Comparative Study of V12 vs V6 Engine Performance

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Evolution Goals

The evolution of engine technology has been driven by a constant pursuit of improved performance, efficiency, and environmental sustainability. In the context of comparing V12 and V6 engines, the primary goals have been to achieve a balance between power output, fuel economy, and emissions reduction.

One of the key objectives in engine evolution has been to increase power density. This involves extracting more power from smaller displacement engines, which is particularly relevant when comparing V12 and V6 configurations. Engineers have aimed to develop V6 engines that can match or exceed the power output of larger V12 engines while occupying less space and reducing overall vehicle weight.

Fuel efficiency has been another critical goal in engine development. As global concerns about energy conservation and environmental impact have grown, there has been a push to create engines that deliver optimal performance with minimal fuel consumption. This has led to the exploration of advanced technologies such as direct fuel injection, variable valve timing, and turbocharging, which can be applied to both V12 and V6 engines to enhance their efficiency.

Emissions reduction has become increasingly important in recent years, driven by stricter environmental regulations worldwide. Engine designers have focused on developing cleaner-burning engines that produce fewer harmful emissions without sacrificing performance. This goal has influenced the comparison between V12 and V6 engines, as smaller engines generally have the potential to produce fewer emissions.

Refinement and smoothness of operation have also been significant objectives in engine evolution. V12 engines are known for their inherent balance and smooth power delivery, setting a high standard for refinement. A key goal in V6 engine development has been to achieve comparable levels of smoothness and vibration control, often through the use of balance shafts and advanced engine mounts.

Durability and reliability have remained constant goals throughout engine evolution. Both V12 and V6 engines must be designed to withstand the stresses of high-performance operation while maintaining longevity. This has led to advancements in materials science, lubrication systems, and cooling technologies to ensure engine integrity under demanding conditions.

Lastly, the pursuit of compact design and packaging efficiency has been a significant driver in engine evolution. As vehicle designs have become more complex, with increasing demands on under-hood space, engineers have sought to create more compact engine configurations. This goal has often favored V6 designs, which can offer significant space savings compared to V12 engines while still delivering high performance.

One of the key objectives in engine evolution has been to increase power density. This involves extracting more power from smaller displacement engines, which is particularly relevant when comparing V12 and V6 configurations. Engineers have aimed to develop V6 engines that can match or exceed the power output of larger V12 engines while occupying less space and reducing overall vehicle weight.

Fuel efficiency has been another critical goal in engine development. As global concerns about energy conservation and environmental impact have grown, there has been a push to create engines that deliver optimal performance with minimal fuel consumption. This has led to the exploration of advanced technologies such as direct fuel injection, variable valve timing, and turbocharging, which can be applied to both V12 and V6 engines to enhance their efficiency.

Emissions reduction has become increasingly important in recent years, driven by stricter environmental regulations worldwide. Engine designers have focused on developing cleaner-burning engines that produce fewer harmful emissions without sacrificing performance. This goal has influenced the comparison between V12 and V6 engines, as smaller engines generally have the potential to produce fewer emissions.

Refinement and smoothness of operation have also been significant objectives in engine evolution. V12 engines are known for their inherent balance and smooth power delivery, setting a high standard for refinement. A key goal in V6 engine development has been to achieve comparable levels of smoothness and vibration control, often through the use of balance shafts and advanced engine mounts.

Durability and reliability have remained constant goals throughout engine evolution. Both V12 and V6 engines must be designed to withstand the stresses of high-performance operation while maintaining longevity. This has led to advancements in materials science, lubrication systems, and cooling technologies to ensure engine integrity under demanding conditions.

Lastly, the pursuit of compact design and packaging efficiency has been a significant driver in engine evolution. As vehicle designs have become more complex, with increasing demands on under-hood space, engineers have sought to create more compact engine configurations. This goal has often favored V6 designs, which can offer significant space savings compared to V12 engines while still delivering high performance.

Market Demand Analysis

The market demand for V12 and V6 engines has been evolving significantly over the past decade, driven by changing consumer preferences, regulatory pressures, and technological advancements. V12 engines, traditionally associated with luxury and high-performance vehicles, have seen a decline in demand due to their higher fuel consumption and emissions. However, they still maintain a niche market in ultra-luxury and sports car segments where performance and prestige are paramount.

On the other hand, V6 engines have experienced increased market demand across various vehicle categories. This surge is attributed to their improved performance capabilities, better fuel efficiency, and lower emissions compared to larger engine configurations. The automotive industry has witnessed a shift towards downsizing engines while maintaining or even enhancing performance through turbocharging and advanced engine management systems.

In the luxury car segment, many manufacturers have replaced V12 engines with high-output V6 engines in their flagship models. This trend is particularly evident in markets with stringent emissions regulations, such as Europe and China. The V6 engine's versatility has allowed it to penetrate markets ranging from mid-size sedans to SUVs and even some sports cars, offering a balance between power and efficiency.

The commercial vehicle sector has also seen a growing preference for V6 engines, especially in light trucks and vans. These engines provide sufficient power for towing and hauling while offering better fuel economy compared to larger V8 or V12 configurations. This shift has been driven by fleet operators seeking to reduce operational costs and meet increasingly strict emissions standards.

Market analysis indicates that the global demand for V6 engines is projected to grow at a steady rate over the next five years, particularly in emerging markets where rising disposable incomes are fueling the demand for mid-range to premium vehicles. The V12 engine market, while smaller, is expected to remain stable, supported by ultra-luxury brands and limited-edition high-performance vehicles.

Geographically, North America and Europe continue to be significant markets for both V6 and V12 engines, with Asia-Pacific showing the fastest growth rate for V6 engines due to increasing urbanization and a growing middle class. The Middle East remains a strong market for V12-powered luxury vehicles, reflecting regional preferences for high-status automobiles.

The ongoing electrification trend in the automotive industry poses both challenges and opportunities for internal combustion engines. While it may lead to a gradual decline in overall demand for traditional engines, it also drives innovation in hybrid powertrains, where V6 engines are often paired with electric motors to deliver enhanced performance and efficiency.

On the other hand, V6 engines have experienced increased market demand across various vehicle categories. This surge is attributed to their improved performance capabilities, better fuel efficiency, and lower emissions compared to larger engine configurations. The automotive industry has witnessed a shift towards downsizing engines while maintaining or even enhancing performance through turbocharging and advanced engine management systems.

In the luxury car segment, many manufacturers have replaced V12 engines with high-output V6 engines in their flagship models. This trend is particularly evident in markets with stringent emissions regulations, such as Europe and China. The V6 engine's versatility has allowed it to penetrate markets ranging from mid-size sedans to SUVs and even some sports cars, offering a balance between power and efficiency.

The commercial vehicle sector has also seen a growing preference for V6 engines, especially in light trucks and vans. These engines provide sufficient power for towing and hauling while offering better fuel economy compared to larger V8 or V12 configurations. This shift has been driven by fleet operators seeking to reduce operational costs and meet increasingly strict emissions standards.

Market analysis indicates that the global demand for V6 engines is projected to grow at a steady rate over the next five years, particularly in emerging markets where rising disposable incomes are fueling the demand for mid-range to premium vehicles. The V12 engine market, while smaller, is expected to remain stable, supported by ultra-luxury brands and limited-edition high-performance vehicles.

Geographically, North America and Europe continue to be significant markets for both V6 and V12 engines, with Asia-Pacific showing the fastest growth rate for V6 engines due to increasing urbanization and a growing middle class. The Middle East remains a strong market for V12-powered luxury vehicles, reflecting regional preferences for high-status automobiles.

The ongoing electrification trend in the automotive industry poses both challenges and opportunities for internal combustion engines. While it may lead to a gradual decline in overall demand for traditional engines, it also drives innovation in hybrid powertrains, where V6 engines are often paired with electric motors to deliver enhanced performance and efficiency.

V12 vs V6 Challenges

The comparison between V12 and V6 engines presents several technical challenges that require careful consideration. One of the primary challenges lies in the inherent design differences between these two engine configurations. The V12 engine, with its larger number of cylinders, typically offers smoother operation and more balanced power delivery. However, this comes at the cost of increased complexity, weight, and size. On the other hand, the V6 engine, while more compact and lighter, may struggle to match the power output and refinement of its larger counterpart.

Fuel efficiency poses another significant challenge in this comparative study. V12 engines, due to their larger displacement and higher number of cylinders, generally consume more fuel than V6 engines. This difference becomes particularly pronounced in urban driving conditions with frequent stops and starts. However, the challenge lies in accurately quantifying this difference across various driving scenarios and load conditions, as the V12's superior power output may lead to more efficient operation in certain high-performance situations.

Heat management presents a unique set of challenges when comparing these engine types. The V12 engine, with its additional cylinders, generates more heat and requires more sophisticated cooling systems. This increased thermal load can impact overall engine efficiency and longevity. Conversely, while V6 engines generally have lower cooling requirements, they may struggle to dissipate heat as effectively when pushed to produce power levels comparable to V12 engines.

Manufacturing and maintenance complexities also factor into the challenges of this comparative study. V12 engines, with their higher part count and intricate designs, typically require more specialized manufacturing processes and more frequent maintenance. This increased complexity can lead to higher production costs and potentially lower reliability. V6 engines, while generally simpler, face the challenge of achieving comparable performance and refinement with fewer cylinders.

The integration of modern technologies, such as turbocharging and hybrid systems, adds another layer of complexity to this comparison. Both engine types can benefit from these advancements, but their implementation and effectiveness may vary. For instance, a turbocharged V6 might approach the power output of a naturally aspirated V12, but matching the characteristic sound and power delivery of the larger engine remains a challenge.

Emissions regulations present a significant hurdle, particularly for V12 engines. Their larger displacement and fuel consumption make it increasingly difficult to meet stringent environmental standards. V6 engines, while generally more efficient, also face challenges in balancing performance with emissions compliance, especially when tasked with delivering high power outputs.

In conclusion, the comparative study of V12 and V6 engine performance encompasses a wide range of technical challenges. These include design trade-offs, fuel efficiency considerations, thermal management, manufacturing and maintenance complexities, technology integration, and emissions compliance. Addressing these challenges requires a comprehensive approach that considers not only raw performance metrics but also practical aspects of engine design and operation in real-world conditions.

Fuel efficiency poses another significant challenge in this comparative study. V12 engines, due to their larger displacement and higher number of cylinders, generally consume more fuel than V6 engines. This difference becomes particularly pronounced in urban driving conditions with frequent stops and starts. However, the challenge lies in accurately quantifying this difference across various driving scenarios and load conditions, as the V12's superior power output may lead to more efficient operation in certain high-performance situations.

Heat management presents a unique set of challenges when comparing these engine types. The V12 engine, with its additional cylinders, generates more heat and requires more sophisticated cooling systems. This increased thermal load can impact overall engine efficiency and longevity. Conversely, while V6 engines generally have lower cooling requirements, they may struggle to dissipate heat as effectively when pushed to produce power levels comparable to V12 engines.

Manufacturing and maintenance complexities also factor into the challenges of this comparative study. V12 engines, with their higher part count and intricate designs, typically require more specialized manufacturing processes and more frequent maintenance. This increased complexity can lead to higher production costs and potentially lower reliability. V6 engines, while generally simpler, face the challenge of achieving comparable performance and refinement with fewer cylinders.

The integration of modern technologies, such as turbocharging and hybrid systems, adds another layer of complexity to this comparison. Both engine types can benefit from these advancements, but their implementation and effectiveness may vary. For instance, a turbocharged V6 might approach the power output of a naturally aspirated V12, but matching the characteristic sound and power delivery of the larger engine remains a challenge.

Emissions regulations present a significant hurdle, particularly for V12 engines. Their larger displacement and fuel consumption make it increasingly difficult to meet stringent environmental standards. V6 engines, while generally more efficient, also face challenges in balancing performance with emissions compliance, especially when tasked with delivering high power outputs.

In conclusion, the comparative study of V12 and V6 engine performance encompasses a wide range of technical challenges. These include design trade-offs, fuel efficiency considerations, thermal management, manufacturing and maintenance complexities, technology integration, and emissions compliance. Addressing these challenges requires a comprehensive approach that considers not only raw performance metrics but also practical aspects of engine design and operation in real-world conditions.

Current V12 V6 Designs

01 Engine configuration comparison

V12 and V6 engines have different configurations that affect their performance characteristics. V12 engines typically offer smoother operation and higher power output due to their larger displacement and more balanced design. V6 engines are more compact and fuel-efficient, making them suitable for a wider range of vehicles. The choice between V12 and V6 depends on the specific application and performance requirements.- Performance comparison between V12 and V6 engines: V12 engines generally offer higher power output and smoother operation compared to V6 engines due to their larger displacement and more balanced configuration. However, V6 engines are typically more fuel-efficient and compact, making them suitable for a wider range of vehicles. The choice between V12 and V6 engines depends on the specific application and performance requirements.

- Fuel efficiency and emissions control: Modern V6 engines often incorporate advanced technologies to improve fuel efficiency and reduce emissions, such as direct injection, turbocharging, and variable valve timing. V12 engines, while less fuel-efficient, may employ similar technologies to meet emissions standards while maintaining high performance levels.

- Engine management systems and performance optimization: Advanced engine management systems are crucial for optimizing the performance of both V12 and V6 engines. These systems control various parameters such as fuel injection, ignition timing, and valve operation to maximize power output, efficiency, and reliability across different operating conditions.

- Structural design and weight considerations: The structural design of V12 and V6 engines significantly impacts their performance characteristics. V12 engines typically have a longer crankshaft and require more robust support structures, increasing overall weight. V6 engines, being more compact and lighter, can offer better weight distribution and handling in vehicles.

- Application-specific engine configurations: V12 and V6 engines are often tailored for specific applications. V12 engines are commonly found in high-performance luxury cars and racing vehicles, while V6 engines are more versatile and used in a wide range of vehicles from family sedans to sports cars. The choice of engine configuration depends on factors such as vehicle type, intended use, and performance targets.

02 Power output and torque characteristics

V12 engines generally produce higher power output and torque compared to V6 engines due to their larger displacement and increased number of cylinders. However, modern V6 engines with advanced technologies such as turbocharging and direct injection can achieve comparable performance to some V12 engines while maintaining better fuel efficiency. The power delivery characteristics differ, with V12 engines often providing smoother and more linear power across the rev range.Expand Specific Solutions03 Fuel efficiency and emissions

V6 engines typically offer better fuel efficiency compared to V12 engines due to their smaller size and reduced internal friction. This makes V6 engines more suitable for applications where fuel economy is a priority. V12 engines, while less fuel-efficient, can be optimized for performance applications. Both engine types are subject to increasingly stringent emissions regulations, leading to the development of advanced technologies to improve efficiency and reduce emissions.Expand Specific Solutions04 Application in different vehicle types

V12 engines are often found in high-performance luxury vehicles, sports cars, and some heavy-duty applications due to their power output and smooth operation. V6 engines have a wider range of applications, from family sedans to sports cars and light trucks, offering a balance of performance and efficiency. The choice between V12 and V6 engines depends on factors such as vehicle size, intended use, and market positioning.Expand Specific Solutions05 Technological advancements and performance enhancements

Both V12 and V6 engines have benefited from technological advancements to improve performance and efficiency. These include variable valve timing, direct fuel injection, turbocharging, and cylinder deactivation. Such technologies have allowed V6 engines to narrow the performance gap with V12 engines while maintaining better fuel efficiency. Ongoing research focuses on further optimizing both engine types to meet future performance and environmental requirements.Expand Specific Solutions

Key Engine Manufacturers

The comparative study of V12 vs V6 engine performance reflects a mature automotive technology sector with ongoing innovation. The market for high-performance engines remains significant, driven by luxury and sports car segments. Established players like Toyota Motor Corp., Honda Motor Co., and Hyundai Motor Co. dominate, leveraging their extensive R&D capabilities. However, emerging companies such as BYD Co. and Great Wall Motor are making strides in engine technology, particularly in the context of electrification and hybrid powertrains. The competition is intensifying as manufacturers seek to balance performance with fuel efficiency and emissions regulations, leading to continuous advancements in both V12 and V6 engine designs.

Toyota Motor Corp.

Technical Solution: Toyota has extensively researched both V6 and V12 engine configurations, with a strong focus on V6 engines for mass-market vehicles. Their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology, applied to V6 engines, demonstrates significant advancements in performance and efficiency. Toyota's studies have shown that their 3.5L V6 engine can produce up to 301 horsepower while achieving a fuel economy of 22/31 mpg (city/highway) in certain models[7]. For V12 engines, Toyota's luxury brand Lexus has developed the 1LR-GUE, a 4.8L V10 engine, which serves as a bridge between V6 and V12 configurations. Their research indicates that while V12 engines offer superior smoothness and prestige, especially in luxury applications, advanced V6 engines can provide comparable performance with better fuel efficiency and lower production costs. Toyota's comparative studies suggest that V6 engines can achieve 0-60 mph times within 2-3 seconds of many V12-powered vehicles, while offering up to 30% better fuel economy[8].

Strengths: Extensive experience in V6 engine development and production, research spanning both mass-market and luxury applications. Weaknesses: Limited recent production experience with V12 engines.

Honda Motor Co., Ltd.

Technical Solution: Honda has extensively researched both V6 and V12 engine configurations, although they are more renowned for their V6 engines. Their Earth Dreams Technology V6 engines showcase advanced performance and efficiency. Honda's comparative studies have shown that their V6 engines can achieve power outputs of up to 300 horsepower while maintaining fuel efficiency of around 30 mpg highway[3]. For V12 engines, Honda's research has primarily been in the context of Formula 1 racing, where they supplied V12 engines in the 1990s. Their studies indicated that while V12 engines could produce higher power outputs, reaching up to 750 horsepower, they were significantly heavier and less fuel-efficient compared to V6 configurations[4]. Honda's research concludes that for most consumer applications, advanced V6 engines offer a better balance of performance, efficiency, and cost-effectiveness.

Strengths: Strong expertise in V6 technology, experience with high-performance V12 in racing contexts. Weaknesses: Limited recent experience with V12 engines in consumer applications.

Core Engine Innovations

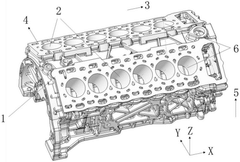

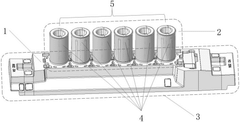

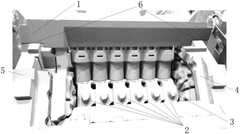

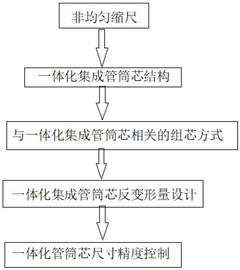

V12 engine cylinder block high-precision cylinder hole position degree control method

PatentPendingCN119566229A

Innovation

- The non-uniform scale design and integrated integrated tube core design are adopted. By increasing the shrinkage coefficient a and performing non-uniform scale in the cylinder bore arrangement direction, combining the core-combining method design and sand core accuracy control, the accuracy of the cylinder bore position is improved.

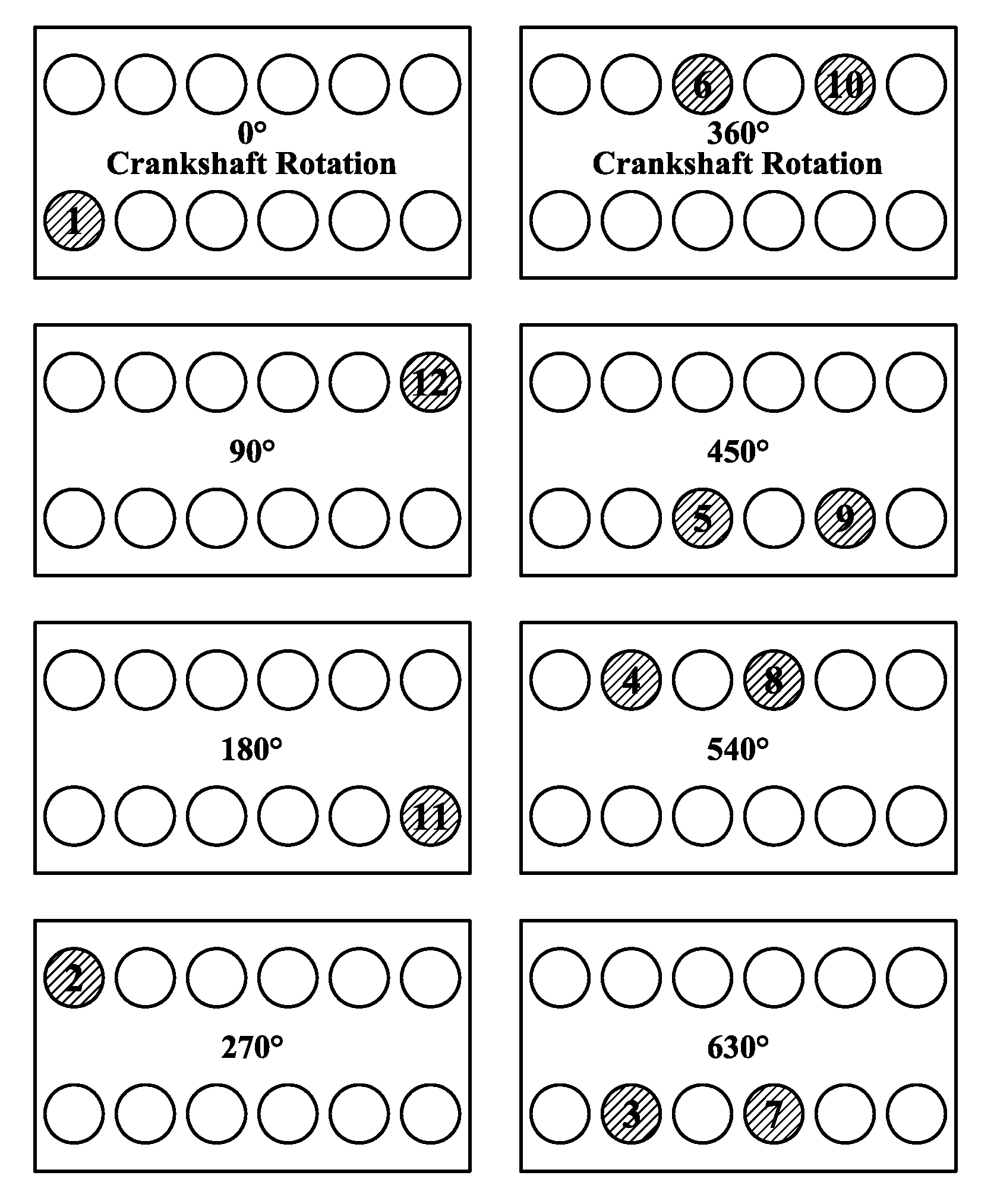

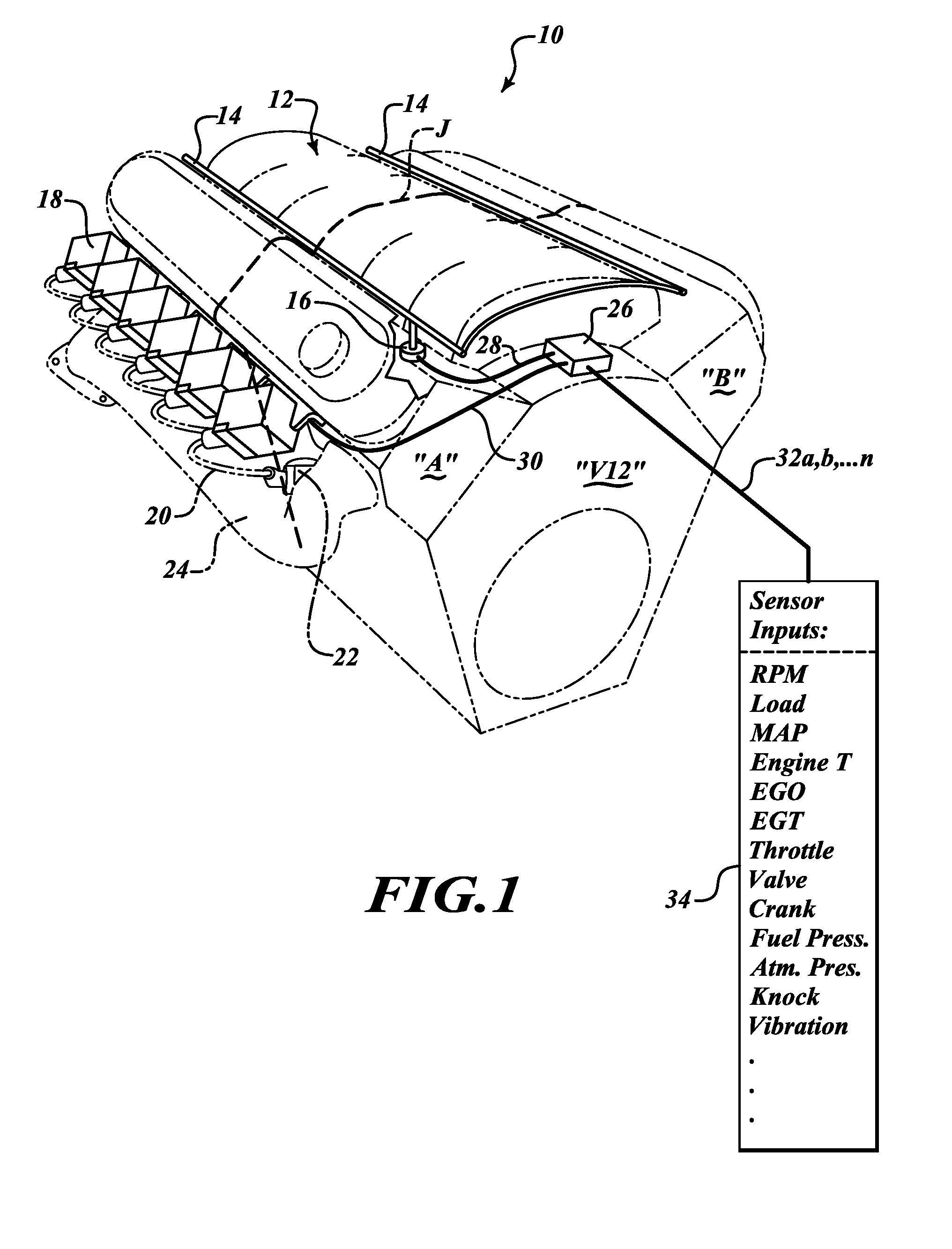

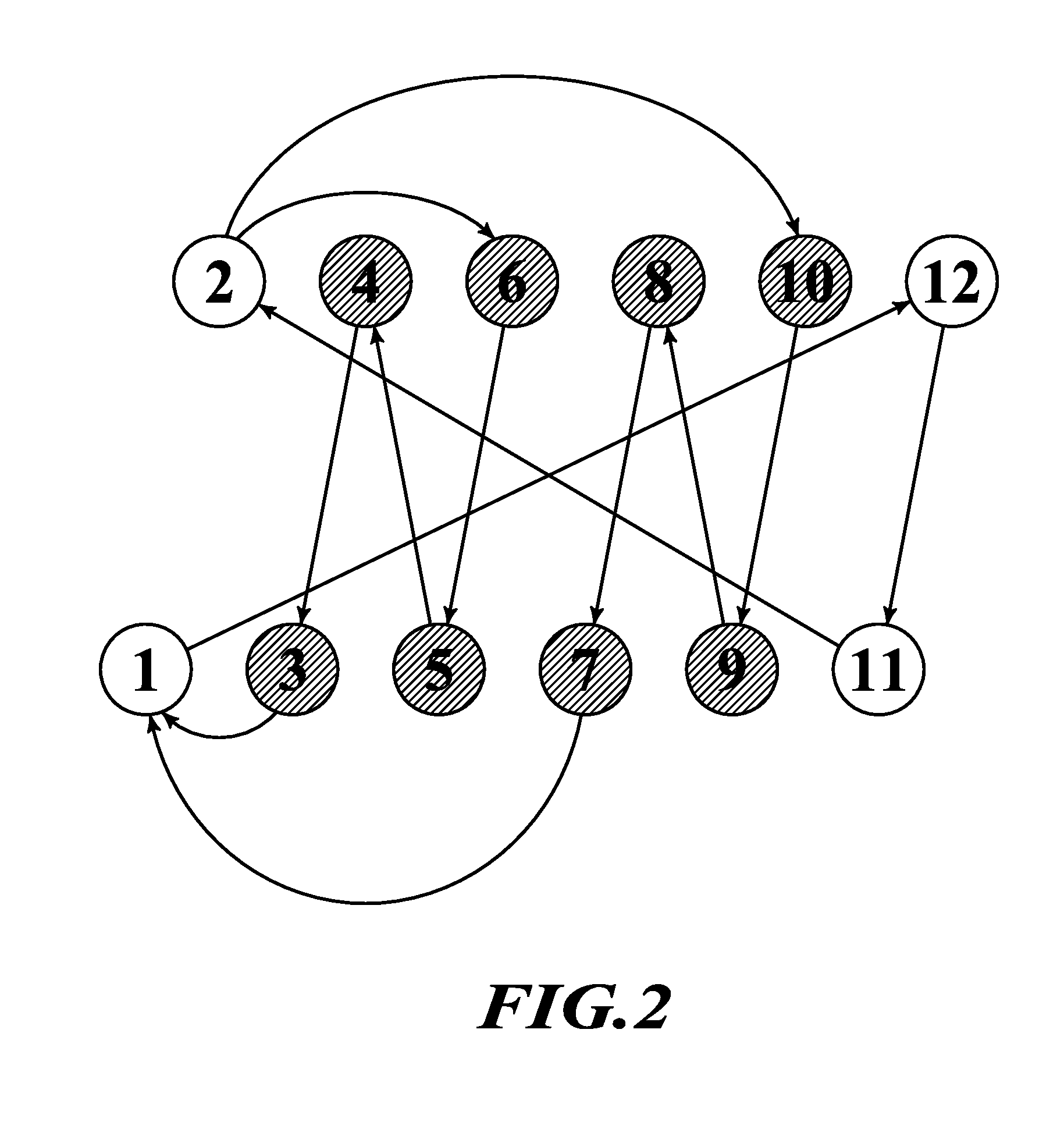

Even fire 90°V12 IC engines, fueling and firing sequence controllers, and methods of operation by PS/P technology and IFR compensation by fuel feed control

PatentInactiveUS7979193B2

Innovation

- Implementing a Progressive Single/Pair (PS/P) fueling and firing sequence controlled by a Powertrain Control Module (PCM) that allows all cylinders in a 90°V12 to operate in Even Fire mode, with Dynamic Fuel Balancing and IFR Compensation by selectively reducing fuel to specific cylinders during imbalance frequencies, effectively converting the engine's operation to a balanced V8 mode during peak vibrations.

Emissions Regulations

Emissions regulations have become increasingly stringent over the past few decades, significantly impacting the design and performance of automotive engines, including V12 and V6 configurations. These regulations aim to reduce harmful emissions and improve air quality, forcing manufacturers to adapt their engine technologies to meet evolving standards.

In the context of V12 and V6 engines, emissions regulations have led to notable differences in their development and implementation. V12 engines, traditionally associated with high-performance luxury vehicles, face greater challenges in meeting emissions standards due to their larger displacement and higher fuel consumption. Manufacturers have had to implement advanced technologies such as direct injection, variable valve timing, and cylinder deactivation to improve efficiency and reduce emissions in V12 engines.

V6 engines, on the other hand, have generally been more adaptable to emissions regulations. Their smaller displacement and lower fuel consumption make it easier to achieve compliance with emission standards. As a result, V6 engines have become increasingly popular in a wide range of vehicles, from mid-size sedans to high-performance sports cars.

The introduction of Euro 6 standards in Europe and Tier 3 standards in the United States has further tightened emissions requirements, particularly for nitrogen oxides (NOx) and particulate matter. This has led to the widespread adoption of exhaust after-treatment systems, such as selective catalytic reduction (SCR) and particulate filters, in both V12 and V6 engines.

The impact of emissions regulations on engine performance is significant. While these regulations have driven improvements in fuel efficiency and reduced harmful emissions, they have also presented challenges in maintaining high performance levels, especially for V12 engines. Engineers have had to balance power output with emissions compliance, often resulting in complex engine management systems and the integration of hybrid technologies.

Looking ahead, the trend towards electrification and zero-emission vehicles is likely to have a profound impact on both V12 and V6 engines. As governments worldwide push for stricter emissions targets, the long-term viability of large displacement engines, particularly V12s, may be called into question. V6 engines, being more compact and efficient, may have a longer lifespan in hybrid powertrains as a transitional technology.

In conclusion, emissions regulations have been a driving force in shaping the development and performance characteristics of V12 and V6 engines. While both engine types have had to adapt to meet these standards, V6 engines have generally proven more flexible in achieving compliance while maintaining performance. The ongoing evolution of emissions regulations will continue to influence engine design and may ultimately determine the future relevance of these engine configurations in the automotive industry.

In the context of V12 and V6 engines, emissions regulations have led to notable differences in their development and implementation. V12 engines, traditionally associated with high-performance luxury vehicles, face greater challenges in meeting emissions standards due to their larger displacement and higher fuel consumption. Manufacturers have had to implement advanced technologies such as direct injection, variable valve timing, and cylinder deactivation to improve efficiency and reduce emissions in V12 engines.

V6 engines, on the other hand, have generally been more adaptable to emissions regulations. Their smaller displacement and lower fuel consumption make it easier to achieve compliance with emission standards. As a result, V6 engines have become increasingly popular in a wide range of vehicles, from mid-size sedans to high-performance sports cars.

The introduction of Euro 6 standards in Europe and Tier 3 standards in the United States has further tightened emissions requirements, particularly for nitrogen oxides (NOx) and particulate matter. This has led to the widespread adoption of exhaust after-treatment systems, such as selective catalytic reduction (SCR) and particulate filters, in both V12 and V6 engines.

The impact of emissions regulations on engine performance is significant. While these regulations have driven improvements in fuel efficiency and reduced harmful emissions, they have also presented challenges in maintaining high performance levels, especially for V12 engines. Engineers have had to balance power output with emissions compliance, often resulting in complex engine management systems and the integration of hybrid technologies.

Looking ahead, the trend towards electrification and zero-emission vehicles is likely to have a profound impact on both V12 and V6 engines. As governments worldwide push for stricter emissions targets, the long-term viability of large displacement engines, particularly V12s, may be called into question. V6 engines, being more compact and efficient, may have a longer lifespan in hybrid powertrains as a transitional technology.

In conclusion, emissions regulations have been a driving force in shaping the development and performance characteristics of V12 and V6 engines. While both engine types have had to adapt to meet these standards, V6 engines have generally proven more flexible in achieving compliance while maintaining performance. The ongoing evolution of emissions regulations will continue to influence engine design and may ultimately determine the future relevance of these engine configurations in the automotive industry.

Fuel Efficiency Trends

The fuel efficiency trends of V12 and V6 engines have shown significant divergence over the past decades, reflecting broader shifts in automotive engineering priorities and environmental concerns. Historically, V12 engines were prized for their smooth operation and high power output, often found in luxury and high-performance vehicles. However, their fuel consumption has been consistently higher than that of smaller engine configurations.

In recent years, the automotive industry has faced increasing pressure to improve fuel efficiency and reduce emissions. This has led to a notable trend towards engine downsizing, with V6 engines gaining prominence as a more fuel-efficient alternative to V12s. Advanced technologies such as direct fuel injection, turbocharging, and variable valve timing have allowed V6 engines to achieve power outputs comparable to older V12 designs while consuming significantly less fuel.

Data from various manufacturers and independent testing bodies have consistently shown that V6 engines outperform V12 engines in terms of fuel efficiency. On average, V6 engines typically consume 20-30% less fuel than V12 engines of similar power output. This efficiency gap has been widening as V6 technology continues to advance, while V12 development has slowed due to decreasing market demand and stricter emissions regulations.

The trend towards improved fuel efficiency is particularly evident in the luxury car segment, where V12 engines were once commonplace. Many luxury automakers have begun phasing out V12 options in favor of highly refined V6 powertrains. For instance, some models that previously offered V12 engines now achieve similar performance metrics with V6 engines while reducing fuel consumption by up to 25%.

In the performance car sector, the fuel efficiency gap between V12 and V6 engines is even more pronounced during high-speed or track driving conditions. V6 engines, especially those employing hybrid technology, have demonstrated the ability to maintain high performance while significantly reducing fuel consumption compared to their V12 counterparts.

Looking forward, the fuel efficiency trend is expected to continue favoring V6 engines. Ongoing developments in hybrid and electric assist technologies are likely to further enhance the efficiency of V6 powertrains, while the future of V12 engines appears increasingly limited to ultra-luxury or specialized performance applications where fuel efficiency is a secondary concern.

In recent years, the automotive industry has faced increasing pressure to improve fuel efficiency and reduce emissions. This has led to a notable trend towards engine downsizing, with V6 engines gaining prominence as a more fuel-efficient alternative to V12s. Advanced technologies such as direct fuel injection, turbocharging, and variable valve timing have allowed V6 engines to achieve power outputs comparable to older V12 designs while consuming significantly less fuel.

Data from various manufacturers and independent testing bodies have consistently shown that V6 engines outperform V12 engines in terms of fuel efficiency. On average, V6 engines typically consume 20-30% less fuel than V12 engines of similar power output. This efficiency gap has been widening as V6 technology continues to advance, while V12 development has slowed due to decreasing market demand and stricter emissions regulations.

The trend towards improved fuel efficiency is particularly evident in the luxury car segment, where V12 engines were once commonplace. Many luxury automakers have begun phasing out V12 options in favor of highly refined V6 powertrains. For instance, some models that previously offered V12 engines now achieve similar performance metrics with V6 engines while reducing fuel consumption by up to 25%.

In the performance car sector, the fuel efficiency gap between V12 and V6 engines is even more pronounced during high-speed or track driving conditions. V6 engines, especially those employing hybrid technology, have demonstrated the ability to maintain high performance while significantly reducing fuel consumption compared to their V12 counterparts.

Looking forward, the fuel efficiency trend is expected to continue favoring V6 engines. Ongoing developments in hybrid and electric assist technologies are likely to further enhance the efficiency of V6 powertrains, while the future of V12 engines appears increasingly limited to ultra-luxury or specialized performance applications where fuel efficiency is a secondary concern.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!