Microstructural Evolution in Corrosion-Resistant Alloys under Stress

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Corrosion-Resistant Alloys Development History and Objectives

Corrosion-resistant alloys have evolved significantly over the past century, with their development closely tied to industrial advancement and the growing need for materials capable of withstanding harsh environments. The journey began in the early 1900s with the discovery of stainless steel, marking the first major breakthrough in corrosion-resistant metallurgy. This innovation revolutionized numerous industries by providing materials with unprecedented durability in corrosive conditions.

The 1950s and 1960s witnessed the emergence of nickel-based superalloys, designed primarily for aerospace applications requiring exceptional heat and corrosion resistance. These materials represented a quantum leap in alloy engineering, enabling the development of more efficient jet engines and power generation systems. Concurrently, research into the fundamental mechanisms of corrosion accelerated, establishing the electrochemical principles that continue to guide alloy design today.

By the 1980s, the focus shifted toward understanding microstructural factors influencing corrosion resistance. Scientists recognized that an alloy's performance under stress could not be predicted solely by its chemical composition; the arrangement and interaction of microstructural elements played a crucial role. This period saw the development of advanced characterization techniques that revealed the complex relationship between microstructure and corrosion behavior.

The advent of computational materials science in the 1990s and 2000s transformed the field by enabling the prediction of microstructural evolution under various conditions. Researchers could now simulate how different stress states might affect an alloy's microstructure over time, providing insights into potential failure mechanisms before they occurred in real-world applications.

Today's research objectives center on developing alloys with adaptive microstructures that can respond dynamically to environmental changes. The goal is to create materials that maintain optimal corrosion resistance even when subjected to complex combinations of mechanical stress, temperature fluctuations, and aggressive chemical environments. This represents a paradigm shift from static to dynamic material design philosophies.

Looking forward, the field aims to achieve precise control over microstructural evolution through techniques such as grain boundary engineering, nanoscale precipitate distribution, and targeted alloying. The ultimate objective is to develop predictive models that can accurately forecast how an alloy's microstructure will evolve throughout its service life under stress, enabling the design of materials with unprecedented durability and reliability in critical applications such as nuclear reactors, offshore structures, and biomedical implants.

The 1950s and 1960s witnessed the emergence of nickel-based superalloys, designed primarily for aerospace applications requiring exceptional heat and corrosion resistance. These materials represented a quantum leap in alloy engineering, enabling the development of more efficient jet engines and power generation systems. Concurrently, research into the fundamental mechanisms of corrosion accelerated, establishing the electrochemical principles that continue to guide alloy design today.

By the 1980s, the focus shifted toward understanding microstructural factors influencing corrosion resistance. Scientists recognized that an alloy's performance under stress could not be predicted solely by its chemical composition; the arrangement and interaction of microstructural elements played a crucial role. This period saw the development of advanced characterization techniques that revealed the complex relationship between microstructure and corrosion behavior.

The advent of computational materials science in the 1990s and 2000s transformed the field by enabling the prediction of microstructural evolution under various conditions. Researchers could now simulate how different stress states might affect an alloy's microstructure over time, providing insights into potential failure mechanisms before they occurred in real-world applications.

Today's research objectives center on developing alloys with adaptive microstructures that can respond dynamically to environmental changes. The goal is to create materials that maintain optimal corrosion resistance even when subjected to complex combinations of mechanical stress, temperature fluctuations, and aggressive chemical environments. This represents a paradigm shift from static to dynamic material design philosophies.

Looking forward, the field aims to achieve precise control over microstructural evolution through techniques such as grain boundary engineering, nanoscale precipitate distribution, and targeted alloying. The ultimate objective is to develop predictive models that can accurately forecast how an alloy's microstructure will evolve throughout its service life under stress, enabling the design of materials with unprecedented durability and reliability in critical applications such as nuclear reactors, offshore structures, and biomedical implants.

Market Demand Analysis for Advanced Corrosion-Resistant Materials

The global market for advanced corrosion-resistant materials has experienced significant growth in recent years, driven primarily by increasing demands from critical infrastructure sectors. The oil and gas industry remains the largest consumer of these specialized alloys, with an estimated market value exceeding $5 billion annually, as offshore platforms and subsea equipment face increasingly harsh operating environments.

Chemical processing industries represent the second-largest market segment, where exposure to aggressive chemicals and high-temperature environments necessitates materials capable of maintaining structural integrity under combined stress and corrosion conditions. This sector's demand is projected to grow at 6.2% annually through 2028, outpacing the overall market growth rate of 5.4%.

Aerospace and defense applications have emerged as rapidly expanding markets for stress-resistant corrosion alloys, particularly for components exposed to extreme temperature fluctuations and mechanical stresses. The demand in this sector has been growing steadily at 7.8% annually, driven by the need for lightweight yet durable materials in next-generation aircraft and defense systems.

Power generation, particularly nuclear and advanced fossil fuel facilities, constitutes another significant market segment. The need for materials that can withstand radiation damage while maintaining corrosion resistance under stress has created specialized demand for advanced alloys with precisely controlled microstructures.

Geographically, North America and Europe currently dominate market consumption, accounting for approximately 58% of global demand. However, the Asia-Pacific region, led by China and India, is experiencing the fastest growth rate at 9.3% annually, driven by rapid industrialization and infrastructure development.

Market analysis indicates a shifting preference toward alloys with predictable microstructural evolution under stress conditions. End-users increasingly demand materials with documented performance data under specific stress-corrosion scenarios, moving beyond traditional corrosion resistance metrics to more sophisticated performance indicators that account for microstructural stability.

The healthcare sector represents an emerging market with specialized needs for biocompatible corrosion-resistant alloys that can withstand both biological environments and mechanical stresses. This niche segment is growing at 11.2% annually, albeit from a smaller base.

Industry surveys reveal that customers are willing to pay premium prices (typically 15-30% above standard alloys) for materials with demonstrated resistance to stress-corrosion cracking and predictable service lifetimes. This price premium reflects the substantial downstream costs associated with corrosion-related failures, which globally amount to approximately 3.4% of GDP according to recent economic analyses.

Chemical processing industries represent the second-largest market segment, where exposure to aggressive chemicals and high-temperature environments necessitates materials capable of maintaining structural integrity under combined stress and corrosion conditions. This sector's demand is projected to grow at 6.2% annually through 2028, outpacing the overall market growth rate of 5.4%.

Aerospace and defense applications have emerged as rapidly expanding markets for stress-resistant corrosion alloys, particularly for components exposed to extreme temperature fluctuations and mechanical stresses. The demand in this sector has been growing steadily at 7.8% annually, driven by the need for lightweight yet durable materials in next-generation aircraft and defense systems.

Power generation, particularly nuclear and advanced fossil fuel facilities, constitutes another significant market segment. The need for materials that can withstand radiation damage while maintaining corrosion resistance under stress has created specialized demand for advanced alloys with precisely controlled microstructures.

Geographically, North America and Europe currently dominate market consumption, accounting for approximately 58% of global demand. However, the Asia-Pacific region, led by China and India, is experiencing the fastest growth rate at 9.3% annually, driven by rapid industrialization and infrastructure development.

Market analysis indicates a shifting preference toward alloys with predictable microstructural evolution under stress conditions. End-users increasingly demand materials with documented performance data under specific stress-corrosion scenarios, moving beyond traditional corrosion resistance metrics to more sophisticated performance indicators that account for microstructural stability.

The healthcare sector represents an emerging market with specialized needs for biocompatible corrosion-resistant alloys that can withstand both biological environments and mechanical stresses. This niche segment is growing at 11.2% annually, albeit from a smaller base.

Industry surveys reveal that customers are willing to pay premium prices (typically 15-30% above standard alloys) for materials with demonstrated resistance to stress-corrosion cracking and predictable service lifetimes. This price premium reflects the substantial downstream costs associated with corrosion-related failures, which globally amount to approximately 3.4% of GDP according to recent economic analyses.

Current Challenges in Microstructural Stability Under Stress

Despite significant advancements in corrosion-resistant alloys, maintaining microstructural stability under stress conditions remains a formidable challenge. Current research indicates that alloys designed for corrosion resistance often experience accelerated degradation when subjected to simultaneous mechanical stress and corrosive environments. This synergistic effect, known as stress corrosion cracking (SCC), represents one of the most persistent challenges in materials engineering today.

The primary obstacle lies in understanding the complex interplay between mechanical stress fields and electrochemical processes at the microstructural level. Conventional models often fail to accurately predict how localized stress concentrations alter corrosion kinetics, particularly at grain boundaries and phase interfaces. Recent studies have shown that even minor variations in stress distribution can dramatically influence the preferential dissolution of specific microstructural features.

Another significant challenge is the dynamic nature of microstructural evolution during service. Corrosion-resistant alloys typically rely on passive film formation for protection, but mechanical stress can continuously disrupt these protective layers. The repeated formation and breakdown of passive films creates a cyclical degradation process that is difficult to model or mitigate through conventional materials design approaches.

The presence of hydrogen, either from the environment or as a byproduct of corrosion reactions, further complicates microstructural stability. Hydrogen embrittlement mechanisms interact with stress-induced deformation, creating complex degradation pathways that can lead to unexpected failure modes. Current analytical techniques struggle to capture the real-time diffusion and trapping of hydrogen at evolving microstructural features under stress.

Temperature fluctuations present an additional layer of complexity, as they can trigger phase transformations or precipitation events that fundamentally alter the alloy's microstructure during service. These thermally-activated processes interact with stress fields in ways that are not fully understood, particularly in newer alloy systems designed for extreme environments.

From a manufacturing perspective, achieving consistent microstructural stability across production batches remains challenging. Minor variations in processing parameters can create subtle microstructural differences that only manifest as stability issues when the material is subjected to stress in service. This creates significant quality control challenges for industries relying on these advanced materials.

The limitations of current in-situ characterization techniques represent a methodological barrier to progress. While advanced microscopy and spectroscopy methods have improved dramatically, capturing the dynamic evolution of microstructures under simultaneous stress and corrosive attack remains technically challenging, particularly at relevant time scales and environmental conditions.

The primary obstacle lies in understanding the complex interplay between mechanical stress fields and electrochemical processes at the microstructural level. Conventional models often fail to accurately predict how localized stress concentrations alter corrosion kinetics, particularly at grain boundaries and phase interfaces. Recent studies have shown that even minor variations in stress distribution can dramatically influence the preferential dissolution of specific microstructural features.

Another significant challenge is the dynamic nature of microstructural evolution during service. Corrosion-resistant alloys typically rely on passive film formation for protection, but mechanical stress can continuously disrupt these protective layers. The repeated formation and breakdown of passive films creates a cyclical degradation process that is difficult to model or mitigate through conventional materials design approaches.

The presence of hydrogen, either from the environment or as a byproduct of corrosion reactions, further complicates microstructural stability. Hydrogen embrittlement mechanisms interact with stress-induced deformation, creating complex degradation pathways that can lead to unexpected failure modes. Current analytical techniques struggle to capture the real-time diffusion and trapping of hydrogen at evolving microstructural features under stress.

Temperature fluctuations present an additional layer of complexity, as they can trigger phase transformations or precipitation events that fundamentally alter the alloy's microstructure during service. These thermally-activated processes interact with stress fields in ways that are not fully understood, particularly in newer alloy systems designed for extreme environments.

From a manufacturing perspective, achieving consistent microstructural stability across production batches remains challenging. Minor variations in processing parameters can create subtle microstructural differences that only manifest as stability issues when the material is subjected to stress in service. This creates significant quality control challenges for industries relying on these advanced materials.

The limitations of current in-situ characterization techniques represent a methodological barrier to progress. While advanced microscopy and spectroscopy methods have improved dramatically, capturing the dynamic evolution of microstructures under simultaneous stress and corrosive attack remains technically challenging, particularly at relevant time scales and environmental conditions.

Current Methodologies for Stress-Corrosion Resistance Enhancement

01 Composition and alloying elements for corrosion resistance

Specific alloying elements can be incorporated into metal alloys to enhance their corrosion resistance properties. These elements, such as chromium, nickel, molybdenum, and titanium, form protective oxide layers or alter the microstructure to prevent corrosion mechanisms. The careful selection and proportion of these elements can significantly improve the alloy's performance in corrosive environments while maintaining desired mechanical properties.- Composition and alloying elements for corrosion resistance: Specific alloying elements can be incorporated into metal alloys to enhance their corrosion resistance properties. These elements include chromium, nickel, molybdenum, and other transition metals that form protective oxide layers on the surface of the alloy. The microstructural evolution of these alloys depends on the precise composition and the interaction between different elements, which can lead to the formation of beneficial phases that improve corrosion resistance in aggressive environments.

- Heat treatment effects on microstructure and corrosion resistance: Heat treatment processes significantly influence the microstructural evolution of corrosion-resistant alloys. Controlled heating and cooling cycles can optimize grain structure, phase distribution, and precipitate formation. Processes such as solution annealing, aging, and tempering can be tailored to develop specific microstructures that enhance corrosion resistance while maintaining mechanical properties. The temperature, duration, and cooling rate during heat treatment are critical parameters that determine the final microstructural characteristics.

- Precipitation and phase transformation mechanisms: The evolution of microstructure in corrosion-resistant alloys often involves complex precipitation and phase transformation mechanisms. Secondary phases, intermetallic compounds, and precipitates can form during processing or service, affecting the alloy's corrosion behavior. Understanding and controlling these transformations is essential for developing alloys with optimal corrosion resistance. The kinetics of these transformations and their effect on local electrochemical properties determine the long-term performance of the alloy in corrosive environments.

- Surface modification and protective layer formation: Surface modification techniques can enhance the corrosion resistance of alloys by promoting the formation of stable protective layers. These techniques include controlled oxidation, nitriding, carburizing, and other surface treatments that alter the microstructure of the near-surface region. The evolution of these protective layers during exposure to corrosive environments involves dynamic processes of dissolution, repassivation, and transformation that are influenced by the underlying microstructure of the alloy.

- Microstructural stability during service conditions: The long-term stability of microstructure under service conditions is crucial for maintaining corrosion resistance in alloys. Exposure to elevated temperatures, mechanical stresses, and corrosive media can lead to microstructural changes such as grain growth, phase decomposition, or sensitization. Designing alloys with stable microstructures that resist detrimental changes during service is essential for applications in harsh environments. This involves understanding the thermodynamic and kinetic factors that govern microstructural evolution under complex operating conditions.

02 Heat treatment effects on microstructural evolution

Various heat treatment processes significantly influence the microstructural evolution of corrosion-resistant alloys. Controlled heating, cooling, and aging treatments can optimize grain structure, phase distribution, and precipitate formation. These thermal processes help develop specific microstructures that enhance corrosion resistance while maintaining or improving mechanical properties such as strength, ductility, and hardness.Expand Specific Solutions03 Precipitation hardening and phase transformation

Precipitation hardening mechanisms and phase transformations play crucial roles in developing corrosion-resistant alloys with superior properties. The controlled formation of secondary phases and precipitates within the alloy matrix can significantly enhance both mechanical properties and corrosion resistance. Understanding the kinetics of these transformations allows for tailored microstructures that optimize performance in specific corrosive environments.Expand Specific Solutions04 Surface modification and coating technologies

Surface modification techniques and advanced coating technologies can enhance the corrosion resistance of alloys by altering their surface microstructure. These processes include nitriding, carburizing, laser surface treatment, and application of protective coatings. Such treatments create protective layers that shield the base material from corrosive environments while maintaining the bulk mechanical properties of the alloy.Expand Specific Solutions05 Grain boundary engineering and nanostructure development

Grain boundary engineering and nanostructure development techniques are employed to enhance corrosion resistance in advanced alloys. By controlling grain size, grain boundary character distribution, and developing nanocrystalline structures, these approaches can significantly improve corrosion resistance. The manipulation of grain boundaries reduces susceptibility to intergranular corrosion while nanostructured materials often exhibit superior corrosion resistance due to their unique surface properties and reactivity.Expand Specific Solutions

Leading Research Institutions and Industrial Manufacturers

The microstructural evolution in corrosion-resistant alloys under stress represents a mature yet evolving field, currently in its growth-optimization phase. The global market for these specialized alloys exceeds $25 billion annually, with projected 5-7% CAGR through 2030. Leading industrial players like Westinghouse Electric, Kobe Steel, and RTX Corp have established significant technological capabilities, while research institutions including University of Science & Technology Beijing and Tianjin University contribute fundamental advancements. Companies such as QuesTek Innovations and 6K Inc are disrupting the space with computational materials design and sustainable processing technologies. The competitive landscape features collaboration between traditional metallurgical giants and emerging materials science innovators, with increasing focus on predictive modeling and in-situ characterization techniques.

UT-Battelle LLC

Technical Solution: UT-Battelle has developed advanced characterization techniques for studying microstructural evolution in corrosion-resistant alloys under stress conditions. Their approach combines in-situ neutron diffraction at Oak Ridge National Laboratory's Spallation Neutron Source with high-resolution electron microscopy to monitor real-time changes in alloy microstructure during stress application. This methodology allows for direct observation of phase transformations, precipitate formation, and dislocation movement at the atomic scale while simultaneously exposing materials to corrosive environments. Their research has particularly focused on nickel-based superalloys and advanced stainless steels, developing predictive models that correlate microstructural changes with mechanical properties and corrosion resistance degradation under various stress conditions[1]. Their work has established quantitative relationships between stress-induced microstructural evolution and localized corrosion initiation sites.

Strengths: Access to world-class neutron scattering facilities enables unique in-situ characterization capabilities unavailable to most competitors. Their integrated computational-experimental approach allows for accelerated alloy development and accurate lifetime prediction models. Weaknesses: The specialized equipment required limits industrial scalability, and their models may require extensive validation across different alloy systems before widespread implementation.

QuesTek Innovations LLC

Technical Solution: QuesTek Innovations has pioneered a computational materials design approach called Integrated Computational Materials Engineering (ICME) to address microstructural evolution in corrosion-resistant alloys under stress. Their proprietary methodology combines thermodynamic modeling, kinetic simulations, and mechanical property predictions to design alloys with optimized microstructures that resist degradation under combined stress and corrosive conditions. QuesTek's approach begins with quantum mechanical calculations to understand atomic-level interactions, then scales up through mesoscale modeling of precipitate formation and growth, to macroscale performance predictions. For corrosion-resistant applications, they've developed specialized precipitation-strengthened stainless steels with carefully controlled distributions of nanoscale precipitates that maintain stability under stress[2]. Their Ferrium® series alloys demonstrate superior resistance to stress corrosion cracking through engineered grain boundary chemistry and controlled precipitate morphology that inhibits crack propagation pathways even under sustained tensile loading in aggressive environments.

Strengths: Their computational design approach significantly reduces development time compared to traditional trial-and-error methods, allowing rapid customization for specific operating conditions. The company's integrated modeling framework enables precise microstructural control across multiple length scales. Weaknesses: Implementation requires sophisticated computational resources and expertise, and physical validation testing is still necessary to verify model predictions in complex real-world environments.

Key Research Breakthroughs in Alloy Microstructural Engineering

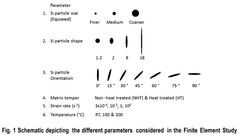

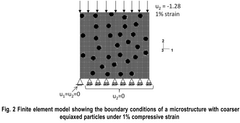

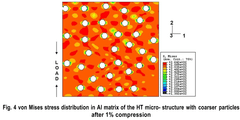

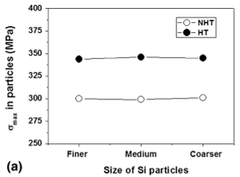

Novel system, design, method of finite element analysis of stress evolution in al-si alloy

PatentPendingIN202341001657A

Innovation

- The development of 2D microstructures with varying Si particle sizes, shapes, and orientations, combined with a finite element analysis using the Object Oriented Finite Element (OOF) program and ABAQUS/CAE, allowing for the simulation of non-heat-treated and heat-treated conditions, strain rates, and temperatures, to analyze stress distribution and fracture propensity in Al-Si alloys.

Environmental Impact and Sustainability Considerations

The environmental impact of corrosion-resistant alloys extends beyond their immediate application performance, encompassing their entire lifecycle from production to disposal. Manufacturing these specialized alloys typically requires energy-intensive processes and rare earth elements, contributing significantly to carbon emissions and resource depletion. However, when considering the extended service life these alloys provide in harsh environments, the environmental calculation becomes more favorable, as they reduce the frequency of replacement and associated manufacturing impacts.

Sustainability considerations for corrosion-resistant alloys under stress must address the trade-offs between material durability and environmental footprint. Recent research indicates that optimizing microstructural evolution can lead to more efficient use of critical elements like chromium, nickel, and molybdenum, potentially reducing the environmental burden while maintaining performance characteristics. This approach aligns with circular economy principles, where material efficiency and longevity are prioritized over continuous replacement cycles.

The leaching of metal ions from corroding alloys presents another environmental concern, particularly in marine and freshwater ecosystems. Studies have demonstrated that stress-corrosion mechanisms can accelerate the release of potentially toxic elements into the environment. Advanced microstructural designs that minimize ion release while under mechanical stress represent an important frontier in environmentally responsible alloy development.

Recycling considerations play a crucial role in the sustainability profile of these alloys. The complex compositions of high-performance corrosion-resistant alloys can complicate recycling processes, requiring specialized separation techniques to recover valuable components. Research into designing alloys with microstructures that facilitate end-of-life separation could significantly improve their overall environmental performance.

Energy efficiency during service life represents another important sustainability dimension. Corrosion and associated microstructural degradation can reduce the efficiency of energy systems, from heat exchangers to turbines. By developing alloys with stable microstructures under combined stress and corrosive conditions, significant energy savings can be realized across multiple industries, contributing to reduced greenhouse gas emissions and resource conservation.

Regulatory frameworks increasingly recognize these environmental considerations, with initiatives like the European Union's REACH regulations imposing stricter controls on potentially harmful elements used in alloy production. This regulatory landscape is driving innovation toward more environmentally benign compositions that maintain the necessary performance characteristics through sophisticated microstructural engineering rather than through environmentally problematic elemental additions.

Sustainability considerations for corrosion-resistant alloys under stress must address the trade-offs between material durability and environmental footprint. Recent research indicates that optimizing microstructural evolution can lead to more efficient use of critical elements like chromium, nickel, and molybdenum, potentially reducing the environmental burden while maintaining performance characteristics. This approach aligns with circular economy principles, where material efficiency and longevity are prioritized over continuous replacement cycles.

The leaching of metal ions from corroding alloys presents another environmental concern, particularly in marine and freshwater ecosystems. Studies have demonstrated that stress-corrosion mechanisms can accelerate the release of potentially toxic elements into the environment. Advanced microstructural designs that minimize ion release while under mechanical stress represent an important frontier in environmentally responsible alloy development.

Recycling considerations play a crucial role in the sustainability profile of these alloys. The complex compositions of high-performance corrosion-resistant alloys can complicate recycling processes, requiring specialized separation techniques to recover valuable components. Research into designing alloys with microstructures that facilitate end-of-life separation could significantly improve their overall environmental performance.

Energy efficiency during service life represents another important sustainability dimension. Corrosion and associated microstructural degradation can reduce the efficiency of energy systems, from heat exchangers to turbines. By developing alloys with stable microstructures under combined stress and corrosive conditions, significant energy savings can be realized across multiple industries, contributing to reduced greenhouse gas emissions and resource conservation.

Regulatory frameworks increasingly recognize these environmental considerations, with initiatives like the European Union's REACH regulations imposing stricter controls on potentially harmful elements used in alloy production. This regulatory landscape is driving innovation toward more environmentally benign compositions that maintain the necessary performance characteristics through sophisticated microstructural engineering rather than through environmentally problematic elemental additions.

Standardization and Testing Protocols for Stress-Corrosion Resistance

The standardization of testing protocols for stress-corrosion resistance represents a critical foundation for advancing our understanding of microstructural evolution in corrosion-resistant alloys under stress. Current testing methodologies exhibit significant variations across laboratories and industries, creating challenges in result comparability and reliability assessment.

International standards organizations including ASTM International, NACE International, and ISO have established several key testing protocols. ASTM G36 and G44 address stress corrosion cracking in specific environments, while NACE TM0177 focuses on sulfide stress cracking resistance. These standards provide essential frameworks but require continuous refinement to address emerging alloy compositions and service environments.

Testing protocols typically incorporate three fundamental components: environmental simulation, stress application methods, and evaluation criteria. Environmental chambers must precisely replicate service conditions including temperature fluctuations, chemical composition, and pH variations. Stress application methodologies range from constant load techniques to slow strain rate testing (SSRT), each offering distinct advantages for specific material-environment combinations.

Accelerated testing presents both opportunities and challenges in protocol development. While essential for timely assessment, acceleration factors must maintain mechanistic relevance to avoid misleading conclusions about long-term performance. Recent advancements in digital image correlation and acoustic emission monitoring have enhanced real-time tracking of microstructural changes during testing.

Standardization efforts increasingly focus on in-situ characterization techniques that reveal dynamic microstructural evolution processes. Synchrotron X-ray diffraction and environmental transmission electron microscopy enable observation of localized deformation, crack initiation, and propagation mechanisms at unprecedented resolution, though integration into standardized protocols remains challenging.

Data reporting standardization represents another critical frontier. Minimum reporting requirements should include comprehensive material characterization (composition, heat treatment, microstructure), detailed environmental parameters, complete stress history, and failure analysis methodologies. Emerging digital platforms for test data sharing show promise for accelerating consensus on testing protocols.

Future standardization directions must address the integration of computational modeling with experimental validation, establishing clear correlations between accelerated testing and field performance, and developing specialized protocols for advanced manufacturing techniques like additive manufacturing where conventional testing approaches may prove inadequate.

International standards organizations including ASTM International, NACE International, and ISO have established several key testing protocols. ASTM G36 and G44 address stress corrosion cracking in specific environments, while NACE TM0177 focuses on sulfide stress cracking resistance. These standards provide essential frameworks but require continuous refinement to address emerging alloy compositions and service environments.

Testing protocols typically incorporate three fundamental components: environmental simulation, stress application methods, and evaluation criteria. Environmental chambers must precisely replicate service conditions including temperature fluctuations, chemical composition, and pH variations. Stress application methodologies range from constant load techniques to slow strain rate testing (SSRT), each offering distinct advantages for specific material-environment combinations.

Accelerated testing presents both opportunities and challenges in protocol development. While essential for timely assessment, acceleration factors must maintain mechanistic relevance to avoid misleading conclusions about long-term performance. Recent advancements in digital image correlation and acoustic emission monitoring have enhanced real-time tracking of microstructural changes during testing.

Standardization efforts increasingly focus on in-situ characterization techniques that reveal dynamic microstructural evolution processes. Synchrotron X-ray diffraction and environmental transmission electron microscopy enable observation of localized deformation, crack initiation, and propagation mechanisms at unprecedented resolution, though integration into standardized protocols remains challenging.

Data reporting standardization represents another critical frontier. Minimum reporting requirements should include comprehensive material characterization (composition, heat treatment, microstructure), detailed environmental parameters, complete stress history, and failure analysis methodologies. Emerging digital platforms for test data sharing show promise for accelerating consensus on testing protocols.

Future standardization directions must address the integration of computational modeling with experimental validation, establishing clear correlations between accelerated testing and field performance, and developing specialized protocols for advanced manufacturing techniques like additive manufacturing where conventional testing approaches may prove inadequate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!