Corrosion Modeling and Life Prediction for Industrial Alloys

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Industrial Alloy Corrosion Background and Objectives

Corrosion of industrial alloys represents one of the most significant challenges in materials engineering, with global economic impacts exceeding $2.5 trillion annually, approximately 3.4% of the world's GDP. The evolution of corrosion science has progressed from empirical observations in ancient civilizations to sophisticated multi-scale modeling approaches in the modern era. This technological progression has been driven by the increasing demands of industries such as aerospace, petrochemical, nuclear power, and marine engineering, where material failure can lead to catastrophic consequences.

The field has witnessed significant paradigm shifts over the past century, moving from simple linear extrapolation methods to complex computational models that incorporate electrochemical, thermodynamic, and microstructural factors. Early corrosion prediction relied heavily on accelerated testing and empirical correlations, which often failed to account for the complex interplay of environmental variables and material properties in real-world applications.

Recent advancements in computational capabilities have enabled the development of more sophisticated modeling approaches, including finite element analysis, molecular dynamics simulations, and machine learning algorithms. These tools have dramatically improved our ability to predict corrosion behavior across multiple time and length scales, from atomic-level interactions to component-level degradation over decades of service life.

The primary objective of current corrosion modeling research is to develop robust, physics-based predictive tools that can accurately forecast the long-term performance of industrial alloys in diverse operating environments. This includes the ability to account for complex phenomena such as localized corrosion, stress corrosion cracking, and corrosion fatigue, which often determine the practical service life of critical components.

Secondary objectives include the integration of corrosion models with broader asset management frameworks, enabling risk-based inspection planning and maintenance optimization. This integration represents a crucial step toward predictive maintenance strategies that can significantly reduce downtime and extend asset lifespans.

The development of standardized methodologies for model validation and uncertainty quantification remains a critical challenge, as the reliability of life prediction models directly impacts safety-critical decisions in industries such as aerospace and nuclear power. Addressing this challenge requires collaborative efforts between academic institutions, industry stakeholders, and regulatory bodies to establish consensus on best practices and acceptance criteria.

Looking forward, the convergence of advanced characterization techniques, high-performance computing, and data-driven approaches promises to revolutionize our understanding of corrosion mechanisms and our ability to predict and mitigate their effects. This technological evolution will be essential for supporting the development of next-generation materials and extending the operational life of existing infrastructure in increasingly demanding service environments.

The field has witnessed significant paradigm shifts over the past century, moving from simple linear extrapolation methods to complex computational models that incorporate electrochemical, thermodynamic, and microstructural factors. Early corrosion prediction relied heavily on accelerated testing and empirical correlations, which often failed to account for the complex interplay of environmental variables and material properties in real-world applications.

Recent advancements in computational capabilities have enabled the development of more sophisticated modeling approaches, including finite element analysis, molecular dynamics simulations, and machine learning algorithms. These tools have dramatically improved our ability to predict corrosion behavior across multiple time and length scales, from atomic-level interactions to component-level degradation over decades of service life.

The primary objective of current corrosion modeling research is to develop robust, physics-based predictive tools that can accurately forecast the long-term performance of industrial alloys in diverse operating environments. This includes the ability to account for complex phenomena such as localized corrosion, stress corrosion cracking, and corrosion fatigue, which often determine the practical service life of critical components.

Secondary objectives include the integration of corrosion models with broader asset management frameworks, enabling risk-based inspection planning and maintenance optimization. This integration represents a crucial step toward predictive maintenance strategies that can significantly reduce downtime and extend asset lifespans.

The development of standardized methodologies for model validation and uncertainty quantification remains a critical challenge, as the reliability of life prediction models directly impacts safety-critical decisions in industries such as aerospace and nuclear power. Addressing this challenge requires collaborative efforts between academic institutions, industry stakeholders, and regulatory bodies to establish consensus on best practices and acceptance criteria.

Looking forward, the convergence of advanced characterization techniques, high-performance computing, and data-driven approaches promises to revolutionize our understanding of corrosion mechanisms and our ability to predict and mitigate their effects. This technological evolution will be essential for supporting the development of next-generation materials and extending the operational life of existing infrastructure in increasingly demanding service environments.

Market Demand Analysis for Corrosion Prediction Solutions

The global market for corrosion prediction solutions has been experiencing significant growth, driven primarily by increasing awareness of the economic impact of corrosion across industries. According to NACE International (now AMPP), the global cost of corrosion is estimated at $2.5 trillion annually, equivalent to approximately 3.4% of global GDP. This substantial economic burden has created a pressing demand for advanced corrosion modeling and life prediction technologies for industrial alloys.

The oil and gas sector represents the largest market segment for corrosion prediction solutions, accounting for approximately 25% of the total market share. This is attributed to the harsh operating environments, including exposure to hydrogen sulfide, carbon dioxide, and saltwater, which accelerate corrosion processes in critical infrastructure. The power generation industry follows closely, particularly in nuclear and thermal power plants where component failure due to corrosion can lead to catastrophic consequences.

Market research indicates a growing demand for predictive maintenance solutions that incorporate real-time corrosion monitoring and life prediction capabilities. End-users are increasingly seeking integrated systems that combine sensor technologies with advanced analytics to provide actionable insights regarding asset integrity. This trend is particularly evident in the chemical processing industry, where corrosion-related incidents can result in production downtime costing up to $500,000 per hour in large facilities.

The aerospace and defense sectors are emerging as high-growth markets for corrosion prediction technologies. With aircraft fleets aging globally and maintenance costs rising, airlines and military organizations are investing in predictive tools to optimize maintenance schedules and extend asset lifespans. Market analysis shows that implementing effective corrosion prediction solutions can reduce maintenance costs by 15-30% while improving safety and reliability.

Geographically, North America dominates the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the fastest growth is projected in emerging economies in Asia and the Middle East, where rapid industrialization and infrastructure development are creating new demand for corrosion management solutions.

Customer requirements are evolving toward more sophisticated, user-friendly platforms that integrate with existing asset management systems. There is particular interest in solutions that can handle complex multi-material systems and provide accurate predictions under variable environmental conditions. Survey data indicates that 78% of industrial customers prioritize accuracy and reliability in corrosion prediction tools, while 65% emphasize ease of integration with existing systems.

The market is also witnessing increased demand for customized solutions tailored to specific industry applications, moving away from generic corrosion models. This trend reflects the growing recognition that corrosion mechanisms vary significantly across different industrial environments and material systems.

The oil and gas sector represents the largest market segment for corrosion prediction solutions, accounting for approximately 25% of the total market share. This is attributed to the harsh operating environments, including exposure to hydrogen sulfide, carbon dioxide, and saltwater, which accelerate corrosion processes in critical infrastructure. The power generation industry follows closely, particularly in nuclear and thermal power plants where component failure due to corrosion can lead to catastrophic consequences.

Market research indicates a growing demand for predictive maintenance solutions that incorporate real-time corrosion monitoring and life prediction capabilities. End-users are increasingly seeking integrated systems that combine sensor technologies with advanced analytics to provide actionable insights regarding asset integrity. This trend is particularly evident in the chemical processing industry, where corrosion-related incidents can result in production downtime costing up to $500,000 per hour in large facilities.

The aerospace and defense sectors are emerging as high-growth markets for corrosion prediction technologies. With aircraft fleets aging globally and maintenance costs rising, airlines and military organizations are investing in predictive tools to optimize maintenance schedules and extend asset lifespans. Market analysis shows that implementing effective corrosion prediction solutions can reduce maintenance costs by 15-30% while improving safety and reliability.

Geographically, North America dominates the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the fastest growth is projected in emerging economies in Asia and the Middle East, where rapid industrialization and infrastructure development are creating new demand for corrosion management solutions.

Customer requirements are evolving toward more sophisticated, user-friendly platforms that integrate with existing asset management systems. There is particular interest in solutions that can handle complex multi-material systems and provide accurate predictions under variable environmental conditions. Survey data indicates that 78% of industrial customers prioritize accuracy and reliability in corrosion prediction tools, while 65% emphasize ease of integration with existing systems.

The market is also witnessing increased demand for customized solutions tailored to specific industry applications, moving away from generic corrosion models. This trend reflects the growing recognition that corrosion mechanisms vary significantly across different industrial environments and material systems.

Current Corrosion Modeling Challenges and Limitations

Despite significant advancements in corrosion modeling for industrial alloys, several fundamental challenges continue to impede the development of truly predictive models. One of the primary limitations is the inherent complexity of corrosion mechanisms, which involve multiple simultaneous electrochemical, chemical, and physical processes occurring across different time and length scales. This multi-physics nature makes comprehensive modeling exceptionally difficult, particularly when attempting to integrate all relevant phenomena into a unified framework.

Current deterministic models often fail to account for the stochastic nature of corrosion initiation and propagation, especially in real-world industrial environments where conditions fluctuate unpredictably. The transition from laboratory-controlled experiments to field applications represents a significant gap, as models calibrated under idealized conditions frequently underperform when applied to actual industrial settings with variable temperature, pressure, flow conditions, and chemical compositions.

Data limitations present another substantial challenge. High-quality, long-term corrosion data across diverse environmental conditions and material compositions remains scarce. This scarcity hampers model validation and calibration efforts, particularly for predicting long-term behavior from accelerated testing results. The extrapolation from short-term laboratory tests to decades-long service life predictions introduces considerable uncertainty that current models struggle to quantify reliably.

Computational constraints also pose significant barriers. Detailed atomistic and microstructural models, while providing valuable mechanistic insights, are computationally intensive and impractical for system-level predictions. Conversely, empirical and semi-empirical models that are computationally efficient often lack the fundamental physical basis necessary for extrapolation beyond their calibration range.

The integration of microstructural evolution with corrosion progression represents another frontier challenge. Current models inadequately capture how material microstructure evolves during service and how these changes affect corrosion susceptibility over time. This limitation is particularly problematic for high-temperature applications where microstructural changes can significantly alter corrosion behavior.

Additionally, most existing models focus on specific corrosion mechanisms in isolation, failing to address the synergistic effects of multiple degradation mechanisms operating simultaneously. The interactions between mechanical loading, environmental factors, and corrosion processes—known as environment-assisted cracking—remain poorly represented in current predictive frameworks.

Finally, there is a persistent gap between academic research and industrial implementation. Many sophisticated modeling approaches developed in research settings lack user-friendly interfaces and integration capabilities with existing industrial asset management systems, limiting their practical adoption in industry decision-making processes.

Current deterministic models often fail to account for the stochastic nature of corrosion initiation and propagation, especially in real-world industrial environments where conditions fluctuate unpredictably. The transition from laboratory-controlled experiments to field applications represents a significant gap, as models calibrated under idealized conditions frequently underperform when applied to actual industrial settings with variable temperature, pressure, flow conditions, and chemical compositions.

Data limitations present another substantial challenge. High-quality, long-term corrosion data across diverse environmental conditions and material compositions remains scarce. This scarcity hampers model validation and calibration efforts, particularly for predicting long-term behavior from accelerated testing results. The extrapolation from short-term laboratory tests to decades-long service life predictions introduces considerable uncertainty that current models struggle to quantify reliably.

Computational constraints also pose significant barriers. Detailed atomistic and microstructural models, while providing valuable mechanistic insights, are computationally intensive and impractical for system-level predictions. Conversely, empirical and semi-empirical models that are computationally efficient often lack the fundamental physical basis necessary for extrapolation beyond their calibration range.

The integration of microstructural evolution with corrosion progression represents another frontier challenge. Current models inadequately capture how material microstructure evolves during service and how these changes affect corrosion susceptibility over time. This limitation is particularly problematic for high-temperature applications where microstructural changes can significantly alter corrosion behavior.

Additionally, most existing models focus on specific corrosion mechanisms in isolation, failing to address the synergistic effects of multiple degradation mechanisms operating simultaneously. The interactions between mechanical loading, environmental factors, and corrosion processes—known as environment-assisted cracking—remain poorly represented in current predictive frameworks.

Finally, there is a persistent gap between academic research and industrial implementation. Many sophisticated modeling approaches developed in research settings lack user-friendly interfaces and integration capabilities with existing industrial asset management systems, limiting their practical adoption in industry decision-making processes.

Existing Corrosion Life Prediction Approaches

01 Corrosion-resistant alloy compositions

Specific alloy compositions can be engineered to provide enhanced corrosion resistance in industrial applications. These compositions typically include precise combinations of elements such as chromium, nickel, molybdenum, and other metals that form protective oxide layers on the surface. The careful balancing of these elements results in alloys that can withstand aggressive environments including acidic, alkaline, or high-temperature conditions, significantly extending the service life of industrial components.- Nickel-based alloys for corrosion resistance: Nickel-based alloys are widely used in industrial applications requiring high corrosion resistance. These alloys typically contain chromium, molybdenum, and other elements that enhance their resistance to various corrosive environments, including acids, alkalis, and seawater. The addition of specific elements in precise proportions can significantly improve the alloy's resistance to pitting, crevice corrosion, and stress corrosion cracking, thereby extending the service life of components in harsh industrial environments.

- Stainless steel compositions with improved durability: Advanced stainless steel compositions are developed to enhance corrosion resistance and extend service life in industrial applications. These steels typically contain optimized levels of chromium, nickel, molybdenum, and nitrogen to provide superior resistance to various forms of corrosion. Surface treatments and microstructural modifications can further improve their performance. These specialized stainless steels are designed for use in aggressive environments where standard grades would fail prematurely, offering improved durability and reduced maintenance requirements.

- Protective coatings and surface treatments: Various protective coatings and surface treatments can be applied to industrial alloys to enhance their corrosion resistance and extend service life. These include metallic coatings, conversion coatings, organic coatings, and thermal spray coatings. Surface modification techniques such as laser surface alloying, ion implantation, and plasma nitriding can also create corrosion-resistant layers on alloy surfaces. These treatments create barriers that prevent direct contact between the base metal and corrosive environments, significantly improving the durability of industrial components.

- Aluminum alloys with enhanced corrosion properties: Specialized aluminum alloys are formulated with elements such as magnesium, silicon, copper, and zinc to provide improved corrosion resistance in industrial applications. These alloys often undergo specific heat treatments and surface modifications to enhance their protective oxide layer. The addition of rare earth elements and transition metals can further improve their resistance to localized corrosion. These lightweight, corrosion-resistant aluminum alloys are particularly valuable in applications where weight reduction is important alongside durability and extended service life.

- Corrosion-resistant alloys for extreme environments: Specialized alloys are developed for extreme industrial environments characterized by high temperatures, pressures, and highly corrosive media. These include superalloys, refractory metal alloys, and custom-designed metal matrices that can withstand severe operating conditions. The careful balancing of alloying elements and processing techniques results in materials with exceptional resistance to oxidation, sulfidation, and other aggressive corrosion mechanisms. These advanced materials significantly extend component service life in the most demanding industrial applications, such as chemical processing, oil and gas extraction, and power generation.

02 Surface treatment techniques for improved corrosion resistance

Various surface treatment methods can be applied to industrial alloys to enhance their corrosion resistance and extend service life. These techniques include passivation, nitriding, carburizing, and the application of protective coatings. Such treatments create barrier layers that prevent direct contact between the base metal and corrosive environments, thereby reducing corrosion rates and improving the durability of industrial components under harsh operating conditions.Expand Specific Solutions03 Heat treatment processes for optimizing alloy performance

Specialized heat treatment processes can significantly improve the corrosion resistance and service life of industrial alloys. These processes include solution annealing, aging, quenching, and tempering, which modify the microstructure of the alloy to optimize its properties. By controlling grain size, phase distribution, and precipitate formation, heat treatments can enhance the alloy's resistance to various forms of corrosion while maintaining or improving mechanical properties required for industrial applications.Expand Specific Solutions04 Corrosion monitoring and prediction systems

Advanced monitoring and prediction systems can be employed to assess and manage the corrosion of industrial alloys in real-time. These systems utilize sensors, electrochemical techniques, and computational models to detect early signs of corrosion and predict the remaining service life of components. By implementing such monitoring strategies, industries can optimize maintenance schedules, prevent catastrophic failures, and extend the operational life of alloy components in corrosive environments.Expand Specific Solutions05 Specialized alloys for extreme environments

Highly specialized alloys have been developed for use in extreme industrial environments where standard materials would rapidly deteriorate. These include high-temperature alloys for furnace components, cryogenic alloys for low-temperature applications, and alloys specifically designed to resist particular corrosive media such as sulfuric acid or molten salts. These advanced materials incorporate precise combinations of elements and innovative manufacturing techniques to achieve exceptional corrosion resistance and extended service life under the most demanding conditions.Expand Specific Solutions

Key Industry Players in Corrosion Modeling Technologies

The corrosion modeling and life prediction for industrial alloys market is currently in a growth phase, with increasing demand driven by aging infrastructure and the need for asset integrity management. The global market size is estimated to exceed $2 billion, expanding at approximately 6-8% CAGR due to rising industrial safety concerns. Technologically, the field shows moderate maturity with significant advancements in computational modeling. Leading players include major steel manufacturers (NIPPON STEEL, JFE Steel), energy companies (State Grid Corp. of China, Siemens Energy), aerospace entities (Rolls Royce, RTX Corp.), and research institutions (Southwest Research Institute, University of Science & Technology Beijing). These organizations are advancing the field through integration of machine learning with traditional electrochemical models, creating more accurate predictive capabilities for complex industrial environments.

JFE Steel Corp.

Technical Solution: JFE Steel has pioneered an advanced corrosion modeling framework specifically tailored for industrial alloys in harsh environments. Their approach integrates electrochemical kinetics with thermodynamic stability calculations to predict corrosion behavior across varying temperature and chemical exposure conditions. The company's LIFECORR (Life-cycle Integrated Forecasting Engine for Corrosion) platform combines multi-physics modeling with statistical analysis of extensive field data to generate accurate life predictions for critical infrastructure components. JFE's methodology incorporates microstructural evolution during service, accounting for phase transformations and precipitation behaviors that influence corrosion susceptibility. Their models have been extensively validated through accelerated laboratory testing and long-term field exposure studies across various industrial applications including maritime structures, chemical processing equipment, and power generation facilities. JFE has recently enhanced their modeling capabilities by implementing machine learning algorithms that identify complex patterns in corrosion behavior based on compositional variations and processing history[5][6]. The company also employs advanced characterization techniques including 3D atom probe tomography to validate atomic-scale aspects of their corrosion models.

Strengths: Exceptional integration of microstructural evolution with corrosion kinetics; extensive validation across multiple industrial sectors; strong capabilities in modeling high-temperature corrosion phenomena. Weaknesses: Some models require extensive computational resources limiting real-time applications; calibration may be necessary when applying to novel alloy compositions outside their established database.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed a comprehensive corrosion modeling system specifically designed for industrial steel alloys in diverse environments. Their approach combines electrochemical impedance spectroscopy (EIS) with advanced computational fluid dynamics (CFD) to model corrosion in complex flow conditions. The company's proprietary NCORR (Nippon Corrosion Rate Resolver) platform integrates microstructural evolution models with environmental parameters to predict localized corrosion phenomena including pitting, crevice corrosion, and stress corrosion cracking. Nippon Steel employs a unique multi-phase modeling approach that accounts for the heterogeneous nature of industrial environments, incorporating variables such as temperature fluctuations, chemical composition variations, and mechanical loading cycles. Their models have been extensively validated using accelerated testing protocols and long-term field exposure studies across various industrial sectors including maritime, chemical processing, and infrastructure applications[2][4]. The company has recently enhanced their modeling capabilities by incorporating machine learning algorithms that analyze historical performance data to improve prediction accuracy.

Strengths: Extensive validation across diverse industrial environments; specialized expertise in steel alloy behavior under corrosive conditions; integration of microstructural evolution with environmental factors. Weaknesses: Models may be optimized primarily for steel alloys rather than more exotic materials; some proprietary aspects limit transparency and adaptability by external researchers.

Advanced Computational Models for Corrosion Simulation

Method for predicting life of corrosion-resistant steel for desulfurization equipment

PatentWO2013058603A3

Innovation

- Development of a comprehensive testing methodology that simulates real operating conditions of desulfurization equipment through sequential hot-air injection, sulfuric acid spraying, and water spraying steps.

- Quantitative correlation between weight loss measurements and corrosion life prediction that accounts for multiple variables including operation/stoppage states, equipment location, flow rates, and temperature.

- Optimization of sulfuric acid solution concentration (5-20 vol%) for accelerated testing that maintains relevance to actual service conditions.

Machine Learning to Accelerate Alloy Design

PatentActiveUS20200257933A1

Innovation

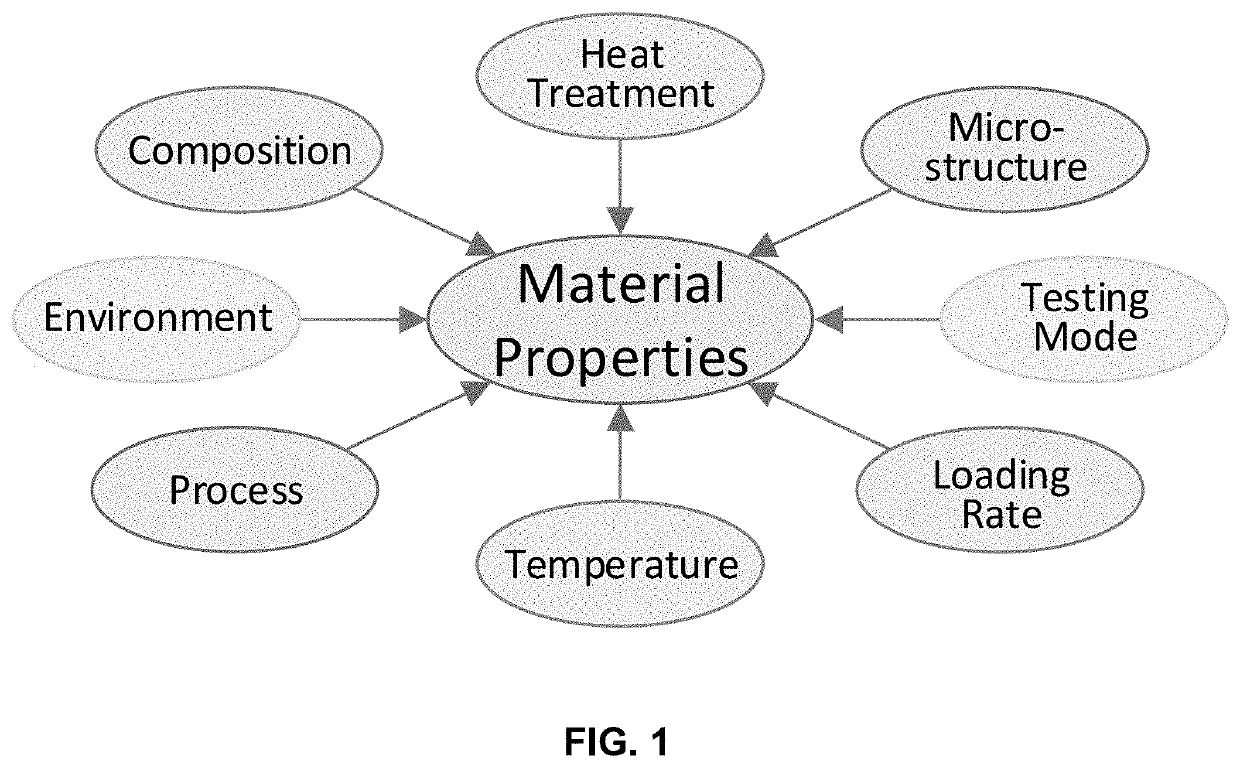

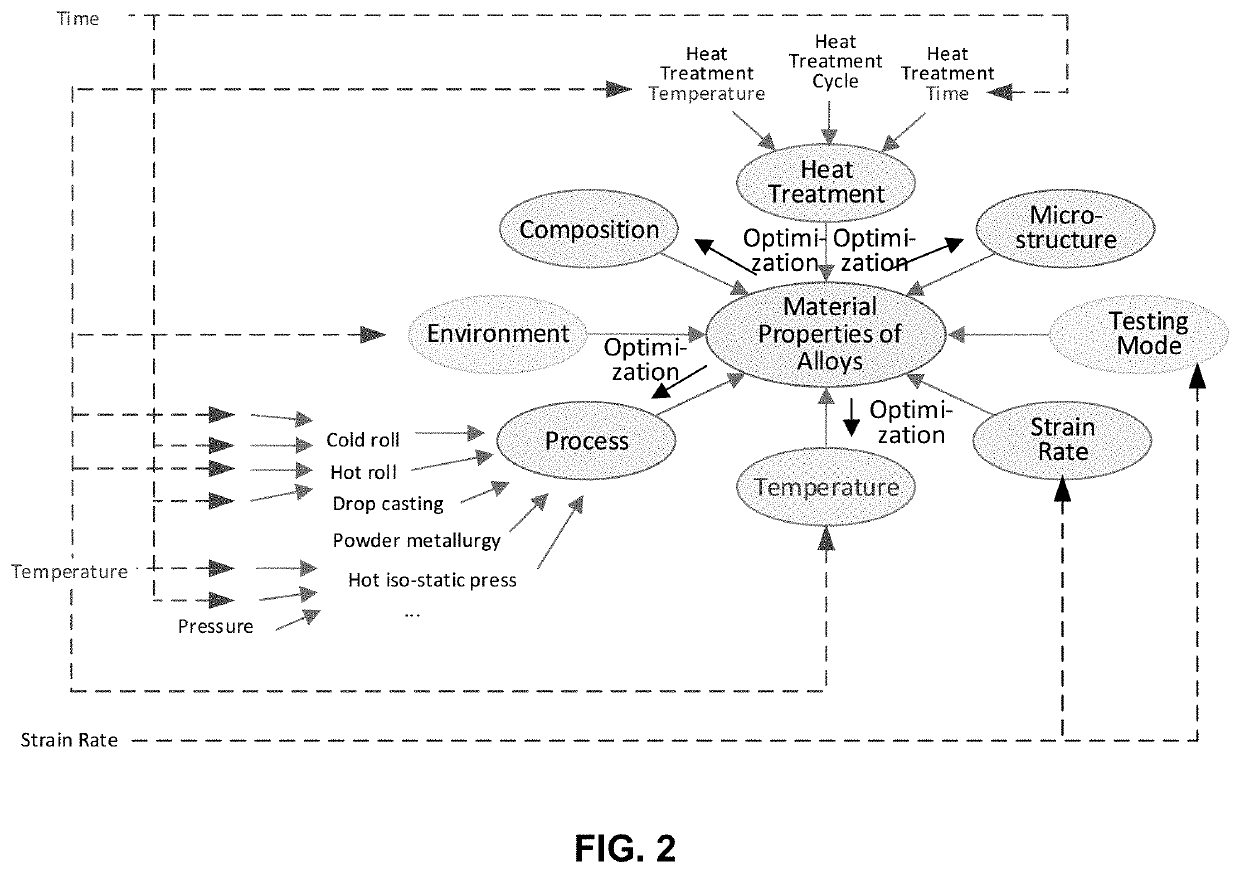

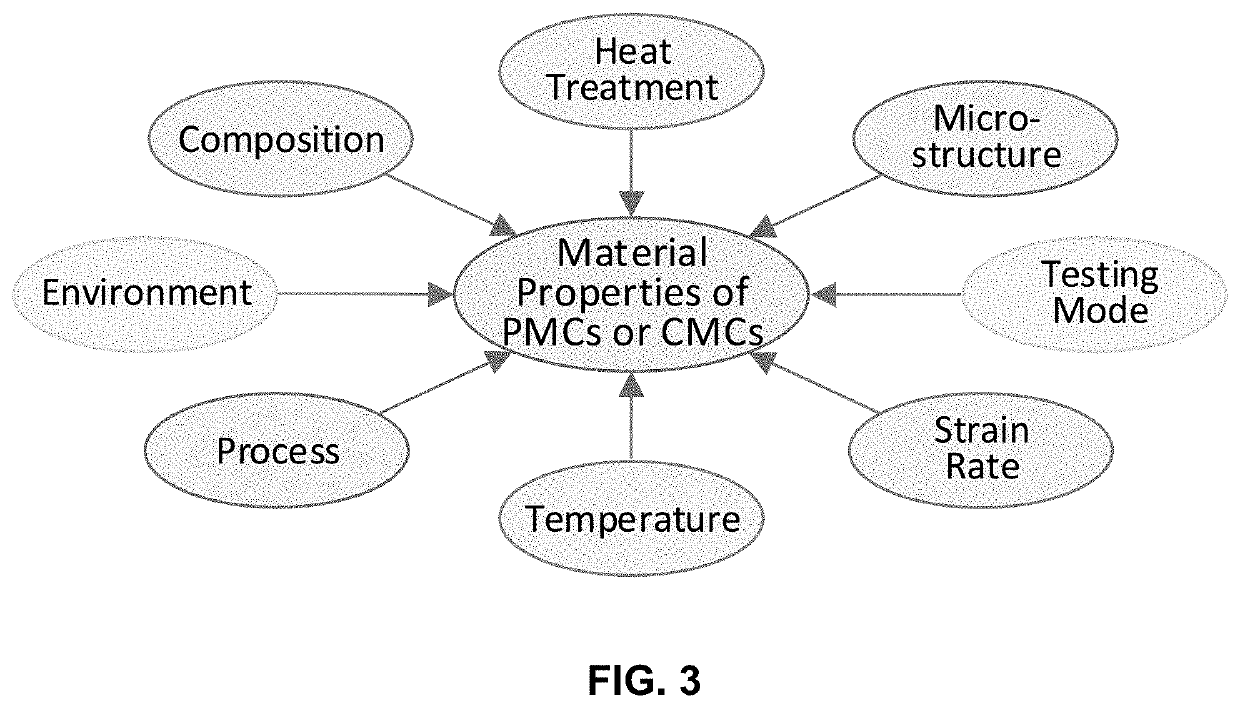

- The application of machine learning (ML) and data analytics to accelerate the design of HEAs and composites by leveraging existing data, using physics-based models and ML algorithms for predicting material properties, and employing ML to optimize AM processes for real-time monitoring and control, thereby reducing development time and costs and improving the quality of AM parts.

Environmental Factors Affecting Corrosion Processes

The corrosion behavior of industrial alloys is significantly influenced by a complex interplay of environmental factors that can accelerate degradation processes or create unique corrosion mechanisms. Temperature stands as one of the most critical factors, with higher temperatures generally accelerating corrosion rates according to the Arrhenius equation, which describes the exponential relationship between reaction rates and temperature. For every 10°C increase, corrosion rates typically double, though this relationship becomes more complex in environments where protective oxide films form or break down at specific temperature thresholds.

Humidity and moisture content create the essential electrolyte medium required for electrochemical corrosion processes. In atmospheric environments, corrosion rates increase dramatically once relative humidity exceeds critical thresholds—typically 60-80% depending on the specific alloy and contaminants present. The time-of-wetness (TOW) parameter has emerged as a crucial metric in corrosion modeling, quantifying the cumulative duration when metal surfaces remain wet enough to sustain corrosion reactions.

Chemical composition of the surrounding environment introduces another dimension of complexity. The presence of chlorides, particularly in marine environments or road deicing salts, aggressively attacks passive films on stainless steels and aluminum alloys through pitting mechanisms. Sulfur compounds, common in industrial and urban atmospheres, form acidic species that accelerate general corrosion rates. Industrial settings often present unique chemical challenges, with process-specific contaminants creating localized corrosion cells.

Pressure effects become particularly relevant in high-pressure applications such as deep-sea equipment or pressure vessels. Increased pressure can alter the solubility of corrosive species and influence the stability of protective films. In subsea applications, hydrostatic pressure can drive corrosive species into microcracks, accelerating stress corrosion cracking mechanisms.

Flow conditions significantly impact corrosion through erosion-corrosion mechanisms, where protective films are mechanically removed by fluid movement, exposing fresh metal surfaces to attack. Stagnant conditions, conversely, can lead to concentration cell corrosion where oxygen or ion gradients develop across metal surfaces. The relationship between flow velocity and corrosion follows a complex pattern, with both very low and very high velocities potentially accelerating specific corrosion mechanisms.

Cyclic environmental conditions often prove more damaging than steady-state exposure. Wet-dry cycling, temperature fluctuations, and alternating chemical environments can disrupt protective films and create stress conditions that accelerate material degradation. These dynamic environmental factors present significant challenges for predictive modeling, requiring time-dependent approaches rather than simple steady-state calculations.

Humidity and moisture content create the essential electrolyte medium required for electrochemical corrosion processes. In atmospheric environments, corrosion rates increase dramatically once relative humidity exceeds critical thresholds—typically 60-80% depending on the specific alloy and contaminants present. The time-of-wetness (TOW) parameter has emerged as a crucial metric in corrosion modeling, quantifying the cumulative duration when metal surfaces remain wet enough to sustain corrosion reactions.

Chemical composition of the surrounding environment introduces another dimension of complexity. The presence of chlorides, particularly in marine environments or road deicing salts, aggressively attacks passive films on stainless steels and aluminum alloys through pitting mechanisms. Sulfur compounds, common in industrial and urban atmospheres, form acidic species that accelerate general corrosion rates. Industrial settings often present unique chemical challenges, with process-specific contaminants creating localized corrosion cells.

Pressure effects become particularly relevant in high-pressure applications such as deep-sea equipment or pressure vessels. Increased pressure can alter the solubility of corrosive species and influence the stability of protective films. In subsea applications, hydrostatic pressure can drive corrosive species into microcracks, accelerating stress corrosion cracking mechanisms.

Flow conditions significantly impact corrosion through erosion-corrosion mechanisms, where protective films are mechanically removed by fluid movement, exposing fresh metal surfaces to attack. Stagnant conditions, conversely, can lead to concentration cell corrosion where oxygen or ion gradients develop across metal surfaces. The relationship between flow velocity and corrosion follows a complex pattern, with both very low and very high velocities potentially accelerating specific corrosion mechanisms.

Cyclic environmental conditions often prove more damaging than steady-state exposure. Wet-dry cycling, temperature fluctuations, and alternating chemical environments can disrupt protective films and create stress conditions that accelerate material degradation. These dynamic environmental factors present significant challenges for predictive modeling, requiring time-dependent approaches rather than simple steady-state calculations.

Economic Impact of Improved Corrosion Prediction

The economic implications of improved corrosion prediction methodologies extend far beyond the immediate technical benefits, representing a significant opportunity for cost reduction across multiple industries. Current estimates indicate that corrosion-related costs account for approximately 3-4% of GDP in industrialized nations, translating to hundreds of billions of dollars annually. Enhanced predictive capabilities for industrial alloy degradation could potentially reduce these costs by 15-30% through more effective maintenance scheduling and asset management.

Primary economic benefits emerge from the extension of asset lifespans. When corrosion behavior can be accurately modeled and predicted, industrial equipment replacement cycles can be optimized based on actual material conditions rather than conservative estimates. This optimization directly translates to capital expenditure reductions, with some industries reporting potential savings of $50-100 million annually for large-scale operations.

Maintenance strategy transformation represents another substantial economic advantage. The shift from reactive or time-based maintenance to predictive maintenance enabled by accurate corrosion modeling reduces both direct maintenance costs and associated operational downtime. Case studies from the oil and gas sector demonstrate maintenance cost reductions of 25-40% when implementing advanced corrosion prediction systems, while simultaneously reducing unplanned downtime by up to 45%.

Insurance and risk management economics also benefit significantly from improved prediction capabilities. More accurate assessment of material degradation enables refined risk profiles, potentially reducing insurance premiums and creating more favorable financing terms for capital-intensive projects. This effect is particularly pronounced in high-risk environments such as offshore operations, where corrosion-related failures carry extreme consequences.

Supply chain optimization presents additional economic opportunities through improved inventory management of replacement parts and materials. With more precise prediction of component lifespans, organizations can reduce safety stock levels and minimize emergency procurement scenarios, generating working capital improvements estimated at 10-15% for maintenance-related inventories.

The broader economic impact extends to environmental and safety considerations, where preventing catastrophic failures due to corrosion can avoid remediation costs, regulatory penalties, and reputational damage. These avoided costs, while difficult to quantify precisely, often exceed direct maintenance savings by orders of magnitude, particularly in environmentally sensitive operations or public infrastructure projects.

Primary economic benefits emerge from the extension of asset lifespans. When corrosion behavior can be accurately modeled and predicted, industrial equipment replacement cycles can be optimized based on actual material conditions rather than conservative estimates. This optimization directly translates to capital expenditure reductions, with some industries reporting potential savings of $50-100 million annually for large-scale operations.

Maintenance strategy transformation represents another substantial economic advantage. The shift from reactive or time-based maintenance to predictive maintenance enabled by accurate corrosion modeling reduces both direct maintenance costs and associated operational downtime. Case studies from the oil and gas sector demonstrate maintenance cost reductions of 25-40% when implementing advanced corrosion prediction systems, while simultaneously reducing unplanned downtime by up to 45%.

Insurance and risk management economics also benefit significantly from improved prediction capabilities. More accurate assessment of material degradation enables refined risk profiles, potentially reducing insurance premiums and creating more favorable financing terms for capital-intensive projects. This effect is particularly pronounced in high-risk environments such as offshore operations, where corrosion-related failures carry extreme consequences.

Supply chain optimization presents additional economic opportunities through improved inventory management of replacement parts and materials. With more precise prediction of component lifespans, organizations can reduce safety stock levels and minimize emergency procurement scenarios, generating working capital improvements estimated at 10-15% for maintenance-related inventories.

The broader economic impact extends to environmental and safety considerations, where preventing catastrophic failures due to corrosion can avoid remediation costs, regulatory penalties, and reputational damage. These avoided costs, while difficult to quantify precisely, often exceed direct maintenance savings by orders of magnitude, particularly in environmentally sensitive operations or public infrastructure projects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!