Corrosion Resistance Optimization via Grain Boundary Engineering

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Grain Boundary Engineering Background and Objectives

Grain Boundary Engineering (GBE) has emerged as a pivotal approach in materials science for enhancing corrosion resistance of metallic materials. The concept was first introduced in the 1980s by Watanabe, who recognized that grain boundaries significantly influence material properties. Over the past four decades, GBE has evolved from theoretical frameworks to practical applications, particularly in industries requiring high-performance materials under corrosive environments.

The evolution of GBE has been marked by significant milestones, including the development of thermomechanical processing techniques in the 1990s, the integration of computational modeling in the early 2000s, and the recent advancements in characterization technologies that enable atomic-level grain boundary analysis. These developments have transformed GBE from a conceptual approach to a sophisticated methodology for tailoring material microstructures.

Current technological trends in GBE focus on controlling the distribution of coincidence site lattice (CSL) boundaries, particularly Σ3 boundaries, which demonstrate superior resistance to intergranular corrosion. The manipulation of grain boundary character distribution (GBCD) through precise processing parameters represents a frontier in materials engineering, offering unprecedented control over material performance in aggressive environments.

The primary objective of GBE in corrosion resistance optimization is to systematically modify the grain boundary network to minimize susceptibility to localized corrosion attacks. This involves increasing the fraction of special boundaries with low energy configurations while reducing random high-angle boundaries that serve as preferential sites for corrosion initiation.

Secondary objectives include developing scalable and cost-effective GBE processes suitable for industrial implementation, establishing standardized methodologies for characterizing grain boundary networks, and creating predictive models that correlate grain boundary characteristics with corrosion behavior across various environmental conditions.

The ultimate goal is to establish GBE as a fundamental design principle in the development of next-generation corrosion-resistant materials. This encompasses not only traditional alloys like stainless steels and nickel-based superalloys but also emerging materials systems including nanocrystalline metals and advanced high-entropy alloys, where grain boundary engineering principles can be leveraged to achieve unprecedented combinations of mechanical properties and corrosion resistance.

Through systematic exploration of the relationship between processing parameters, resultant grain boundary structures, and corrosion performance, GBE aims to provide a scientific foundation for designing materials with tailored microstructures optimized for specific corrosive environments, thereby extending component lifespans and enhancing reliability in critical applications.

The evolution of GBE has been marked by significant milestones, including the development of thermomechanical processing techniques in the 1990s, the integration of computational modeling in the early 2000s, and the recent advancements in characterization technologies that enable atomic-level grain boundary analysis. These developments have transformed GBE from a conceptual approach to a sophisticated methodology for tailoring material microstructures.

Current technological trends in GBE focus on controlling the distribution of coincidence site lattice (CSL) boundaries, particularly Σ3 boundaries, which demonstrate superior resistance to intergranular corrosion. The manipulation of grain boundary character distribution (GBCD) through precise processing parameters represents a frontier in materials engineering, offering unprecedented control over material performance in aggressive environments.

The primary objective of GBE in corrosion resistance optimization is to systematically modify the grain boundary network to minimize susceptibility to localized corrosion attacks. This involves increasing the fraction of special boundaries with low energy configurations while reducing random high-angle boundaries that serve as preferential sites for corrosion initiation.

Secondary objectives include developing scalable and cost-effective GBE processes suitable for industrial implementation, establishing standardized methodologies for characterizing grain boundary networks, and creating predictive models that correlate grain boundary characteristics with corrosion behavior across various environmental conditions.

The ultimate goal is to establish GBE as a fundamental design principle in the development of next-generation corrosion-resistant materials. This encompasses not only traditional alloys like stainless steels and nickel-based superalloys but also emerging materials systems including nanocrystalline metals and advanced high-entropy alloys, where grain boundary engineering principles can be leveraged to achieve unprecedented combinations of mechanical properties and corrosion resistance.

Through systematic exploration of the relationship between processing parameters, resultant grain boundary structures, and corrosion performance, GBE aims to provide a scientific foundation for designing materials with tailored microstructures optimized for specific corrosive environments, thereby extending component lifespans and enhancing reliability in critical applications.

Market Demand for Enhanced Corrosion Resistant Materials

The global market for corrosion-resistant materials has been experiencing significant growth, driven primarily by increasing industrial activities in developing economies and the rising awareness about the economic impact of corrosion-related failures. According to recent market analyses, the global corrosion inhibitors market alone is valued at over $7 billion and is projected to grow at a CAGR of 4.5% through 2027.

Industries such as oil and gas, chemical processing, marine, aerospace, and automotive are particularly demanding enhanced corrosion-resistant solutions. The oil and gas sector, for instance, faces severe corrosion challenges in offshore platforms, pipelines, and refineries, with annual corrosion-related costs estimated at $1.4 billion in the U.S. alone. These industries are actively seeking advanced materials that can withstand harsh operating environments while maintaining structural integrity over extended periods.

The economic implications of corrosion are substantial, with global costs estimated at approximately 3.4% of global GDP annually. This translates to over $2.5 trillion, highlighting the immense market potential for effective corrosion mitigation technologies. Grain Boundary Engineering (GBE) presents a promising approach to address these challenges by fundamentally altering material properties at the microstructural level.

Environmental regulations are also driving market demand for corrosion-resistant materials. Stricter policies regarding emissions, waste disposal, and environmental protection are pushing industries to adopt more durable materials that require less frequent replacement and maintenance. This regulatory landscape creates additional market pull for GBE-enhanced materials that can offer superior performance while reducing environmental impact.

The healthcare and biomedical sectors represent emerging markets for corrosion-resistant materials. Implantable medical devices, surgical instruments, and diagnostic equipment require materials that can withstand both corrosive bodily fluids and sterilization processes. The global medical device market, valued at approximately $430 billion, presents significant opportunities for advanced corrosion-resistant materials developed through GBE techniques.

Regional market analysis indicates that Asia-Pacific, particularly China and India, is experiencing the fastest growth in demand for corrosion-resistant materials due to rapid industrialization and infrastructure development. North America and Europe maintain strong demand driven by aging infrastructure replacement needs and stringent safety regulations in critical industries.

Customer requirements are evolving beyond mere corrosion resistance to include multifunctional properties such as lightweight construction, thermal stability, and compatibility with advanced manufacturing techniques like additive manufacturing. This trend creates opportunities for GBE approaches that can simultaneously enhance multiple material properties while maintaining cost-effectiveness.

Industries such as oil and gas, chemical processing, marine, aerospace, and automotive are particularly demanding enhanced corrosion-resistant solutions. The oil and gas sector, for instance, faces severe corrosion challenges in offshore platforms, pipelines, and refineries, with annual corrosion-related costs estimated at $1.4 billion in the U.S. alone. These industries are actively seeking advanced materials that can withstand harsh operating environments while maintaining structural integrity over extended periods.

The economic implications of corrosion are substantial, with global costs estimated at approximately 3.4% of global GDP annually. This translates to over $2.5 trillion, highlighting the immense market potential for effective corrosion mitigation technologies. Grain Boundary Engineering (GBE) presents a promising approach to address these challenges by fundamentally altering material properties at the microstructural level.

Environmental regulations are also driving market demand for corrosion-resistant materials. Stricter policies regarding emissions, waste disposal, and environmental protection are pushing industries to adopt more durable materials that require less frequent replacement and maintenance. This regulatory landscape creates additional market pull for GBE-enhanced materials that can offer superior performance while reducing environmental impact.

The healthcare and biomedical sectors represent emerging markets for corrosion-resistant materials. Implantable medical devices, surgical instruments, and diagnostic equipment require materials that can withstand both corrosive bodily fluids and sterilization processes. The global medical device market, valued at approximately $430 billion, presents significant opportunities for advanced corrosion-resistant materials developed through GBE techniques.

Regional market analysis indicates that Asia-Pacific, particularly China and India, is experiencing the fastest growth in demand for corrosion-resistant materials due to rapid industrialization and infrastructure development. North America and Europe maintain strong demand driven by aging infrastructure replacement needs and stringent safety regulations in critical industries.

Customer requirements are evolving beyond mere corrosion resistance to include multifunctional properties such as lightweight construction, thermal stability, and compatibility with advanced manufacturing techniques like additive manufacturing. This trend creates opportunities for GBE approaches that can simultaneously enhance multiple material properties while maintaining cost-effectiveness.

Current State and Challenges in Corrosion Resistance Technologies

Corrosion resistance technologies have evolved significantly over the past decades, with current approaches encompassing various methodologies across different material systems. Traditional corrosion mitigation strategies primarily rely on protective coatings, inhibitors, cathodic protection, and material selection. However, these conventional methods often face limitations in harsh environments or over extended service periods, necessitating more advanced solutions.

Grain Boundary Engineering (GBE) represents one of the most promising frontiers in corrosion resistance optimization. This approach focuses on manipulating the crystallographic character and distribution of grain boundaries to enhance material properties, particularly corrosion resistance. Current GBE techniques include thermomechanical processing, special heat treatments, and controlled deformation processes that can significantly alter grain boundary character distribution.

The global landscape of corrosion resistance technologies shows regional specialization patterns. North American and European research institutions lead in fundamental research on grain boundary phenomena, while Asian countries, particularly Japan and South Korea, excel in industrial applications of GBE for corrosion resistance. China has rapidly expanded its research capacity in this field, focusing on cost-effective implementation strategies.

Despite significant progress, several critical challenges persist in GBE for corrosion resistance. The primary technical hurdle involves achieving precise control over grain boundary character distribution in complex alloy systems at industrial scales. Current processing techniques often result in heterogeneous microstructures that limit the effectiveness of GBE treatments.

Another major challenge is the limited understanding of the exact mechanisms by which specific grain boundary structures enhance corrosion resistance. While correlations between certain coincidence site lattice (CSL) boundaries and improved corrosion behavior have been established, the fundamental electrochemical processes at engineered grain boundaries remain incompletely understood.

The scalability of GBE techniques presents a significant industrial challenge. Laboratory-scale successes often prove difficult to translate to mass production environments without compromising the engineered microstructure. This scale-up problem has restricted widespread industrial adoption of GBE for corrosion resistance applications.

Economic factors also constrain implementation, as GBE processes typically require precise control of processing parameters, specialized equipment, and additional processing steps that increase production costs. The cost-benefit analysis often does not favor GBE implementation except in high-value applications where corrosion failure carries extreme consequences.

Environmental considerations present another dimension of challenges, as some traditional corrosion prevention methods involve environmentally harmful substances. GBE offers a potentially greener alternative but requires further development to fully replace conventional approaches across all applications.

Grain Boundary Engineering (GBE) represents one of the most promising frontiers in corrosion resistance optimization. This approach focuses on manipulating the crystallographic character and distribution of grain boundaries to enhance material properties, particularly corrosion resistance. Current GBE techniques include thermomechanical processing, special heat treatments, and controlled deformation processes that can significantly alter grain boundary character distribution.

The global landscape of corrosion resistance technologies shows regional specialization patterns. North American and European research institutions lead in fundamental research on grain boundary phenomena, while Asian countries, particularly Japan and South Korea, excel in industrial applications of GBE for corrosion resistance. China has rapidly expanded its research capacity in this field, focusing on cost-effective implementation strategies.

Despite significant progress, several critical challenges persist in GBE for corrosion resistance. The primary technical hurdle involves achieving precise control over grain boundary character distribution in complex alloy systems at industrial scales. Current processing techniques often result in heterogeneous microstructures that limit the effectiveness of GBE treatments.

Another major challenge is the limited understanding of the exact mechanisms by which specific grain boundary structures enhance corrosion resistance. While correlations between certain coincidence site lattice (CSL) boundaries and improved corrosion behavior have been established, the fundamental electrochemical processes at engineered grain boundaries remain incompletely understood.

The scalability of GBE techniques presents a significant industrial challenge. Laboratory-scale successes often prove difficult to translate to mass production environments without compromising the engineered microstructure. This scale-up problem has restricted widespread industrial adoption of GBE for corrosion resistance applications.

Economic factors also constrain implementation, as GBE processes typically require precise control of processing parameters, specialized equipment, and additional processing steps that increase production costs. The cost-benefit analysis often does not favor GBE implementation except in high-value applications where corrosion failure carries extreme consequences.

Environmental considerations present another dimension of challenges, as some traditional corrosion prevention methods involve environmentally harmful substances. GBE offers a potentially greener alternative but requires further development to fully replace conventional approaches across all applications.

Current Grain Boundary Modification Techniques

01 Grain boundary engineering for austenitic stainless steels

Grain boundary engineering techniques applied to austenitic stainless steels can significantly improve corrosion resistance. This involves controlling the distribution of special grain boundaries, particularly twin boundaries, through thermomechanical processing. The increased fraction of special grain boundaries reduces susceptibility to intergranular corrosion and stress corrosion cracking by limiting the continuous network of random high-angle grain boundaries that are preferential sites for corrosion attack.- Grain boundary engineering for improved corrosion resistance: Grain boundary engineering involves controlling the structure and properties of grain boundaries to enhance corrosion resistance in materials. By manipulating the grain boundary character distribution, particularly increasing the fraction of special boundaries such as twin boundaries or coincidence site lattice boundaries, the susceptibility to intergranular corrosion can be significantly reduced. This approach creates more stable grain boundaries that act as barriers to corrosion propagation.

- Thermomechanical processing techniques for grain boundary optimization: Various thermomechanical processing techniques can be employed to optimize grain boundary structures for enhanced corrosion resistance. These include controlled deformation, annealing treatments, and cyclic processing. Such processes promote the formation of low-energy grain boundaries and optimize grain size distribution, resulting in materials with superior resistance to corrosive environments. The specific parameters of these processes can be tailored to different alloy systems.

- Alloying elements and their effect on grain boundary properties: The addition of specific alloying elements can significantly influence grain boundary properties and corrosion behavior. Elements such as chromium, molybdenum, and nitrogen can segregate to grain boundaries, modifying their electrochemical properties and enhancing corrosion resistance. The controlled addition of these elements, combined with appropriate heat treatments, can create protective films at grain boundaries that inhibit corrosion initiation and propagation.

- Nanocrystalline materials and grain boundary engineering: Nanocrystalline materials offer unique opportunities for grain boundary engineering to improve corrosion resistance. The high volume fraction of grain boundaries in these materials can be engineered to create corrosion-resistant interfaces. Techniques such as severe plastic deformation, rapid solidification, and controlled crystallization can be used to develop nanostructured materials with optimized grain boundary networks that provide enhanced resistance to various forms of corrosion.

- Advanced characterization and modeling of grain boundaries for corrosion prediction: Advanced characterization techniques and computational modeling approaches are essential for understanding and predicting the relationship between grain boundary structure and corrosion behavior. Electron backscatter diffraction (EBSD), transmission electron microscopy (TEM), and atom probe tomography enable detailed analysis of grain boundary character. These experimental methods, combined with computational models, allow for the design of optimized grain boundary networks with enhanced corrosion resistance in various environments.

02 Thermomechanical processing methods for grain boundary optimization

Various thermomechanical processing methods can be employed to optimize grain boundary structure for enhanced corrosion resistance. These include controlled deformation followed by annealing treatments, cyclic strain-annealing processes, and grain boundary engineering through sequential cold working and heat treatment. These processes promote the formation of coincidence site lattice (CSL) boundaries while reducing random high-angle grain boundaries, resulting in improved resistance to intergranular corrosion.Expand Specific Solutions03 Alloying elements and their effects on grain boundary properties

The addition of specific alloying elements can significantly influence grain boundary properties and corrosion resistance. Elements such as chromium, molybdenum, and nitrogen can segregate to grain boundaries, forming protective films that enhance corrosion resistance. Other elements like boron and rare earth metals can modify grain boundary energy and cohesion, reducing susceptibility to intergranular corrosion by strengthening grain boundaries against preferential attack.Expand Specific Solutions04 Nanocrystalline materials and grain refinement techniques

Nanocrystalline materials with ultrafine grain structures offer enhanced corrosion resistance through grain refinement techniques. Methods such as severe plastic deformation, equal channel angular pressing, and high-pressure torsion can produce materials with nanoscale grain sizes. The increased volume fraction of grain boundaries in these materials can improve corrosion resistance by promoting the formation of more uniform passive films and reducing the electrochemical potential difference between grain boundaries and grain interiors.Expand Specific Solutions05 Advanced characterization techniques for grain boundary analysis

Advanced characterization techniques are essential for analyzing grain boundary structures and their relationship to corrosion resistance. Electron backscatter diffraction (EBSD), transmission electron microscopy (TEM), and atom probe tomography enable detailed examination of grain boundary character distribution, misorientation angles, and chemical segregation at grain boundaries. These techniques help establish correlations between grain boundary engineering parameters and corrosion performance, guiding the development of materials with optimized grain boundary structures.Expand Specific Solutions

Leading Organizations in Corrosion Resistance Research

Grain Boundary Engineering for corrosion resistance optimization is currently in a growth phase, with the market expanding as industries seek enhanced material durability. The global market is estimated at $2-3 billion, driven by aerospace, automotive, and energy sectors. Technologically, this field is advancing from experimental to commercial implementation, with varying maturity levels across applications. Leading research institutions like MIT and IMR-CAS are pioneering fundamental advances, while industrial players demonstrate different specialization levels: NIPPON STEEL and Outokumpu focus on large-scale implementation; Mitsubishi Materials and General Electric develop specialized applications; and emerging companies like Terves pursue niche innovations. The competitive landscape shows a collaborative ecosystem between academic institutions and industrial manufacturers working to bridge theoretical understanding with practical applications.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced grain boundary engineering (GBE) techniques focusing on the manipulation of grain boundary character distribution (GBCD) to enhance corrosion resistance in metallic materials. Their approach involves thermomechanical processing with controlled annealing and deformation cycles to increase the fraction of special boundaries (particularly Σ3 twin boundaries) while reducing random high-angle grain boundaries that are susceptible to corrosion. MIT researchers have demonstrated that materials with over 70% special boundaries can exhibit up to 10-fold improvement in intergranular corrosion resistance[1]. Their recent innovations include the development of predictive computational models that combine machine learning algorithms with crystallographic principles to optimize processing parameters for specific alloy systems, enabling tailored microstructures with enhanced resistance to various corrosive environments[2].

Strengths: Cutting-edge computational modeling capabilities that enable precise prediction of grain boundary evolution; strong interdisciplinary approach combining materials science, computational methods, and electrochemistry. Weaknesses: Technologies often require sophisticated processing equipment and precise control parameters that may be challenging to implement in large-scale industrial production.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed proprietary thermomechanical treatment processes specifically designed for grain boundary engineering in stainless steels and high-performance alloys. Their technology focuses on creating optimized microstructures through carefully controlled deformation and annealing sequences that promote the formation of coincidence site lattice (CSL) boundaries while minimizing random high-angle grain boundaries. Their patented "NSSC" (Nippon Steel Stainless Steel) process incorporates precise temperature control during hot rolling and subsequent heat treatments to achieve grain boundary networks with over 80% special boundaries in austenitic stainless steels[3]. This approach has been successfully implemented in their commercial production of corrosion-resistant materials for chemical processing equipment, nuclear power plants, and marine applications, demonstrating up to 5x improvement in stress corrosion cracking resistance compared to conventional processing methods[4].

Strengths: Extensive industrial-scale implementation experience; integrated approach combining fundamental research with practical manufacturing considerations; established quality control systems for consistent production. Weaknesses: Technologies primarily optimized for specific steel grades in their product portfolio; relatively high production costs compared to conventional steel processing.

Key Innovations in Grain Boundary Structure Control

High corrosion-resistant alloy excellent in grain-boundary corrosion resistance

PatentInactiveJP2010159438A

Innovation

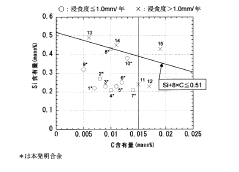

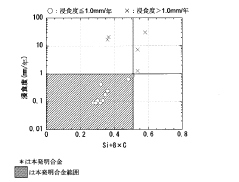

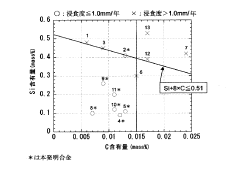

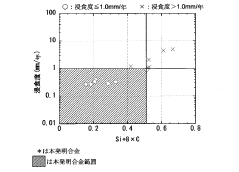

- The development of Fe-based and Ni-based alloys with controlled C and Si contents, adhering to the relationship Si + 8 × C ≤ 0.51, effectively suppresses the precipitation of intermetallic compounds, ensuring excellent intergranular corrosion resistance.

Environmental Impact of Advanced Corrosion Resistant Materials

The development of advanced corrosion-resistant materials through grain boundary engineering represents a significant step forward in sustainable materials science. These materials demonstrate substantially reduced environmental footprints compared to conventional corrosion protection methods that often rely on toxic coatings or frequent replacement of degraded components.

Traditional corrosion prevention frequently involves environmentally harmful substances such as hexavalent chromium compounds, heavy metal-based paints, and volatile organic compounds (VOCs). By contrast, grain boundary engineered materials achieve corrosion resistance through structural optimization rather than chemical treatments, eliminating the release of these hazardous substances into ecosystems.

The extended service life of grain boundary engineered materials delivers substantial environmental benefits through reduced resource consumption. Studies indicate that optimized grain boundary structures can extend component lifespans by 30-50% in aggressive environments, directly translating to proportional reductions in raw material extraction, energy consumption, and manufacturing emissions associated with replacement parts.

Carbon footprint analyses reveal that the production of grain boundary engineered materials typically requires only 5-15% additional energy input during manufacturing compared to conventional materials, while delivering lifecycle emission reductions of 25-40% when accounting for extended service life and reduced maintenance requirements.

Water conservation represents another significant environmental advantage. Conventional corrosion protection often involves water-intensive processes for surface preparation and treatment. Grain boundary engineering reduces water consumption by minimizing these requirements, with some implementations demonstrating water usage reductions of up to 60% across the material lifecycle.

The recyclability of grain boundary engineered materials further enhances their environmental profile. Unlike components with multiple material layers or chemical treatments that complicate recycling, these materials maintain homogeneous compositions that facilitate end-of-life recovery and reprocessing. This characteristic supports circular economy principles and reduces landfill waste.

Environmental risk assessments indicate that grain boundary engineered materials pose minimal ecotoxicological threats during service life. The absence of leachable toxic compounds means these materials can be safely deployed in sensitive environments including marine applications, drinking water infrastructure, and agricultural settings without risk of contamination.

Looking forward, life cycle assessment (LCA) methodologies are being refined specifically for grain boundary engineered materials to better quantify their environmental advantages. Early results suggest that widespread adoption could contribute significantly to industrial sustainability goals, particularly in sectors where corrosion-related failures drive frequent component replacement.

Traditional corrosion prevention frequently involves environmentally harmful substances such as hexavalent chromium compounds, heavy metal-based paints, and volatile organic compounds (VOCs). By contrast, grain boundary engineered materials achieve corrosion resistance through structural optimization rather than chemical treatments, eliminating the release of these hazardous substances into ecosystems.

The extended service life of grain boundary engineered materials delivers substantial environmental benefits through reduced resource consumption. Studies indicate that optimized grain boundary structures can extend component lifespans by 30-50% in aggressive environments, directly translating to proportional reductions in raw material extraction, energy consumption, and manufacturing emissions associated with replacement parts.

Carbon footprint analyses reveal that the production of grain boundary engineered materials typically requires only 5-15% additional energy input during manufacturing compared to conventional materials, while delivering lifecycle emission reductions of 25-40% when accounting for extended service life and reduced maintenance requirements.

Water conservation represents another significant environmental advantage. Conventional corrosion protection often involves water-intensive processes for surface preparation and treatment. Grain boundary engineering reduces water consumption by minimizing these requirements, with some implementations demonstrating water usage reductions of up to 60% across the material lifecycle.

The recyclability of grain boundary engineered materials further enhances their environmental profile. Unlike components with multiple material layers or chemical treatments that complicate recycling, these materials maintain homogeneous compositions that facilitate end-of-life recovery and reprocessing. This characteristic supports circular economy principles and reduces landfill waste.

Environmental risk assessments indicate that grain boundary engineered materials pose minimal ecotoxicological threats during service life. The absence of leachable toxic compounds means these materials can be safely deployed in sensitive environments including marine applications, drinking water infrastructure, and agricultural settings without risk of contamination.

Looking forward, life cycle assessment (LCA) methodologies are being refined specifically for grain boundary engineered materials to better quantify their environmental advantages. Early results suggest that widespread adoption could contribute significantly to industrial sustainability goals, particularly in sectors where corrosion-related failures drive frequent component replacement.

Industry Standards and Testing Protocols for Corrosion Resistance

The standardization of corrosion testing methodologies is crucial for ensuring consistent evaluation of materials across different industries. ASTM International has established several key standards for corrosion testing, including ASTM G1 for preparation and cleaning of test specimens, ASTM G31 for laboratory immersion testing, and ASTM B117 for salt spray (fog) testing. These standards provide detailed protocols for specimen preparation, test conditions, and data analysis, enabling reliable comparison of results across different laboratories.

ISO standards complement ASTM with additional specifications, particularly ISO 9223 which classifies atmospheric corrosivity categories and ISO 8407 which details procedures for removing corrosion products from test specimens. The NACE International (now part of AMPP) contributes specialized standards for the oil and gas industry, such as NACE TM0169 for laboratory corrosion testing of metals.

Electrochemical testing protocols have gained prominence for their ability to provide accelerated results. Potentiodynamic polarization testing (ASTM G59) and electrochemical impedance spectroscopy (EIS) offer quantitative data on corrosion mechanisms and rates. These techniques are particularly valuable for evaluating grain boundary engineered materials, as they can detect localized corrosion phenomena at grain boundaries.

Industry-specific standards have emerged to address unique corrosion challenges. The automotive industry follows SAE J2334 for cyclic corrosion testing, while the aerospace sector adheres to ASTM F1110 for sandwich corrosion testing. The nuclear industry has developed specialized protocols under ASTM G28 for intergranular corrosion testing of stainless steels.

Quality assurance frameworks require regular calibration of testing equipment and participation in interlaboratory studies to ensure reproducibility. The implementation of digital imaging and analysis techniques has enhanced the objectivity of corrosion assessment, allowing for automated measurement of pit density, depth, and distribution—parameters particularly relevant to grain boundary engineered materials.

Recent developments include the integration of machine learning algorithms to predict long-term corrosion behavior based on accelerated test results. This approach is especially valuable for grain boundary engineered materials, where traditional testing may not fully capture the complex corrosion mechanisms at modified grain boundaries. Additionally, in-situ monitoring techniques are gaining traction for their ability to observe corrosion processes in real-time under service conditions.

ISO standards complement ASTM with additional specifications, particularly ISO 9223 which classifies atmospheric corrosivity categories and ISO 8407 which details procedures for removing corrosion products from test specimens. The NACE International (now part of AMPP) contributes specialized standards for the oil and gas industry, such as NACE TM0169 for laboratory corrosion testing of metals.

Electrochemical testing protocols have gained prominence for their ability to provide accelerated results. Potentiodynamic polarization testing (ASTM G59) and electrochemical impedance spectroscopy (EIS) offer quantitative data on corrosion mechanisms and rates. These techniques are particularly valuable for evaluating grain boundary engineered materials, as they can detect localized corrosion phenomena at grain boundaries.

Industry-specific standards have emerged to address unique corrosion challenges. The automotive industry follows SAE J2334 for cyclic corrosion testing, while the aerospace sector adheres to ASTM F1110 for sandwich corrosion testing. The nuclear industry has developed specialized protocols under ASTM G28 for intergranular corrosion testing of stainless steels.

Quality assurance frameworks require regular calibration of testing equipment and participation in interlaboratory studies to ensure reproducibility. The implementation of digital imaging and analysis techniques has enhanced the objectivity of corrosion assessment, allowing for automated measurement of pit density, depth, and distribution—parameters particularly relevant to grain boundary engineered materials.

Recent developments include the integration of machine learning algorithms to predict long-term corrosion behavior based on accelerated test results. This approach is especially valuable for grain boundary engineered materials, where traditional testing may not fully capture the complex corrosion mechanisms at modified grain boundaries. Additionally, in-situ monitoring techniques are gaining traction for their ability to observe corrosion processes in real-time under service conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!