Corrosion Fatigue Behavior in Structural Applications

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Corrosion Fatigue Background and Objectives

Corrosion fatigue represents a critical degradation mechanism that affects structural materials exposed to both cyclic loading and corrosive environments simultaneously. This phenomenon has been recognized since the early 20th century, with significant research milestones occurring in the 1950s when researchers first documented the synergistic effects between mechanical fatigue and electrochemical corrosion processes. The evolution of this field has been driven by catastrophic failures in critical infrastructure, including the collapse of bridges, premature failure of offshore structures, and accidents in aerospace components.

The technical landscape has progressed from empirical observations to mechanistic understanding, with advances in materials science, electrochemistry, and fracture mechanics contributing to our current knowledge base. Recent developments in high-resolution characterization techniques have enabled researchers to observe corrosion fatigue crack initiation and propagation at unprecedented scales, revealing complex interactions between microstructural features and environmental factors.

Industry trends indicate growing concern regarding corrosion fatigue in aging infrastructure, particularly as structures are increasingly required to operate beyond their original design lifespans. The economic impact of corrosion fatigue is substantial, with annual costs estimated at billions of dollars across various sectors including transportation, energy, and manufacturing. This has accelerated research into more durable materials and protective systems.

The primary technical objectives of corrosion fatigue research focus on several key areas. First, developing predictive models that accurately capture the complex interactions between mechanical loading, environmental variables, and material properties. Second, establishing standardized testing methodologies that can reliably simulate service conditions and accelerate the evaluation of new materials and protective systems. Third, advancing fundamental understanding of initiation mechanisms at the microstructural level.

Additional objectives include creating comprehensive databases of corrosion fatigue performance for various material-environment combinations, developing in-situ monitoring techniques for early detection of damage, and formulating design guidelines that account for corrosion fatigue effects in structural applications. The ultimate goal is to transition from reactive maintenance approaches to proactive design strategies that inherently address corrosion fatigue concerns.

The technological trajectory suggests increasing integration of computational modeling with experimental validation, allowing for more accurate life prediction and risk assessment. Emerging research directions include the development of self-healing materials, advanced surface treatments, and smart coating systems specifically designed to mitigate corrosion fatigue damage in aggressive environments.

The technical landscape has progressed from empirical observations to mechanistic understanding, with advances in materials science, electrochemistry, and fracture mechanics contributing to our current knowledge base. Recent developments in high-resolution characterization techniques have enabled researchers to observe corrosion fatigue crack initiation and propagation at unprecedented scales, revealing complex interactions between microstructural features and environmental factors.

Industry trends indicate growing concern regarding corrosion fatigue in aging infrastructure, particularly as structures are increasingly required to operate beyond their original design lifespans. The economic impact of corrosion fatigue is substantial, with annual costs estimated at billions of dollars across various sectors including transportation, energy, and manufacturing. This has accelerated research into more durable materials and protective systems.

The primary technical objectives of corrosion fatigue research focus on several key areas. First, developing predictive models that accurately capture the complex interactions between mechanical loading, environmental variables, and material properties. Second, establishing standardized testing methodologies that can reliably simulate service conditions and accelerate the evaluation of new materials and protective systems. Third, advancing fundamental understanding of initiation mechanisms at the microstructural level.

Additional objectives include creating comprehensive databases of corrosion fatigue performance for various material-environment combinations, developing in-situ monitoring techniques for early detection of damage, and formulating design guidelines that account for corrosion fatigue effects in structural applications. The ultimate goal is to transition from reactive maintenance approaches to proactive design strategies that inherently address corrosion fatigue concerns.

The technological trajectory suggests increasing integration of computational modeling with experimental validation, allowing for more accurate life prediction and risk assessment. Emerging research directions include the development of self-healing materials, advanced surface treatments, and smart coating systems specifically designed to mitigate corrosion fatigue damage in aggressive environments.

Market Demand for Corrosion-Resistant Structural Materials

The global market for corrosion-resistant structural materials has experienced significant growth in recent years, driven by increasing awareness of the economic impact of corrosion-related failures. According to NACE International (National Association of Corrosion Engineers), the global cost of corrosion is estimated at $2.5 trillion annually, equivalent to approximately 3.4% of global GDP. This substantial economic burden has created a robust demand for advanced materials that can withstand both corrosive environments and cyclic loading conditions.

The oil and gas industry represents one of the largest market segments for corrosion-resistant structural materials, with offshore platforms, pipelines, and processing facilities operating in highly aggressive environments. The market value for corrosion-resistant alloys in this sector alone reached $7.6 billion in 2022, with projected growth rates of 6.8% through 2028. This demand is particularly strong in regions with extensive offshore operations such as the Gulf of Mexico, North Sea, and emerging fields in Southeast Asia and West Africa.

Infrastructure development constitutes another major market driver, especially in coastal and industrial zones where structures are exposed to both atmospheric corrosion and mechanical stresses. The construction industry's demand for corrosion-resistant reinforcement materials has grown at 5.2% annually since 2018, with particular emphasis on bridges, marine structures, and chemical processing facilities. This trend is expected to accelerate as aging infrastructure in developed nations requires replacement and emerging economies invest in new construction projects.

The aerospace and automotive industries have also emerged as significant consumers of advanced corrosion-resistant materials. Weight reduction initiatives combined with durability requirements have pushed manufacturers toward specialized aluminum alloys, titanium composites, and corrosion-resistant steel variants. The aerospace sector alone accounts for approximately $3.8 billion in annual spending on these specialized materials, with automotive applications adding another $5.2 billion to market demand.

Geographically, North America and Europe currently lead in consumption of premium corrosion-resistant structural materials, accounting for 58% of global market share. However, the Asia-Pacific region demonstrates the fastest growth rate at 8.7% annually, driven by rapid industrialization in China, India, and Southeast Asian nations. This regional shift reflects both expanding industrial capacity and increasing regulatory requirements for structural safety and longevity in developing economies.

The market is further segmented by material type, with stainless steels maintaining the largest share (42%), followed by specialized aluminum alloys (27%), titanium alloys (15%), and various composites and coated materials (16%). Recent market trends indicate growing interest in hybrid materials and surface treatment technologies that can provide enhanced corrosion fatigue resistance while maintaining competitive pricing structures.

The oil and gas industry represents one of the largest market segments for corrosion-resistant structural materials, with offshore platforms, pipelines, and processing facilities operating in highly aggressive environments. The market value for corrosion-resistant alloys in this sector alone reached $7.6 billion in 2022, with projected growth rates of 6.8% through 2028. This demand is particularly strong in regions with extensive offshore operations such as the Gulf of Mexico, North Sea, and emerging fields in Southeast Asia and West Africa.

Infrastructure development constitutes another major market driver, especially in coastal and industrial zones where structures are exposed to both atmospheric corrosion and mechanical stresses. The construction industry's demand for corrosion-resistant reinforcement materials has grown at 5.2% annually since 2018, with particular emphasis on bridges, marine structures, and chemical processing facilities. This trend is expected to accelerate as aging infrastructure in developed nations requires replacement and emerging economies invest in new construction projects.

The aerospace and automotive industries have also emerged as significant consumers of advanced corrosion-resistant materials. Weight reduction initiatives combined with durability requirements have pushed manufacturers toward specialized aluminum alloys, titanium composites, and corrosion-resistant steel variants. The aerospace sector alone accounts for approximately $3.8 billion in annual spending on these specialized materials, with automotive applications adding another $5.2 billion to market demand.

Geographically, North America and Europe currently lead in consumption of premium corrosion-resistant structural materials, accounting for 58% of global market share. However, the Asia-Pacific region demonstrates the fastest growth rate at 8.7% annually, driven by rapid industrialization in China, India, and Southeast Asian nations. This regional shift reflects both expanding industrial capacity and increasing regulatory requirements for structural safety and longevity in developing economies.

The market is further segmented by material type, with stainless steels maintaining the largest share (42%), followed by specialized aluminum alloys (27%), titanium alloys (15%), and various composites and coated materials (16%). Recent market trends indicate growing interest in hybrid materials and surface treatment technologies that can provide enhanced corrosion fatigue resistance while maintaining competitive pricing structures.

Current Challenges in Corrosion Fatigue Research

Despite significant advancements in corrosion fatigue research, several critical challenges continue to impede comprehensive understanding and effective mitigation strategies. One primary challenge lies in the complex interaction mechanisms between corrosion and fatigue processes. The synergistic effect often produces damage that exceeds the sum of individual degradation mechanisms, making prediction models inherently difficult to develop with sufficient accuracy for real-world applications.

Environmental variability presents another substantial obstacle. Structural components frequently operate in fluctuating conditions where temperature, humidity, chemical exposure, and mechanical loading patterns change unpredictably. These variations create testing difficulties as laboratory simulations struggle to replicate the full spectrum of environmental conditions encountered in service life.

Scale transition from laboratory specimens to full-scale structures remains problematic. Most research relies on small-scale specimens under controlled conditions, but extrapolating these findings to large structures introduces significant uncertainties. The size effect, stress distribution differences, and manufacturing variations all contribute to discrepancies between predicted and actual performance.

Accelerated testing methodologies constitute a persistent challenge. Corrosion fatigue often develops over decades in real structures, necessitating accelerated testing for practical research timeframes. However, current acceleration methods may inadvertently alter damage mechanisms, raising questions about the validity of extrapolated service life predictions.

Advanced materials and coatings introduce additional complexities. While engineered to enhance corrosion fatigue resistance, these materials often exhibit unique degradation patterns that are not fully characterized. The long-term performance of novel alloys, composites, and surface treatments remains difficult to predict without extensive field validation.

Data acquisition from in-service structures presents significant technical hurdles. Non-destructive evaluation techniques for detecting early-stage corrosion fatigue damage lack sufficient sensitivity and reliability, particularly in complex geometries or inaccessible locations. This limitation hampers the development of condition-based maintenance strategies.

Computational modeling faces substantial challenges in accurately representing the multiphysics nature of corrosion fatigue. Current models struggle to integrate electrochemical processes, mechanical loading, material microstructure evolution, and environmental factors into unified predictive frameworks that can function across different time and length scales.

Standardization issues further complicate research efforts. Diverse testing protocols and evaluation criteria across industries and research institutions make comparative analysis difficult, hindering knowledge transfer and consensus-building on best practices for corrosion fatigue assessment and mitigation.

Environmental variability presents another substantial obstacle. Structural components frequently operate in fluctuating conditions where temperature, humidity, chemical exposure, and mechanical loading patterns change unpredictably. These variations create testing difficulties as laboratory simulations struggle to replicate the full spectrum of environmental conditions encountered in service life.

Scale transition from laboratory specimens to full-scale structures remains problematic. Most research relies on small-scale specimens under controlled conditions, but extrapolating these findings to large structures introduces significant uncertainties. The size effect, stress distribution differences, and manufacturing variations all contribute to discrepancies between predicted and actual performance.

Accelerated testing methodologies constitute a persistent challenge. Corrosion fatigue often develops over decades in real structures, necessitating accelerated testing for practical research timeframes. However, current acceleration methods may inadvertently alter damage mechanisms, raising questions about the validity of extrapolated service life predictions.

Advanced materials and coatings introduce additional complexities. While engineered to enhance corrosion fatigue resistance, these materials often exhibit unique degradation patterns that are not fully characterized. The long-term performance of novel alloys, composites, and surface treatments remains difficult to predict without extensive field validation.

Data acquisition from in-service structures presents significant technical hurdles. Non-destructive evaluation techniques for detecting early-stage corrosion fatigue damage lack sufficient sensitivity and reliability, particularly in complex geometries or inaccessible locations. This limitation hampers the development of condition-based maintenance strategies.

Computational modeling faces substantial challenges in accurately representing the multiphysics nature of corrosion fatigue. Current models struggle to integrate electrochemical processes, mechanical loading, material microstructure evolution, and environmental factors into unified predictive frameworks that can function across different time and length scales.

Standardization issues further complicate research efforts. Diverse testing protocols and evaluation criteria across industries and research institutions make comparative analysis difficult, hindering knowledge transfer and consensus-building on best practices for corrosion fatigue assessment and mitigation.

Existing Mitigation Strategies for Corrosion Fatigue

01 Corrosion fatigue testing methods and apparatus

Various testing methods and apparatus have been developed to evaluate corrosion fatigue behavior of materials. These include specialized equipment for simultaneous application of cyclic loading and corrosive environments, monitoring crack propagation, and measuring fatigue life under corrosive conditions. Advanced testing techniques allow for real-time observation of material degradation and precise control of environmental parameters to simulate actual service conditions.- Corrosion fatigue testing methods and apparatus: Various testing methods and apparatus have been developed to evaluate corrosion fatigue behavior of materials. These include specialized equipment for simultaneous application of cyclic loading and corrosive environments, monitoring crack initiation and propagation, and measuring fatigue life under corrosive conditions. Advanced techniques incorporate real-time monitoring capabilities and environmental control systems to simulate specific service conditions.

- Corrosion resistant alloys and materials: Development of specialized alloys and materials with enhanced resistance to corrosion fatigue. These materials are designed with specific chemical compositions and microstructures that improve resistance to both cyclic loading and corrosive attack. Innovations include precipitation-hardened alloys, surface-treated materials, and composite structures that maintain mechanical properties while providing corrosion protection in aggressive environments.

- Surface treatments and coatings for corrosion fatigue prevention: Various surface treatments and coating technologies have been developed to enhance corrosion fatigue resistance. These include protective layers that isolate the base material from corrosive environments while maintaining mechanical integrity under cyclic loading. Techniques such as nitriding, carburizing, shot peening, and application of specialized coatings can significantly improve the corrosion fatigue life of components exposed to harsh environments.

- Environmental factors affecting corrosion fatigue: Research on how different environmental factors influence corrosion fatigue behavior. Studies examine the effects of temperature, pH, solution chemistry, oxygen content, and flow conditions on fatigue crack initiation and propagation in corrosive environments. Understanding these relationships helps in predicting component life and developing appropriate mitigation strategies for specific service environments.

- Computational models and prediction methods: Advanced computational models and prediction methods for assessing corrosion fatigue behavior. These include finite element analysis, machine learning algorithms, and physics-based models that integrate corrosion kinetics with fatigue mechanics. Such approaches enable more accurate prediction of component life, optimization of inspection intervals, and development of design guidelines for components operating in corrosive environments under cyclic loading.

02 Corrosion resistant alloys and compositions

Development of specialized alloys and material compositions with enhanced resistance to corrosion fatigue. These materials are designed with specific elemental compositions to withstand cyclic loading in corrosive environments. The formulations typically include elements that form protective oxide layers, inhibit crack propagation, or provide microstructural stability under combined mechanical and chemical stresses, resulting in improved service life in aggressive environments.Expand Specific Solutions03 Surface treatments and coatings for corrosion fatigue resistance

Surface modification techniques and protective coatings that enhance resistance to corrosion fatigue. These treatments create barrier layers that prevent direct contact between the base material and corrosive media while maintaining mechanical integrity under cyclic loading. Methods include application of specialized coatings, surface hardening processes, and creation of compressive residual stresses that inhibit crack initiation and propagation in corrosive environments.Expand Specific Solutions04 Environmental factors affecting corrosion fatigue

Analysis of how environmental conditions influence corrosion fatigue behavior. Factors such as temperature, pH, solution chemistry, oxygen content, and flow conditions significantly impact the degradation mechanisms and fatigue life of materials. Understanding these environmental interactions helps in predicting service life and developing appropriate mitigation strategies for components operating in specific corrosive environments under cyclic loading conditions.Expand Specific Solutions05 Computational models and prediction methods

Advanced computational approaches for modeling and predicting corrosion fatigue behavior. These include finite element analysis, machine learning algorithms, and physics-based models that simulate the combined effects of mechanical cycling and electrochemical processes. Such models help in estimating component lifetimes, optimizing material selection, and developing preventive maintenance schedules for structures operating in corrosive environments under cyclic loading.Expand Specific Solutions

Leading Organizations in Corrosion Fatigue Research

Corrosion fatigue behavior in structural applications is currently in a growth phase, with the market expanding due to increasing infrastructure development and aging assets worldwide. The global market size for corrosion prevention and monitoring is estimated at $8-10 billion annually, with steady growth projected. From a technical maturity perspective, the field shows varying levels of advancement across sectors. Academic institutions like Tianjin University, Louisiana State University, and Southwest Jiaotong University are driving fundamental research, while industrial players demonstrate different specialization levels. Companies like NIPPON STEEL, Bekaert SA, and Hyundai Motor are implementing advanced corrosion fatigue mitigation technologies in their respective sectors. The Boeing Co. and Southwest Research Institute represent mature technical capabilities in aerospace applications, while emerging players like Integran Technologies are introducing innovative nanocrystalline solutions to address persistent challenges in this critical field.

Svenska Kullagerfabriken AB

Technical Solution: SKF (Svenska Kullagerfabriken AB) has developed specialized technologies addressing corrosion fatigue in bearing applications that extend to broader structural components. Their approach combines materials engineering with tribology and surface science to create solutions for rotating equipment operating in corrosive environments. SKF has pioneered the development of stainless bearing steels with optimized nitrogen content that provides enhanced corrosion resistance without compromising fatigue strength, critical for applications in marine and chemical processing environments. Their research has led to the creation of proprietary heat treatment processes that produce beneficial compressive residual stresses in the subsurface region, significantly improving resistance to both mechanical fatigue and corrosion fatigue. SKF has developed advanced ceramic-metal composite materials that offer superior corrosion fatigue resistance compared to traditional bearing steels, with laboratory testing showing up to 5 times longer service life in corrosive environments under cyclic loading. They've also implemented specialized coating technologies, including diamond-like carbon coatings modified with corrosion-inhibiting elements, which provide both wear resistance and corrosion protection while maintaining dimensional precision critical for bearing applications.

Strengths: Exceptional expertise in tribological systems provides unique insights into corrosion fatigue at contact surfaces. Their solutions are extensively validated through both laboratory testing and field experience in demanding applications. Weaknesses: Primary focus on bearing applications may limit direct transferability to some structural applications. Their premium materials and processes result in higher initial costs, though these may be offset by extended service life.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed advanced corrosion fatigue mitigation strategies for structural steel applications through their proprietary microalloying techniques. Their approach combines controlled additions of chromium, molybdenum, and copper to create steels with enhanced resistance to corrosion fatigue in marine and industrial environments. The company has implemented a dual-phase steel microstructure that effectively interrupts crack propagation pathways, significantly extending component lifetimes under cyclic loading in corrosive media. Their research has demonstrated that optimized heat treatment processes can create beneficial compressive residual stresses at the surface, improving fatigue resistance by up to 40% compared to conventional structural steels. NIPPON STEEL has also pioneered the application of specialized surface treatments, including fine particle peening and nitriding processes, which create hardened surface layers that resist both corrosion initiation and fatigue crack nucleation in aggressive environments.

Strengths: Superior microstructural control through advanced metallurgical processes, resulting in excellent corrosion fatigue resistance in harsh environments. Their integrated approach combining alloy design, processing, and surface treatments provides comprehensive protection. Weaknesses: Higher production costs compared to standard structural steels, and some treatments may require specialized equipment not readily available in all fabrication facilities.

Critical Patents and Research in Corrosion Fatigue

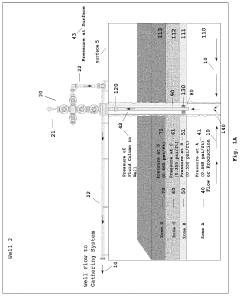

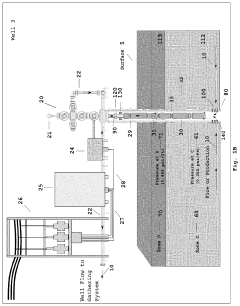

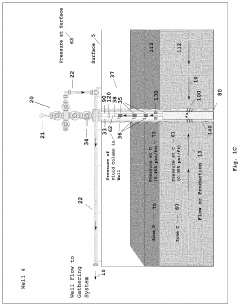

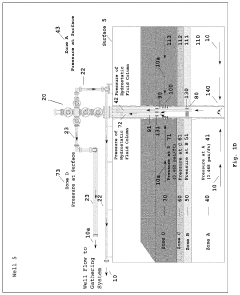

System, method, and apparatus for generating hydroelectric power from subsurface wells

PatentActiveUS20230323851A1

Innovation

- The use of nickel-base alloy compositions, including nickel, iron, chromium, molybdenum, copper, niobium, titanium, and aluminum, to construct hydraulic turbine components that provide enhanced corrosion resistance for handling corrosive subsurface fluids.

Suface impact fatique corrosion machine for biomedical implants and fixators

PatentActiveIN3401CHE2015A

Innovation

- The development of a Surface Impact Fatigue Corrosion Machine (SIFCM) to test the fatigue corrosion resistance of implant materials using simulated body fluids, involving cyclic loading and corrosion testing, with specific techniques like heat treatment and surface modification to enhance mechanical properties and corrosion resistance.

Environmental Factors Affecting Corrosion Fatigue

Corrosion fatigue is significantly influenced by various environmental factors that can accelerate material degradation and structural failure. The presence of corrosive media, particularly chloride-containing environments such as seawater, industrial atmospheres, and de-icing salts, dramatically intensifies fatigue damage mechanisms. These environments create electrochemical reactions at crack tips, accelerating crack propagation rates by up to 10-100 times compared to non-corrosive conditions.

Temperature plays a crucial role in corrosion fatigue behavior, with elevated temperatures typically accelerating both corrosion reactions and fatigue crack growth. Research indicates that for every 10°C increase in temperature, corrosion rates can double in many metal systems, while simultaneously reducing fatigue life. Conversely, extremely low temperatures may reduce corrosion rates but can introduce other challenges such as material embrittlement.

Humidity levels significantly impact corrosion fatigue, particularly in atmospheric conditions. Studies show that relative humidity above 70% creates conditions where moisture films can form on metal surfaces, enabling electrochemical corrosion processes even without visible water presence. This moisture film formation represents a critical threshold for accelerated corrosion fatigue damage in many structural applications.

pH variations in the surrounding environment create distinct corrosion mechanisms. Acidic environments (pH < 4) typically accelerate anodic dissolution and hydrogen embrittlement in steels and aluminum alloys, while alkaline environments may form protective films on some materials but accelerate corrosion in others, such as aluminum. The relationship between pH and corrosion fatigue is highly material-specific and non-linear across the pH spectrum.

Oxygen concentration significantly influences corrosion fatigue through its role in cathodic reactions. Dissolved oxygen levels above 5 ppm in aqueous environments can dramatically accelerate corrosion processes. However, the relationship is complex, as oxygen can also contribute to protective oxide film formation in certain materials and conditions.

Flow conditions and fluid dynamics around structural components create varying corrosion patterns. High-velocity flows can remove protective films through erosion-corrosion mechanisms, while stagnant conditions may allow concentration cells to develop. Research indicates that flow velocities exceeding 3 m/s significantly increase corrosion fatigue damage in many pipeline and marine applications.

Cyclic wetting and drying, common in atmospheric exposure, creates particularly aggressive conditions for corrosion fatigue. These cycles concentrate corrosive species through evaporation and prevent the formation of stable protective films, resulting in accelerated material degradation compared to continuously wet or dry conditions.

Temperature plays a crucial role in corrosion fatigue behavior, with elevated temperatures typically accelerating both corrosion reactions and fatigue crack growth. Research indicates that for every 10°C increase in temperature, corrosion rates can double in many metal systems, while simultaneously reducing fatigue life. Conversely, extremely low temperatures may reduce corrosion rates but can introduce other challenges such as material embrittlement.

Humidity levels significantly impact corrosion fatigue, particularly in atmospheric conditions. Studies show that relative humidity above 70% creates conditions where moisture films can form on metal surfaces, enabling electrochemical corrosion processes even without visible water presence. This moisture film formation represents a critical threshold for accelerated corrosion fatigue damage in many structural applications.

pH variations in the surrounding environment create distinct corrosion mechanisms. Acidic environments (pH < 4) typically accelerate anodic dissolution and hydrogen embrittlement in steels and aluminum alloys, while alkaline environments may form protective films on some materials but accelerate corrosion in others, such as aluminum. The relationship between pH and corrosion fatigue is highly material-specific and non-linear across the pH spectrum.

Oxygen concentration significantly influences corrosion fatigue through its role in cathodic reactions. Dissolved oxygen levels above 5 ppm in aqueous environments can dramatically accelerate corrosion processes. However, the relationship is complex, as oxygen can also contribute to protective oxide film formation in certain materials and conditions.

Flow conditions and fluid dynamics around structural components create varying corrosion patterns. High-velocity flows can remove protective films through erosion-corrosion mechanisms, while stagnant conditions may allow concentration cells to develop. Research indicates that flow velocities exceeding 3 m/s significantly increase corrosion fatigue damage in many pipeline and marine applications.

Cyclic wetting and drying, common in atmospheric exposure, creates particularly aggressive conditions for corrosion fatigue. These cycles concentrate corrosive species through evaporation and prevent the formation of stable protective films, resulting in accelerated material degradation compared to continuously wet or dry conditions.

Testing Standards and Qualification Methods

The standardization of testing methodologies for corrosion fatigue is critical for ensuring reliability and safety in structural applications. ASTM International has developed several key standards, including ASTM E466 for constant amplitude fatigue testing and ASTM G129 specifically for slow strain rate testing in corrosive environments. These standards provide detailed protocols for specimen preparation, environmental control, loading parameters, and data analysis.

ISO standards complement these with ISO 11782 for corrosion fatigue testing of metallic implant materials and ISO 12106 for axial strain-controlled fatigue testing. These standards ensure global consistency in testing approaches and facilitate international collaboration in research and development efforts.

For qualification methods, the industry employs a multi-tiered approach. Initial screening typically involves accelerated testing under exaggerated environmental conditions to rapidly identify susceptible material-environment combinations. These tests often utilize salt spray chambers (ASTM B117) or potentiostatic electrochemical techniques to simulate decades of exposure in weeks or months.

Intermediate qualification involves more representative testing with actual service environments and realistic loading conditions. This includes variable amplitude loading patterns that better reflect real-world structural applications. Advanced qualification methods incorporate fracture mechanics approaches, using pre-cracked specimens to evaluate crack growth rates under combined corrosive and cyclic loading (ASTM E647).

Digital image correlation and acoustic emission monitoring have emerged as valuable non-destructive evaluation techniques for real-time assessment during qualification testing. These methods allow for early detection of crack initiation and propagation, providing insights into failure mechanisms that traditional methods might miss.

Qualification protocols often specify minimum performance thresholds based on statistical analysis of multiple test results. The Weibull distribution is commonly employed to characterize the scatter in fatigue life data and establish reliability-based acceptance criteria. This probabilistic approach acknowledges the inherent variability in corrosion fatigue behavior and provides a framework for risk-based design decisions.

Recent developments in qualification methods include the integration of computational models with experimental validation. Finite element analysis coupled with corrosion kinetics models allows for virtual testing of complex geometries under various environmental conditions, reducing the need for extensive physical testing and accelerating the qualification process.

ISO standards complement these with ISO 11782 for corrosion fatigue testing of metallic implant materials and ISO 12106 for axial strain-controlled fatigue testing. These standards ensure global consistency in testing approaches and facilitate international collaboration in research and development efforts.

For qualification methods, the industry employs a multi-tiered approach. Initial screening typically involves accelerated testing under exaggerated environmental conditions to rapidly identify susceptible material-environment combinations. These tests often utilize salt spray chambers (ASTM B117) or potentiostatic electrochemical techniques to simulate decades of exposure in weeks or months.

Intermediate qualification involves more representative testing with actual service environments and realistic loading conditions. This includes variable amplitude loading patterns that better reflect real-world structural applications. Advanced qualification methods incorporate fracture mechanics approaches, using pre-cracked specimens to evaluate crack growth rates under combined corrosive and cyclic loading (ASTM E647).

Digital image correlation and acoustic emission monitoring have emerged as valuable non-destructive evaluation techniques for real-time assessment during qualification testing. These methods allow for early detection of crack initiation and propagation, providing insights into failure mechanisms that traditional methods might miss.

Qualification protocols often specify minimum performance thresholds based on statistical analysis of multiple test results. The Weibull distribution is commonly employed to characterize the scatter in fatigue life data and establish reliability-based acceptance criteria. This probabilistic approach acknowledges the inherent variability in corrosion fatigue behavior and provides a framework for risk-based design decisions.

Recent developments in qualification methods include the integration of computational models with experimental validation. Finite element analysis coupled with corrosion kinetics models allows for virtual testing of complex geometries under various environmental conditions, reducing the need for extensive physical testing and accelerating the qualification process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!