Corrosion-Resistant Alloy Design for Harsh Industrial Environments

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Corrosion-Resistant Alloy Evolution and Objectives

Corrosion-resistant alloys have evolved significantly over the past century, transitioning from simple metallic compositions to sophisticated engineered materials designed to withstand increasingly demanding industrial environments. The development trajectory began with basic carbon steels protected by simple coatings, progressing through stainless steel innovations in the early 20th century, to today's advanced superalloys and metal matrix composites. This evolution has been driven by expanding industrial applications in chemical processing, offshore oil and gas, nuclear power generation, and aerospace sectors.

The fundamental challenge in corrosion-resistant alloy design lies in balancing multiple material properties: corrosion resistance, mechanical strength, thermal stability, and economic viability. Historical approaches focused primarily on chromium and nickel additions to form passive oxide layers, but modern solutions incorporate complex multi-element systems with precisely controlled microstructures.

Recent technological advancements have accelerated development through computational materials science, enabling rapid virtual testing of novel alloy compositions before physical prototyping. High-throughput experimentation techniques have further revolutionized the field, allowing researchers to test hundreds of compositional variations simultaneously, dramatically reducing development timelines.

The global market for corrosion-resistant alloys continues to expand, currently estimated at $7.5 billion annually with projected growth rates of 6-8% through 2028. This growth is particularly pronounced in emerging economies where rapid industrialization drives demand for materials capable of withstanding harsh chemical environments while maintaining structural integrity.

The primary objective of current research focuses on developing next-generation alloys that can withstand multiple simultaneous corrosion mechanisms (pitting, crevice, stress corrosion cracking) while maintaining performance at elevated temperatures (>800°C). Secondary objectives include reducing critical raw material dependencies, particularly for elements facing supply constraints such as cobalt and rare earth metals.

Environmental sustainability has emerged as a crucial consideration, with increasing emphasis on designing alloys that not only resist corrosion but also enable longer service lifetimes, reduced maintenance requirements, and eventual recyclability. This holistic approach represents a paradigm shift from purely performance-based metrics to lifecycle environmental impact assessment.

Looking forward, the field aims to develop predictive models that can accurately forecast alloy performance over decades of service life, addressing the fundamental challenge that accelerated laboratory testing often fails to replicate real-world degradation mechanisms accurately. Success in this domain would transform industrial maintenance strategies and enable more precise lifecycle management of critical infrastructure components.

The fundamental challenge in corrosion-resistant alloy design lies in balancing multiple material properties: corrosion resistance, mechanical strength, thermal stability, and economic viability. Historical approaches focused primarily on chromium and nickel additions to form passive oxide layers, but modern solutions incorporate complex multi-element systems with precisely controlled microstructures.

Recent technological advancements have accelerated development through computational materials science, enabling rapid virtual testing of novel alloy compositions before physical prototyping. High-throughput experimentation techniques have further revolutionized the field, allowing researchers to test hundreds of compositional variations simultaneously, dramatically reducing development timelines.

The global market for corrosion-resistant alloys continues to expand, currently estimated at $7.5 billion annually with projected growth rates of 6-8% through 2028. This growth is particularly pronounced in emerging economies where rapid industrialization drives demand for materials capable of withstanding harsh chemical environments while maintaining structural integrity.

The primary objective of current research focuses on developing next-generation alloys that can withstand multiple simultaneous corrosion mechanisms (pitting, crevice, stress corrosion cracking) while maintaining performance at elevated temperatures (>800°C). Secondary objectives include reducing critical raw material dependencies, particularly for elements facing supply constraints such as cobalt and rare earth metals.

Environmental sustainability has emerged as a crucial consideration, with increasing emphasis on designing alloys that not only resist corrosion but also enable longer service lifetimes, reduced maintenance requirements, and eventual recyclability. This holistic approach represents a paradigm shift from purely performance-based metrics to lifecycle environmental impact assessment.

Looking forward, the field aims to develop predictive models that can accurately forecast alloy performance over decades of service life, addressing the fundamental challenge that accelerated laboratory testing often fails to replicate real-world degradation mechanisms accurately. Success in this domain would transform industrial maintenance strategies and enable more precise lifecycle management of critical infrastructure components.

Industrial Market Demand for Advanced Corrosion Solutions

The global market for corrosion-resistant materials has experienced significant growth in recent years, driven by increasing demands across multiple industrial sectors. The oil and gas industry remains one of the primary consumers of advanced corrosion solutions, with offshore platforms, pipelines, and refineries operating in environments where saltwater, hydrogen sulfide, and carbon dioxide create highly corrosive conditions. According to industry reports, corrosion costs in this sector alone exceed $7 billion annually, creating substantial demand for innovative alloy solutions.

Chemical processing industries represent another major market segment, where equipment must withstand exposure to acids, alkalis, and various reactive compounds at elevated temperatures. The need for materials that can maintain structural integrity while handling increasingly aggressive chemical formulations has intensified as manufacturers push operational boundaries to improve efficiency and output.

Power generation facilities, particularly those utilizing advanced technologies such as supercritical steam systems and concentrated solar power, require materials capable of withstanding both high temperatures and corrosive environments. The transition toward cleaner energy sources has not eliminated corrosion challenges but rather transformed them, creating new material requirements for hydrogen storage, fuel cells, and carbon capture technologies.

Marine applications constitute a growing market for corrosion-resistant alloys, with shipbuilding, offshore wind farms, and underwater infrastructure requiring materials that can withstand prolonged seawater exposure. The expansion of offshore renewable energy installations has significantly increased demand for specialized corrosion-resistant components that can operate reliably with minimal maintenance in remote locations.

Mining and metallurgical operations present some of the most demanding environments for materials, combining abrasive wear with chemical attack from process fluids. Equipment failure due to corrosion in these settings can result in substantial production losses and safety hazards, driving investment in advanced alloy solutions.

Market analysis indicates that industries are increasingly prioritizing total lifecycle costs over initial investment, recognizing that premium corrosion-resistant materials often deliver superior long-term value despite higher upfront costs. This shift in purchasing philosophy has expanded opportunities for advanced alloy systems that offer extended service life and reduced maintenance requirements.

Regulatory pressures have further stimulated market demand, with stricter environmental and safety standards compelling industries to adopt more durable materials that minimize the risk of containment failures and subsequent environmental contamination. This regulatory landscape has created particular opportunities for alloys that can replace traditional materials containing environmentally problematic elements such as chromium, while maintaining or improving corrosion resistance.

Chemical processing industries represent another major market segment, where equipment must withstand exposure to acids, alkalis, and various reactive compounds at elevated temperatures. The need for materials that can maintain structural integrity while handling increasingly aggressive chemical formulations has intensified as manufacturers push operational boundaries to improve efficiency and output.

Power generation facilities, particularly those utilizing advanced technologies such as supercritical steam systems and concentrated solar power, require materials capable of withstanding both high temperatures and corrosive environments. The transition toward cleaner energy sources has not eliminated corrosion challenges but rather transformed them, creating new material requirements for hydrogen storage, fuel cells, and carbon capture technologies.

Marine applications constitute a growing market for corrosion-resistant alloys, with shipbuilding, offshore wind farms, and underwater infrastructure requiring materials that can withstand prolonged seawater exposure. The expansion of offshore renewable energy installations has significantly increased demand for specialized corrosion-resistant components that can operate reliably with minimal maintenance in remote locations.

Mining and metallurgical operations present some of the most demanding environments for materials, combining abrasive wear with chemical attack from process fluids. Equipment failure due to corrosion in these settings can result in substantial production losses and safety hazards, driving investment in advanced alloy solutions.

Market analysis indicates that industries are increasingly prioritizing total lifecycle costs over initial investment, recognizing that premium corrosion-resistant materials often deliver superior long-term value despite higher upfront costs. This shift in purchasing philosophy has expanded opportunities for advanced alloy systems that offer extended service life and reduced maintenance requirements.

Regulatory pressures have further stimulated market demand, with stricter environmental and safety standards compelling industries to adopt more durable materials that minimize the risk of containment failures and subsequent environmental contamination. This regulatory landscape has created particular opportunities for alloys that can replace traditional materials containing environmentally problematic elements such as chromium, while maintaining or improving corrosion resistance.

Current Challenges in Harsh Environment Materials

The development of corrosion-resistant alloys for harsh industrial environments faces numerous technical challenges that limit their widespread application and effectiveness. One of the primary obstacles is the complex multi-mechanism degradation that occurs in extreme conditions, where materials must simultaneously withstand combinations of high temperature, pressure, mechanical stress, and aggressive chemical environments. These synergistic effects often accelerate material failure beyond what individual degradation mechanisms would predict.

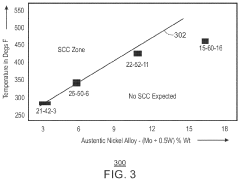

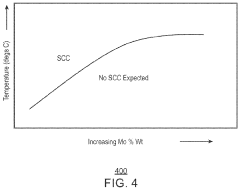

Material scientists struggle with the trade-off between corrosion resistance and mechanical properties. Traditional approaches that enhance corrosion resistance, such as increasing chromium or molybdenum content, often compromise mechanical strength, ductility, or thermal stability. This fundamental materials science challenge has yet to be fully resolved, particularly for applications requiring both high-temperature strength and corrosion resistance.

Localized corrosion phenomena, including pitting, crevice corrosion, and stress corrosion cracking, remain particularly difficult to predict and mitigate. These failure modes can initiate catastrophically with minimal warning signs, making them especially dangerous in critical industrial applications. Current testing protocols often fail to accurately simulate these localized phenomena in laboratory settings.

The economic constraints of alloy development present another significant challenge. High-performance corrosion-resistant alloys typically contain expensive elements like nickel, molybdenum, and tungsten, driving material costs to levels that limit widespread industrial adoption. Finding cost-effective alternatives without sacrificing performance remains an ongoing challenge.

Manufacturing difficulties further complicate the situation. Many highly corrosion-resistant alloys exhibit poor processability, including challenges in casting, forming, machining, and welding. These processing limitations restrict the geometries and applications where these materials can be effectively deployed.

The lack of comprehensive, long-term performance data in actual service environments creates uncertainty in material selection and lifetime prediction. Accelerated testing methods often fail to accurately represent the complex degradation mechanisms that occur over decades of service, leading to either overly conservative designs or unexpected failures.

Emerging industrial applications, including hydrogen production, carbon capture, and advanced energy systems, present novel corrosive environments for which existing alloys were not specifically designed. These new applications often involve unique combinations of temperature, pressure, and chemical species that push beyond the validated performance envelope of current materials.

Material scientists struggle with the trade-off between corrosion resistance and mechanical properties. Traditional approaches that enhance corrosion resistance, such as increasing chromium or molybdenum content, often compromise mechanical strength, ductility, or thermal stability. This fundamental materials science challenge has yet to be fully resolved, particularly for applications requiring both high-temperature strength and corrosion resistance.

Localized corrosion phenomena, including pitting, crevice corrosion, and stress corrosion cracking, remain particularly difficult to predict and mitigate. These failure modes can initiate catastrophically with minimal warning signs, making them especially dangerous in critical industrial applications. Current testing protocols often fail to accurately simulate these localized phenomena in laboratory settings.

The economic constraints of alloy development present another significant challenge. High-performance corrosion-resistant alloys typically contain expensive elements like nickel, molybdenum, and tungsten, driving material costs to levels that limit widespread industrial adoption. Finding cost-effective alternatives without sacrificing performance remains an ongoing challenge.

Manufacturing difficulties further complicate the situation. Many highly corrosion-resistant alloys exhibit poor processability, including challenges in casting, forming, machining, and welding. These processing limitations restrict the geometries and applications where these materials can be effectively deployed.

The lack of comprehensive, long-term performance data in actual service environments creates uncertainty in material selection and lifetime prediction. Accelerated testing methods often fail to accurately represent the complex degradation mechanisms that occur over decades of service, leading to either overly conservative designs or unexpected failures.

Emerging industrial applications, including hydrogen production, carbon capture, and advanced energy systems, present novel corrosive environments for which existing alloys were not specifically designed. These new applications often involve unique combinations of temperature, pressure, and chemical species that push beyond the validated performance envelope of current materials.

Existing Alloy Formulations and Protection Mechanisms

01 Nickel-based alloys for corrosion resistance

Nickel-based alloys are widely used for their excellent corrosion resistance properties in aggressive environments. These alloys typically contain chromium, molybdenum, and other elements that enhance their resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. The high nickel content provides stability in reducing environments while chromium offers protection in oxidizing conditions. These alloys are particularly valuable in applications involving high temperatures and harsh chemical environments.- Nickel-based alloys for corrosion resistance: Nickel-based alloys are widely used for their excellent corrosion resistance properties in aggressive environments. These alloys typically contain chromium, molybdenum, and other elements that enhance their resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. They are particularly effective in acidic environments and high-temperature applications where conventional materials would fail.

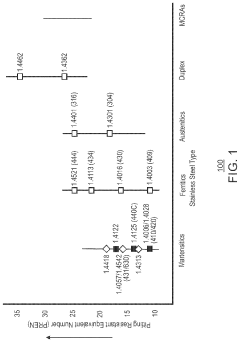

- Stainless steel compositions with improved corrosion resistance: Specialized stainless steel compositions have been developed to provide enhanced corrosion resistance. These steels typically contain higher levels of chromium, nickel, and molybdenum, along with controlled amounts of other elements such as nitrogen, copper, and silicon. The precise balance of these elements creates a passive oxide layer that protects the underlying metal from corrosive attack, making these alloys suitable for use in marine environments, chemical processing, and other demanding applications.

- Surface treatments and coatings for improved corrosion resistance: Various surface treatments and coating technologies can significantly enhance the corrosion resistance of metal alloys. These include passivation treatments, conversion coatings, electroplating, thermal spray coatings, and advanced thin-film deposition techniques. Such treatments create protective barriers that isolate the base metal from corrosive environments or alter the surface chemistry to make it more resistant to corrosive attack, thereby extending the service life of components in harsh environments.

- Copper-based alloys for specific corrosion environments: Copper-based alloys offer excellent corrosion resistance in specific environments, particularly seawater and other chloride-containing media. These alloys, including various brasses, bronzes, and copper-nickels, contain elements such as tin, aluminum, nickel, and zinc in carefully controlled proportions to optimize their corrosion resistance. They are widely used in marine applications, heat exchangers, and plumbing systems where resistance to biofouling and dezincification is also important.

- High-temperature corrosion resistant alloys: Specialized alloys have been developed to resist corrosion at elevated temperatures, where conventional materials would rapidly degrade. These high-temperature alloys typically contain significant amounts of chromium, aluminum, and silicon, which form stable, adherent oxide scales that protect against further oxidation. Additional elements such as yttrium, hafnium, and rare earth metals are often added to improve the adherence of these protective scales. These materials are crucial in applications such as gas turbines, industrial furnaces, and petrochemical processing equipment.

02 Stainless steel compositions with enhanced corrosion resistance

Specialized stainless steel compositions have been developed to provide superior corrosion resistance in specific environments. These steels typically contain carefully balanced amounts of chromium, nickel, molybdenum, and nitrogen to optimize their performance. The addition of elements like nitrogen can significantly improve resistance to pitting corrosion, while molybdenum enhances resistance in chloride-containing environments. Heat treatment processes are often employed to optimize the microstructure and further enhance the corrosion resistance properties of these alloys.Expand Specific Solutions03 Copper-based alloys for marine applications

Copper-based alloys demonstrate excellent resistance to biofouling and corrosion in marine environments. These alloys, including various brasses and bronzes, contain elements such as tin, aluminum, nickel, and zinc in specific proportions to enhance their performance in seawater. The natural antimicrobial properties of copper help prevent biological growth on surfaces, while the alloying elements improve mechanical properties and corrosion resistance. These materials are particularly valuable for ship components, offshore structures, and desalination plants where exposure to seawater is constant.Expand Specific Solutions04 Surface treatments and coatings for improved corrosion resistance

Various surface treatments and coating technologies have been developed to enhance the corrosion resistance of metal alloys. These include passivation treatments, conversion coatings, electroplating, and advanced thin-film deposition techniques. The treatments create protective barrier layers that isolate the base metal from corrosive environments or alter the surface chemistry to make it more resistant to attack. Some coatings also incorporate corrosion inhibitors or sacrificial elements that preferentially corrode to protect the underlying material.Expand Specific Solutions05 High-temperature corrosion resistant alloys

Specialized alloys have been formulated to resist corrosion at elevated temperatures, where conventional materials would rapidly degrade. These high-temperature alloys typically contain significant amounts of chromium, aluminum, and silicon, which form stable, adherent oxide layers that protect against further oxidation. Additional elements like rare earth metals may be added to improve the adhesion and integrity of these protective scales. These materials are crucial for applications in power generation, petrochemical processing, and aerospace industries where components must withstand both high temperatures and corrosive environments.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The corrosion-resistant alloy market is currently in a growth phase, with increasing demand driven by harsh industrial environments across energy, chemical, and manufacturing sectors. The global market size is estimated at $7-9 billion annually with projected 5-7% CAGR through 2030. Technologically, the field shows varying maturity levels, with companies like QuesTek Innovations leading in computational alloy design, while established players such as NIPPON STEEL, BorgWarner, and Höganäs AB dominate traditional manufacturing. Research institutions including University of Science & Technology Beijing and Norwegian University of Science & Technology are advancing fundamental corrosion science. The competitive landscape features collaboration between specialized materials developers (Crucible Industries, Proterial) and application-focused companies (ExxonMobil Chemical, Safran Helicopter Engines), indicating a trend toward customized alloy solutions for specific industrial environments.

QuesTek Innovations LLC

Technical Solution: QuesTek employs Integrated Computational Materials Engineering (ICME) methodology to design corrosion-resistant alloys from the atomic level up. Their proprietary Materials by Design® approach combines quantum mechanics, thermodynamics, and kinetic modeling to predict material properties before physical production. For harsh industrial environments, QuesTek has developed Ferrium® S53® steel with exceptional corrosion resistance while maintaining high strength and toughness. Their process involves four key steps: 1) Identifying performance requirements, 2) Computational modeling of microstructure, 3) Designing processing parameters, and 4) Accelerated testing validation. This approach has resulted in alloys with up to 10x improved corrosion resistance compared to traditional materials while maintaining or enhancing mechanical properties.

Strengths: Significantly reduced development time (3-5 years vs 10-15 years for traditional methods); highly customizable solutions for specific environmental challenges; data-driven approach minimizes trial-and-error. Weaknesses: Higher initial development costs; requires sophisticated computational infrastructure; limited production scale compared to major steel manufacturers.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has pioneered advanced corrosion-resistant alloys through their proprietary Super-OLAC (On-Line Accelerated Cooling) technology, which enables precise microstructural control during production. Their flagship solution for harsh industrial environments is the NAR series (Nippon Steel Anti-corRosion) of stainless steels, featuring optimized chromium, molybdenum, and nitrogen content. These alloys demonstrate superior resistance to pitting, crevice corrosion, and stress corrosion cracking in aggressive media. Nippon Steel's approach includes surface modification techniques like their patented Shot Blast Nitriding (SBN) process that creates a nitrogen-enriched layer up to 50μm deep, significantly enhancing surface hardness and corrosion resistance. For extremely corrosive environments, they've developed duplex stainless steels with balanced austenite-ferrite microstructures that provide both strength and exceptional corrosion resistance, particularly in chloride-containing environments common in chemical processing and offshore applications.

Strengths: Extensive production capacity enabling economies of scale; comprehensive testing facilities for simulating diverse corrosive environments; vertical integration from raw material to finished product ensures quality control. Weaknesses: Higher cost compared to conventional alloys; some specialized grades have limited availability; complex processing requirements may limit manufacturing flexibility.

Critical Patents and Metallurgical Innovations

High performance alloy for corrosion resistance

PatentActiveUS20230339006A1

Innovation

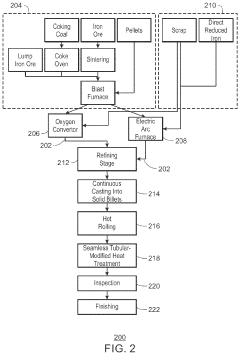

- A corrosion-resistant alloy with a composition of 13-15 wt. % chromium, 5-7 wt. % nickel, and 2.5-4.5 wt. % molybdenum, along with a manufacturing process that includes refining to remove nitrogen and hydrogen, and heat treatment to increase molybdenum content beyond its solubility limit, forming a seamless tubular with enhanced corrosion resistance.

Corrosion-resistant, high-hardness alloy composition and method for producing same

PatentActiveUS20170218484A1

Innovation

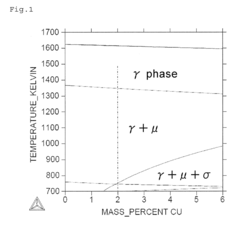

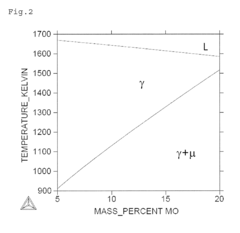

- A Ni—Co—Cr—Mo—Fe—Cu-based alloy composition with optimized chemical and heat treatment conditions, including 15.5% Cr, 7.5% Mo, 0% to 30% Co, 4.5% Fe, and 0.5% to 4.0% Cu, with γ phase crystal structure and Vickers hardness of 500 HV or more, achieved through homogenization, cold processing, and aging treatment.

Environmental Impact and Sustainability Considerations

The development of corrosion-resistant alloys must be evaluated not only for their technical performance but also for their environmental footprint throughout their lifecycle. Traditional corrosion protection methods often involve toxic substances like hexavalent chromium and heavy metals, which pose significant environmental and health risks. Modern alloy design increasingly prioritizes reducing or eliminating these harmful components while maintaining or improving corrosion resistance performance.

Life Cycle Assessment (LCA) studies reveal that while corrosion-resistant alloys may require more energy-intensive production processes initially, their extended service life often results in a lower environmental impact compared to frequently replaced conventional materials. For instance, high-performance nickel-based alloys in chemical processing equipment can operate for decades without replacement, significantly reducing waste generation and resource consumption over time.

The mining and extraction of alloying elements present substantial environmental challenges, particularly for rare earth elements and strategic metals like molybdenum and niobium. Sustainable alloy design now incorporates considerations for material sourcing, emphasizing elements with lower extraction impacts or those available from recycled sources. Advanced metallurgical processes are being developed to utilize lower-grade ores and secondary sources, reducing the environmental burden of primary extraction.

End-of-life recyclability represents another critical sustainability factor for corrosion-resistant alloys. Highly alloyed materials can present recycling challenges due to the difficulty in separating and recovering individual elements. However, their inherent value often drives higher recycling rates compared to commodity metals. Emerging technologies in metallurgical separation are improving the recovery rates of valuable elements from complex alloy systems, creating more closed-loop material cycles.

Water conservation considerations are increasingly important in corrosion-resistant alloy applications, particularly in water treatment facilities and desalination plants. Advanced alloys that can withstand aggressive chloride environments enable more efficient water purification processes with lower energy requirements and chemical usage. Similarly, in renewable energy systems, corrosion-resistant materials extend the operational lifetime of components exposed to harsh environments, enhancing the sustainability profile of these clean energy technologies.

Regulatory frameworks worldwide are evolving to address the environmental impacts of materials used in industrial applications. The European Union's REACH regulations, China's environmental protection initiatives, and similar programs in other regions are driving innovation toward more environmentally benign corrosion protection solutions. Companies developing new corrosion-resistant alloys must navigate these complex regulatory landscapes while meeting performance requirements for harsh industrial environments.

Life Cycle Assessment (LCA) studies reveal that while corrosion-resistant alloys may require more energy-intensive production processes initially, their extended service life often results in a lower environmental impact compared to frequently replaced conventional materials. For instance, high-performance nickel-based alloys in chemical processing equipment can operate for decades without replacement, significantly reducing waste generation and resource consumption over time.

The mining and extraction of alloying elements present substantial environmental challenges, particularly for rare earth elements and strategic metals like molybdenum and niobium. Sustainable alloy design now incorporates considerations for material sourcing, emphasizing elements with lower extraction impacts or those available from recycled sources. Advanced metallurgical processes are being developed to utilize lower-grade ores and secondary sources, reducing the environmental burden of primary extraction.

End-of-life recyclability represents another critical sustainability factor for corrosion-resistant alloys. Highly alloyed materials can present recycling challenges due to the difficulty in separating and recovering individual elements. However, their inherent value often drives higher recycling rates compared to commodity metals. Emerging technologies in metallurgical separation are improving the recovery rates of valuable elements from complex alloy systems, creating more closed-loop material cycles.

Water conservation considerations are increasingly important in corrosion-resistant alloy applications, particularly in water treatment facilities and desalination plants. Advanced alloys that can withstand aggressive chloride environments enable more efficient water purification processes with lower energy requirements and chemical usage. Similarly, in renewable energy systems, corrosion-resistant materials extend the operational lifetime of components exposed to harsh environments, enhancing the sustainability profile of these clean energy technologies.

Regulatory frameworks worldwide are evolving to address the environmental impacts of materials used in industrial applications. The European Union's REACH regulations, China's environmental protection initiatives, and similar programs in other regions are driving innovation toward more environmentally benign corrosion protection solutions. Companies developing new corrosion-resistant alloys must navigate these complex regulatory landscapes while meeting performance requirements for harsh industrial environments.

Economic Analysis and Implementation Cost-Benefit

The economic implications of implementing corrosion-resistant alloys in harsh industrial environments extend far beyond the initial material costs. When conducting a comprehensive cost-benefit analysis, organizations must consider the entire lifecycle economics of these specialized materials.

Initial investment in corrosion-resistant alloys typically represents a premium of 2-5 times the cost of standard carbon steel alternatives. For example, nickel-based superalloys can cost $20-50 per kilogram compared to $1-2 for carbon steel. However, this capital expenditure must be evaluated against the substantial long-term operational savings these materials enable.

Maintenance cost reduction constitutes a primary economic benefit, with corrosion-resistant installations demonstrating 60-80% lower maintenance requirements over their operational lifetime. This translates to fewer production interruptions, with studies indicating that unplanned downtime in chemical processing facilities can cost $20,000-50,000 per hour. The extended service life of corrosion-resistant components—often 3-5 times longer than conventional materials—further enhances the return on investment calculation.

Energy efficiency improvements represent another significant economic advantage. Corrosion-resistant surfaces maintain optimal heat transfer characteristics and fluid dynamics, resulting in 5-15% greater operational efficiency in heat exchangers and process equipment. This efficiency preservation directly impacts operational expenditures through reduced energy consumption.

Risk mitigation value must also be quantified when assessing implementation benefits. Catastrophic failures due to corrosion can result in environmental remediation costs exceeding $1 million per incident, not including potential regulatory penalties and reputational damage. Insurance premium reductions of 10-25% are often available for facilities utilizing advanced corrosion-resistant materials in critical applications.

Implementation strategies significantly impact the cost-benefit equation. Selective application of corrosion-resistant alloys to critical components rather than facility-wide implementation can optimize the economic return. Hybrid approaches, such as corrosion-resistant cladding over conventional structural materials, offer 60-70% of the protection at 30-40% of the cost of solid alloy construction.

The payback period for corrosion-resistant alloy implementation typically ranges from 2-5 years in highly corrosive environments, with internal rate of return calculations frequently exceeding 25% over the installation lifetime. This favorable economic profile has driven increasing adoption across chemical processing, offshore oil and gas, and advanced manufacturing sectors despite the higher initial investment requirements.

Initial investment in corrosion-resistant alloys typically represents a premium of 2-5 times the cost of standard carbon steel alternatives. For example, nickel-based superalloys can cost $20-50 per kilogram compared to $1-2 for carbon steel. However, this capital expenditure must be evaluated against the substantial long-term operational savings these materials enable.

Maintenance cost reduction constitutes a primary economic benefit, with corrosion-resistant installations demonstrating 60-80% lower maintenance requirements over their operational lifetime. This translates to fewer production interruptions, with studies indicating that unplanned downtime in chemical processing facilities can cost $20,000-50,000 per hour. The extended service life of corrosion-resistant components—often 3-5 times longer than conventional materials—further enhances the return on investment calculation.

Energy efficiency improvements represent another significant economic advantage. Corrosion-resistant surfaces maintain optimal heat transfer characteristics and fluid dynamics, resulting in 5-15% greater operational efficiency in heat exchangers and process equipment. This efficiency preservation directly impacts operational expenditures through reduced energy consumption.

Risk mitigation value must also be quantified when assessing implementation benefits. Catastrophic failures due to corrosion can result in environmental remediation costs exceeding $1 million per incident, not including potential regulatory penalties and reputational damage. Insurance premium reductions of 10-25% are often available for facilities utilizing advanced corrosion-resistant materials in critical applications.

Implementation strategies significantly impact the cost-benefit equation. Selective application of corrosion-resistant alloys to critical components rather than facility-wide implementation can optimize the economic return. Hybrid approaches, such as corrosion-resistant cladding over conventional structural materials, offer 60-70% of the protection at 30-40% of the cost of solid alloy construction.

The payback period for corrosion-resistant alloy implementation typically ranges from 2-5 years in highly corrosive environments, with internal rate of return calculations frequently exceeding 25% over the installation lifetime. This favorable economic profile has driven increasing adoption across chemical processing, offshore oil and gas, and advanced manufacturing sectors despite the higher initial investment requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!