Comparative Performance of Naturally Aspirated vs Turbocharged V12 Engines

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution

The V12 engine has a rich history dating back to the early 20th century. Initially developed for luxury automobiles and racing cars, these engines were prized for their smooth operation and impressive power output. The evolution of V12 engines can be traced through several key phases, each marked by significant technological advancements.

In the 1920s and 1930s, V12 engines gained prominence in high-end vehicles and motorsports. Manufacturers like Packard, Cadillac, and Lincoln introduced V12 engines in their flagship models, setting new standards for performance and refinement. During this period, naturally aspirated V12 engines were the norm, relying on large displacements to generate power.

The post-World War II era saw a decline in V12 usage for passenger cars, as V8 engines became more popular due to their lower cost and improved fuel efficiency. However, V12 engines continued to evolve in the realm of high-performance and luxury vehicles. Ferrari, in particular, became synonymous with V12 engines, using them in their most prestigious models.

The 1960s and 1970s witnessed further refinements in V12 technology, with advancements in materials science and manufacturing techniques allowing for higher revving engines and improved reliability. Lamborghini's introduction of the mid-engine V12 layout in the Miura marked a significant milestone in supercar design.

The 1980s and 1990s saw a resurgence of V12 engines in luxury sedans, with brands like BMW and Mercedes-Benz introducing V12 options in their flagship models. These engines focused on smooth power delivery and refinement, often featuring advanced electronic engine management systems.

The turn of the millennium brought about a new era for V12 engines, with the introduction of turbocharging technology. While some manufacturers, like Ferrari, initially resisted turbocharging to maintain the traditional high-revving character of their V12 engines, others embraced forced induction to meet increasingly stringent emissions regulations while boosting performance.

In recent years, the debate between naturally aspirated and turbocharged V12 engines has intensified. Naturally aspirated V12s, championed by brands like Ferrari and Lamborghini, continue to offer linear power delivery and an iconic engine note. Conversely, turbocharged V12s, as seen in some Bentley and Aston Martin models, provide massive torque figures and improved fuel efficiency.

The future of V12 engines faces challenges from stricter emissions standards and the shift towards electrification. However, their legacy in automotive history and their continued presence in ultra-luxury and high-performance vehicles ensure that the V12 engine's evolution will remain a fascinating subject for enthusiasts and engineers alike.

In the 1920s and 1930s, V12 engines gained prominence in high-end vehicles and motorsports. Manufacturers like Packard, Cadillac, and Lincoln introduced V12 engines in their flagship models, setting new standards for performance and refinement. During this period, naturally aspirated V12 engines were the norm, relying on large displacements to generate power.

The post-World War II era saw a decline in V12 usage for passenger cars, as V8 engines became more popular due to their lower cost and improved fuel efficiency. However, V12 engines continued to evolve in the realm of high-performance and luxury vehicles. Ferrari, in particular, became synonymous with V12 engines, using them in their most prestigious models.

The 1960s and 1970s witnessed further refinements in V12 technology, with advancements in materials science and manufacturing techniques allowing for higher revving engines and improved reliability. Lamborghini's introduction of the mid-engine V12 layout in the Miura marked a significant milestone in supercar design.

The 1980s and 1990s saw a resurgence of V12 engines in luxury sedans, with brands like BMW and Mercedes-Benz introducing V12 options in their flagship models. These engines focused on smooth power delivery and refinement, often featuring advanced electronic engine management systems.

The turn of the millennium brought about a new era for V12 engines, with the introduction of turbocharging technology. While some manufacturers, like Ferrari, initially resisted turbocharging to maintain the traditional high-revving character of their V12 engines, others embraced forced induction to meet increasingly stringent emissions regulations while boosting performance.

In recent years, the debate between naturally aspirated and turbocharged V12 engines has intensified. Naturally aspirated V12s, championed by brands like Ferrari and Lamborghini, continue to offer linear power delivery and an iconic engine note. Conversely, turbocharged V12s, as seen in some Bentley and Aston Martin models, provide massive torque figures and improved fuel efficiency.

The future of V12 engines faces challenges from stricter emissions standards and the shift towards electrification. However, their legacy in automotive history and their continued presence in ultra-luxury and high-performance vehicles ensure that the V12 engine's evolution will remain a fascinating subject for enthusiasts and engineers alike.

Market Demand Analysis

The market demand for high-performance V12 engines, both naturally aspirated and turbocharged, has been evolving significantly in recent years. Luxury and sports car manufacturers continue to invest in V12 technology, driven by the prestige and performance associated with these powerplants. However, the market is experiencing a shift towards more efficient and environmentally friendly solutions.

Naturally aspirated V12 engines have traditionally been favored for their linear power delivery, immediate throttle response, and iconic exhaust note. These characteristics are highly valued in the ultra-luxury and high-performance sports car segments. Brands like Ferrari, Lamborghini, and Aston Martin have maintained a strong presence in this market, catering to enthusiasts who prioritize the pure driving experience offered by naturally aspirated engines.

On the other hand, turbocharged V12 engines have gained traction due to their ability to deliver higher power outputs while potentially improving fuel efficiency. This technology has become increasingly popular among luxury car manufacturers such as Mercedes-Benz and BMW, who seek to balance performance with stricter emissions regulations. The demand for turbocharged V12 engines is particularly strong in markets where fuel economy and emissions standards are becoming more stringent.

The overall market size for V12 engines remains relatively niche but lucrative. While exact figures are challenging to pinpoint due to the exclusive nature of these engines, industry reports suggest that annual production numbers for V12-powered vehicles are in the low thousands globally. This limited production contributes to the exclusivity and high price points of vehicles equipped with these engines.

Market trends indicate a gradual shift towards electrification, even in the high-performance segment. This transition is influencing the demand for both naturally aspirated and turbocharged V12 engines. Some manufacturers are exploring hybrid V12 powertrains as a bridge technology, combining the prestige of the V12 with improved efficiency and reduced emissions.

Despite the push towards electrification, there remains a dedicated consumer base for V12 engines, particularly in emerging markets where luxury car sales continue to grow. These markets value the status and performance associated with V12-powered vehicles, sustaining demand for both naturally aspirated and turbocharged variants.

In conclusion, while the market for V12 engines faces challenges from evolving regulations and technological shifts, there continues to be a significant demand for both naturally aspirated and turbocharged variants. The future market trajectory will likely be shaped by advancements in hybrid technology and the ability of manufacturers to adapt V12 engines to meet increasingly stringent environmental standards while maintaining their performance appeal.

Naturally aspirated V12 engines have traditionally been favored for their linear power delivery, immediate throttle response, and iconic exhaust note. These characteristics are highly valued in the ultra-luxury and high-performance sports car segments. Brands like Ferrari, Lamborghini, and Aston Martin have maintained a strong presence in this market, catering to enthusiasts who prioritize the pure driving experience offered by naturally aspirated engines.

On the other hand, turbocharged V12 engines have gained traction due to their ability to deliver higher power outputs while potentially improving fuel efficiency. This technology has become increasingly popular among luxury car manufacturers such as Mercedes-Benz and BMW, who seek to balance performance with stricter emissions regulations. The demand for turbocharged V12 engines is particularly strong in markets where fuel economy and emissions standards are becoming more stringent.

The overall market size for V12 engines remains relatively niche but lucrative. While exact figures are challenging to pinpoint due to the exclusive nature of these engines, industry reports suggest that annual production numbers for V12-powered vehicles are in the low thousands globally. This limited production contributes to the exclusivity and high price points of vehicles equipped with these engines.

Market trends indicate a gradual shift towards electrification, even in the high-performance segment. This transition is influencing the demand for both naturally aspirated and turbocharged V12 engines. Some manufacturers are exploring hybrid V12 powertrains as a bridge technology, combining the prestige of the V12 with improved efficiency and reduced emissions.

Despite the push towards electrification, there remains a dedicated consumer base for V12 engines, particularly in emerging markets where luxury car sales continue to grow. These markets value the status and performance associated with V12-powered vehicles, sustaining demand for both naturally aspirated and turbocharged variants.

In conclusion, while the market for V12 engines faces challenges from evolving regulations and technological shifts, there continues to be a significant demand for both naturally aspirated and turbocharged variants. The future market trajectory will likely be shaped by advancements in hybrid technology and the ability of manufacturers to adapt V12 engines to meet increasingly stringent environmental standards while maintaining their performance appeal.

NA vs Turbo Challenges

The comparison between naturally aspirated and turbocharged V12 engines presents several significant challenges in terms of performance, design, and implementation. These challenges stem from the fundamental differences in how these two engine types generate power and respond to driver inputs.

One of the primary challenges lies in managing heat and thermal efficiency. Turbocharged engines, by their nature, generate more heat due to the compression of intake air. This excess heat can lead to increased wear on engine components and potential reliability issues if not properly managed. Cooling systems for turbocharged V12 engines must be more robust and efficient compared to their naturally aspirated counterparts, often requiring larger radiators and more complex intercooler setups.

Power delivery characteristics pose another significant challenge. Naturally aspirated V12 engines typically offer linear power delivery and immediate throttle response, which many enthusiasts and drivers prefer. In contrast, turbocharged engines can suffer from turbo lag, a delay between throttle input and power delivery as the turbocharger spools up. Engineers must work to minimize this lag in turbocharged V12 engines to maintain the responsiveness expected from a high-performance powerplant.

Packaging and weight distribution present additional hurdles. Turbocharged engines require extra components such as turbochargers, intercoolers, and associated plumbing, which can increase the overall weight and complexity of the engine. This added weight and the need for additional space can affect the vehicle's balance and handling characteristics, requiring careful consideration in chassis design and weight distribution.

Fuel efficiency and emissions compliance create further challenges. While turbocharged engines can be more fuel-efficient at partial loads, they may consume more fuel under full boost. Balancing performance with fuel economy and meeting increasingly stringent emissions regulations is a complex task for both engine types, but particularly for high-displacement V12 engines.

Sound quality and character are crucial aspects of the V12 engine experience. Naturally aspirated V12s are renowned for their distinctive, spine-tingling exhaust notes. Turbocharged engines, however, can muffle this sound due to the turbocharger acting as a sound damper. Engineers must work to preserve the emotive auditory experience while adhering to noise regulations, often employing complex exhaust systems and sound engineering techniques.

Lastly, cost and complexity factors cannot be overlooked. Turbocharged V12 engines generally involve higher production costs due to additional components and more complex control systems. This increased complexity can also impact long-term reliability and maintenance requirements, potentially affecting the overall ownership experience and brand perception.

One of the primary challenges lies in managing heat and thermal efficiency. Turbocharged engines, by their nature, generate more heat due to the compression of intake air. This excess heat can lead to increased wear on engine components and potential reliability issues if not properly managed. Cooling systems for turbocharged V12 engines must be more robust and efficient compared to their naturally aspirated counterparts, often requiring larger radiators and more complex intercooler setups.

Power delivery characteristics pose another significant challenge. Naturally aspirated V12 engines typically offer linear power delivery and immediate throttle response, which many enthusiasts and drivers prefer. In contrast, turbocharged engines can suffer from turbo lag, a delay between throttle input and power delivery as the turbocharger spools up. Engineers must work to minimize this lag in turbocharged V12 engines to maintain the responsiveness expected from a high-performance powerplant.

Packaging and weight distribution present additional hurdles. Turbocharged engines require extra components such as turbochargers, intercoolers, and associated plumbing, which can increase the overall weight and complexity of the engine. This added weight and the need for additional space can affect the vehicle's balance and handling characteristics, requiring careful consideration in chassis design and weight distribution.

Fuel efficiency and emissions compliance create further challenges. While turbocharged engines can be more fuel-efficient at partial loads, they may consume more fuel under full boost. Balancing performance with fuel economy and meeting increasingly stringent emissions regulations is a complex task for both engine types, but particularly for high-displacement V12 engines.

Sound quality and character are crucial aspects of the V12 engine experience. Naturally aspirated V12s are renowned for their distinctive, spine-tingling exhaust notes. Turbocharged engines, however, can muffle this sound due to the turbocharger acting as a sound damper. Engineers must work to preserve the emotive auditory experience while adhering to noise regulations, often employing complex exhaust systems and sound engineering techniques.

Lastly, cost and complexity factors cannot be overlooked. Turbocharged V12 engines generally involve higher production costs due to additional components and more complex control systems. This increased complexity can also impact long-term reliability and maintenance requirements, potentially affecting the overall ownership experience and brand perception.

Current V12 Solutions

01 Engine control and optimization

V12 engine performance can be enhanced through advanced control systems and optimization techniques. This includes electronic engine management, fuel injection control, and adaptive algorithms to improve efficiency and power output across various operating conditions.- Engine control and optimization: V12 engine performance can be enhanced through advanced control systems and optimization techniques. This includes electronic engine management, fuel injection control, and adaptive algorithms to improve efficiency and power output across various operating conditions.

- Turbocharging and supercharging: Forced induction systems, such as turbochargers and superchargers, are employed to boost V12 engine performance. These systems increase air intake, allowing for more fuel combustion and resulting in higher power output and improved efficiency.

- Combustion chamber design: Optimizing the combustion chamber design in V12 engines can lead to improved performance. This includes refining the shape, size, and positioning of valves, pistons, and fuel injectors to enhance fuel-air mixture, combustion efficiency, and overall engine output.

- Materials and manufacturing techniques: Utilizing advanced materials and manufacturing techniques can significantly impact V12 engine performance. This includes the use of lightweight alloys, composite materials, and precision manufacturing processes to reduce weight, improve heat dissipation, and enhance overall engine efficiency.

- Exhaust system optimization: Enhancing the exhaust system design can improve V12 engine performance by reducing back pressure and optimizing exhaust gas flow. This may involve the use of variable valve timing, tuned exhaust manifolds, and advanced catalytic converter designs to balance performance and emissions.

02 Turbocharging and supercharging

Forced induction systems such as turbochargers and superchargers are employed to boost V12 engine performance. These systems increase air intake, allowing for more fuel combustion and resulting in higher power output and improved torque characteristics.Expand Specific Solutions03 Combustion chamber design

Optimizing the combustion chamber design in V12 engines can lead to improved performance. This includes considerations for piston crown shape, valve positioning, and cylinder head design to enhance fuel mixture, combustion efficiency, and overall engine output.Expand Specific Solutions04 Materials and manufacturing techniques

The use of advanced materials and manufacturing techniques can significantly impact V12 engine performance. Lightweight alloys, composite materials, and precision manufacturing processes contribute to reduced engine weight, improved heat dissipation, and enhanced durability.Expand Specific Solutions05 Exhaust system optimization

Enhancing the exhaust system design can improve V12 engine performance by reducing back pressure and optimizing exhaust gas flow. This includes the use of variable exhaust systems, high-flow catalytic converters, and tuned exhaust manifolds to maximize power output and engine efficiency.Expand Specific Solutions

Key Engine Manufacturers

The competition landscape for "Comparative Performance of Naturally Aspirated vs Turbocharged V12 Engines" is characterized by a mature industry with established players and ongoing technological advancements. The market size is substantial, driven by luxury and high-performance vehicle segments. Technologically, both naturally aspirated and turbocharged V12 engines are well-developed, with companies like Ford, Toyota, Jaguar Land Rover, and Volkswagen leading innovation. Emerging players such as BorgWarner and Continental Automotive Technologies are pushing advancements in turbocharging technology, while traditional manufacturers continue to refine naturally aspirated designs. The industry is experiencing a shift towards turbocharging for improved efficiency and power output, though naturally aspirated engines maintain a niche in the ultra-luxury and motorsport sectors.

Ford Global Technologies LLC

Technical Solution: While Ford doesn't currently produce V12 engines, they have extensive experience with both naturally aspirated and turbocharged engines. Their EcoBoost technology, applied to smaller displacement engines, demonstrates their turbocharging expertise. For example, the 3.5-liter EcoBoost V6 produces up to 450 horsepower and 510 lb-ft of torque in some applications[10]. Ford uses twin-turbochargers, direct fuel injection, and variable cam timing to achieve high power output and improved fuel efficiency. They have also developed advanced thermal management systems and integrated exhaust manifolds to optimize turbocharger performance[11]. Ford's research into materials like graphene for engine components could potentially be applied to future high-performance engines[12].

Strengths: High specific output, good low-end torque, and improved fuel efficiency. Weaknesses: Potential for increased complexity and heat management challenges.

BorgWarner, Inc.

Technical Solution: As a leading supplier of turbocharger technology, BorgWarner has significant expertise in forced induction systems applicable to V12 engines. They have developed advanced turbocharger technologies such as variable geometry turbochargers (VGT) and dual-volute turbochargers[13]. BorgWarner's eTurbo™ system combines a traditional turbocharger with an electric motor, allowing for faster response times and reduced lag[14]. Their regulated two-stage (R2S®) turbocharging system uses two sequentially arranged turbochargers to provide a broader power band[15]. While not specific to V12 engines, these technologies could be adapted to enhance the performance of turbocharged V12 powerplants, potentially surpassing naturally aspirated V12s in both power output and efficiency.

Strengths: Cutting-edge turbocharger technology, potential for high power output and improved efficiency. Weaknesses: Increased system complexity, potential for higher costs.

Core V12 Innovations

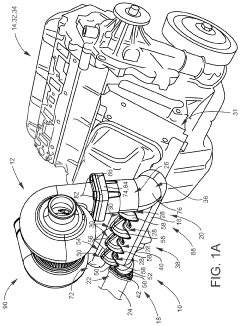

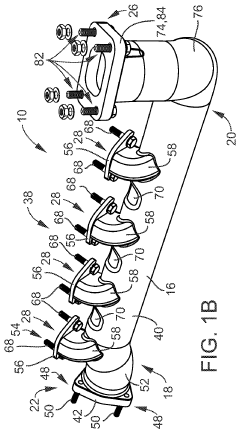

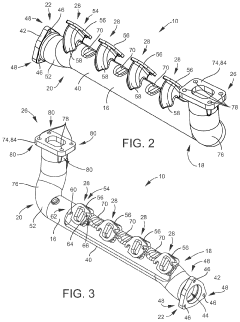

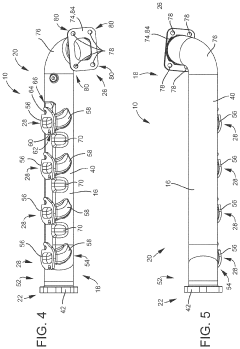

Replacement exhaust manifold for retrofitting a turbocharger to an engine

PatentActiveUS20210262378A1

Innovation

- A replacement exhaust manifold designed for retrofitting a turbocharger onto non-turbo diesel engines, featuring a central channel body, exhaust connection, turbo connection, and multiple exhaust ports, allowing for attachment to the engine without replacing it or lifting the truck body, and made of cast ductile iron with specific flange configurations for secure sealing.

Control of a vehicle having an automatic transmission to compensate for ambient air density

PatentActiveUS20210025489A1

Innovation

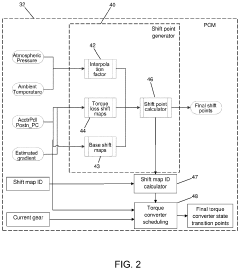

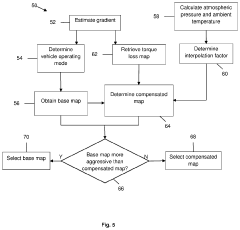

- A method for controlling automatic transmissions that involves receiving signals for vehicle operating mode, ambient air density, and gradient, using base and torque loss maps to determine aggressive gear shift points, and interpolating between them based on air density and gradient to ensure optimal shifting strategy, even when air density is low.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, significantly impacting the development and performance of both naturally aspirated and turbocharged V12 engines. These regulations aim to reduce harmful emissions and improve air quality, forcing manufacturers to adapt their engine designs to meet new standards.

For naturally aspirated V12 engines, meeting emissions regulations has become increasingly challenging. These engines typically rely on larger displacements to generate power, which can result in higher fuel consumption and emissions. Manufacturers have had to implement various technologies to improve efficiency and reduce emissions, such as variable valve timing, direct fuel injection, and advanced engine management systems. However, these measures often come at the cost of reduced power output or increased complexity.

Turbocharged V12 engines, on the other hand, have shown greater adaptability to emissions regulations. The use of turbocharging allows for downsizing, enabling manufacturers to achieve similar power outputs with smaller engine displacements. This reduction in displacement often leads to improved fuel efficiency and lower emissions. Additionally, turbocharging technology has advanced significantly, with innovations like variable geometry turbochargers and electric compressors further enhancing efficiency and emissions control.

The introduction of Euro 6 and similar standards worldwide has placed even greater emphasis on reducing nitrogen oxides (NOx) and particulate matter emissions. This has led to the widespread adoption of exhaust gas recirculation (EGR) systems and particulate filters in both naturally aspirated and turbocharged V12 engines. However, turbocharged engines generally have an advantage in managing NOx emissions due to their ability to precisely control air-fuel ratios across a wider range of operating conditions.

Carbon dioxide (CO2) emissions have also become a focal point of regulations, with many countries implementing fleet-wide CO2 targets. This has further incentivized the shift towards turbocharged engines, as their improved efficiency typically results in lower CO2 emissions compared to naturally aspirated counterparts of similar power output.

The impact of emissions regulations on V12 engines extends beyond just the engine itself. Manufacturers have had to invest heavily in aftertreatment systems, such as three-way catalytic converters and selective catalytic reduction (SCR) systems, to ensure compliance. These systems add complexity, weight, and cost to the overall vehicle, affecting performance and design considerations.

Looking ahead, the trend towards electrification and hybrid powertrains is likely to have a significant impact on V12 engine development. Mild hybrid systems and plug-in hybrid configurations are being explored as ways to further reduce emissions while maintaining the performance characteristics that V12 engines are known for. This evolution may ultimately lead to a shift in the balance between naturally aspirated and turbocharged V12 engines, as manufacturers seek to optimize their powertrains for both performance and regulatory compliance.

For naturally aspirated V12 engines, meeting emissions regulations has become increasingly challenging. These engines typically rely on larger displacements to generate power, which can result in higher fuel consumption and emissions. Manufacturers have had to implement various technologies to improve efficiency and reduce emissions, such as variable valve timing, direct fuel injection, and advanced engine management systems. However, these measures often come at the cost of reduced power output or increased complexity.

Turbocharged V12 engines, on the other hand, have shown greater adaptability to emissions regulations. The use of turbocharging allows for downsizing, enabling manufacturers to achieve similar power outputs with smaller engine displacements. This reduction in displacement often leads to improved fuel efficiency and lower emissions. Additionally, turbocharging technology has advanced significantly, with innovations like variable geometry turbochargers and electric compressors further enhancing efficiency and emissions control.

The introduction of Euro 6 and similar standards worldwide has placed even greater emphasis on reducing nitrogen oxides (NOx) and particulate matter emissions. This has led to the widespread adoption of exhaust gas recirculation (EGR) systems and particulate filters in both naturally aspirated and turbocharged V12 engines. However, turbocharged engines generally have an advantage in managing NOx emissions due to their ability to precisely control air-fuel ratios across a wider range of operating conditions.

Carbon dioxide (CO2) emissions have also become a focal point of regulations, with many countries implementing fleet-wide CO2 targets. This has further incentivized the shift towards turbocharged engines, as their improved efficiency typically results in lower CO2 emissions compared to naturally aspirated counterparts of similar power output.

The impact of emissions regulations on V12 engines extends beyond just the engine itself. Manufacturers have had to invest heavily in aftertreatment systems, such as three-way catalytic converters and selective catalytic reduction (SCR) systems, to ensure compliance. These systems add complexity, weight, and cost to the overall vehicle, affecting performance and design considerations.

Looking ahead, the trend towards electrification and hybrid powertrains is likely to have a significant impact on V12 engine development. Mild hybrid systems and plug-in hybrid configurations are being explored as ways to further reduce emissions while maintaining the performance characteristics that V12 engines are known for. This evolution may ultimately lead to a shift in the balance between naturally aspirated and turbocharged V12 engines, as manufacturers seek to optimize their powertrains for both performance and regulatory compliance.

Fuel Efficiency Impact

The fuel efficiency impact of naturally aspirated versus turbocharged V12 engines is a critical consideration in the automotive industry, particularly for high-performance vehicles. Naturally aspirated V12 engines have traditionally been known for their smooth power delivery and linear response, but they often struggle with fuel efficiency due to their large displacement and constant high-volume air intake. In contrast, turbocharged V12 engines have gained popularity for their ability to deliver comparable or superior power output while potentially improving fuel economy.

Turbocharged V12 engines can achieve better fuel efficiency through several mechanisms. Firstly, they allow for engine downsizing, which reduces overall engine weight and friction losses. By forcing more air into the combustion chamber, turbochargers enable smaller engines to produce power equivalent to larger naturally aspirated units. This downsizing effect can lead to reduced fuel consumption during normal driving conditions when the turbocharger is not fully engaged.

Additionally, turbochargers make use of exhaust gases that would otherwise be wasted, converting this energy into increased intake air pressure. This energy recovery contributes to overall engine efficiency. Turbocharged engines also benefit from more precise fuel injection and combustion control, as the forced induction allows for better atomization of fuel and more complete combustion.

However, the fuel efficiency gains of turbocharged V12 engines are not without caveats. Under high-load conditions or during aggressive acceleration, turbocharged engines may consume more fuel than their naturally aspirated counterparts due to the enriched fuel mixture required to prevent knock and manage higher combustion temperatures. This phenomenon, known as "boost fuel," can offset efficiency gains in certain driving scenarios.

Real-world fuel efficiency comparisons between naturally aspirated and turbocharged V12 engines often show mixed results. While turbocharged engines generally demonstrate better efficiency in standardized test cycles, the actual fuel consumption can vary significantly based on driving style and conditions. Drivers who frequently exploit the full power of turbocharged engines may find that fuel efficiency advantages diminish or disappear entirely.

Manufacturers have implemented various technologies to address these challenges and further improve the fuel efficiency of turbocharged V12 engines. These include variable geometry turbochargers, electric turbochargers, and advanced engine management systems that optimize boost pressure and fuel delivery based on driving conditions. Some automakers have also adopted hybrid technologies in conjunction with turbocharged V12 engines to further enhance fuel efficiency, particularly in low-speed urban driving scenarios.

Turbocharged V12 engines can achieve better fuel efficiency through several mechanisms. Firstly, they allow for engine downsizing, which reduces overall engine weight and friction losses. By forcing more air into the combustion chamber, turbochargers enable smaller engines to produce power equivalent to larger naturally aspirated units. This downsizing effect can lead to reduced fuel consumption during normal driving conditions when the turbocharger is not fully engaged.

Additionally, turbochargers make use of exhaust gases that would otherwise be wasted, converting this energy into increased intake air pressure. This energy recovery contributes to overall engine efficiency. Turbocharged engines also benefit from more precise fuel injection and combustion control, as the forced induction allows for better atomization of fuel and more complete combustion.

However, the fuel efficiency gains of turbocharged V12 engines are not without caveats. Under high-load conditions or during aggressive acceleration, turbocharged engines may consume more fuel than their naturally aspirated counterparts due to the enriched fuel mixture required to prevent knock and manage higher combustion temperatures. This phenomenon, known as "boost fuel," can offset efficiency gains in certain driving scenarios.

Real-world fuel efficiency comparisons between naturally aspirated and turbocharged V12 engines often show mixed results. While turbocharged engines generally demonstrate better efficiency in standardized test cycles, the actual fuel consumption can vary significantly based on driving style and conditions. Drivers who frequently exploit the full power of turbocharged engines may find that fuel efficiency advantages diminish or disappear entirely.

Manufacturers have implemented various technologies to address these challenges and further improve the fuel efficiency of turbocharged V12 engines. These include variable geometry turbochargers, electric turbochargers, and advanced engine management systems that optimize boost pressure and fuel delivery based on driving conditions. Some automakers have also adopted hybrid technologies in conjunction with turbocharged V12 engines to further enhance fuel efficiency, particularly in low-speed urban driving scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!