Comparative Study of Stainless Steels and Superalloys

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metallurgical Background and Research Objectives

The evolution of metallurgical materials has been a cornerstone of industrial advancement since the early 20th century. Stainless steels, first developed in the 1910s, revolutionized manufacturing by offering corrosion resistance combined with mechanical strength. Superalloys emerged later in the 1940s as a response to the demanding requirements of aerospace applications, particularly jet engines that required materials capable of withstanding extreme temperatures while maintaining structural integrity.

The technological trajectory of these materials has been characterized by continuous refinement in composition and processing techniques. Stainless steels have evolved from basic chromium-containing alloys to sophisticated formulations incorporating nickel, molybdenum, and nitrogen to enhance specific properties. Similarly, superalloys have progressed from simple nickel-chromium systems to complex multi-component alloys with precisely controlled microstructures achieved through advanced solidification techniques and heat treatments.

Current trends indicate a growing convergence in certain application spaces where the performance boundaries between advanced stainless steels and entry-level superalloys are becoming increasingly blurred. This convergence presents both challenges and opportunities for materials scientists and engineers seeking optimal cost-performance solutions for critical applications.

The primary objective of this research is to conduct a comprehensive comparative analysis of stainless steels and superalloys across multiple performance dimensions. This includes mechanical properties (tensile strength, fatigue resistance, creep behavior), environmental resistance (oxidation, corrosion, sulfidation), fabricability (forming, machining, joining), and economic considerations (raw material costs, processing expenses, lifecycle economics).

Secondary objectives include identifying specific application spaces where material substitution may be viable, mapping the performance-cost frontier between these material classes, and forecasting future development pathways that might further alter the competitive landscape between these materials.

This research aims to establish a systematic framework for material selection decisions in high-performance applications, particularly in energy generation, chemical processing, and aerospace sectors where the choice between stainless steels and superalloys has significant technical and economic implications. By clarifying the technical boundaries and economic trade-offs between these material classes, this study will provide valuable guidance for engineering design decisions and strategic materials development initiatives.

The technological trajectory of these materials has been characterized by continuous refinement in composition and processing techniques. Stainless steels have evolved from basic chromium-containing alloys to sophisticated formulations incorporating nickel, molybdenum, and nitrogen to enhance specific properties. Similarly, superalloys have progressed from simple nickel-chromium systems to complex multi-component alloys with precisely controlled microstructures achieved through advanced solidification techniques and heat treatments.

Current trends indicate a growing convergence in certain application spaces where the performance boundaries between advanced stainless steels and entry-level superalloys are becoming increasingly blurred. This convergence presents both challenges and opportunities for materials scientists and engineers seeking optimal cost-performance solutions for critical applications.

The primary objective of this research is to conduct a comprehensive comparative analysis of stainless steels and superalloys across multiple performance dimensions. This includes mechanical properties (tensile strength, fatigue resistance, creep behavior), environmental resistance (oxidation, corrosion, sulfidation), fabricability (forming, machining, joining), and economic considerations (raw material costs, processing expenses, lifecycle economics).

Secondary objectives include identifying specific application spaces where material substitution may be viable, mapping the performance-cost frontier between these material classes, and forecasting future development pathways that might further alter the competitive landscape between these materials.

This research aims to establish a systematic framework for material selection decisions in high-performance applications, particularly in energy generation, chemical processing, and aerospace sectors where the choice between stainless steels and superalloys has significant technical and economic implications. By clarifying the technical boundaries and economic trade-offs between these material classes, this study will provide valuable guidance for engineering design decisions and strategic materials development initiatives.

Market Applications and Industry Demand Analysis

The global market for stainless steels and superalloys continues to expand significantly, driven by increasing demand across multiple high-value industries. The aerospace sector represents one of the largest consumers of superalloys, with an estimated market value exceeding $5 billion annually. This demand is primarily fueled by the need for materials capable of withstanding extreme temperatures and stress conditions in aircraft engines and structural components. Industry forecasts project a compound annual growth rate of 7-8% for aerospace-grade superalloys through 2030, reflecting the ongoing expansion of commercial aviation and defense sectors.

In the energy sector, particularly power generation and oil & gas industries, the demand for both stainless steels and superalloys has shown remarkable resilience despite fluctuations in energy prices. The transition toward cleaner energy solutions has created new market opportunities, with superalloys being increasingly utilized in natural gas turbines and advanced nuclear reactors. The chemical processing industry represents another significant market, valued at approximately $3.2 billion for specialized corrosion-resistant alloys.

Medical applications constitute a rapidly growing market segment, especially for specific grades of stainless steel and nickel-based superalloys. The global medical implant market, which heavily relies on these materials, is expanding at nearly 6% annually, driven by aging populations in developed economies and improving healthcare access in emerging markets. Surgical instruments and equipment manufacturing also maintain steady demand for premium stainless steel variants.

Automotive and transportation sectors present evolving demand patterns, with high-temperature applications in turbochargers and exhaust systems creating niche markets for superalloys. Meanwhile, the shift toward electric vehicles is reshaping material requirements, with greater emphasis on thermal management properties rather than traditional combustion engine applications.

Regional analysis reveals significant market variations, with North America and Europe maintaining strong demand for high-performance superalloys in aerospace and medical applications. The Asia-Pacific region, particularly China and India, demonstrates the fastest growth rates across multiple application segments, driven by rapid industrialization and infrastructure development. These emerging markets are increasingly focused on developing domestic production capabilities for advanced alloys, potentially altering global supply dynamics.

Price sensitivity varies considerably across application segments, with aerospace and defense sectors demonstrating relatively inelastic demand due to certification requirements and performance specifications. In contrast, general industrial applications show greater price sensitivity, creating distinct market segments with different competitive dynamics and profit margins.

In the energy sector, particularly power generation and oil & gas industries, the demand for both stainless steels and superalloys has shown remarkable resilience despite fluctuations in energy prices. The transition toward cleaner energy solutions has created new market opportunities, with superalloys being increasingly utilized in natural gas turbines and advanced nuclear reactors. The chemical processing industry represents another significant market, valued at approximately $3.2 billion for specialized corrosion-resistant alloys.

Medical applications constitute a rapidly growing market segment, especially for specific grades of stainless steel and nickel-based superalloys. The global medical implant market, which heavily relies on these materials, is expanding at nearly 6% annually, driven by aging populations in developed economies and improving healthcare access in emerging markets. Surgical instruments and equipment manufacturing also maintain steady demand for premium stainless steel variants.

Automotive and transportation sectors present evolving demand patterns, with high-temperature applications in turbochargers and exhaust systems creating niche markets for superalloys. Meanwhile, the shift toward electric vehicles is reshaping material requirements, with greater emphasis on thermal management properties rather than traditional combustion engine applications.

Regional analysis reveals significant market variations, with North America and Europe maintaining strong demand for high-performance superalloys in aerospace and medical applications. The Asia-Pacific region, particularly China and India, demonstrates the fastest growth rates across multiple application segments, driven by rapid industrialization and infrastructure development. These emerging markets are increasingly focused on developing domestic production capabilities for advanced alloys, potentially altering global supply dynamics.

Price sensitivity varies considerably across application segments, with aerospace and defense sectors demonstrating relatively inelastic demand due to certification requirements and performance specifications. In contrast, general industrial applications show greater price sensitivity, creating distinct market segments with different competitive dynamics and profit margins.

Current Technological Status and Material Limitations

The global landscape of advanced materials for high-performance applications is currently dominated by stainless steels and superalloys, with each material category exhibiting distinct technological maturity levels. Stainless steels have reached a relatively mature development stage with widespread industrial adoption across sectors including construction, automotive, and consumer goods. In contrast, superalloys remain in an active innovation phase, primarily serving specialized high-temperature applications in aerospace, power generation, and chemical processing industries.

Current stainless steel technology has achieved significant advancements in corrosion resistance through precise control of chromium, nickel, and molybdenum content. The 300-series austenitic stainless steels represent the most widely utilized variants, offering excellent formability and weldability. However, these materials face limitations in extreme temperature environments exceeding 650°C, where mechanical properties deteriorate substantially and oxidation resistance becomes compromised.

Superalloys, particularly nickel-based variants like Inconel and Hastelloy, have pushed performance boundaries with service temperatures reaching 1100°C in oxidizing environments. These materials achieve their exceptional properties through complex precipitation strengthening mechanisms and carefully engineered microstructures. Despite these advantages, superalloys face significant manufacturing challenges including poor machinability, complex heat treatment requirements, and substantially higher raw material costs—often 5-10 times that of premium stainless steels.

A critical technological barrier for both material classes involves the trade-off between mechanical properties and corrosion resistance. Enhancing strength through precipitation hardening or work hardening frequently compromises corrosion performance, creating a persistent engineering dilemma. This challenge is particularly evident in applications requiring both high mechanical loads and aggressive chemical environments.

Recent research has focused on addressing these limitations through advanced processing techniques. Powder metallurgy, additive manufacturing, and directional solidification have emerged as promising approaches for superalloys, enabling more precise microstructural control. For stainless steels, developments in thermomechanical processing and nitrogen alloying have extended performance boundaries, though significant gaps remain compared to superalloys.

Material availability represents another constraint, with critical elements for superalloys including cobalt, rhenium, and hafnium facing supply chain vulnerabilities. Geopolitical factors and mining limitations have created price volatility for these strategic materials, driving interest in reduced-content or alternative alloy systems. This situation contrasts with stainless steels, which primarily utilize more abundant elements like chromium, nickel, and manganese.

Current stainless steel technology has achieved significant advancements in corrosion resistance through precise control of chromium, nickel, and molybdenum content. The 300-series austenitic stainless steels represent the most widely utilized variants, offering excellent formability and weldability. However, these materials face limitations in extreme temperature environments exceeding 650°C, where mechanical properties deteriorate substantially and oxidation resistance becomes compromised.

Superalloys, particularly nickel-based variants like Inconel and Hastelloy, have pushed performance boundaries with service temperatures reaching 1100°C in oxidizing environments. These materials achieve their exceptional properties through complex precipitation strengthening mechanisms and carefully engineered microstructures. Despite these advantages, superalloys face significant manufacturing challenges including poor machinability, complex heat treatment requirements, and substantially higher raw material costs—often 5-10 times that of premium stainless steels.

A critical technological barrier for both material classes involves the trade-off between mechanical properties and corrosion resistance. Enhancing strength through precipitation hardening or work hardening frequently compromises corrosion performance, creating a persistent engineering dilemma. This challenge is particularly evident in applications requiring both high mechanical loads and aggressive chemical environments.

Recent research has focused on addressing these limitations through advanced processing techniques. Powder metallurgy, additive manufacturing, and directional solidification have emerged as promising approaches for superalloys, enabling more precise microstructural control. For stainless steels, developments in thermomechanical processing and nitrogen alloying have extended performance boundaries, though significant gaps remain compared to superalloys.

Material availability represents another constraint, with critical elements for superalloys including cobalt, rhenium, and hafnium facing supply chain vulnerabilities. Geopolitical factors and mining limitations have created price volatility for these strategic materials, driving interest in reduced-content or alternative alloy systems. This situation contrasts with stainless steels, which primarily utilize more abundant elements like chromium, nickel, and manganese.

Contemporary Material Solutions and Processing Methods

01 Composition and manufacturing of high-performance stainless steels

High-performance stainless steels with specific compositions of chromium, nickel, and other alloying elements are developed to enhance corrosion resistance and mechanical properties. These steels undergo specialized manufacturing processes including precise heat treatments, controlled cooling, and specific forming techniques to achieve desired microstructures. The resulting materials exhibit superior strength, ductility, and resistance to various corrosive environments while maintaining good formability for industrial applications.- Composition and manufacturing of stainless steels: Stainless steels are iron-based alloys containing chromium, which provides corrosion resistance. The manufacturing process involves specific heat treatments and processing techniques to achieve desired properties. Various elements like nickel, molybdenum, and nitrogen can be added to enhance specific characteristics such as strength, ductility, and resistance to different types of corrosion. The precise control of composition and processing parameters is crucial for obtaining optimal performance in different applications.

- Heat treatment processes for superalloys: Heat treatment processes are essential for developing the desired microstructure and properties in superalloys. These processes include solution treatment, aging, annealing, and quenching. The specific temperature, time, and cooling rate parameters significantly influence the final properties of the alloy. Proper heat treatment can enhance mechanical properties, creep resistance, and high-temperature stability, which are crucial for applications in aerospace, power generation, and other demanding environments.

- Corrosion resistance improvements in alloys: Improving corrosion resistance in stainless steels and superalloys involves specific alloying elements and surface treatments. Chromium forms a passive oxide layer that protects against corrosion, while molybdenum enhances resistance to pitting corrosion. Nitrogen can improve resistance to crevice corrosion. Surface treatments such as passivation, electropolishing, and application of protective coatings can further enhance corrosion resistance. These improvements are particularly important for applications in aggressive environments such as marine, chemical processing, and oil and gas industries.

- Mechanical properties enhancement techniques: Various techniques are employed to enhance the mechanical properties of stainless steels and superalloys. These include grain refinement, precipitation hardening, solid solution strengthening, and work hardening. The addition of specific alloying elements like titanium, aluminum, and niobium can form strengthening precipitates. Cold working followed by appropriate heat treatment can significantly improve strength while maintaining adequate ductility. These enhancement techniques are crucial for applications requiring high strength, fatigue resistance, and toughness at elevated temperatures.

- Welding and joining methods for high-performance alloys: Specialized welding and joining methods are required for stainless steels and superalloys to maintain their properties in the joint area. Techniques include gas tungsten arc welding, electron beam welding, laser welding, and diffusion bonding. Proper selection of filler materials, pre-heating, post-weld heat treatment, and controlled cooling rates are essential to prevent issues such as hot cracking, sensitization, and formation of detrimental phases. These methods ensure that the joined components maintain their structural integrity and corrosion resistance in service conditions.

02 Heat treatment processes for superalloys

Specialized heat treatment processes are critical for optimizing the properties of superalloys. These processes include solution annealing, aging treatments, and controlled cooling regimes that develop specific precipitate structures within the alloy matrix. Such treatments enhance high-temperature strength, creep resistance, and thermal stability of superalloys, making them suitable for extreme operating conditions in aerospace, power generation, and chemical processing industries.Expand Specific Solutions03 Nickel-based superalloys for high-temperature applications

Nickel-based superalloys are engineered for exceptional performance in high-temperature environments. These materials contain carefully balanced compositions of nickel with additions of chromium, cobalt, molybdenum, tungsten, aluminum, and titanium to form strengthening precipitates. The microstructural stability and oxidation resistance of these alloys make them ideal for gas turbine components, jet engines, and other applications requiring strength retention at elevated temperatures up to 1000°C and beyond.Expand Specific Solutions04 Joining and welding techniques for stainless steels and superalloys

Specialized joining and welding techniques are developed for stainless steels and superalloys to maintain their unique properties in the joint region. These methods include controlled-atmosphere welding, specialized filler materials, pre- and post-weld heat treatments, and advanced bonding processes. Such techniques prevent sensitization, minimize distortion, and ensure that welded components maintain corrosion resistance, strength, and other critical properties required for demanding service environments.Expand Specific Solutions05 Surface treatments and coatings for enhanced performance

Surface treatments and specialized coatings are applied to stainless steels and superalloys to enhance their performance characteristics. These processes include nitriding, carburizing, aluminizing, and the application of thermal barrier or oxidation-resistant coatings. Such treatments create modified surface layers that improve wear resistance, fatigue strength, corrosion protection, and high-temperature oxidation resistance while maintaining the beneficial bulk properties of the underlying alloy.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The stainless steel and superalloy market is currently in a mature growth phase, with an estimated global market size exceeding $180 billion. Technical innovation is primarily driven by aerospace, energy, and automotive sectors demanding higher performance materials. The competitive landscape features established industrial giants like Rolls Royce, Nippon Steel, and General Electric focusing on large-scale production, while specialized innovators such as QuesTek Innovations and Sandvik Intellectual Property lead in material science R&D. Academic-industrial partnerships with institutions like Northeastern University and Xi'an Jiaotong University are accelerating technological advancement. The industry is trending toward computational materials design, additive manufacturing integration, and sustainable production methods, with companies like Siemens Energy and Safran investing heavily in next-generation alloy development.

QuesTek Innovations LLC

Technical Solution: QuesTek employs an Integrated Computational Materials Engineering (ICME) approach for developing advanced stainless steels and superalloys. Their proprietary Materials by Design® methodology combines quantum mechanics, thermodynamics, and kinetic modeling to design alloys at the atomic level. For stainless steels, they've developed Ferrium® S53®, an ultra-high-strength corrosion-resistant steel that achieves superior stress corrosion cracking resistance while maintaining high strength levels (>1400 MPa). In superalloys, QuesTek has created nickel-based systems with optimized gamma prime precipitate distributions that deliver exceptional high-temperature performance up to 1100°C while reducing costly elements like rhenium and ruthenium[1]. Their computational approach allows for rapid iteration through virtual prototypes, reducing development time from decades to just a few years while precisely tailoring microstructures for specific property combinations[3].

Strengths: Accelerated materials development timeline (80% faster than traditional methods); precise property optimization through computational modeling; reduced dependency on expensive alloying elements. Weaknesses: Higher initial development costs; requires sophisticated computational infrastructure; some properties still require extensive physical validation despite modeling advances.

ROLLS ROYCE PLC

Technical Solution: Rolls-Royce has developed proprietary nickel-based superalloys specifically engineered for extreme aerospace environments. Their RR1000 superalloy represents a significant advancement, containing approximately 15% chromium, 15% cobalt, 5% molybdenum, 3.6% titanium, and 3% aluminum with controlled additions of hafnium, tantalum, and zirconium[1]. This composition delivers exceptional creep resistance at temperatures exceeding 700°C while maintaining fatigue strength critical for rotating components. Rolls-Royce employs a sophisticated powder metallurgy route for these superalloys, involving gas atomization to produce ultra-clean powders followed by hot isostatic pressing (HIP) and specialized heat treatments to optimize the gamma/gamma-prime microstructure. Their manufacturing process includes proprietary directional solidification and single crystal growth techniques for turbine blades, achieving temperature capabilities up to 1150°C in their most advanced components[3]. For stainless steel applications in less demanding sections, Rolls-Royce has developed custom martensitic grades with enhanced nitrogen content that deliver superior corrosion resistance while maintaining the necessary mechanical properties for aerospace applications. Their integrated computational materials engineering approach enables microstructural optimization across multiple length scales, resulting in components with tailored property gradients to address specific operational requirements[5].

Strengths: Exceptional high-temperature performance (up to 1150°C); sophisticated manufacturing capabilities including single crystal growth; comprehensive testing facilities allowing simulation of actual service conditions. Weaknesses: Extremely high production costs; complex manufacturing processes requiring specialized equipment; heavy reliance on strategic elements (rhenium, ruthenium) with supply chain vulnerabilities.

Key Innovations in Alloy Composition and Properties

Oxidation state sensors and methods for transition metal alloys

PatentInactiveUS20120040467A1

Innovation

- A non-destructive method involving the application of an oxidation state sensor molecule to discriminate between transition metals in different oxidation states on the alloy surface, allowing for the determination of degradation distribution without damaging the component.

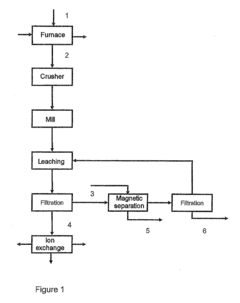

Recycling of superalloys with the aid of an alkali metal salt bath

PatentInactiveUS20090255372A1

Innovation

- A process involving digestion of superalloys in a salt melt composed of 60-95% NaOH and 5-40% Na2SO4, with optional addition of sodium carbonate, followed by hydrometallurgical working-up to separate individual metals, utilizing a directly or indirectly heated furnace at temperatures between 800-1200°C, and subsequent magnetic separation to recover valuable metals like nickel, cobalt, and rhenium.

Environmental Impact and Sustainability Considerations

The environmental footprint of materials selection in high-performance applications has become increasingly critical as industries face mounting pressure to reduce their ecological impact. When comparing stainless steels and superalloys, lifecycle assessment reveals significant differences in environmental performance across production, use, and end-of-life phases.

Production of superalloys typically requires more energy-intensive processes than stainless steels, with nickel-based superalloys demanding up to 3-4 times more energy per unit mass. This translates to substantially higher carbon emissions during manufacturing. Recent studies indicate that producing one ton of nickel-based superalloy generates approximately 16-20 tons of CO2 equivalent, compared to 4-6 tons for austenitic stainless steel.

Water consumption and land use impacts also differ markedly between these material classes. Mining operations for superalloy constituents like nickel, cobalt, and rare elements often result in greater habitat disruption and water pollution risks than the primarily iron-based extraction for stainless steels. However, technological advancements in mining practices are gradually reducing these disparities.

From a resource depletion perspective, superalloys incorporate several critical raw materials with supply vulnerability concerns. Elements such as rhenium, hafnium, and certain rare earth metals face potential scarcity issues, while stainless steels rely predominantly on more abundant resources. This raises long-term sustainability questions for superalloy-dependent industries.

Recyclability represents a significant advantage for stainless steels, with recovery rates exceeding 80% in developed economies. Superalloys, while technically recyclable, face challenges in separation and recovery due to their complex compositions, resulting in lower effective recycling rates of 40-60%. Emerging technologies in metallurgical separation are addressing this gap, potentially improving superalloy circularity.

Service life considerations partially offset production impacts, as superalloys' superior performance in extreme environments can extend component lifespans by 2-3 times compared to stainless steel alternatives. This longevity factor significantly improves their lifetime environmental assessment, particularly in aerospace and power generation applications.

Industry initiatives are increasingly focusing on developing lower-impact variants of both material classes. Research into reduced-nickel stainless steels and superalloys with decreased critical element content shows promise for maintaining performance while improving sustainability profiles. Additionally, advanced manufacturing techniques like additive manufacturing are reducing material waste during production by up to 40% compared to traditional subtractive processes.

Production of superalloys typically requires more energy-intensive processes than stainless steels, with nickel-based superalloys demanding up to 3-4 times more energy per unit mass. This translates to substantially higher carbon emissions during manufacturing. Recent studies indicate that producing one ton of nickel-based superalloy generates approximately 16-20 tons of CO2 equivalent, compared to 4-6 tons for austenitic stainless steel.

Water consumption and land use impacts also differ markedly between these material classes. Mining operations for superalloy constituents like nickel, cobalt, and rare elements often result in greater habitat disruption and water pollution risks than the primarily iron-based extraction for stainless steels. However, technological advancements in mining practices are gradually reducing these disparities.

From a resource depletion perspective, superalloys incorporate several critical raw materials with supply vulnerability concerns. Elements such as rhenium, hafnium, and certain rare earth metals face potential scarcity issues, while stainless steels rely predominantly on more abundant resources. This raises long-term sustainability questions for superalloy-dependent industries.

Recyclability represents a significant advantage for stainless steels, with recovery rates exceeding 80% in developed economies. Superalloys, while technically recyclable, face challenges in separation and recovery due to their complex compositions, resulting in lower effective recycling rates of 40-60%. Emerging technologies in metallurgical separation are addressing this gap, potentially improving superalloy circularity.

Service life considerations partially offset production impacts, as superalloys' superior performance in extreme environments can extend component lifespans by 2-3 times compared to stainless steel alternatives. This longevity factor significantly improves their lifetime environmental assessment, particularly in aerospace and power generation applications.

Industry initiatives are increasingly focusing on developing lower-impact variants of both material classes. Research into reduced-nickel stainless steels and superalloys with decreased critical element content shows promise for maintaining performance while improving sustainability profiles. Additionally, advanced manufacturing techniques like additive manufacturing are reducing material waste during production by up to 40% compared to traditional subtractive processes.

Cost-Benefit Analysis of Material Selection

When evaluating material selection for critical applications, cost-benefit analysis provides essential insights into the economic viability of choosing between stainless steels and superalloys. Initial acquisition costs represent a significant differentiator, with stainless steels typically ranging from $2-10 per kilogram while superalloys can command $20-100 per kilogram or higher, depending on specific compositions and market conditions.

However, focusing solely on purchase price overlooks the total cost of ownership across the material's service life. Superalloys demonstrate superior longevity in extreme environments, potentially offering service lifespans 2-5 times longer than conventional stainless steels when exposed to high temperatures and corrosive conditions. This extended operational life significantly reduces replacement frequency and associated downtime costs.

Maintenance requirements further impact the economic equation. Stainless steels generally require more frequent inspection and potential replacement in demanding applications, whereas superalloys' enhanced resistance to creep, fatigue, and corrosion translates to reduced maintenance intervals and lower associated labor costs. Industry data suggests maintenance savings of 30-50% over a ten-year operational period when utilizing appropriate superalloys.

Energy efficiency considerations also favor superalloys in high-temperature applications. Their superior thermal stability allows systems to operate at higher temperatures with improved efficiency. For power generation applications, this can translate to 2-4% higher thermal efficiency, yielding substantial operational savings over equipment lifetime despite higher initial material costs.

Risk mitigation represents another critical factor in the cost-benefit calculation. Component failure in critical applications can result in catastrophic consequences, including production losses, safety incidents, and reputational damage. The enhanced reliability of superalloys in extreme environments provides an insurance effect that, while difficult to quantify precisely, offers significant value in high-stakes applications like aerospace, nuclear, and petrochemical processing.

Recyclability and end-of-life considerations must also factor into comprehensive analysis. Both material categories offer good recyclability, though specialized superalloy compositions may require more sophisticated recycling processes. The higher intrinsic value of superalloys can partially offset initial costs through improved salvage value at end-of-life, typically recovering 30-45% of original material costs compared to 15-25% for stainless steels.

However, focusing solely on purchase price overlooks the total cost of ownership across the material's service life. Superalloys demonstrate superior longevity in extreme environments, potentially offering service lifespans 2-5 times longer than conventional stainless steels when exposed to high temperatures and corrosive conditions. This extended operational life significantly reduces replacement frequency and associated downtime costs.

Maintenance requirements further impact the economic equation. Stainless steels generally require more frequent inspection and potential replacement in demanding applications, whereas superalloys' enhanced resistance to creep, fatigue, and corrosion translates to reduced maintenance intervals and lower associated labor costs. Industry data suggests maintenance savings of 30-50% over a ten-year operational period when utilizing appropriate superalloys.

Energy efficiency considerations also favor superalloys in high-temperature applications. Their superior thermal stability allows systems to operate at higher temperatures with improved efficiency. For power generation applications, this can translate to 2-4% higher thermal efficiency, yielding substantial operational savings over equipment lifetime despite higher initial material costs.

Risk mitigation represents another critical factor in the cost-benefit calculation. Component failure in critical applications can result in catastrophic consequences, including production losses, safety incidents, and reputational damage. The enhanced reliability of superalloys in extreme environments provides an insurance effect that, while difficult to quantify precisely, offers significant value in high-stakes applications like aerospace, nuclear, and petrochemical processing.

Recyclability and end-of-life considerations must also factor into comprehensive analysis. Both material categories offer good recyclability, though specialized superalloy compositions may require more sophisticated recycling processes. The higher intrinsic value of superalloys can partially offset initial costs through improved salvage value at end-of-life, typically recovering 30-45% of original material costs compared to 15-25% for stainless steels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!