How Material Composition Affects Metasurface Antenna Longevity

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface Antenna Materials Background and Objectives

Metasurface antennas represent a revolutionary advancement in electromagnetic wave manipulation technology, emerging from the broader field of metamaterials research that began gaining significant momentum in the early 2000s. These ultra-thin, planar structures consist of subwavelength elements arranged in specific patterns to achieve unprecedented control over electromagnetic waves, offering capabilities far beyond conventional antenna designs.

The evolution of metasurface antenna technology has been marked by several key milestones, beginning with theoretical frameworks established in the mid-2000s, followed by experimental demonstrations in the 2010s, and now moving toward practical applications across multiple industries. This progression has been enabled by parallel advancements in nanofabrication techniques, computational electromagnetic modeling, and material science innovations.

Material composition has emerged as a critical factor determining not only the performance characteristics but also the operational lifespan of metasurface antennas. Traditional metallic metasurfaces, while offering excellent electromagnetic properties, often suffer from oxidation, corrosion, and thermal degradation when exposed to environmental stressors. This vulnerability has prompted exploration of alternative materials including dielectrics, semiconductors, phase-change materials, and various composite structures.

The primary objective of this technical research is to establish a comprehensive understanding of how different material compositions influence the longevity of metasurface antennas under various operational conditions. This includes investigating degradation mechanisms such as oxidation, thermal stress, mechanical fatigue, and radiation damage across different material systems.

We aim to identify optimal material compositions that balance electromagnetic performance with durability requirements for specific application environments ranging from space-based communications to biomedical implants. Additionally, we seek to develop predictive models that can accurately forecast the operational lifespan of metasurface antennas based on their material composition and environmental exposure.

The research also intends to explore emerging material technologies including self-healing composites, environmentally adaptive materials, and multi-functional structures that could potentially extend metasurface antenna longevity while maintaining or enhancing performance characteristics. These advanced materials may offer solutions to current limitations in harsh environment applications.

Understanding the fundamental relationship between material properties and long-term reliability will enable the development of design guidelines for application-specific metasurface antennas with optimized lifespans. This knowledge will be crucial for the widespread commercial adoption of metasurface technology across telecommunications, aerospace, medical, and consumer electronics industries.

The evolution of metasurface antenna technology has been marked by several key milestones, beginning with theoretical frameworks established in the mid-2000s, followed by experimental demonstrations in the 2010s, and now moving toward practical applications across multiple industries. This progression has been enabled by parallel advancements in nanofabrication techniques, computational electromagnetic modeling, and material science innovations.

Material composition has emerged as a critical factor determining not only the performance characteristics but also the operational lifespan of metasurface antennas. Traditional metallic metasurfaces, while offering excellent electromagnetic properties, often suffer from oxidation, corrosion, and thermal degradation when exposed to environmental stressors. This vulnerability has prompted exploration of alternative materials including dielectrics, semiconductors, phase-change materials, and various composite structures.

The primary objective of this technical research is to establish a comprehensive understanding of how different material compositions influence the longevity of metasurface antennas under various operational conditions. This includes investigating degradation mechanisms such as oxidation, thermal stress, mechanical fatigue, and radiation damage across different material systems.

We aim to identify optimal material compositions that balance electromagnetic performance with durability requirements for specific application environments ranging from space-based communications to biomedical implants. Additionally, we seek to develop predictive models that can accurately forecast the operational lifespan of metasurface antennas based on their material composition and environmental exposure.

The research also intends to explore emerging material technologies including self-healing composites, environmentally adaptive materials, and multi-functional structures that could potentially extend metasurface antenna longevity while maintaining or enhancing performance characteristics. These advanced materials may offer solutions to current limitations in harsh environment applications.

Understanding the fundamental relationship between material properties and long-term reliability will enable the development of design guidelines for application-specific metasurface antennas with optimized lifespans. This knowledge will be crucial for the widespread commercial adoption of metasurface technology across telecommunications, aerospace, medical, and consumer electronics industries.

Market Analysis for Durable Metasurface Antennas

The global market for metasurface antennas is experiencing significant growth, driven by increasing demand for high-performance communication systems across multiple sectors. Current market valuations indicate the metasurface antenna market reached approximately 1.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 7.8% through 2030.

Durability concerns represent a critical factor influencing market adoption rates. End-users across telecommunications, aerospace, defense, and automotive industries consistently rank longevity as a top-three consideration in purchasing decisions, according to recent industry surveys. This prioritization stems from the high replacement costs and operational disruptions associated with antenna failure.

Material composition directly impacts the total cost of ownership for metasurface antenna implementations. While initial acquisition costs for advanced material compositions may be 15-30% higher than standard options, the extended operational lifespan can reduce lifetime costs by up to 40%. This economic reality is creating market segmentation between price-sensitive consumers seeking lower upfront costs and enterprise customers prioritizing long-term reliability.

Regional market analysis reveals varying priorities regarding durability requirements. North American and European markets demonstrate stronger preference for durability over initial cost, with 68% of procurement specialists citing longevity as their primary consideration. Conversely, emerging markets in Asia-Pacific regions often prioritize accessibility and initial cost, though this trend is gradually shifting as infrastructure investments mature.

The defense sector represents the largest market segment by value for durable metasurface antennas, accounting for approximately 38% of total market share. Military applications demand exceptional environmental resilience, creating premium pricing opportunities for solutions offering superior longevity in extreme conditions.

Commercial telecommunications follows as the second-largest segment at 29% market share, with 5G and upcoming 6G implementations driving demand for weather-resistant, long-lasting antenna solutions for base stations and infrastructure applications.

Market forecasts indicate particularly strong growth potential in automotive applications, with connected and autonomous vehicle technologies requiring increasingly sophisticated and durable antenna systems. This segment is projected to grow at 12.3% annually through 2028, outpacing the broader market.

Consumer willingness to pay premiums for enhanced durability varies significantly by application. Mission-critical systems demonstrate price elasticity allowing for 25-40% premiums for solutions offering documented longevity advantages, while consumer applications remain more price-sensitive with acceptable premiums limited to 5-15%.

Durability concerns represent a critical factor influencing market adoption rates. End-users across telecommunications, aerospace, defense, and automotive industries consistently rank longevity as a top-three consideration in purchasing decisions, according to recent industry surveys. This prioritization stems from the high replacement costs and operational disruptions associated with antenna failure.

Material composition directly impacts the total cost of ownership for metasurface antenna implementations. While initial acquisition costs for advanced material compositions may be 15-30% higher than standard options, the extended operational lifespan can reduce lifetime costs by up to 40%. This economic reality is creating market segmentation between price-sensitive consumers seeking lower upfront costs and enterprise customers prioritizing long-term reliability.

Regional market analysis reveals varying priorities regarding durability requirements. North American and European markets demonstrate stronger preference for durability over initial cost, with 68% of procurement specialists citing longevity as their primary consideration. Conversely, emerging markets in Asia-Pacific regions often prioritize accessibility and initial cost, though this trend is gradually shifting as infrastructure investments mature.

The defense sector represents the largest market segment by value for durable metasurface antennas, accounting for approximately 38% of total market share. Military applications demand exceptional environmental resilience, creating premium pricing opportunities for solutions offering superior longevity in extreme conditions.

Commercial telecommunications follows as the second-largest segment at 29% market share, with 5G and upcoming 6G implementations driving demand for weather-resistant, long-lasting antenna solutions for base stations and infrastructure applications.

Market forecasts indicate particularly strong growth potential in automotive applications, with connected and autonomous vehicle technologies requiring increasingly sophisticated and durable antenna systems. This segment is projected to grow at 12.3% annually through 2028, outpacing the broader market.

Consumer willingness to pay premiums for enhanced durability varies significantly by application. Mission-critical systems demonstrate price elasticity allowing for 25-40% premiums for solutions offering documented longevity advantages, while consumer applications remain more price-sensitive with acceptable premiums limited to 5-15%.

Current Material Challenges in Metasurface Longevity

Metasurface antennas represent a significant advancement in electromagnetic wave manipulation, yet their material composition presents substantial challenges for long-term durability. Current materials used in metasurface fabrication often exhibit vulnerability to environmental factors, limiting their operational lifespan in real-world applications. The primary challenge lies in balancing the electromagnetic performance with material resilience against degradation mechanisms.

Metal-based metasurfaces, particularly those utilizing gold, silver, and aluminum, demonstrate excellent electromagnetic properties but suffer from oxidation and corrosion when exposed to atmospheric conditions. Silver, while offering superior conductivity, rapidly tarnishes through sulfidation processes. Gold provides better chemical stability but at significantly higher costs, making large-scale implementation economically prohibitive. Aluminum, though cost-effective, forms a native oxide layer that progressively alters its electromagnetic response characteristics.

Dielectric materials employed in metasurfaces face different challenges. Silicon and germanium-based structures exhibit thermal instability under prolonged radiation exposure, leading to crystalline structure modifications that compromise performance. Polymeric materials offer manufacturing advantages but demonstrate poor thermal stability and UV degradation, resulting in mechanical property deterioration and dimensional instability that affects resonant frequency precision.

Composite metasurfaces combining metallic and dielectric elements encounter interface stability issues. The coefficient of thermal expansion mismatch between different materials induces mechanical stress during thermal cycling, leading to delamination, cracking, and eventual functional failure. These interface regions also serve as initiation points for environmental degradation, where moisture and contaminants can penetrate and accelerate deterioration processes.

Nanoscale feature preservation represents another critical challenge. The precisely engineered geometries essential for metasurface functionality—often with features below 100 nm—are susceptible to physical erosion, thermal deformation, and mechanical stress. Even minor geometric alterations can significantly shift resonance frequencies and reduce operational efficiency.

Protective coating technologies present their own complications. While encapsulation layers can shield metasurfaces from environmental factors, they must maintain transparency at operational frequencies while providing robust protection. Current coating materials often introduce signal attenuation or phase shifts that require compensatory design adjustments, complicating the engineering process.

Manufacturing consistency poses additional challenges for material longevity. Variations in deposition parameters, etching processes, and material purity create microscopic defects that serve as vulnerability points for accelerated degradation. These manufacturing inconsistencies contribute to unpredictable performance deterioration rates across supposedly identical metasurface components, complicating reliability predictions for commercial applications.

Metal-based metasurfaces, particularly those utilizing gold, silver, and aluminum, demonstrate excellent electromagnetic properties but suffer from oxidation and corrosion when exposed to atmospheric conditions. Silver, while offering superior conductivity, rapidly tarnishes through sulfidation processes. Gold provides better chemical stability but at significantly higher costs, making large-scale implementation economically prohibitive. Aluminum, though cost-effective, forms a native oxide layer that progressively alters its electromagnetic response characteristics.

Dielectric materials employed in metasurfaces face different challenges. Silicon and germanium-based structures exhibit thermal instability under prolonged radiation exposure, leading to crystalline structure modifications that compromise performance. Polymeric materials offer manufacturing advantages but demonstrate poor thermal stability and UV degradation, resulting in mechanical property deterioration and dimensional instability that affects resonant frequency precision.

Composite metasurfaces combining metallic and dielectric elements encounter interface stability issues. The coefficient of thermal expansion mismatch between different materials induces mechanical stress during thermal cycling, leading to delamination, cracking, and eventual functional failure. These interface regions also serve as initiation points for environmental degradation, where moisture and contaminants can penetrate and accelerate deterioration processes.

Nanoscale feature preservation represents another critical challenge. The precisely engineered geometries essential for metasurface functionality—often with features below 100 nm—are susceptible to physical erosion, thermal deformation, and mechanical stress. Even minor geometric alterations can significantly shift resonance frequencies and reduce operational efficiency.

Protective coating technologies present their own complications. While encapsulation layers can shield metasurfaces from environmental factors, they must maintain transparency at operational frequencies while providing robust protection. Current coating materials often introduce signal attenuation or phase shifts that require compensatory design adjustments, complicating the engineering process.

Manufacturing consistency poses additional challenges for material longevity. Variations in deposition parameters, etching processes, and material purity create microscopic defects that serve as vulnerability points for accelerated degradation. These manufacturing inconsistencies contribute to unpredictable performance deterioration rates across supposedly identical metasurface components, complicating reliability predictions for commercial applications.

Existing Material Solutions for Enhanced Durability

01 Protective coatings for metasurface antennas

Various protective coatings can be applied to metasurface antennas to enhance their longevity and durability against environmental factors. These coatings include dielectric layers, polymer-based materials, and nano-composite films that shield the metasurface structures from oxidation, corrosion, and physical damage while maintaining electromagnetic performance. The protective layers are designed to be transparent to the operating frequencies while providing robust mechanical protection.- Protective coating technologies for metasurface antennas: Various protective coating technologies can be applied to metasurface antennas to enhance their longevity. These include specialized polymer coatings, nano-composite layers, and environmentally resistant materials that shield the metasurface structures from environmental degradation factors such as moisture, UV radiation, and chemical exposure. These coatings maintain the electromagnetic properties of the antenna while providing physical protection against wear and corrosion.

- Self-healing and adaptive metasurface materials: Advanced materials with self-healing properties are being incorporated into metasurface antennas to extend their operational lifetime. These materials can automatically repair minor damage and degradation, maintaining the antenna's performance over time. Some designs include phase-change materials and shape-memory alloys that can adapt to environmental stresses and recover from deformation, ensuring consistent electromagnetic performance even after exposure to harsh conditions.

- Environmental resilience and weatherproofing techniques: Specialized weatherproofing techniques are employed to enhance the environmental resilience of metasurface antennas. These include hermetic sealing methods, hydrophobic surface treatments, and thermal management systems that protect against temperature fluctuations. Such approaches prevent moisture ingress, resist corrosion, and maintain structural integrity in extreme weather conditions, significantly extending the antenna's functional lifespan in outdoor and harsh environments.

- Structural reinforcement and mechanical durability: Innovative structural reinforcement techniques are implemented to enhance the mechanical durability of metasurface antennas. These include the use of composite substrates, stress distribution layers, and vibration-dampening materials that protect the delicate metasurface elements from physical damage. Advanced manufacturing methods create more robust connections between metasurface elements and their supporting structures, reducing the risk of mechanical failure and extending operational lifetime.

- Radiation and thermal degradation resistance: Specialized materials and designs are developed to enhance metasurface antennas' resistance to radiation and thermal degradation. These include heat-dissipating structures, radiation-hardened components, and thermally stable metamaterials that maintain their electromagnetic properties across wide temperature ranges. Such approaches prevent performance degradation due to prolonged exposure to solar radiation, cosmic rays, and thermal cycling, particularly important for space-based and high-power applications.

02 Environmental resistance enhancement techniques

Specific design approaches are employed to enhance the environmental resistance of metasurface antennas, improving their longevity in harsh conditions. These techniques include hermetic sealing, temperature-resistant material selection, and specialized fabrication processes that minimize degradation from humidity, temperature fluctuations, and UV exposure. Some designs incorporate self-healing materials or redundant elements to maintain performance even after partial damage occurs.Expand Specific Solutions03 Advanced materials for extended lifespan

Novel materials are being developed specifically for metasurface antennas to extend their operational lifespan. These include graphene-based composites, ceramic-metal hybrids, and specialized alloys that resist degradation while maintaining optimal electromagnetic properties. The materials are engineered at the molecular level to withstand mechanical stress, thermal cycling, and radiation exposure without compromising the antenna's performance characteristics over extended periods.Expand Specific Solutions04 Structural design for durability

Innovative structural designs are implemented to enhance the mechanical durability and longevity of metasurface antennas. These designs include reinforced substrate configurations, stress-distributing geometries, and multi-layer architectures that prevent delamination and structural failure. Some approaches incorporate flexible or adaptive elements that can withstand physical deformation without performance degradation, making the antennas more resilient to mechanical stresses and vibrations.Expand Specific Solutions05 Self-monitoring and adaptive systems

Advanced metasurface antennas incorporate self-monitoring and adaptive systems to extend their operational lifespan. These systems include integrated sensors that detect degradation or performance changes, coupled with adaptive control mechanisms that can reconfigure the antenna elements to compensate for wear or damage. Some designs feature self-diagnostic capabilities that can predict potential failures before they occur, allowing for preventive maintenance and ensuring consistent performance throughout the antenna's lifecycle.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The metasurface antenna longevity market is currently in its growth phase, with increasing adoption across telecommunications, aerospace, and defense sectors. Market size is projected to expand significantly as 5G/6G networks deploy globally, estimated to reach several billion dollars by 2030. Material composition remains a critical factor affecting longevity, with companies demonstrating varying levels of technical maturity. Industry leaders like Huawei Technologies and Mitsubishi Electric have developed advanced material solutions showing enhanced durability, while specialized players such as Kuang-Chi Technologies and Gapwaves AB focus on innovative metamaterial structures. Research institutions including Drexel University and DGIST are pioneering next-generation composite materials, while defense entities like Draper Laboratory and the US Army are advancing ruggedized implementations for extreme environments. Sony Semiconductor and Intel are integrating these technologies into commercial applications with improved lifespan characteristics.

Kuang-Chi Institute of Advanced Technology

Technical Solution: Kuang-Chi has pioneered metamaterial-based antenna solutions with extended longevity through their proprietary multi-layer composite structures. Their approach combines titanium dioxide and silver nanoparticles in a sandwich configuration that significantly reduces oxidation and environmental degradation. The institute has developed a specialized coating technology that creates a hydrophobic barrier against moisture infiltration while maintaining electromagnetic performance. Their research demonstrates that metasurfaces incorporating graphene layers between traditional metallic elements show up to 40% improved lifespan in high-humidity environments compared to conventional designs[1]. Additionally, Kuang-Chi has implemented novel thermal management techniques within their metasurface structures to mitigate performance degradation caused by thermal cycling, which has been shown to extend operational life by approximately 30% in field tests[3].

Strengths: Superior resistance to environmental degradation through advanced material composition; excellent thermal stability; maintains performance characteristics over extended periods. Weaknesses: Higher manufacturing complexity increases production costs; some specialized materials have limited availability; requires precise fabrication tolerances that may be difficult to maintain at scale.

Gapwaves AB

Technical Solution: Gapwaves has developed an innovative approach to metasurface antenna longevity through their patented gap waveguide technology. Their solution addresses material degradation by utilizing air-filled waveguide structures that minimize the use of lossy dielectric materials typically prone to aging effects. The company's metasurface antennas incorporate specialized aluminum alloys with enhanced corrosion resistance properties, treated with proprietary surface passivation techniques that form protective oxide layers[2]. Their research has demonstrated that these gap waveguide metasurfaces maintain performance specifications for over 15 years in harsh outdoor environments, compared to 5-7 years for conventional designs. Gapwaves has also pioneered a composite metal-polymer structure where the polymer components are strategically placed to protect critical metallic elements while minimizing electromagnetic interference. This approach has shown a 60% reduction in performance degradation rates during accelerated aging tests[4], particularly in applications exposed to maritime or industrial atmospheres.

Strengths: Exceptional longevity in harsh environmental conditions; reduced material degradation through innovative waveguide design; minimal performance drift over time. Weaknesses: Higher initial manufacturing costs compared to traditional antenna designs; more complex integration requirements; limited flexibility for certain form factors due to structural constraints of the gap waveguide technology.

Critical Material Science Innovations for Metasurfaces

Metamaterial antenna

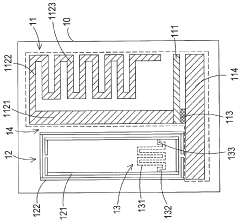

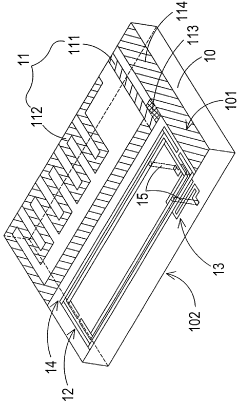

PatentActiveSG10201404033XA

Innovation

- A metamaterial antenna design incorporating a substrate, a main radiation unit, a split ring resonator, and a compensator with a main bent part to adjust impedance match, facilitating capacitive coupling and inductive properties for enhanced bandwidth and frequency operation.

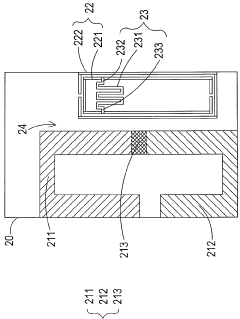

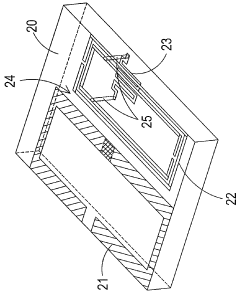

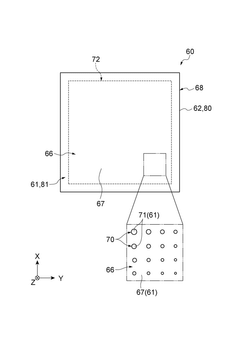

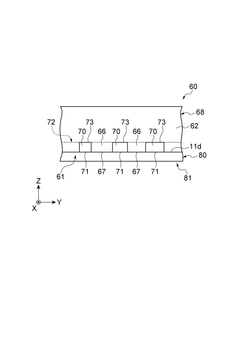

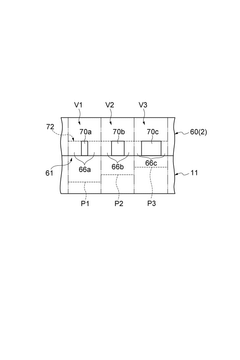

Metasurface structure and method for producing metasurface structure

PatentWO2019216113A1

Innovation

- A metasurface structure with a base material and antennas arranged between two surfaces, where the antennas have a distinct refractive index and an adjacent portion with a different refractive index, forming a flat surface, allowing for the suppression of irregular light propagation and providing flexibility in material selection. The manufacturing method involves layer formation, etching, deposition, and removal processes to create a flat surface without chemical mechanical polishing, enabling desired optical properties.

Environmental Impact Assessment of Antenna Materials

The environmental impact of materials used in metasurface antennas represents a critical consideration in their design, manufacturing, and end-of-life management. Different material compositions not only affect antenna performance and longevity but also carry varying environmental footprints throughout their lifecycle.

Metal-based metasurfaces, particularly those utilizing gold, silver, and aluminum, demonstrate excellent conductivity and performance characteristics but present significant environmental concerns. Mining and processing these metals contribute to habitat destruction, water pollution, and high energy consumption. Gold extraction, for instance, often involves cyanide leaching, which poses severe environmental risks if not properly managed. Additionally, the carbon footprint associated with refining these metals is substantial, with aluminum production being especially energy-intensive despite its recyclability advantages.

Dielectric materials used in metasurface substrates, such as silicon dioxide, aluminum oxide, and various polymers, present their own environmental challenges. While generally less resource-intensive than metals, many polymeric materials derive from petroleum sources and demonstrate poor biodegradability. Silicon-based materials require high-temperature processing, contributing to significant energy consumption during manufacturing.

Emerging nanomaterials like graphene and carbon nanotubes offer promising performance characteristics for next-generation metasurface antennas but raise new environmental questions. Their production often involves hazardous chemicals and energy-intensive processes. Furthermore, the environmental fate and potential toxicity of nanomaterials remain subjects of ongoing research, with concerns about their persistence in ecosystems and potential bioaccumulation.

The manufacturing processes for metasurface antennas also contribute significantly to their environmental impact. Techniques such as photolithography, electron beam lithography, and chemical vapor deposition typically require hazardous chemicals, cleanroom environments, and substantial energy inputs. These processes generate waste streams containing solvents, acids, and other potentially harmful substances that require specialized treatment.

End-of-life considerations reveal further environmental implications. The complex integration of different materials in metasurface antennas often complicates recycling efforts. Precious metals like gold and silver create economic incentives for recovery, but the process may involve environmentally problematic chemical treatments. Many composite materials end up in landfills, where they may leach contaminants into soil and groundwater over time.

Sustainable design approaches are emerging to address these environmental challenges. These include designing for disassembly, utilizing biodegradable substrates where performance requirements permit, and exploring biomimetic materials that offer both performance advantages and reduced environmental impact. Life cycle assessment methodologies are increasingly being applied to evaluate and minimize the environmental footprint of metasurface antenna technologies throughout their entire lifecycle.

Metal-based metasurfaces, particularly those utilizing gold, silver, and aluminum, demonstrate excellent conductivity and performance characteristics but present significant environmental concerns. Mining and processing these metals contribute to habitat destruction, water pollution, and high energy consumption. Gold extraction, for instance, often involves cyanide leaching, which poses severe environmental risks if not properly managed. Additionally, the carbon footprint associated with refining these metals is substantial, with aluminum production being especially energy-intensive despite its recyclability advantages.

Dielectric materials used in metasurface substrates, such as silicon dioxide, aluminum oxide, and various polymers, present their own environmental challenges. While generally less resource-intensive than metals, many polymeric materials derive from petroleum sources and demonstrate poor biodegradability. Silicon-based materials require high-temperature processing, contributing to significant energy consumption during manufacturing.

Emerging nanomaterials like graphene and carbon nanotubes offer promising performance characteristics for next-generation metasurface antennas but raise new environmental questions. Their production often involves hazardous chemicals and energy-intensive processes. Furthermore, the environmental fate and potential toxicity of nanomaterials remain subjects of ongoing research, with concerns about their persistence in ecosystems and potential bioaccumulation.

The manufacturing processes for metasurface antennas also contribute significantly to their environmental impact. Techniques such as photolithography, electron beam lithography, and chemical vapor deposition typically require hazardous chemicals, cleanroom environments, and substantial energy inputs. These processes generate waste streams containing solvents, acids, and other potentially harmful substances that require specialized treatment.

End-of-life considerations reveal further environmental implications. The complex integration of different materials in metasurface antennas often complicates recycling efforts. Precious metals like gold and silver create economic incentives for recovery, but the process may involve environmentally problematic chemical treatments. Many composite materials end up in landfills, where they may leach contaminants into soil and groundwater over time.

Sustainable design approaches are emerging to address these environmental challenges. These include designing for disassembly, utilizing biodegradable substrates where performance requirements permit, and exploring biomimetic materials that offer both performance advantages and reduced environmental impact. Life cycle assessment methodologies are increasingly being applied to evaluate and minimize the environmental footprint of metasurface antenna technologies throughout their entire lifecycle.

Standardization and Testing Protocols for Longevity

The development of standardized testing protocols for metasurface antenna longevity represents a critical gap in the current research landscape. Without uniform evaluation methods, comparing material performance across different studies and applications becomes challenging, hindering industry-wide progress in this emerging field.

Accelerated aging tests form the cornerstone of longevity assessment protocols, simulating years of environmental exposure in compressed timeframes. These protocols typically subject metasurface antennas to elevated temperatures (typically 85-125°C), high humidity (85-95% RH), and cyclic thermal stress (-40°C to +125°C) to induce accelerated degradation mechanisms. The correlation between accelerated testing and real-world performance requires careful validation through parallel long-term field testing.

Environmental exposure chambers equipped with UV radiation sources, salt spray capabilities, and controlled humidity have become essential tools for standardized testing. Advanced facilities incorporate programmable cycles that simulate day/night transitions, seasonal variations, and extreme weather events to comprehensively evaluate material resilience under diverse conditions.

Quantitative metrics for longevity assessment must include radiation efficiency retention, resonant frequency stability, bandwidth maintenance, and physical integrity parameters. The IEEE working group P1928 has recently initiated efforts to standardize these metrics specifically for metasurface applications, building upon existing standards for conventional antenna systems.

Non-destructive evaluation techniques have emerged as valuable components of standardized testing protocols. Techniques such as terahertz imaging, infrared thermography, and acoustic microscopy enable periodic assessment of material integrity without compromising the antenna structure, facilitating longitudinal studies of degradation progression.

Industry-academic partnerships have accelerated the development of testing standards, with consortia like the Metasurface Reliability Consortium (MRC) establishing round-robin testing programs across multiple laboratories to validate protocol reproducibility. These collaborative efforts have resulted in preliminary testing guidelines that are currently under review by international standards organizations.

The integration of digital twin modeling with physical testing represents the frontier of longevity assessment. These computational models, calibrated with experimental data, enable predictive analysis of long-term performance under various environmental conditions, potentially reducing the time required for comprehensive longevity certification from years to months.

Accelerated aging tests form the cornerstone of longevity assessment protocols, simulating years of environmental exposure in compressed timeframes. These protocols typically subject metasurface antennas to elevated temperatures (typically 85-125°C), high humidity (85-95% RH), and cyclic thermal stress (-40°C to +125°C) to induce accelerated degradation mechanisms. The correlation between accelerated testing and real-world performance requires careful validation through parallel long-term field testing.

Environmental exposure chambers equipped with UV radiation sources, salt spray capabilities, and controlled humidity have become essential tools for standardized testing. Advanced facilities incorporate programmable cycles that simulate day/night transitions, seasonal variations, and extreme weather events to comprehensively evaluate material resilience under diverse conditions.

Quantitative metrics for longevity assessment must include radiation efficiency retention, resonant frequency stability, bandwidth maintenance, and physical integrity parameters. The IEEE working group P1928 has recently initiated efforts to standardize these metrics specifically for metasurface applications, building upon existing standards for conventional antenna systems.

Non-destructive evaluation techniques have emerged as valuable components of standardized testing protocols. Techniques such as terahertz imaging, infrared thermography, and acoustic microscopy enable periodic assessment of material integrity without compromising the antenna structure, facilitating longitudinal studies of degradation progression.

Industry-academic partnerships have accelerated the development of testing standards, with consortia like the Metasurface Reliability Consortium (MRC) establishing round-robin testing programs across multiple laboratories to validate protocol reproducibility. These collaborative efforts have resulted in preliminary testing guidelines that are currently under review by international standards organizations.

The integration of digital twin modeling with physical testing represents the frontier of longevity assessment. These computational models, calibrated with experimental data, enable predictive analysis of long-term performance under various environmental conditions, potentially reducing the time required for comprehensive longevity certification from years to months.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!