Metasurface Antennas: Integration Challenges and Solutions

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface Antenna Technology Evolution and Objectives

Metasurface antennas represent a revolutionary advancement in electromagnetic wave manipulation technology, emerging from the broader field of metamaterials research that gained significant momentum in the early 2000s. These ultra-thin, planar structures consist of subwavelength elements arranged in specific patterns to achieve unprecedented control over electromagnetic wavefronts. The evolution of this technology can be traced back to frequency selective surfaces and reflectarrays, but metasurfaces have transcended these predecessors through their ability to manipulate phase, amplitude, and polarization with exceptional precision.

The technological progression of metasurface antennas has followed several distinct phases. Initially, research focused on passive metasurfaces with fixed functionalities, demonstrating basic principles of wavefront manipulation. This was followed by the development of reconfigurable metasurfaces incorporating tunable elements such as varactors, PIN diodes, and MEMS switches, enabling dynamic control of electromagnetic properties. The most recent evolutionary stage has seen the emergence of digitally programmable metasurfaces and intelligent metasurfaces integrated with sensing and computational capabilities.

A significant milestone in metasurface antenna development was the theoretical formulation of generalized laws of reflection and refraction for metasurfaces by Capasso's group in 2011, which provided the fundamental framework for designing metasurfaces with arbitrary wavefront control. This breakthrough catalyzed rapid advancement in the field, leading to numerous practical implementations across the electromagnetic spectrum.

The primary technical objectives for metasurface antennas center around overcoming several critical limitations. First is the achievement of wideband operation, as conventional metasurfaces typically exhibit narrow bandwidth due to their resonant nature. Second is the development of efficient reconfiguration mechanisms that maintain high performance while enabling dynamic functionality. Third is the miniaturization and integration with existing RF systems without compromising performance or increasing complexity.

Looking forward, the field aims to realize fully integrated, multifunctional metasurface antennas capable of simultaneous sensing, communication, and energy harvesting. This includes the development of self-adaptive metasurfaces that can autonomously reconfigure in response to changing environmental conditions or user requirements. Additionally, researchers are pursuing metasurface designs that operate across multiple frequency bands simultaneously, potentially revolutionizing spectrum utilization in next-generation wireless systems.

The convergence of metasurface technology with artificial intelligence and advanced manufacturing techniques represents the frontier of development, with the ultimate goal of creating intelligent electromagnetic surfaces that can be seamlessly integrated into everyday objects and infrastructure.

The technological progression of metasurface antennas has followed several distinct phases. Initially, research focused on passive metasurfaces with fixed functionalities, demonstrating basic principles of wavefront manipulation. This was followed by the development of reconfigurable metasurfaces incorporating tunable elements such as varactors, PIN diodes, and MEMS switches, enabling dynamic control of electromagnetic properties. The most recent evolutionary stage has seen the emergence of digitally programmable metasurfaces and intelligent metasurfaces integrated with sensing and computational capabilities.

A significant milestone in metasurface antenna development was the theoretical formulation of generalized laws of reflection and refraction for metasurfaces by Capasso's group in 2011, which provided the fundamental framework for designing metasurfaces with arbitrary wavefront control. This breakthrough catalyzed rapid advancement in the field, leading to numerous practical implementations across the electromagnetic spectrum.

The primary technical objectives for metasurface antennas center around overcoming several critical limitations. First is the achievement of wideband operation, as conventional metasurfaces typically exhibit narrow bandwidth due to their resonant nature. Second is the development of efficient reconfiguration mechanisms that maintain high performance while enabling dynamic functionality. Third is the miniaturization and integration with existing RF systems without compromising performance or increasing complexity.

Looking forward, the field aims to realize fully integrated, multifunctional metasurface antennas capable of simultaneous sensing, communication, and energy harvesting. This includes the development of self-adaptive metasurfaces that can autonomously reconfigure in response to changing environmental conditions or user requirements. Additionally, researchers are pursuing metasurface designs that operate across multiple frequency bands simultaneously, potentially revolutionizing spectrum utilization in next-generation wireless systems.

The convergence of metasurface technology with artificial intelligence and advanced manufacturing techniques represents the frontier of development, with the ultimate goal of creating intelligent electromagnetic surfaces that can be seamlessly integrated into everyday objects and infrastructure.

Market Applications and Demand Analysis for Metasurface Antennas

The global market for metasurface antennas is experiencing significant growth driven by the increasing demand for high-performance communication systems across multiple sectors. The telecommunications industry represents the largest market segment, with 5G and upcoming 6G networks requiring advanced antenna solutions capable of beam steering, multiple-input-multiple-output (MIMO) operations, and efficient spectrum utilization. Metasurface antennas offer substantial advantages in these applications due to their compact form factor, electronic beam steering capabilities, and potential for cost reduction in mass production.

In the aerospace and defense sectors, metasurface antennas are gaining traction for radar systems, satellite communications, and electronic warfare applications. These sectors value the low profile and conformal nature of metasurface antennas, which can be integrated into aircraft skins or vehicle surfaces without compromising aerodynamics or increasing radar cross-section.

Consumer electronics represents another rapidly expanding market for metasurface antennas. As devices become smaller and more feature-rich, traditional antenna designs face significant space constraints. Metasurface antennas offer a solution by providing high performance in an ultra-thin form factor, making them ideal for smartphones, wearable devices, and Internet of Things (IoT) applications.

The automotive industry is increasingly adopting advanced radar and communication systems for autonomous driving and vehicle-to-everything (V2X) communications. Metasurface antennas can enable seamless integration of these systems into vehicle designs without compromising aesthetics or aerodynamics, driving demand in this sector.

Market analysis indicates that the global metasurface antenna market is projected to grow substantially over the next decade. This growth is fueled by the increasing need for high-data-rate communications, the proliferation of connected devices, and the advancement of autonomous systems across industries.

Regional analysis shows North America currently leading the market due to significant investments in defense and telecommunications infrastructure. However, Asia-Pacific is expected to witness the fastest growth rate, driven by rapid technological adoption in countries like China, Japan, and South Korea, particularly in 5G deployment and consumer electronics manufacturing.

Despite the promising market outlook, several factors could influence adoption rates. These include manufacturing scalability challenges, integration complexities with existing systems, and the need for standardization across industries. Additionally, the cost-performance ratio compared to conventional antenna technologies remains a critical factor for widespread commercial adoption.

In the aerospace and defense sectors, metasurface antennas are gaining traction for radar systems, satellite communications, and electronic warfare applications. These sectors value the low profile and conformal nature of metasurface antennas, which can be integrated into aircraft skins or vehicle surfaces without compromising aerodynamics or increasing radar cross-section.

Consumer electronics represents another rapidly expanding market for metasurface antennas. As devices become smaller and more feature-rich, traditional antenna designs face significant space constraints. Metasurface antennas offer a solution by providing high performance in an ultra-thin form factor, making them ideal for smartphones, wearable devices, and Internet of Things (IoT) applications.

The automotive industry is increasingly adopting advanced radar and communication systems for autonomous driving and vehicle-to-everything (V2X) communications. Metasurface antennas can enable seamless integration of these systems into vehicle designs without compromising aesthetics or aerodynamics, driving demand in this sector.

Market analysis indicates that the global metasurface antenna market is projected to grow substantially over the next decade. This growth is fueled by the increasing need for high-data-rate communications, the proliferation of connected devices, and the advancement of autonomous systems across industries.

Regional analysis shows North America currently leading the market due to significant investments in defense and telecommunications infrastructure. However, Asia-Pacific is expected to witness the fastest growth rate, driven by rapid technological adoption in countries like China, Japan, and South Korea, particularly in 5G deployment and consumer electronics manufacturing.

Despite the promising market outlook, several factors could influence adoption rates. These include manufacturing scalability challenges, integration complexities with existing systems, and the need for standardization across industries. Additionally, the cost-performance ratio compared to conventional antenna technologies remains a critical factor for widespread commercial adoption.

Current Integration Challenges and Technical Limitations

Despite significant advancements in metasurface antenna technology, several critical integration challenges continue to impede widespread commercial adoption. Fabrication precision remains a primary obstacle, as metasurfaces typically require sub-wavelength structures with dimensions in the micrometer or nanometer range. Current manufacturing processes struggle to consistently produce these structures with the required accuracy, especially when scaling to mass production. Even minor fabrication errors can significantly degrade antenna performance, resulting in frequency shifts, pattern distortion, and efficiency reduction.

Material compatibility presents another substantial challenge. Metasurface antennas often incorporate diverse materials with different thermal, mechanical, and electrical properties. The integration of these heterogeneous materials into existing RF systems frequently leads to interface issues, thermal expansion mismatches, and reliability concerns. Additionally, many advanced metasurface designs utilize exotic materials that are difficult to process using standard semiconductor fabrication techniques.

Packaging and environmental protection represent significant technical limitations. Metasurface antennas are inherently sensitive to their immediate environment, with performance characteristics easily altered by proximity to other components or exposure to environmental factors. Developing protective enclosures that shield these sensitive structures without degrading their electromagnetic performance remains problematic, particularly for applications requiring operation in harsh environments.

Cost-effectiveness constitutes a major barrier to commercial integration. Current fabrication methods for high-performance metasurface antennas often involve expensive equipment and complex multi-step processes. The economic viability of these antennas is further challenged by yield issues and quality control difficulties inherent in manufacturing nanoscale structures.

System-level integration presents unique challenges related to feeding mechanisms and control systems. Efficiently coupling RF energy to metasurface structures requires sophisticated feed networks that must be precisely aligned with the metasurface elements. For tunable or reconfigurable metasurface antennas, the integration of control elements (such as PIN diodes, varactors, or MEMS switches) adds another layer of complexity, requiring careful consideration of biasing networks, control signal routing, and potential electromagnetic interference.

Characterization and testing limitations further complicate development efforts. Standard antenna measurement techniques often prove inadequate for accurately assessing metasurface performance, particularly for near-field effects and complex radiation patterns. The lack of standardized testing methodologies specifically tailored for metasurface antennas hinders meaningful comparison between different designs and technologies.

Material compatibility presents another substantial challenge. Metasurface antennas often incorporate diverse materials with different thermal, mechanical, and electrical properties. The integration of these heterogeneous materials into existing RF systems frequently leads to interface issues, thermal expansion mismatches, and reliability concerns. Additionally, many advanced metasurface designs utilize exotic materials that are difficult to process using standard semiconductor fabrication techniques.

Packaging and environmental protection represent significant technical limitations. Metasurface antennas are inherently sensitive to their immediate environment, with performance characteristics easily altered by proximity to other components or exposure to environmental factors. Developing protective enclosures that shield these sensitive structures without degrading their electromagnetic performance remains problematic, particularly for applications requiring operation in harsh environments.

Cost-effectiveness constitutes a major barrier to commercial integration. Current fabrication methods for high-performance metasurface antennas often involve expensive equipment and complex multi-step processes. The economic viability of these antennas is further challenged by yield issues and quality control difficulties inherent in manufacturing nanoscale structures.

System-level integration presents unique challenges related to feeding mechanisms and control systems. Efficiently coupling RF energy to metasurface structures requires sophisticated feed networks that must be precisely aligned with the metasurface elements. For tunable or reconfigurable metasurface antennas, the integration of control elements (such as PIN diodes, varactors, or MEMS switches) adds another layer of complexity, requiring careful consideration of biasing networks, control signal routing, and potential electromagnetic interference.

Characterization and testing limitations further complicate development efforts. Standard antenna measurement techniques often prove inadequate for accurately assessing metasurface performance, particularly for near-field effects and complex radiation patterns. The lack of standardized testing methodologies specifically tailored for metasurface antennas hinders meaningful comparison between different designs and technologies.

Current Integration Solutions and Implementation Approaches

01 Metasurface design for antenna performance enhancement

Metasurfaces can be designed with specific patterns and structures to enhance antenna performance characteristics such as gain, bandwidth, and radiation efficiency. These engineered surfaces manipulate electromagnetic waves through sub-wavelength elements arranged in specific patterns, enabling beam steering, focusing, and polarization control. Advanced design methodologies incorporate computational techniques to optimize the metasurface structure for specific antenna applications.- Metasurface antenna design principles: Metasurface antennas utilize engineered surfaces with sub-wavelength structures to manipulate electromagnetic waves. These designs incorporate periodic arrangements of resonant elements to achieve desired radiation patterns, beam steering capabilities, and enhanced gain. The metasurface structures can be designed to control phase, amplitude, and polarization of electromagnetic waves, enabling advanced functionalities beyond conventional antennas while maintaining a compact form factor.

- Integration with communication systems: Metasurface antennas can be integrated into various communication systems including 5G/6G networks, satellite communications, and IoT devices. The integration enables improved signal quality, extended coverage range, and enhanced data throughput. These antennas can be configured to operate across multiple frequency bands simultaneously, making them suitable for modern communication systems that require multi-band operation while maintaining a low profile and reduced interference.

- Fabrication and manufacturing techniques: Advanced fabrication techniques for metasurface antennas include printed circuit board technology, MEMS processing, nanolithography, and additive manufacturing. These methods enable precise creation of sub-wavelength structures required for metasurface functionality. Manufacturing processes have been developed to ensure cost-effective mass production while maintaining the precise geometric features necessary for optimal electromagnetic performance. Novel materials including flexible substrates allow for conformal applications on curved surfaces.

- Reconfigurable and tunable metasurface antennas: Reconfigurable metasurface antennas incorporate active components such as PIN diodes, varactors, or MEMS switches to dynamically modify their electromagnetic properties. This enables real-time beam steering, frequency tuning, and polarization control without physical repositioning. The reconfigurability allows a single antenna to adapt to changing communication requirements, environmental conditions, or user needs, making these systems highly versatile for applications requiring adaptive performance.

- Integration with radar and sensing systems: Metasurface antennas can be integrated with radar and sensing systems to enhance detection capabilities, improve resolution, and reduce system size. These integrated solutions enable advanced functionalities such as multi-target tracking, imaging, and environmental monitoring. The metasurface structures can be designed to focus electromagnetic energy in specific directions or create custom radiation patterns optimized for particular sensing applications, while maintaining compatibility with existing signal processing frameworks.

02 Integration of metasurfaces with communication systems

Metasurface antennas can be integrated with various communication systems including 5G/6G networks, satellite communications, and IoT devices. The integration enables improved signal quality, extended coverage range, and enhanced data transmission rates. These systems benefit from the compact form factor of metasurface antennas while achieving superior electromagnetic performance compared to conventional antenna technologies.Expand Specific Solutions03 Reconfigurable and tunable metasurface antennas

Reconfigurable metasurface antennas incorporate active elements such as PIN diodes, varactors, or MEMS switches that enable dynamic control of electromagnetic properties. These designs allow real-time adjustment of operating frequency, radiation pattern, and polarization without physical modification of the antenna structure. The tunability provides adaptability to changing communication requirements and environmental conditions, making these antennas suitable for multi-band and multi-functional applications.Expand Specific Solutions04 Fabrication techniques for metasurface antennas

Advanced fabrication methods for metasurface antennas include printed circuit board technology, microfabrication processes, additive manufacturing, and nanolithography. These techniques enable precise creation of sub-wavelength structures required for effective metasurface operation. Material selection plays a crucial role in fabrication, with options including conventional dielectrics, metamaterials, and novel 2D materials that provide specific electromagnetic properties while maintaining structural integrity and environmental stability.Expand Specific Solutions05 Metasurface antennas for specialized applications

Metasurface antennas are being developed for specialized applications including automotive radar systems, medical imaging devices, aerospace communications, and wearable technology. These applications benefit from the compact size, conformal nature, and high performance of metasurface antennas. Customized designs address specific requirements such as operation in harsh environments, integration with curved surfaces, and compatibility with other electronic components while maintaining electromagnetic performance.Expand Specific Solutions

Leading Companies and Research Institutions in Metasurface Technology

Metasurface antennas represent an emerging technology at the intersection of electromagnetics and materials science, currently in the early growth phase with increasing market adoption. The global market is expanding rapidly, driven by applications in satellite communications, 5G, and defense sectors. Technologically, the field shows varying maturity levels across different applications. Leading research institutions like California Institute of Technology, CNRS, and universities in China are advancing fundamental science, while commercial players demonstrate different specialization levels. Kymeta and Pivotal Commware lead in satellite communications applications with holographic beamforming technology, while established companies like Huawei and Murata Manufacturing integrate metasurface technologies into broader telecommunications portfolios. Defense contractors like Airbus Defence & Space are exploring military applications, indicating the technology's strategic importance across multiple sectors.

Kymeta Corp.

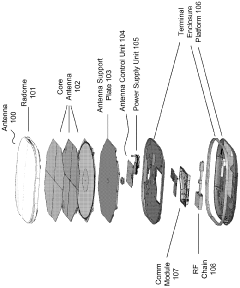

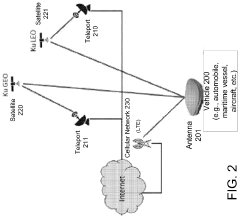

Technical Solution: Kymeta has developed a revolutionary approach to metasurface antenna integration through their mTenna technology platform. Their solution utilizes liquid crystal-based reconfigurable metasurfaces that enable electronic beam steering without traditional mechanical components. The technology employs a holographic principle where the metasurface is dynamically tuned to form specific radiation patterns by controlling the liquid crystal elements with applied voltage. This creates a software-defined antenna capable of tracking satellites in motion. Kymeta's integration approach addresses challenges through a modular design architecture that separates the metasurface layer from the control electronics, allowing for simplified manufacturing and maintenance. Their u8 terminal incorporates this technology with integrated modems and services, demonstrating a complete system solution that overcomes traditional integration barriers between RF components and digital control systems[1][2].

Strengths: Eliminates moving parts, reducing mechanical failures; enables low-profile form factors suitable for mobile platforms; provides software-defined flexibility for multi-band operation. Weaknesses: Higher power consumption compared to passive antennas; liquid crystal technology has temperature sensitivity limitations; manufacturing complexity increases costs compared to conventional antennas.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has pioneered an integrated approach to metasurface antenna challenges through their "MetaEngine" architecture. This solution combines reconfigurable intelligent surfaces (RIS) with advanced signal processing to enhance 5G/6G network performance. Their metasurface implementation utilizes PIN diodes and varactor-based unit cells arranged in programmable arrays that can be dynamically reconfigured through digital control signals. Huawei's integration strategy addresses manufacturing challenges by developing specialized ASIC controllers that manage thousands of metasurface elements with reduced complexity. They've implemented a hierarchical control architecture that divides the metasurface into independently addressable sub-arrays, significantly reducing control line complexity. For thermal management, Huawei employs a passive cooling solution with specialized thermal interface materials between the active elements and heat dissipation layers. Their approach also includes advanced calibration algorithms that compensate for manufacturing variations and environmental effects[3][4].

Strengths: Highly scalable architecture suitable for various deployment scenarios; excellent integration with existing network infrastructure; sophisticated digital control enables adaptive beamforming capabilities. Weaknesses: Higher power consumption than passive solutions; complex calibration requirements for optimal performance; potential interference issues in dense deployment scenarios requiring additional coordination mechanisms.

Key Patents and Research Breakthroughs in Metasurface Integration

Active metasurface architectures

PatentWO2024127193A1

Innovation

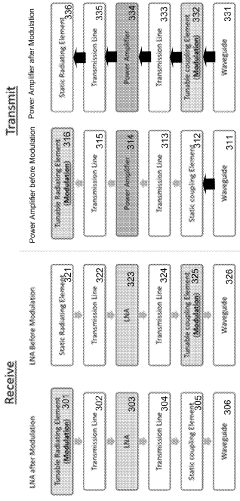

- Incorporating low noise amplifiers (LNAs) and power amplifiers (PAs) into the metasurface to amplify signals closer to the radiating elements, distributing power and heat more evenly, and replacing central amplifiers with distributed arrays for reduced size and cost.

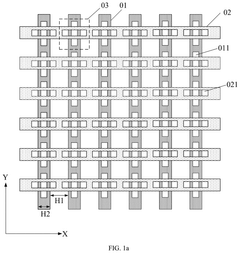

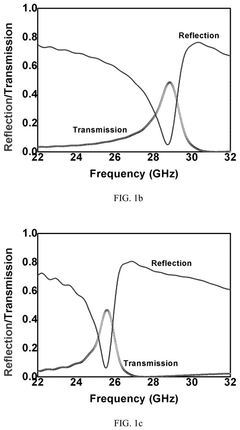

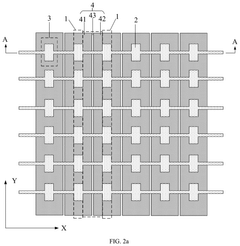

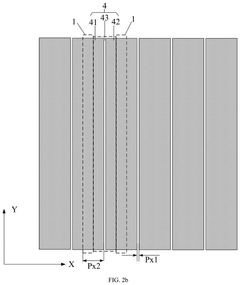

Meta-surface, antenna module, and electronic device

PatentPendingUS20240364016A1

Innovation

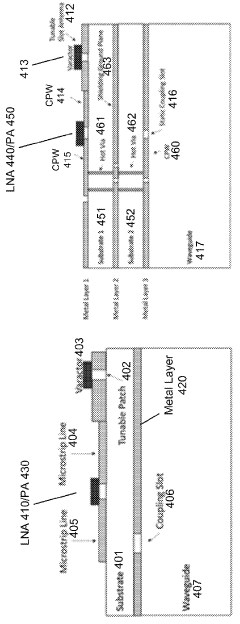

- A meta-surface design is introduced, featuring a tunable dielectric layer between two substrates with electrode layers and a filling structure that reduces the gap between electrode strips, increasing capacitance and radiation area, thereby improving transmission and reflection efficiency.

Manufacturing Scalability and Cost Considerations

The manufacturing scalability of metasurface antennas represents a critical challenge in their widespread adoption across commercial applications. Current fabrication methods predominantly rely on cleanroom-based techniques such as electron-beam lithography and photolithography, which offer excellent precision but at prohibitively high costs for mass production. These processes typically require specialized equipment investments exceeding $1-5 million and involve time-consuming sequential patterning that limits throughput to small-area samples.

Cost considerations extend beyond equipment to include operational expenses, with cleanroom maintenance averaging $500-1000 per square foot annually. Material selection further impacts manufacturing economics, as traditional noble metals like gold and silver provide excellent electromagnetic performance but at premium prices. Alternative materials such as aluminum and copper offer cost advantages but may introduce performance trade-offs that must be carefully balanced against economic benefits.

Emerging manufacturing approaches show promise for addressing these scalability challenges. Roll-to-roll nanoimprint lithography demonstrates potential for continuous production of metasurface antennas on flexible substrates at rates exceeding 10 m²/min. Similarly, large-area soft lithography techniques have achieved feature resolutions below 100 nm across areas exceeding 300 mm diameter, representing significant progress toward industrial-scale production.

Additive manufacturing technologies, particularly direct laser writing and aerosol jet printing, are evolving to enable customized metasurface production with reduced material waste. These approaches offer particular advantages for low-to-medium volume applications where design flexibility outweighs the economies of scale provided by traditional manufacturing methods.

The economic viability of metasurface antennas ultimately depends on achieving a sustainable balance between performance requirements and manufacturing costs. Industry analysis suggests that unit costs must decrease by approximately 60-80% from current research-grade prototypes to enable competitive commercial deployment. This cost reduction pathway will likely require hybrid manufacturing approaches that combine high-precision patterning for critical features with more economical processes for non-critical elements.

Standardization efforts across the supply chain represent another crucial factor in manufacturing scalability. The development of common design rules, material specifications, and quality control methodologies would facilitate more efficient production scaling and potentially enable specialized manufacturing facilities to serve multiple application domains, thereby distributing capital equipment costs across a broader product portfolio.

Cost considerations extend beyond equipment to include operational expenses, with cleanroom maintenance averaging $500-1000 per square foot annually. Material selection further impacts manufacturing economics, as traditional noble metals like gold and silver provide excellent electromagnetic performance but at premium prices. Alternative materials such as aluminum and copper offer cost advantages but may introduce performance trade-offs that must be carefully balanced against economic benefits.

Emerging manufacturing approaches show promise for addressing these scalability challenges. Roll-to-roll nanoimprint lithography demonstrates potential for continuous production of metasurface antennas on flexible substrates at rates exceeding 10 m²/min. Similarly, large-area soft lithography techniques have achieved feature resolutions below 100 nm across areas exceeding 300 mm diameter, representing significant progress toward industrial-scale production.

Additive manufacturing technologies, particularly direct laser writing and aerosol jet printing, are evolving to enable customized metasurface production with reduced material waste. These approaches offer particular advantages for low-to-medium volume applications where design flexibility outweighs the economies of scale provided by traditional manufacturing methods.

The economic viability of metasurface antennas ultimately depends on achieving a sustainable balance between performance requirements and manufacturing costs. Industry analysis suggests that unit costs must decrease by approximately 60-80% from current research-grade prototypes to enable competitive commercial deployment. This cost reduction pathway will likely require hybrid manufacturing approaches that combine high-precision patterning for critical features with more economical processes for non-critical elements.

Standardization efforts across the supply chain represent another crucial factor in manufacturing scalability. The development of common design rules, material specifications, and quality control methodologies would facilitate more efficient production scaling and potentially enable specialized manufacturing facilities to serve multiple application domains, thereby distributing capital equipment costs across a broader product portfolio.

Electromagnetic Compatibility and Regulatory Standards

The integration of metasurface antennas into commercial and military systems necessitates strict adherence to electromagnetic compatibility (EMC) standards and regulatory frameworks. These standards ensure that devices operate without causing harmful interference to other systems while maintaining resilience against external electromagnetic disturbances.

Metasurface antennas present unique EMC challenges due to their complex electromagnetic field distributions and potential for unintended radiation patterns. The highly resonant nature of metasurface structures can lead to increased susceptibility to external electromagnetic interference (EMI) and may generate unexpected harmonic emissions that must be carefully managed to meet regulatory requirements.

International regulatory bodies such as the Federal Communications Commission (FCC), European Telecommunications Standards Institute (ETSI), and International Telecommunication Union (ITU) have established specific emission limits across various frequency bands. Metasurface antenna designers must navigate these regulations, which often vary by region and application domain. For instance, automotive radar applications utilizing metasurface technology must comply with standards like CISPR 25, while consumer electronics implementations must adhere to FCC Part 15 or EN 55032.

Testing methodologies for metasurface antennas require adaptation of traditional EMC assessment protocols. Standard test procedures may not adequately capture the unique radiation characteristics of metasurfaces, necessitating specialized test setups and measurement techniques. Near-field scanning and spherical measurement systems have proven particularly valuable for characterizing the complex field patterns generated by these advanced antenna structures.

Shielding and isolation strategies represent critical design considerations for metasurface integration. Techniques such as electromagnetic bandgap structures, frequency selective surfaces, and metamaterial absorbers can be implemented to mitigate unwanted coupling and radiation. These approaches must be incorporated early in the design process rather than as afterthoughts to ensure compliance without compromising performance.

The dynamic reconfigurability of certain metasurface designs introduces additional regulatory complexities. Systems capable of beam steering or frequency tuning must maintain compliance across their entire operational envelope, requiring comprehensive testing across multiple configurations and operating modes. Software-defined control systems for reconfigurable metasurfaces must incorporate safeguards to prevent operation in unauthorized frequency bands or power levels.

Looking forward, regulatory frameworks are evolving to address emerging technologies like metasurface antennas. Industry stakeholders are actively participating in standards development organizations to establish testing methodologies and compliance guidelines specifically tailored to metasurface implementations. This collaborative approach will be essential for facilitating broader adoption while ensuring electromagnetic compatibility in increasingly crowded spectral environments.

Metasurface antennas present unique EMC challenges due to their complex electromagnetic field distributions and potential for unintended radiation patterns. The highly resonant nature of metasurface structures can lead to increased susceptibility to external electromagnetic interference (EMI) and may generate unexpected harmonic emissions that must be carefully managed to meet regulatory requirements.

International regulatory bodies such as the Federal Communications Commission (FCC), European Telecommunications Standards Institute (ETSI), and International Telecommunication Union (ITU) have established specific emission limits across various frequency bands. Metasurface antenna designers must navigate these regulations, which often vary by region and application domain. For instance, automotive radar applications utilizing metasurface technology must comply with standards like CISPR 25, while consumer electronics implementations must adhere to FCC Part 15 or EN 55032.

Testing methodologies for metasurface antennas require adaptation of traditional EMC assessment protocols. Standard test procedures may not adequately capture the unique radiation characteristics of metasurfaces, necessitating specialized test setups and measurement techniques. Near-field scanning and spherical measurement systems have proven particularly valuable for characterizing the complex field patterns generated by these advanced antenna structures.

Shielding and isolation strategies represent critical design considerations for metasurface integration. Techniques such as electromagnetic bandgap structures, frequency selective surfaces, and metamaterial absorbers can be implemented to mitigate unwanted coupling and radiation. These approaches must be incorporated early in the design process rather than as afterthoughts to ensure compliance without compromising performance.

The dynamic reconfigurability of certain metasurface designs introduces additional regulatory complexities. Systems capable of beam steering or frequency tuning must maintain compliance across their entire operational envelope, requiring comprehensive testing across multiple configurations and operating modes. Software-defined control systems for reconfigurable metasurfaces must incorporate safeguards to prevent operation in unauthorized frequency bands or power levels.

Looking forward, regulatory frameworks are evolving to address emerging technologies like metasurface antennas. Industry stakeholders are actively participating in standards development organizations to establish testing methodologies and compliance guidelines specifically tailored to metasurface implementations. This collaborative approach will be essential for facilitating broader adoption while ensuring electromagnetic compatibility in increasingly crowded spectral environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!