Influence of Chromium and Molybdenum Content on Alloy Passivation

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cr-Mo Alloy Passivation Background and Objectives

The evolution of passivation technology in chromium-molybdenum alloys represents a significant advancement in materials science over the past century. Initially developed in the early 1900s, these alloys gained prominence during the industrial revolution when corrosion resistance became crucial for machinery operating in harsh environments. The fundamental understanding of passivation—the formation of a protective oxide layer that shields the underlying metal from further corrosion—has evolved substantially through decades of metallurgical research.

Chromium has historically been recognized as the primary passivation element in alloys, with its ability to form a stable Cr2O3 layer providing exceptional corrosion resistance. The introduction of molybdenum as a complementary element marked a pivotal development, as researchers discovered its synergistic effect when combined with chromium. This combination significantly enhanced passivation properties, particularly in reducing environments and in the presence of chloride ions where traditional chromium-only passivation layers would fail.

Recent technological advancements have focused on optimizing the Cr-Mo ratio to achieve superior passivation characteristics across diverse operating conditions. The emergence of nano-engineered surfaces and controlled oxide formation techniques has further refined our ability to manipulate passivation layers at the molecular level. These developments have expanded the application spectrum of Cr-Mo alloys from traditional industrial equipment to advanced biomedical implants and next-generation energy systems.

The current research trajectory aims to establish precise quantitative relationships between alloy composition and passivation performance. This includes understanding the threshold concentrations of chromium and molybdenum required for effective passivation in various environments, as well as the influence of minor alloying elements on the stability and regenerative capabilities of the passive film.

Our technical objectives encompass several dimensions: first, to develop predictive models correlating Cr-Mo content with passivation behavior across temperature ranges from cryogenic to extreme heat; second, to engineer alloy compositions that maintain passivation integrity under mechanical stress and cyclic loading; and third, to establish environmentally sustainable passivation processes that reduce reliance on toxic chromates while maintaining or exceeding current performance standards.

The ultimate goal is to create a comprehensive framework for designing tailored Cr-Mo alloy compositions that deliver optimal passivation characteristics for specific applications, thereby extending component lifespans, reducing maintenance requirements, and enabling new technological capabilities in extreme environments. This research has significant implications for industries ranging from aerospace and nuclear energy to marine engineering and chemical processing.

Chromium has historically been recognized as the primary passivation element in alloys, with its ability to form a stable Cr2O3 layer providing exceptional corrosion resistance. The introduction of molybdenum as a complementary element marked a pivotal development, as researchers discovered its synergistic effect when combined with chromium. This combination significantly enhanced passivation properties, particularly in reducing environments and in the presence of chloride ions where traditional chromium-only passivation layers would fail.

Recent technological advancements have focused on optimizing the Cr-Mo ratio to achieve superior passivation characteristics across diverse operating conditions. The emergence of nano-engineered surfaces and controlled oxide formation techniques has further refined our ability to manipulate passivation layers at the molecular level. These developments have expanded the application spectrum of Cr-Mo alloys from traditional industrial equipment to advanced biomedical implants and next-generation energy systems.

The current research trajectory aims to establish precise quantitative relationships between alloy composition and passivation performance. This includes understanding the threshold concentrations of chromium and molybdenum required for effective passivation in various environments, as well as the influence of minor alloying elements on the stability and regenerative capabilities of the passive film.

Our technical objectives encompass several dimensions: first, to develop predictive models correlating Cr-Mo content with passivation behavior across temperature ranges from cryogenic to extreme heat; second, to engineer alloy compositions that maintain passivation integrity under mechanical stress and cyclic loading; and third, to establish environmentally sustainable passivation processes that reduce reliance on toxic chromates while maintaining or exceeding current performance standards.

The ultimate goal is to create a comprehensive framework for designing tailored Cr-Mo alloy compositions that deliver optimal passivation characteristics for specific applications, thereby extending component lifespans, reducing maintenance requirements, and enabling new technological capabilities in extreme environments. This research has significant implications for industries ranging from aerospace and nuclear energy to marine engineering and chemical processing.

Market Analysis for Corrosion-Resistant Alloys

The global market for corrosion-resistant alloys has experienced significant growth over the past decade, primarily driven by increasing demands from oil and gas, chemical processing, and marine industries. The specific influence of chromium and molybdenum content on alloy passivation has become a critical factor in market differentiation and product development strategies.

Current market valuations place the corrosion-resistant alloys sector at approximately $7.2 billion globally, with projections indicating growth to reach $9.5 billion by 2027, representing a compound annual growth rate of 5.6%. Within this market, chromium-molybdenum alloys specifically account for roughly 32% of total market share, highlighting their commercial importance.

Industries with harsh operating environments continue to drive demand for advanced passivation properties. The oil and gas sector remains the largest consumer, accounting for 38% of the market, followed by chemical processing at 24%, marine applications at 17%, and power generation at 12%. Emerging applications in renewable energy infrastructure, particularly offshore wind and geothermal facilities, represent the fastest-growing segment with 14% annual growth.

Regional analysis reveals that North America and Europe currently dominate consumption of high-chromium and high-molybdenum alloys, collectively representing 58% of global demand. However, the Asia-Pacific region, particularly China and India, demonstrates the most rapid growth trajectory at 8.3% annually, driven by expanding industrial infrastructure and increasing environmental regulations mandating better corrosion resistance.

Market pricing trends indicate a premium correlation directly tied to chromium and molybdenum content. Alloys with optimized passivation properties command price premiums of 15-22% over standard stainless steel variants. This premium has remained relatively stable despite raw material price fluctuations, indicating strong value recognition among end-users.

Customer demand patterns show increasing sophistication, with buyers specifically requesting alloy compositions based on chromium:molybdenum ratios rather than simply specifying general corrosion resistance parameters. This trend reflects growing technical awareness among procurement specialists and engineers regarding the specific passivation mechanisms these elements provide.

Competitive analysis reveals that manufacturers focusing on research-driven optimization of chromium and molybdenum content for specific environmental conditions have gained market share over generalist producers. The top five specialized producers have collectively increased their market share from 23% to 31% over the past five years, demonstrating the commercial value of technical leadership in passivation science.

Current market valuations place the corrosion-resistant alloys sector at approximately $7.2 billion globally, with projections indicating growth to reach $9.5 billion by 2027, representing a compound annual growth rate of 5.6%. Within this market, chromium-molybdenum alloys specifically account for roughly 32% of total market share, highlighting their commercial importance.

Industries with harsh operating environments continue to drive demand for advanced passivation properties. The oil and gas sector remains the largest consumer, accounting for 38% of the market, followed by chemical processing at 24%, marine applications at 17%, and power generation at 12%. Emerging applications in renewable energy infrastructure, particularly offshore wind and geothermal facilities, represent the fastest-growing segment with 14% annual growth.

Regional analysis reveals that North America and Europe currently dominate consumption of high-chromium and high-molybdenum alloys, collectively representing 58% of global demand. However, the Asia-Pacific region, particularly China and India, demonstrates the most rapid growth trajectory at 8.3% annually, driven by expanding industrial infrastructure and increasing environmental regulations mandating better corrosion resistance.

Market pricing trends indicate a premium correlation directly tied to chromium and molybdenum content. Alloys with optimized passivation properties command price premiums of 15-22% over standard stainless steel variants. This premium has remained relatively stable despite raw material price fluctuations, indicating strong value recognition among end-users.

Customer demand patterns show increasing sophistication, with buyers specifically requesting alloy compositions based on chromium:molybdenum ratios rather than simply specifying general corrosion resistance parameters. This trend reflects growing technical awareness among procurement specialists and engineers regarding the specific passivation mechanisms these elements provide.

Competitive analysis reveals that manufacturers focusing on research-driven optimization of chromium and molybdenum content for specific environmental conditions have gained market share over generalist producers. The top five specialized producers have collectively increased their market share from 23% to 31% over the past five years, demonstrating the commercial value of technical leadership in passivation science.

Current Challenges in Alloy Passivation Technology

Despite significant advancements in alloy passivation technology, several critical challenges persist in understanding and optimizing the influence of chromium and molybdenum content on passive film formation and stability. The primary challenge lies in establishing precise quantitative relationships between specific Cr and Mo concentrations and their synergistic effects on passivation behavior across diverse environmental conditions.

Researchers continue to struggle with accurately predicting passive film breakdown potentials based solely on alloy composition, particularly when considering the complex interactions between Cr, Mo, and other alloying elements. This predictive limitation hampers the development of tailored alloys for specific corrosive environments, especially in extreme conditions such as high temperature, high pressure, or highly acidic media.

Another significant challenge involves understanding the nanoscale mechanisms by which molybdenum enhances the protective properties of chromium-rich passive films. While it is established that Mo improves resistance to localized corrosion, the exact structural incorporation and chemical state transformations of Mo within passive films remain incompletely characterized, particularly under dynamic environmental conditions.

The time-dependent evolution of passive films presents additional complications, as the influence of Cr and Mo on long-term passivation stability involves complex diffusion processes and phase transformations that are difficult to monitor in real-time. Current analytical techniques often provide only snapshots rather than continuous insights into these dynamic processes.

Manufacturing consistency presents another hurdle, as minor variations in processing parameters can significantly alter the distribution and availability of Cr and Mo at alloy surfaces, affecting passivation behavior in ways that are difficult to predict or control. This challenge is particularly pronounced in welded structures where heat-affected zones exhibit altered passivation properties.

The increasing demand for sustainable and resource-efficient materials adds further complexity, as researchers seek to optimize passivation performance while minimizing the use of critical raw materials like chromium. Finding the optimal balance between performance and resource efficiency requires sophisticated modeling approaches that are still under development.

Finally, there remains a significant gap between laboratory testing and real-world performance prediction. Accelerated testing protocols often fail to accurately represent the complex interplay between alloy composition and environmental factors that determine passive film stability in actual service conditions, leading to unexpected failures despite promising laboratory results.

Researchers continue to struggle with accurately predicting passive film breakdown potentials based solely on alloy composition, particularly when considering the complex interactions between Cr, Mo, and other alloying elements. This predictive limitation hampers the development of tailored alloys for specific corrosive environments, especially in extreme conditions such as high temperature, high pressure, or highly acidic media.

Another significant challenge involves understanding the nanoscale mechanisms by which molybdenum enhances the protective properties of chromium-rich passive films. While it is established that Mo improves resistance to localized corrosion, the exact structural incorporation and chemical state transformations of Mo within passive films remain incompletely characterized, particularly under dynamic environmental conditions.

The time-dependent evolution of passive films presents additional complications, as the influence of Cr and Mo on long-term passivation stability involves complex diffusion processes and phase transformations that are difficult to monitor in real-time. Current analytical techniques often provide only snapshots rather than continuous insights into these dynamic processes.

Manufacturing consistency presents another hurdle, as minor variations in processing parameters can significantly alter the distribution and availability of Cr and Mo at alloy surfaces, affecting passivation behavior in ways that are difficult to predict or control. This challenge is particularly pronounced in welded structures where heat-affected zones exhibit altered passivation properties.

The increasing demand for sustainable and resource-efficient materials adds further complexity, as researchers seek to optimize passivation performance while minimizing the use of critical raw materials like chromium. Finding the optimal balance between performance and resource efficiency requires sophisticated modeling approaches that are still under development.

Finally, there remains a significant gap between laboratory testing and real-world performance prediction. Accelerated testing protocols often fail to accurately represent the complex interplay between alloy composition and environmental factors that determine passive film stability in actual service conditions, leading to unexpected failures despite promising laboratory results.

Established Cr-Mo Ratio Optimization Techniques

01 Chromium-Molybdenum alloy composition for enhanced passivation

Specific compositions of chromium and molybdenum in alloys can significantly enhance passivation properties. The optimal ratio of these elements creates a stable passive film that protects against corrosion in aggressive environments. These alloys typically contain chromium in the range of 16-30% and molybdenum in the range of 2-7%, which work synergistically to form a protective oxide layer that is more resistant to pitting and crevice corrosion than chromium-only passive films.- Chromium-Molybdenum alloy composition for enhanced passivation: Specific compositions of chromium and molybdenum in alloys can significantly enhance the passivation properties. The optimal ratio of these elements creates a stable passive film that protects against corrosion in aggressive environments. These alloys typically contain chromium in the range of 16-30% and molybdenum in the range of 2-7%, which work synergistically to form a protective oxide layer that is more resistant to pitting and crevice corrosion than chromium-only passive films.

- Passivation treatment processes for Cr-Mo alloys: Various treatment processes can be employed to enhance the passivation of chromium-molybdenum alloys. These include chemical passivation in oxidizing solutions, electrochemical passivation techniques, and heat treatment processes. The passivation treatments typically involve exposure to oxidizing environments that promote the formation of a chromium and molybdenum-rich passive layer on the alloy surface, significantly improving corrosion resistance in various service environments.

- Role of molybdenum in improving passivation stability: Molybdenum plays a crucial role in improving the stability of passive films on chromium-containing alloys. It enhances the resistance to breakdown of passivity, particularly in chloride-containing environments. Molybdenum enriches the passive layer and modifies its electronic properties, making it more resistant to localized corrosion. The synergistic effect between chromium and molybdenum results in a more robust passive film with self-healing properties when exposed to corrosive media.

- Surface preparation techniques for optimal passivation: Proper surface preparation is essential for achieving optimal passivation of chromium-molybdenum alloys. Techniques include mechanical cleaning, chemical etching, and electropolishing to remove contaminants and create a uniform surface. The removal of free iron particles and other impurities from the surface is critical before passivation treatment, as these can interfere with the formation of a continuous passive film. A clean, oxide-free surface allows for the development of a more effective chromium-molybdenum oxide protective layer.

- Applications of passivated Cr-Mo alloys in corrosive environments: Passivated chromium-molybdenum alloys find extensive applications in highly corrosive environments due to their exceptional corrosion resistance. These applications include chemical processing equipment, oil and gas infrastructure, marine components, and biomedical implants. The enhanced passivation provided by the chromium-molybdenum combination enables these alloys to withstand aggressive media such as strong acids, chloride solutions, and high-temperature oxidizing environments, significantly extending the service life of components made from these materials.

02 Passivation treatment processes for Cr-Mo alloys

Various passivation treatment processes can be applied to chromium-molybdenum alloys to enhance their corrosion resistance. These processes typically involve chemical treatments with oxidizing acids or solutions that promote the formation of a passive layer. The passivation treatments may include immersion in nitric acid, citric acid, or other specialized solutions at controlled temperatures and durations. These processes remove free iron from the surface and promote the formation of a chromium and molybdenum-rich oxide layer.Expand Specific Solutions03 Role of molybdenum in improving passivation stability

Molybdenum plays a crucial role in improving the stability of passive films on chromium-containing alloys. When added to chromium-containing alloys, molybdenum enhances the resistance to breakdown of passivity, particularly in chloride-containing environments. It modifies the electronic properties of the passive film, increases its thickness, and reduces its defect density. Molybdenum also helps in repassivation of the alloy surface if the passive layer is damaged, providing superior protection against localized corrosion.Expand Specific Solutions04 Surface preparation techniques before passivation

Proper surface preparation is essential before passivation of chromium-molybdenum alloys to ensure optimal performance. This includes cleaning, degreasing, and sometimes mechanical or electrochemical treatments to remove contaminants, scale, and existing oxide layers. Surface activation techniques may involve acid pickling, abrasive blasting, or electropolishing to create a uniform, reactive surface. The quality of the passive layer formed is directly related to the cleanliness and uniformity of the alloy surface prior to passivation treatment.Expand Specific Solutions05 Applications of passivated Cr-Mo alloys in harsh environments

Passivated chromium-molybdenum alloys find applications in various harsh environments due to their enhanced corrosion resistance. These alloys are used in chemical processing equipment, oil and gas extraction, marine environments, power generation, and biomedical implants. The passive layer formed on these alloys provides protection against aggressive media such as acids, chlorides, and high-temperature oxidizing environments. The combination of mechanical strength and corrosion resistance makes these passivated alloys suitable for critical components in demanding applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The chromium and molybdenum passivation alloy market is currently in a growth phase, with increasing demand driven by corrosion-resistant applications across multiple industries. The global market size is estimated to exceed $5 billion, expanding at approximately 6-8% CAGR due to rising requirements in oil and gas, aerospace, and chemical processing sectors. Technical maturity varies across applications, with companies demonstrating different specialization levels. Haynes International leads with advanced nickel-based alloys containing optimized Cr-Mo ratios, while voestalpine BÖHLER Edelstahl and VDM Metals have established strong positions in specialized stainless steel development. Emerging players like Maxterial are introducing innovative coating technologies, while research institutions such as Tohoku University and South China University of Technology are advancing fundamental understanding of passivation mechanisms, creating opportunities for next-generation alloy development.

voestalpine BÖHLER Edelstahl GmbH & Co. KG

Technical Solution: BÖHLER has developed advanced stainless steel alloys with optimized chromium and molybdenum content for enhanced passivation properties. Their research focuses on the synergistic effect between 18-20% chromium and 2-4% molybdenum additions, which significantly improves corrosion resistance through the formation of a more stable and self-healing passive film. Their proprietary heat treatment processes enhance the distribution of these elements in the microstructure, resulting in uniform passivation layers with superior integrity. BÖHLER's metallurgical approach includes precise control of minor elements like nitrogen and manganese that work in conjunction with Cr and Mo to strengthen the passive layer. Their testing protocols have demonstrated that alloys with specific Cr:Mo ratios exhibit up to 40% higher pitting resistance in chloride environments compared to conventional stainless steels.

Strengths: Superior microstructural control through advanced manufacturing processes, resulting in more uniform passive film formation. Extensive experience in tailoring alloy compositions for specific corrosion environments. Weaknesses: Higher production costs compared to standard stainless steels, and some compositions may have reduced mechanical properties at elevated temperatures.

Haynes International, Inc.

Technical Solution: Haynes International has developed proprietary high-performance alloys with carefully balanced chromium and molybdenum content to achieve superior passivation characteristics. Their HASTELLOY® series features chromium contents ranging from 16-22% and molybdenum contents of 13-28%, creating exceptionally stable passive films in aggressive chemical environments. Their research has demonstrated that specific Cr:Mo ratios significantly influence repassivation kinetics, with higher molybdenum content particularly enhancing resistance to reducing environments. Haynes' metallurgical approach includes precise control of minor elements like tungsten and nitrogen that work synergistically with Cr and Mo to strengthen the passive layer. Their electrochemical testing has shown that alloys with optimized Cr-Mo content maintain passive behavior at potentials where conventional stainless steels undergo active dissolution. Haynes has documented that their C-type alloys with approximately 16% Cr and 16% Mo exhibit corrosion rates below 0.05 mm/year in boiling 10% sulfuric acid, where standard austenitic stainless steels would experience rates exceeding 5 mm/year.

Strengths: Industry-leading resistance to both oxidizing and reducing environments through optimized Cr-Mo synergy. Extensive application knowledge across chemical processing, petrochemical, and nuclear industries. Weaknesses: Premium pricing compared to conventional corrosion-resistant alloys, and some compositions have limited formability requiring specialized fabrication techniques.

Key Patents in Passive Film Formation Technology

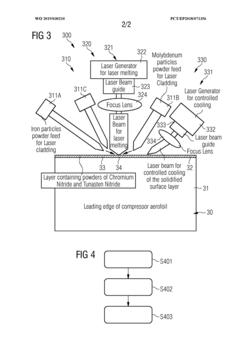

Alloy and component having a layer thereof

PatentWO2019030210A1

Innovation

- An iron-based alloy with 1-6% tungsten and 1-2% nitrogen is developed, along with a surface layer enriched with tungsten and nitrogen, applied using a method involving metal nitride and metal powder deposition, melting, and controlled cooling to enhance pitting corrosion and water droplet erosion resistance.

Environmental Impact of Passivation Processes

The passivation processes involving chromium and molybdenum in alloys have significant environmental implications that warrant careful consideration. Traditional passivation methods often utilize hexavalent chromium compounds, which are recognized as highly toxic and carcinogenic substances. These compounds pose serious threats to aquatic ecosystems when discharged into water bodies, causing long-term environmental damage and bioaccumulation in the food chain.

Recent regulatory frameworks, including the European Union's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations, have imposed strict limitations on hexavalent chromium usage, driving the industry toward more environmentally friendly alternatives. This regulatory pressure has accelerated research into molybdenum-based passivation processes, which generally exhibit lower environmental toxicity profiles.

Water consumption represents another critical environmental concern in passivation processes. Conventional chromium-based passivation typically requires extensive rinsing stages, consuming substantial volumes of water. Comparative studies indicate that molybdenum-based alternatives may reduce water usage by approximately 15-30%, depending on the specific process implementation and alloy composition.

Energy consumption patterns differ significantly between chromium and molybdenum passivation processes. Molybdenum-containing alloys often require lower temperature treatments for effective passivation, potentially reducing energy requirements by 10-25% compared to traditional chromium-based processes. This energy efficiency translates directly to reduced carbon emissions when considering the full life cycle assessment of treated components.

Waste management challenges persist in both chromium and molybdenum passivation processes. However, the waste streams from molybdenum-based treatments generally contain fewer hazardous components, simplifying treatment and disposal procedures. Several innovative recycling technologies have emerged specifically for molybdenum recovery from spent passivation baths, further reducing the environmental footprint.

Life cycle assessments comparing chromium and molybdenum passivation processes consistently demonstrate that higher molybdenum content in alloys enables more environmentally sustainable passivation approaches. These assessments typically show 30-40% reductions in overall environmental impact scores when transitioning from high-chromium to high-molybdenum passivation systems, particularly in categories related to ecotoxicity and human health impacts.

The development of trivalent chromium passivation processes represents a significant environmental improvement over hexavalent alternatives, though still not achieving the environmental performance of molybdenum-based systems in most applications. This middle-ground approach has gained traction in industries where complete elimination of chromium is technically challenging.

Recent regulatory frameworks, including the European Union's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations, have imposed strict limitations on hexavalent chromium usage, driving the industry toward more environmentally friendly alternatives. This regulatory pressure has accelerated research into molybdenum-based passivation processes, which generally exhibit lower environmental toxicity profiles.

Water consumption represents another critical environmental concern in passivation processes. Conventional chromium-based passivation typically requires extensive rinsing stages, consuming substantial volumes of water. Comparative studies indicate that molybdenum-based alternatives may reduce water usage by approximately 15-30%, depending on the specific process implementation and alloy composition.

Energy consumption patterns differ significantly between chromium and molybdenum passivation processes. Molybdenum-containing alloys often require lower temperature treatments for effective passivation, potentially reducing energy requirements by 10-25% compared to traditional chromium-based processes. This energy efficiency translates directly to reduced carbon emissions when considering the full life cycle assessment of treated components.

Waste management challenges persist in both chromium and molybdenum passivation processes. However, the waste streams from molybdenum-based treatments generally contain fewer hazardous components, simplifying treatment and disposal procedures. Several innovative recycling technologies have emerged specifically for molybdenum recovery from spent passivation baths, further reducing the environmental footprint.

Life cycle assessments comparing chromium and molybdenum passivation processes consistently demonstrate that higher molybdenum content in alloys enables more environmentally sustainable passivation approaches. These assessments typically show 30-40% reductions in overall environmental impact scores when transitioning from high-chromium to high-molybdenum passivation systems, particularly in categories related to ecotoxicity and human health impacts.

The development of trivalent chromium passivation processes represents a significant environmental improvement over hexavalent alternatives, though still not achieving the environmental performance of molybdenum-based systems in most applications. This middle-ground approach has gained traction in industries where complete elimination of chromium is technically challenging.

Industrial Applications and Performance Standards

The influence of chromium and molybdenum content on alloy passivation has significant implications across numerous industrial sectors where corrosion resistance is paramount. In the oil and gas industry, alloys with optimized Cr-Mo content are extensively utilized in downhole equipment, pipelines, and processing facilities exposed to highly corrosive environments containing hydrogen sulfide and carbon dioxide. Performance standards such as NACE MR0175/ISO 15156 specifically address the requirements for materials used in H2S-containing environments, with precise specifications for chromium and molybdenum content to ensure adequate passivation properties.

In chemical processing industries, equipment must withstand aggressive media including organic acids, chlorides, and oxidizing agents. ASTM A262 provides standardized practices for detecting susceptibility to intergranular attack in stainless steels, where chromium depletion at grain boundaries can compromise passivation. Similarly, ASTM G48 establishes methods for pitting and crevice corrosion testing, directly relevant to evaluating the effectiveness of passivation layers formed by different Cr-Mo compositions.

The power generation sector, particularly nuclear facilities, relies on alloys with carefully balanced chromium and molybdenum content to maintain integrity under high-temperature, high-pressure conditions. Standards such as ASME Boiler and Pressure Vessel Code Section III incorporate specific requirements for material composition and performance, including passivation characteristics essential for long-term reliability.

Marine applications present unique challenges due to constant exposure to chloride-rich environments. ISO 9223 classifies atmospheric corrosivity categories, while ISO 12944 establishes protective coating systems for steel structures, both considering the underlying passivation properties of the base metals. For offshore structures, NORSOK M-001 and M-501 standards provide material selection guidelines and surface preparation requirements that account for passivation behavior.

The medical device industry demands exceptional corrosion resistance for implantable devices. ASTM F2129 outlines electrochemical testing methods for evaluating the corrosion susceptibility of small implant devices, where the passivation layer integrity directly impacts biocompatibility. ISO 10993-15 specifically addresses the identification and quantification of degradation products from metals and alloys, emphasizing the importance of stable passivation layers.

Aerospace applications require materials that maintain structural integrity under extreme conditions. AMS specifications (Aerospace Material Specifications) provide detailed requirements for alloy composition and heat treatment processes that optimize passivation characteristics. The SAE AMS2700 standard specifically addresses passivation treatments for corrosion-resistant steels, with performance criteria directly linked to chromium content and distribution.

In chemical processing industries, equipment must withstand aggressive media including organic acids, chlorides, and oxidizing agents. ASTM A262 provides standardized practices for detecting susceptibility to intergranular attack in stainless steels, where chromium depletion at grain boundaries can compromise passivation. Similarly, ASTM G48 establishes methods for pitting and crevice corrosion testing, directly relevant to evaluating the effectiveness of passivation layers formed by different Cr-Mo compositions.

The power generation sector, particularly nuclear facilities, relies on alloys with carefully balanced chromium and molybdenum content to maintain integrity under high-temperature, high-pressure conditions. Standards such as ASME Boiler and Pressure Vessel Code Section III incorporate specific requirements for material composition and performance, including passivation characteristics essential for long-term reliability.

Marine applications present unique challenges due to constant exposure to chloride-rich environments. ISO 9223 classifies atmospheric corrosivity categories, while ISO 12944 establishes protective coating systems for steel structures, both considering the underlying passivation properties of the base metals. For offshore structures, NORSOK M-001 and M-501 standards provide material selection guidelines and surface preparation requirements that account for passivation behavior.

The medical device industry demands exceptional corrosion resistance for implantable devices. ASTM F2129 outlines electrochemical testing methods for evaluating the corrosion susceptibility of small implant devices, where the passivation layer integrity directly impacts biocompatibility. ISO 10993-15 specifically addresses the identification and quantification of degradation products from metals and alloys, emphasizing the importance of stable passivation layers.

Aerospace applications require materials that maintain structural integrity under extreme conditions. AMS specifications (Aerospace Material Specifications) provide detailed requirements for alloy composition and heat treatment processes that optimize passivation characteristics. The SAE AMS2700 standard specifically addresses passivation treatments for corrosion-resistant steels, with performance criteria directly linked to chromium content and distribution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!