Comparison of Metasurface Antennas and Traditional Antennas

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface Antenna Evolution and Objectives

Metasurface antennas represent a revolutionary advancement in antenna technology, emerging from the broader field of metamaterials research that gained significant momentum in the early 2000s. These engineered surfaces consist of subwavelength elements arranged in specific patterns to manipulate electromagnetic waves in ways conventional materials cannot. The evolution of metasurface antennas can be traced back to the theoretical work on transformation optics and negative refractive index materials by pioneers such as Sir John Pendry and Victor Veselago.

The development trajectory has progressed from bulky three-dimensional metamaterial structures to planar, two-dimensional metasurfaces that offer significantly improved manufacturability while maintaining exceptional electromagnetic control capabilities. This transition marked a critical turning point around 2011-2013, when researchers demonstrated that metasurfaces could achieve many of the same functionalities as their three-dimensional counterparts but with reduced complexity and cost.

Recent technological advancements have further accelerated metasurface antenna development, particularly in fabrication techniques such as nanolithography, 3D printing, and MEMS technology. These manufacturing innovations have enabled increasingly complex and precise metasurface designs that can operate across broader frequency ranges with enhanced performance metrics.

The primary objective of metasurface antenna technology is to overcome fundamental limitations of traditional antennas regarding size, bandwidth, efficiency, and beam-forming capabilities. Traditional antennas are constrained by physical principles such as the half-wavelength resonance requirement and the gain-bandwidth product limitation. Metasurfaces aim to transcend these constraints through engineered electromagnetic responses that can be tailored with unprecedented freedom.

Specific technical goals include developing ultra-thin antennas with high gain, achieving wide-angle beam scanning without mechanical components, enabling multi-band operation from a single compact device, and creating dynamically reconfigurable antenna systems that can adapt to changing communication requirements in real-time.

The long-term vision for metasurface antenna technology encompasses integration into next-generation communication systems, particularly for 5G/6G networks, satellite communications, automotive radar, medical imaging, and Internet of Things (IoT) applications. The miniaturization potential and performance advantages make metasurface antennas particularly attractive for these applications where space constraints and performance demands are simultaneously high.

As the technology continues to mature, research is increasingly focused on addressing challenges related to bandwidth limitations, fabrication complexity, and active tuning mechanisms to realize the full potential of metasurface antennas across diverse application domains.

The development trajectory has progressed from bulky three-dimensional metamaterial structures to planar, two-dimensional metasurfaces that offer significantly improved manufacturability while maintaining exceptional electromagnetic control capabilities. This transition marked a critical turning point around 2011-2013, when researchers demonstrated that metasurfaces could achieve many of the same functionalities as their three-dimensional counterparts but with reduced complexity and cost.

Recent technological advancements have further accelerated metasurface antenna development, particularly in fabrication techniques such as nanolithography, 3D printing, and MEMS technology. These manufacturing innovations have enabled increasingly complex and precise metasurface designs that can operate across broader frequency ranges with enhanced performance metrics.

The primary objective of metasurface antenna technology is to overcome fundamental limitations of traditional antennas regarding size, bandwidth, efficiency, and beam-forming capabilities. Traditional antennas are constrained by physical principles such as the half-wavelength resonance requirement and the gain-bandwidth product limitation. Metasurfaces aim to transcend these constraints through engineered electromagnetic responses that can be tailored with unprecedented freedom.

Specific technical goals include developing ultra-thin antennas with high gain, achieving wide-angle beam scanning without mechanical components, enabling multi-band operation from a single compact device, and creating dynamically reconfigurable antenna systems that can adapt to changing communication requirements in real-time.

The long-term vision for metasurface antenna technology encompasses integration into next-generation communication systems, particularly for 5G/6G networks, satellite communications, automotive radar, medical imaging, and Internet of Things (IoT) applications. The miniaturization potential and performance advantages make metasurface antennas particularly attractive for these applications where space constraints and performance demands are simultaneously high.

As the technology continues to mature, research is increasingly focused on addressing challenges related to bandwidth limitations, fabrication complexity, and active tuning mechanisms to realize the full potential of metasurface antennas across diverse application domains.

Market Analysis for Advanced Antenna Technologies

The global antenna market is experiencing significant growth, driven by the rapid expansion of wireless communication technologies and the increasing demand for high-performance connectivity solutions. Currently valued at approximately 21.4 billion USD in 2023, the market is projected to reach 32.5 billion USD by 2028, representing a compound annual growth rate (CAGR) of 8.7%. This growth trajectory is particularly pronounced in regions with accelerating 5G deployment, such as North America, East Asia, and parts of Europe.

Metasurface antennas are emerging as a disruptive technology within this expanding market. While traditional antennas still dominate with over 85% market share, metasurface solutions are experiencing the fastest growth rate at 23.6% annually. This accelerated adoption is primarily driven by their superior performance characteristics in advanced applications where size, weight, and power consumption are critical factors.

The telecommunications sector remains the largest consumer of advanced antenna technologies, accounting for 42% of the total market. However, aerospace and defense applications are showing the strongest interest in metasurface technologies, with adoption rates increasing by 31% year-over-year. This is largely attributed to the need for low-profile, conformal antennas with electronic beam steering capabilities in modern military and space systems.

Consumer electronics represents another significant growth segment, particularly as smart devices continue to proliferate. The demand for smaller, more efficient antennas that can be integrated into compact devices is creating a 17.8% annual growth opportunity specifically for metasurface solutions in this sector.

Regionally, North America leads in metasurface antenna research and adoption with 38% of global implementations, followed by Asia-Pacific at 32% and Europe at 24%. China, in particular, has increased its investment in metasurface technology by 41% over the past three years, signaling its strategic importance in the country's telecommunications infrastructure development.

Key market drivers include the ongoing rollout of 5G networks worldwide, the increasing demand for satellite communications, the growth of Internet of Things (IoT) applications, and the push for more efficient radar systems in autonomous vehicles. These factors collectively contribute to a projected 27% annual growth rate for metasurface antennas through 2028, significantly outpacing the broader antenna market.

Price sensitivity remains a challenge, with metasurface solutions currently commanding a premium of 2.5-4x compared to traditional alternatives. However, this gap is expected to narrow to 1.5-2x by 2026 as manufacturing processes mature and economies of scale are realized.

Metasurface antennas are emerging as a disruptive technology within this expanding market. While traditional antennas still dominate with over 85% market share, metasurface solutions are experiencing the fastest growth rate at 23.6% annually. This accelerated adoption is primarily driven by their superior performance characteristics in advanced applications where size, weight, and power consumption are critical factors.

The telecommunications sector remains the largest consumer of advanced antenna technologies, accounting for 42% of the total market. However, aerospace and defense applications are showing the strongest interest in metasurface technologies, with adoption rates increasing by 31% year-over-year. This is largely attributed to the need for low-profile, conformal antennas with electronic beam steering capabilities in modern military and space systems.

Consumer electronics represents another significant growth segment, particularly as smart devices continue to proliferate. The demand for smaller, more efficient antennas that can be integrated into compact devices is creating a 17.8% annual growth opportunity specifically for metasurface solutions in this sector.

Regionally, North America leads in metasurface antenna research and adoption with 38% of global implementations, followed by Asia-Pacific at 32% and Europe at 24%. China, in particular, has increased its investment in metasurface technology by 41% over the past three years, signaling its strategic importance in the country's telecommunications infrastructure development.

Key market drivers include the ongoing rollout of 5G networks worldwide, the increasing demand for satellite communications, the growth of Internet of Things (IoT) applications, and the push for more efficient radar systems in autonomous vehicles. These factors collectively contribute to a projected 27% annual growth rate for metasurface antennas through 2028, significantly outpacing the broader antenna market.

Price sensitivity remains a challenge, with metasurface solutions currently commanding a premium of 2.5-4x compared to traditional alternatives. However, this gap is expected to narrow to 1.5-2x by 2026 as manufacturing processes mature and economies of scale are realized.

Technical Challenges in Metasurface vs Traditional Antennas

Metasurface antennas represent a significant departure from traditional antenna designs, bringing both promising advantages and considerable technical challenges. The fundamental challenge lies in the complex electromagnetic interactions within metasurfaces, which require sophisticated modeling techniques beyond those used for conventional antennas. Current simulation tools often struggle to efficiently model the intricate subwavelength structures that comprise metasurfaces, leading to computational bottlenecks in the design process.

Manufacturing precision presents another major hurdle. While traditional antennas can tolerate certain fabrication tolerances, metasurface antennas demand extremely precise fabrication at the micro or nano scale. Even minor deviations in the metasurface elements can significantly alter performance characteristics, requiring advanced manufacturing techniques that increase production complexity and cost.

Bandwidth limitations remain a persistent challenge for metasurface antennas. Traditional antennas typically offer broader operational bandwidths, whereas metasurfaces often exhibit narrowband behavior due to their resonant nature. Engineers must develop innovative approaches to expand the usable frequency range without compromising other performance metrics.

Power handling capabilities present additional complications. Traditional antennas have well-established power handling limits, but metasurface antennas may experience localized field enhancements that create potential failure points under high-power operation. This necessitates careful thermal management and material selection to prevent performance degradation or physical damage.

Environmental stability poses significant concerns for practical deployment. Traditional antennas benefit from decades of engineering refinements for durability, while metasurface antennas must still prove their resilience against temperature fluctuations, humidity, mechanical stress, and other environmental factors that could alter their precisely engineered electromagnetic properties.

Integration challenges arise when incorporating metasurface antennas into existing systems. The unique feeding mechanisms and impedance characteristics of metasurfaces often require specialized interface circuits, complicating their adoption as drop-in replacements for conventional antennas in established systems.

Characterization and testing methodologies represent another technical barrier. Standard antenna measurement techniques may prove inadequate for fully capturing the performance of metasurface antennas, particularly their near-field behaviors and phase characteristics. This necessitates the development of new measurement protocols and equipment specifically tailored to metasurface evaluation.

Cost-effectiveness remains a significant obstacle to widespread adoption. The complex design processes, precise manufacturing requirements, and specialized materials often result in higher production costs compared to traditional antennas, creating economic barriers to commercial implementation despite their technical advantages.

Manufacturing precision presents another major hurdle. While traditional antennas can tolerate certain fabrication tolerances, metasurface antennas demand extremely precise fabrication at the micro or nano scale. Even minor deviations in the metasurface elements can significantly alter performance characteristics, requiring advanced manufacturing techniques that increase production complexity and cost.

Bandwidth limitations remain a persistent challenge for metasurface antennas. Traditional antennas typically offer broader operational bandwidths, whereas metasurfaces often exhibit narrowband behavior due to their resonant nature. Engineers must develop innovative approaches to expand the usable frequency range without compromising other performance metrics.

Power handling capabilities present additional complications. Traditional antennas have well-established power handling limits, but metasurface antennas may experience localized field enhancements that create potential failure points under high-power operation. This necessitates careful thermal management and material selection to prevent performance degradation or physical damage.

Environmental stability poses significant concerns for practical deployment. Traditional antennas benefit from decades of engineering refinements for durability, while metasurface antennas must still prove their resilience against temperature fluctuations, humidity, mechanical stress, and other environmental factors that could alter their precisely engineered electromagnetic properties.

Integration challenges arise when incorporating metasurface antennas into existing systems. The unique feeding mechanisms and impedance characteristics of metasurfaces often require specialized interface circuits, complicating their adoption as drop-in replacements for conventional antennas in established systems.

Characterization and testing methodologies represent another technical barrier. Standard antenna measurement techniques may prove inadequate for fully capturing the performance of metasurface antennas, particularly their near-field behaviors and phase characteristics. This necessitates the development of new measurement protocols and equipment specifically tailored to metasurface evaluation.

Cost-effectiveness remains a significant obstacle to widespread adoption. The complex design processes, precise manufacturing requirements, and specialized materials often result in higher production costs compared to traditional antennas, creating economic barriers to commercial implementation despite their technical advantages.

Current Metasurface Antenna Design Approaches

01 Design principles of metasurface antennas

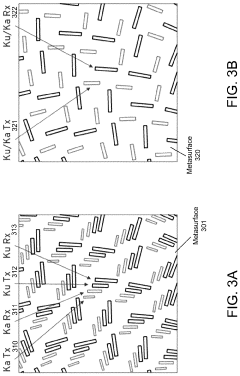

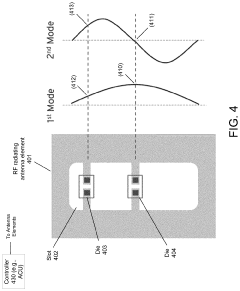

Metasurface antennas utilize engineered surfaces with sub-wavelength structures to manipulate electromagnetic waves in ways not possible with traditional antennas. These antennas employ periodic or quasi-periodic arrangements of resonant elements to control phase, amplitude, and polarization of electromagnetic waves. The design principles involve careful patterning of metallic or dielectric elements on substrates to achieve desired radiation characteristics, beamforming capabilities, and frequency responses that can exceed the limitations of conventional antenna designs.- Design principles of metasurface antennas: Metasurface antennas utilize engineered surfaces with sub-wavelength structures to manipulate electromagnetic waves in ways not possible with traditional antennas. These surfaces can control phase, amplitude, and polarization of waves with high precision, enabling beam steering, focusing, and pattern shaping capabilities. The design typically involves arrays of resonant elements arranged in specific patterns to achieve desired radiation characteristics, offering advantages in miniaturization and integration compared to conventional antenna designs.

- Performance comparison between metasurface and traditional antennas: Metasurface antennas generally offer higher gain, wider bandwidth, and more compact form factors compared to traditional antennas. While conventional antennas rely on resonant structures with dimensions comparable to the wavelength, metasurfaces can achieve similar or superior performance with significantly reduced thickness. Traditional antennas typically have simpler designs and manufacturing processes but lack the flexibility in beam control and pattern reconfigurability that metasurfaces provide. The efficiency and radiation pattern control of metasurface antennas often exceed those of conventional designs in similar form factors.

- Fabrication techniques for metasurface antennas: Manufacturing metasurface antennas requires precision fabrication techniques to create sub-wavelength structures with accurate dimensions and spacing. Common methods include photolithography, electron beam lithography, and advanced printing techniques. These processes enable the creation of complex patterns necessary for controlling electromagnetic wave behavior. In contrast to traditional antennas that can often be manufactured using conventional PCB processes, metasurface antennas may require specialized equipment and cleanroom environments to achieve the necessary precision for optimal performance.

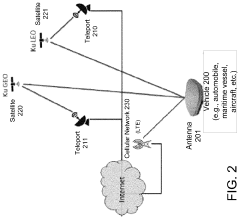

- Applications of metasurface antennas in communication systems: Metasurface antennas are increasingly deployed in advanced communication systems, particularly in 5G/6G networks, satellite communications, and IoT devices. Their ability to provide electronically steerable beams without mechanical parts makes them ideal for MIMO systems and beam-forming applications. The compact nature of metasurface antennas allows for integration into space-constrained devices while maintaining high performance. Traditional antennas continue to be used in applications where cost and simplicity are prioritized over advanced functionality, but metasurface designs are becoming more prevalent as manufacturing costs decrease.

- Reconfigurable and tunable antenna technologies: Reconfigurable metasurface antennas represent a significant advancement over both static metasurfaces and traditional reconfigurable antennas. These designs incorporate active elements such as varactors, PIN diodes, or MEMS switches to dynamically alter the electromagnetic properties of the surface. This enables real-time adjustment of radiation patterns, operating frequencies, and polarization states. Traditional reconfigurable antennas typically rely on switching between discrete elements or mechanical adjustments, whereas metasurface-based solutions offer more degrees of freedom and finer control over antenna characteristics, making them particularly valuable for cognitive radio and adaptive communication systems.

02 Performance comparison between metasurface and traditional antennas

Metasurface antennas offer several advantages over traditional antennas including reduced profile, enhanced bandwidth, improved gain, and greater beam-steering capabilities. While traditional antennas rely on resonant structures with dimensions comparable to the wavelength, metasurfaces can achieve similar or superior performance with significantly reduced thickness. Metasurface designs can also provide multi-band operation and polarization control that would require more complex implementations in conventional antenna systems, though they may involve more complex manufacturing processes.Expand Specific Solutions03 Integration of metasurface antennas in communication systems

Metasurface antennas are increasingly being integrated into modern communication systems, particularly for 5G/6G networks, satellite communications, and IoT applications. Their compact form factor and ability to be conformally mounted on various surfaces make them ideal for space-constrained applications. These antennas can be designed to provide wide-angle scanning capabilities, frequency selectivity, and adaptive beamforming, enabling more efficient spectrum utilization and improved signal quality in complex propagation environments.Expand Specific Solutions04 Fabrication techniques for metasurface antennas

Advanced fabrication techniques are essential for producing metasurface antennas with precise sub-wavelength features. These include photolithography, electron beam lithography, nanoimprint lithography, and additive manufacturing processes. Each technique offers different capabilities in terms of resolution, scalability, and material compatibility. The choice of fabrication method significantly impacts the performance, cost, and mass-production feasibility of metasurface antennas, with newer techniques enabling increasingly complex designs that were previously impossible to manufacture.Expand Specific Solutions05 Reconfigurable and tunable antenna technologies

Both metasurface and traditional antennas can be designed with reconfigurable and tunable capabilities, though the implementation approaches differ significantly. Metasurface antennas often achieve reconfigurability through integration with active components like varactors, PIN diodes, or MEMS switches that can dynamically alter the electromagnetic properties of the surface. This enables adaptive frequency response, beam steering, and polarization control without mechanical movement. These capabilities are particularly valuable for cognitive radio systems, MIMO applications, and adaptive radar systems that must operate across multiple frequency bands or changing environments.Expand Specific Solutions

Leading Companies and Research Institutions in Antenna Industry

Metasurface antennas represent a disruptive innovation in the antenna industry, currently transitioning from early development to commercial adoption. The market is experiencing rapid growth, projected to reach significant scale as these antennas offer advantages in form factor, beam steering capabilities, and integration flexibility over traditional designs. Technology maturity varies across players: Kymeta Corp. leads with commercial satellite communication products, while Huawei, Samsung, and BOE Technology are advancing integration into consumer electronics. Research institutions like Southeast University, Johns Hopkins University, and CNRS are driving fundamental innovations. Military and aerospace applications are being developed by entities like Dassault Aviation and government agencies. The competitive landscape features both specialized startups and established telecommunications giants, with intellectual property becoming increasingly important as the technology matures.

Kymeta Corp.

Technical Solution: Kymeta has pioneered electronically steerable metamaterial-based flat panel antennas, specifically their mTenna technology. Their approach uses liquid crystal-based metasurfaces to create holographic beam forming without mechanical moving parts. The technology employs a thin metamaterial layer that can be electronically tuned to control electromagnetic wave propagation, effectively creating a dynamic holographic pattern that forms and steers the beam. This allows for satellite tracking and communication with significantly reduced form factor compared to traditional parabolic dishes[1][3]. Their latest KymetaConnect platform integrates these metasurface antennas with hybrid network connectivity solutions, enabling seamless transitions between satellite and cellular networks while maintaining a low profile installation footprint.

Strengths: Extremely low profile design (less than 10cm thick); elimination of mechanical moving parts increases reliability; software-defined beam steering enables rapid tracking. Weaknesses: Higher power consumption than some traditional solutions; complex manufacturing process increases unit cost; performance in extreme weather conditions can be more variable than traditional rigid dish antennas.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed advanced metasurface antenna technology for 5G and beyond communications, focusing on Reconfigurable Intelligent Surface (RIS) implementations. Their approach uses programmable metasurfaces with integrated control circuits that can dynamically manipulate electromagnetic waves through phase shifting, amplitude control, and polarization adjustment. These metasurfaces function as intelligent reflectors or transmitters that can overcome non-line-of-sight limitations in millimeter-wave communications[2][4]. Huawei's implementation includes thousands of sub-wavelength unit cells with embedded PIN diodes or varactors that enable real-time reconfiguration based on channel conditions. Their systems demonstrate up to 30% coverage enhancement in urban environments compared to traditional antenna arrays, while requiring significantly less power than active beamforming solutions. Recent developments include AI-controlled metasurfaces that adaptively optimize wireless environments.

Strengths: Highly energy-efficient compared to active MIMO systems; enables coverage in previously challenging environments; compatible with existing network infrastructure. Weaknesses: Requires sophisticated control algorithms; performance dependent on environmental factors; deployment complexity in existing infrastructure.

Key Patents and Breakthroughs in Metasurface Technology

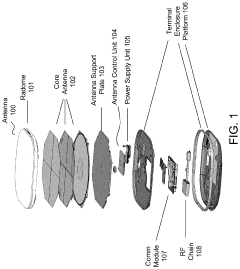

Shared aperture multi-band metasurface electronically scanned antenna (ESA)

PatentPendingUS20240072454A1

Innovation

- A shared aperture multi-band metasurface electronically scanned antenna (ESA) with dynamically configurable RF radiating elements, utilizing interleaved sub-arrays and integrated varactor circuits to control resonances, allowing operation across multiple frequency bands, including Ka and Ku bands, within a single aperture.

Meta-surface antenna manufactured using mass transfer technology

PatentPendingJP2025013343A

Innovation

- The use of tunable capacitance devices within unit cells of metasurface antennas, combined with mass transfer techniques and self-assembly processes, allows for independent control of each element's resonance frequency and simplifies the manufacturing process.

Performance Metrics and Benchmarking Methodologies

To effectively compare metasurface antennas with traditional antennas, standardized performance metrics and benchmarking methodologies are essential. These frameworks enable objective evaluation across diverse antenna technologies and applications, providing quantifiable data for engineering decisions.

Gain and directivity serve as primary performance indicators, with metasurface antennas typically demonstrating higher gain-to-size ratios compared to conventional designs. Measurement protocols must account for the unique electromagnetic properties of metasurfaces, requiring specialized near-field and far-field testing configurations. Bandwidth measurement presents particular challenges for metasurface antennas, as their resonant characteristics often differ fundamentally from traditional radiating elements.

Efficiency metrics require careful consideration when benchmarking these technologies. While traditional antennas have well-established efficiency measurement protocols, metasurface antennas demand modified approaches that account for their surface wave manipulation mechanisms and potential losses in the metasurface structure. Radiation pattern stability across operating frequencies represents another critical performance parameter requiring standardized measurement methodologies.

Size, weight, and form factor comparisons necessitate normalized metrics such as gain-per-unit-volume or efficiency-per-unit-weight to provide meaningful benchmarks between these disparate technologies. Such normalization enables fair comparison between compact metasurface designs and larger traditional antennas with similar performance characteristics.

Computational electromagnetic simulation plays a vital role in benchmarking, with finite-difference time-domain (FDTD) and finite element method (FEM) approaches commonly employed. However, metasurface structures often require higher mesh densities and specialized boundary conditions, increasing computational complexity compared to traditional antenna simulations.

Environmental resilience testing protocols must evaluate performance under varying conditions including temperature fluctuations, humidity, mechanical stress, and radiation exposure. Metasurface antennas may exhibit different environmental sensitivities due to their often complex material compositions and fabrication techniques.

Cost-performance ratio analysis provides essential benchmarking data for commercial applications, incorporating manufacturing complexity, material costs, and scalability factors. While traditional antennas benefit from established manufacturing processes, metasurface antennas often require specialized fabrication techniques that impact their economic viability despite potentially superior technical performance.

Standardized testing environments, including anechoic chambers with appropriate absorber materials and calibrated measurement equipment, ensure reproducible benchmarking results. Industry-standard reference antennas should be employed to validate measurement accuracy and provide consistent comparison baselines between different research groups and manufacturers.

Gain and directivity serve as primary performance indicators, with metasurface antennas typically demonstrating higher gain-to-size ratios compared to conventional designs. Measurement protocols must account for the unique electromagnetic properties of metasurfaces, requiring specialized near-field and far-field testing configurations. Bandwidth measurement presents particular challenges for metasurface antennas, as their resonant characteristics often differ fundamentally from traditional radiating elements.

Efficiency metrics require careful consideration when benchmarking these technologies. While traditional antennas have well-established efficiency measurement protocols, metasurface antennas demand modified approaches that account for their surface wave manipulation mechanisms and potential losses in the metasurface structure. Radiation pattern stability across operating frequencies represents another critical performance parameter requiring standardized measurement methodologies.

Size, weight, and form factor comparisons necessitate normalized metrics such as gain-per-unit-volume or efficiency-per-unit-weight to provide meaningful benchmarks between these disparate technologies. Such normalization enables fair comparison between compact metasurface designs and larger traditional antennas with similar performance characteristics.

Computational electromagnetic simulation plays a vital role in benchmarking, with finite-difference time-domain (FDTD) and finite element method (FEM) approaches commonly employed. However, metasurface structures often require higher mesh densities and specialized boundary conditions, increasing computational complexity compared to traditional antenna simulations.

Environmental resilience testing protocols must evaluate performance under varying conditions including temperature fluctuations, humidity, mechanical stress, and radiation exposure. Metasurface antennas may exhibit different environmental sensitivities due to their often complex material compositions and fabrication techniques.

Cost-performance ratio analysis provides essential benchmarking data for commercial applications, incorporating manufacturing complexity, material costs, and scalability factors. While traditional antennas benefit from established manufacturing processes, metasurface antennas often require specialized fabrication techniques that impact their economic viability despite potentially superior technical performance.

Standardized testing environments, including anechoic chambers with appropriate absorber materials and calibrated measurement equipment, ensure reproducible benchmarking results. Industry-standard reference antennas should be employed to validate measurement accuracy and provide consistent comparison baselines between different research groups and manufacturers.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability and cost analysis of metasurface antennas compared to traditional antennas reveals significant differences in production methodologies, economic viability, and mass-market potential. Traditional antennas typically rely on well-established manufacturing processes involving metal fabrication, precision machining, and assembly of discrete components. These processes have benefited from decades of industrial optimization, resulting in streamlined production lines and predictable costs.

Metasurface antennas, conversely, leverage advanced microfabrication techniques borrowed from the semiconductor industry, including photolithography, electron beam lithography, and nanoimprint lithography. While these techniques enable the creation of intricate sub-wavelength structures necessary for metasurfaces, they currently present higher per-unit costs for small to medium production volumes compared to traditional antenna manufacturing.

The economic crossover point occurs at higher production volumes, where metasurface antennas demonstrate superior scalability potential. Once initial tooling and setup costs are amortized, the planar nature of metasurfaces allows for batch processing similar to integrated circuits, potentially reducing per-unit costs dramatically at scale. Industry analyses suggest that production runs exceeding 100,000 units could make metasurface antennas more economically viable than their traditional counterparts for certain applications.

Material considerations also impact manufacturing economics. Traditional antennas primarily utilize copper, aluminum, and other common metals with established supply chains and relatively stable pricing. Metasurface antennas often incorporate specialized dielectric substrates, precise metallization layers, and occasionally exotic materials, introducing potential supply chain vulnerabilities and price volatility.

Equipment investment represents another critical cost factor. Traditional antenna production relies on conventional manufacturing equipment with lower capital expenditure requirements. Metasurface fabrication necessitates clean room facilities and specialized lithography equipment, translating to higher initial investment but potentially lower variable costs at scale.

Looking forward, emerging manufacturing technologies such as roll-to-roll nanoimprinting and additive manufacturing processes show promise for dramatically reducing metasurface production costs. These approaches could potentially decrease manufacturing time by 60-80% while maintaining the precision required for millimeter-wave and terahertz applications, further enhancing the economic viability of metasurface antennas for mass-market deployment in next-generation communication systems.

Metasurface antennas, conversely, leverage advanced microfabrication techniques borrowed from the semiconductor industry, including photolithography, electron beam lithography, and nanoimprint lithography. While these techniques enable the creation of intricate sub-wavelength structures necessary for metasurfaces, they currently present higher per-unit costs for small to medium production volumes compared to traditional antenna manufacturing.

The economic crossover point occurs at higher production volumes, where metasurface antennas demonstrate superior scalability potential. Once initial tooling and setup costs are amortized, the planar nature of metasurfaces allows for batch processing similar to integrated circuits, potentially reducing per-unit costs dramatically at scale. Industry analyses suggest that production runs exceeding 100,000 units could make metasurface antennas more economically viable than their traditional counterparts for certain applications.

Material considerations also impact manufacturing economics. Traditional antennas primarily utilize copper, aluminum, and other common metals with established supply chains and relatively stable pricing. Metasurface antennas often incorporate specialized dielectric substrates, precise metallization layers, and occasionally exotic materials, introducing potential supply chain vulnerabilities and price volatility.

Equipment investment represents another critical cost factor. Traditional antenna production relies on conventional manufacturing equipment with lower capital expenditure requirements. Metasurface fabrication necessitates clean room facilities and specialized lithography equipment, translating to higher initial investment but potentially lower variable costs at scale.

Looking forward, emerging manufacturing technologies such as roll-to-roll nanoimprinting and additive manufacturing processes show promise for dramatically reducing metasurface production costs. These approaches could potentially decrease manufacturing time by 60-80% while maintaining the precision required for millimeter-wave and terahertz applications, further enhancing the economic viability of metasurface antennas for mass-market deployment in next-generation communication systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!