at end-of-life. These particles present emerging environmental concerns, particularly in marine environments where UHMWPE composites might find applications in offshore structures or maritime equipment.

Recent research has explored more sustainable approaches to UHMWPE composite manufacturing, including solvent-free processing methods and the incorporation of bio-based reinforcements alongside carbon fibers. These hybrid approaches aim to maintain the superior mechanical properties while reducing environmental impact. Additionally, thermal recycling techniques that preserve the valuable carbon fiber component while recovering energy from the polymer matrix show promise for closing the material loop.

The balance between performance requirements—particularly those related to managing residual stresses and preventing catastrophic failure modes—and environmental considerations remains a key challenge for widespread adoption. Future developments in this field will likely focus on designing carbon/UHMWPE composites with both optimal mechanical properties and improved end-of-life recyclability, potentially through the use of reversible bonding agents or more compatible fiber treatments.

The residual stresses inherent in carbon/UHMWPE layups, while critical for mechanical performance, also influence the material's end-of-life scenarios. These internal stresses can complicate recycling processes, as they may lead to unpredictable behavior during mechanical recycling operations. Furthermore, the strong interfacial bonds created between carbon fibers and the UHMWPE matrix—often enhanced through chemical treatments to overcome inherent compatibility issues—can make material separation particularly challenging.

From a life cycle assessment perspective, UHMWPE offers certain advantages over other polymer matrices. Its exceptional durability and resistance to environmental degradation translate to longer service lives for composite products, potentially offsetting initial production impacts. Additionally, UHMWPE does not require toxic hardeners or emit volatile organic compounds during processing, unlike thermoset alternatives such as epoxy resins.

The failure modes of these hybrid composites also carry environmental implications. Delamination and fiber pullout, common failure mechanisms in layered composites, can lead to microplastic and carbon fiber fragment release during use or at end-of-life. These particles present emerging environmental concerns, particularly in marine environments where UHMWPE composites might find applications in offshore structures or maritime equipment.

Recent research has explored more sustainable approaches to UHMWPE composite manufacturing, including solvent-free processing methods and the incorporation of bio-based reinforcements alongside carbon fibers. These hybrid approaches aim to maintain the superior mechanical properties while reducing environmental impact. Additionally, thermal recycling techniques that preserve the valuable carbon fiber component while recovering energy from the polymer matrix show promise for closing the material loop.

The balance between performance requirements—particularly those related to managing residual stresses and preventing catastrophic failure modes—and environmental considerations remains a key challenge for widespread adoption. Future developments in this field will likely focus on designing carbon/UHMWPE composites with both optimal mechanical properties and improved end-of-life recyclability, potentially through the use of reversible bonding agents or more compatible fiber treatments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!