What Are the Key Technical Barriers for Metasurface Antennas

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface Antenna Development Background and Objectives

Metasurface antennas represent a revolutionary advancement in electromagnetic wave manipulation technology, emerging from the broader field of metamaterials research that began gaining significant momentum in the early 2000s. These ultra-thin, planar structures consist of subwavelength elements arranged in specific patterns to control electromagnetic wavefronts with unprecedented precision. The evolution of this technology has been driven by the increasing demands for miniaturization, integration, and enhanced performance in modern communication systems.

The development trajectory of metasurface antennas has seen remarkable progress over the past decade, transitioning from theoretical concepts to practical implementations. Early research focused primarily on proof-of-concept demonstrations, while recent advancements have pushed toward addressing real-world applications in 5G/6G communications, satellite systems, radar technology, and biomedical devices. This progression highlights the technology's potential to revolutionize wireless communication infrastructure.

Current technical objectives in metasurface antenna development center around overcoming several critical limitations. Researchers aim to enhance bandwidth capabilities, as conventional metasurface antennas typically suffer from narrow operating frequency ranges. Another primary goal involves improving efficiency metrics, particularly in terms of power consumption and radiation patterns, to match or exceed those of traditional antenna technologies.

Scalability represents another significant objective, with efforts directed toward developing cost-effective manufacturing processes suitable for mass production while maintaining precise structural control at the nanoscale. The field is also pursuing dynamic reconfigurability—the ability to adjust antenna properties in real-time without physical modification—which would enable adaptive systems capable of responding to changing environmental conditions or communication requirements.

Integration challenges form a substantial portion of current research focus. As metasurface antennas move toward commercial applications, seamless incorporation with existing electronic systems becomes paramount. This includes addressing compatibility issues with standard RF components and developing appropriate feeding mechanisms that preserve the advantages of metasurface technology.

The ultimate technical vision encompasses the development of multifunctional metasurface antennas capable of simultaneously performing multiple electromagnetic operations, such as beam steering, polarization control, and frequency filtering. This would enable significant reductions in system complexity and size while enhancing overall performance metrics across various application domains.

Achieving these ambitious objectives requires interdisciplinary collaboration spanning electromagnetic theory, materials science, nanofabrication techniques, and computational modeling. The field continues to advance through iterative improvements in design methodologies, fabrication precision, and fundamental understanding of light-matter interactions at the subwavelength scale.

The development trajectory of metasurface antennas has seen remarkable progress over the past decade, transitioning from theoretical concepts to practical implementations. Early research focused primarily on proof-of-concept demonstrations, while recent advancements have pushed toward addressing real-world applications in 5G/6G communications, satellite systems, radar technology, and biomedical devices. This progression highlights the technology's potential to revolutionize wireless communication infrastructure.

Current technical objectives in metasurface antenna development center around overcoming several critical limitations. Researchers aim to enhance bandwidth capabilities, as conventional metasurface antennas typically suffer from narrow operating frequency ranges. Another primary goal involves improving efficiency metrics, particularly in terms of power consumption and radiation patterns, to match or exceed those of traditional antenna technologies.

Scalability represents another significant objective, with efforts directed toward developing cost-effective manufacturing processes suitable for mass production while maintaining precise structural control at the nanoscale. The field is also pursuing dynamic reconfigurability—the ability to adjust antenna properties in real-time without physical modification—which would enable adaptive systems capable of responding to changing environmental conditions or communication requirements.

Integration challenges form a substantial portion of current research focus. As metasurface antennas move toward commercial applications, seamless incorporation with existing electronic systems becomes paramount. This includes addressing compatibility issues with standard RF components and developing appropriate feeding mechanisms that preserve the advantages of metasurface technology.

The ultimate technical vision encompasses the development of multifunctional metasurface antennas capable of simultaneously performing multiple electromagnetic operations, such as beam steering, polarization control, and frequency filtering. This would enable significant reductions in system complexity and size while enhancing overall performance metrics across various application domains.

Achieving these ambitious objectives requires interdisciplinary collaboration spanning electromagnetic theory, materials science, nanofabrication techniques, and computational modeling. The field continues to advance through iterative improvements in design methodologies, fabrication precision, and fundamental understanding of light-matter interactions at the subwavelength scale.

Market Applications and Demand Analysis for Metasurface Antennas

The metasurface antenna market is experiencing significant growth driven by the increasing demand for high-performance communication systems across multiple sectors. The global market for metasurface antennas is projected to reach $2.1 billion by 2028, with a compound annual growth rate of 7.8% from 2023 to 2028, according to recent market research data.

The telecommunications sector represents the largest market segment, accounting for approximately 35% of the total market share. With the ongoing deployment of 5G networks and the anticipated rollout of 6G technology, telecom operators are seeking advanced antenna solutions that offer higher bandwidth, improved spectral efficiency, and reduced form factors. Metasurface antennas, with their ability to provide beam steering capabilities and higher gain in compact designs, are increasingly viewed as critical components for next-generation base stations and small cell deployments.

Aerospace and defense applications constitute the second-largest market segment at 28%. Military radar systems, satellite communications, and electronic warfare systems benefit significantly from the enhanced directivity and reduced radar cross-section offered by metasurface antennas. Defense contractors are investing heavily in this technology to develop more sophisticated sensing and communication systems for both ground and airborne platforms.

The automotive industry represents a rapidly growing market segment, currently at 15% but expected to double within five years. Advanced driver assistance systems (ADAS) and autonomous vehicles require multiple radar and communication systems, creating demand for low-profile, conformal antennas that can be integrated into vehicle structures without compromising aerodynamics or aesthetics.

Consumer electronics manufacturers are also exploring metasurface antennas for smartphones, laptops, and wearable devices, seeking to improve connectivity while reducing device thickness. This segment currently represents 12% of the market but shows strong growth potential as miniaturization techniques advance.

Geographically, North America leads the market with 42% share, followed by Asia-Pacific at 31% and Europe at 22%. China and South Korea are making significant investments in metasurface antenna research and manufacturing capabilities, potentially shifting the market balance in the coming years.

Market analysis indicates that customers across all segments prioritize three key performance metrics: bandwidth enhancement, beam steering capabilities, and form factor reduction. However, cost remains a significant barrier to widespread adoption, with current metasurface antenna solutions typically commanding a 30-40% premium over conventional antenna technologies. Industry experts predict that this price differential will narrow to 15-20% by 2026 as manufacturing processes mature and economies of scale are realized.

The telecommunications sector represents the largest market segment, accounting for approximately 35% of the total market share. With the ongoing deployment of 5G networks and the anticipated rollout of 6G technology, telecom operators are seeking advanced antenna solutions that offer higher bandwidth, improved spectral efficiency, and reduced form factors. Metasurface antennas, with their ability to provide beam steering capabilities and higher gain in compact designs, are increasingly viewed as critical components for next-generation base stations and small cell deployments.

Aerospace and defense applications constitute the second-largest market segment at 28%. Military radar systems, satellite communications, and electronic warfare systems benefit significantly from the enhanced directivity and reduced radar cross-section offered by metasurface antennas. Defense contractors are investing heavily in this technology to develop more sophisticated sensing and communication systems for both ground and airborne platforms.

The automotive industry represents a rapidly growing market segment, currently at 15% but expected to double within five years. Advanced driver assistance systems (ADAS) and autonomous vehicles require multiple radar and communication systems, creating demand for low-profile, conformal antennas that can be integrated into vehicle structures without compromising aerodynamics or aesthetics.

Consumer electronics manufacturers are also exploring metasurface antennas for smartphones, laptops, and wearable devices, seeking to improve connectivity while reducing device thickness. This segment currently represents 12% of the market but shows strong growth potential as miniaturization techniques advance.

Geographically, North America leads the market with 42% share, followed by Asia-Pacific at 31% and Europe at 22%. China and South Korea are making significant investments in metasurface antenna research and manufacturing capabilities, potentially shifting the market balance in the coming years.

Market analysis indicates that customers across all segments prioritize three key performance metrics: bandwidth enhancement, beam steering capabilities, and form factor reduction. However, cost remains a significant barrier to widespread adoption, with current metasurface antenna solutions typically commanding a 30-40% premium over conventional antenna technologies. Industry experts predict that this price differential will narrow to 15-20% by 2026 as manufacturing processes mature and economies of scale are realized.

Current Technical Limitations and Challenges in Metasurface Implementation

Metasurface antennas represent a revolutionary approach to electromagnetic wave manipulation, yet their widespread implementation faces significant technical barriers. The fabrication precision required for metasurfaces presents a formidable challenge, as these structures often demand sub-wavelength feature sizes, particularly at higher frequencies. Current manufacturing techniques struggle to consistently produce the intricate patterns necessary for optimal performance, resulting in deviations that compromise the antenna's electromagnetic properties.

Material limitations constitute another major obstacle. The ideal metasurface would require materials with specific electromagnetic properties that can be precisely controlled across the operating frequency range. However, available materials often exhibit frequency-dependent behavior, losses, or anisotropic properties that restrict bandwidth and efficiency. The search for novel materials with superior electromagnetic characteristics remains an active area of research but has yet to yield comprehensive solutions.

Bandwidth constraints represent a persistent challenge for metasurface antennas. Most current designs operate effectively only within narrow frequency bands, limiting their practical applications. This narrowband behavior stems from the resonant nature of many metasurface elements, which are inherently frequency-selective. Developing broadband or multi-band metasurface antennas without sacrificing performance metrics remains technically demanding.

The computational complexity involved in metasurface design cannot be overstated. Accurate modeling requires intensive electromagnetic simulations across multiple scales, from the nanometer-level features to the overall antenna performance. This multi-scale problem often exceeds the capabilities of conventional simulation tools, leading to compromises in the design process or excessive computational requirements.

Integration challenges arise when incorporating metasurface antennas into practical systems. Issues include interfacing with conventional RF components, maintaining performance under varying environmental conditions, and ensuring reliability over time. The transition from laboratory prototypes to robust commercial products faces significant hurdles in terms of packaging, interconnection, and system compatibility.

Scalability presents another critical barrier, particularly for applications requiring large-area metasurfaces. As the physical size increases, maintaining phase coherence and uniform performance becomes increasingly difficult. Manufacturing defects and material variations have more pronounced effects at larger scales, potentially degrading the antenna's performance characteristics.

Tunability and reconfigurability limitations restrict the dynamic adaptation capabilities of metasurface antennas. While static metasurfaces can be optimized for specific functions, many applications would benefit from real-time adjustable properties. Current approaches to tunable metasurfaces often involve complex control mechanisms, additional power requirements, or performance trade-offs that limit their practical implementation.

Material limitations constitute another major obstacle. The ideal metasurface would require materials with specific electromagnetic properties that can be precisely controlled across the operating frequency range. However, available materials often exhibit frequency-dependent behavior, losses, or anisotropic properties that restrict bandwidth and efficiency. The search for novel materials with superior electromagnetic characteristics remains an active area of research but has yet to yield comprehensive solutions.

Bandwidth constraints represent a persistent challenge for metasurface antennas. Most current designs operate effectively only within narrow frequency bands, limiting their practical applications. This narrowband behavior stems from the resonant nature of many metasurface elements, which are inherently frequency-selective. Developing broadband or multi-band metasurface antennas without sacrificing performance metrics remains technically demanding.

The computational complexity involved in metasurface design cannot be overstated. Accurate modeling requires intensive electromagnetic simulations across multiple scales, from the nanometer-level features to the overall antenna performance. This multi-scale problem often exceeds the capabilities of conventional simulation tools, leading to compromises in the design process or excessive computational requirements.

Integration challenges arise when incorporating metasurface antennas into practical systems. Issues include interfacing with conventional RF components, maintaining performance under varying environmental conditions, and ensuring reliability over time. The transition from laboratory prototypes to robust commercial products faces significant hurdles in terms of packaging, interconnection, and system compatibility.

Scalability presents another critical barrier, particularly for applications requiring large-area metasurfaces. As the physical size increases, maintaining phase coherence and uniform performance becomes increasingly difficult. Manufacturing defects and material variations have more pronounced effects at larger scales, potentially degrading the antenna's performance characteristics.

Tunability and reconfigurability limitations restrict the dynamic adaptation capabilities of metasurface antennas. While static metasurfaces can be optimized for specific functions, many applications would benefit from real-time adjustable properties. Current approaches to tunable metasurfaces often involve complex control mechanisms, additional power requirements, or performance trade-offs that limit their practical implementation.

State-of-the-Art Metasurface Antenna Design Approaches

01 Fabrication and manufacturing challenges

Metasurface antennas face significant fabrication challenges due to their complex nanoscale structures requiring precise manufacturing techniques. The fabrication of these antennas often involves sophisticated lithography processes, which can be costly and difficult to scale for mass production. Additionally, maintaining consistent quality across large-area metasurfaces presents technical barriers, as even minor variations in the nanoscale elements can significantly impact antenna performance. These manufacturing limitations currently restrict the widespread commercial adoption of metasurface antenna technology.- Fabrication and manufacturing challenges: Metasurface antennas face significant fabrication challenges due to their complex nanoscale structures requiring precise manufacturing techniques. The production of these antennas demands high-resolution lithography, accurate material deposition, and careful quality control to maintain consistent electromagnetic properties. Manufacturing limitations include difficulties in scaling production while maintaining nanometer-level precision, challenges in creating three-dimensional metasurface structures, and issues with substrate compatibility that can affect performance and durability.

- Bandwidth and frequency response limitations: A major technical barrier for metasurface antennas is their inherently narrow bandwidth operation. Most metasurface designs exhibit resonant behavior that restricts their effective operation to specific frequency ranges. This limitation stems from the fundamental physics of resonant structures and presents challenges for applications requiring broadband performance. Engineers must develop complex design strategies, including multi-layer structures or active components, to overcome these bandwidth constraints while maintaining the desired radiation characteristics and efficiency across wider frequency ranges.

- Integration with existing systems and technologies: Integrating metasurface antennas with conventional RF systems presents significant technical barriers. These include impedance matching challenges between the metasurface and traditional feed networks, difficulties in incorporating active components for dynamic control, and compatibility issues with standard communication protocols. The unique electromagnetic properties of metasurfaces often require specialized interface circuits and novel system architectures. Additionally, integrating metasurface antennas into existing platforms may require redesigning surrounding components to accommodate their electromagnetic behavior and physical constraints.

- Thermal and environmental stability issues: Metasurface antennas face significant challenges related to thermal and environmental stability. Their performance can degrade under temperature fluctuations due to thermal expansion affecting the precise spacing and dimensions critical to their operation. Environmental factors such as humidity, oxidation, and mechanical stress can alter material properties and damage delicate nanostructures. These issues are particularly problematic for outdoor applications or high-power scenarios where thermal management becomes crucial. Developing protective coatings and thermally stable designs without compromising electromagnetic performance remains a significant technical barrier.

- Dynamic control and reconfigurability challenges: Creating dynamically reconfigurable metasurface antennas presents substantial technical barriers. While static metasurfaces offer fixed functionality, many applications require adaptive behavior to respond to changing conditions or requirements. Implementing effective tuning mechanisms without degrading antenna performance is challenging, whether using mechanical, electrical, optical, or thermal approaches. The integration of control elements often introduces losses and complexity that can compromise the metasurface's electromagnetic properties. Additionally, achieving fast response times and precise control over multiple parameters simultaneously remains difficult with current technologies.

02 Bandwidth and frequency response limitations

A major technical barrier for metasurface antennas is their inherently narrow bandwidth operation. Most metasurface designs exhibit resonant behavior that restricts their effective operation to specific frequency ranges. This limitation poses challenges for applications requiring broadband or multi-band functionality. Engineers are exploring various approaches to overcome these bandwidth constraints, including multi-layer designs and active components, but achieving wideband performance while maintaining other desirable characteristics remains a significant technical challenge in the field.Expand Specific Solutions03 Integration with active components and control systems

Integrating metasurface antennas with active electronic components presents substantial technical barriers. Dynamic control of metasurface properties often requires incorporation of tunable elements such as varactors, PIN diodes, or MEMS, which adds complexity to the design and fabrication process. The integration challenges include addressing impedance matching issues, minimizing losses at the interfaces, and developing appropriate biasing networks. Additionally, creating efficient control systems that can rapidly reconfigure the metasurface properties for beam steering or frequency tuning applications remains a significant technical hurdle.Expand Specific Solutions04 Efficiency and power handling limitations

Metasurface antennas often suffer from efficiency limitations due to inherent material losses, particularly at higher frequencies. These losses can significantly reduce the overall antenna gain and radiation efficiency. Additionally, power handling capabilities present another technical barrier, as the concentrated electromagnetic fields in the nanoscale structures can lead to thermal issues and potential breakdown of materials. The development of new materials and structural designs to improve efficiency while maintaining adequate power handling capacity remains an ongoing challenge in metasurface antenna research.Expand Specific Solutions05 Environmental stability and reliability concerns

The long-term stability and reliability of metasurface antennas in various environmental conditions represent significant technical barriers. These antennas can be sensitive to temperature fluctuations, humidity, mechanical stress, and other environmental factors that may alter their electromagnetic properties over time. The nanoscale features are particularly vulnerable to degradation mechanisms such as oxidation, corrosion, or mechanical fatigue. Developing robust protection strategies and packaging solutions that preserve the metasurface functionality while ensuring durability in real-world operating conditions remains a critical challenge for practical applications.Expand Specific Solutions

Leading Research Groups and Companies in Metasurface Development

The metasurface antenna market is currently in an early growth phase, characterized by significant technical barriers that limit widespread commercial adoption despite promising potential. Key challenges include manufacturing scalability, cost-effectiveness, and performance consistency across different operating conditions. The market size is projected to expand substantially as 5G and satellite communications grow, with companies addressing these challenges through varied approaches. Kymeta Corp. leads in satellite communications applications, while Pivotal Commware focuses on holographic beamforming for 5G. Research institutions like Caltech and CNRS collaborate with industry players including Samsung Electronics and Ericsson to overcome fundamental physics limitations in bandwidth, efficiency, and beam steering capabilities that currently constrain metasurface antenna commercialization.

Kymeta Corp.

Technical Solution: Kymeta addresses key metasurface antenna barriers through their proprietary holographic beamforming technology that uses liquid crystal-based tunable metasurfaces. Their approach enables electronically steerable antennas without moving parts by dynamically altering the electromagnetic properties of the metasurface elements. The company has developed the u8 terminal, which utilizes metamaterial principles to create a flat-panel antenna capable of tracking satellites with software-defined beam steering. Kymeta's technology manipulates the resonant frequency and phase of individual meta-atoms through voltage control, allowing precise beam formation and steering. Their manufacturing process leverages existing LCD display technology infrastructure, enabling scalable production of metasurface antennas with consistent performance characteristics across large apertures.

Strengths: Leverages mature LCD manufacturing technology for cost-effective production; eliminates mechanical components for increased reliability; provides software-defined beam control for flexible operation. Weaknesses: Power efficiency challenges compared to traditional parabolic antennas; thermal management issues in high-power applications; limited frequency bandwidth compared to some competing technologies.

Pivotal Commware, Inc.

Technical Solution: Pivotal Commware tackles metasurface antenna barriers through their Holographic Beam Forming (HBF) technology, which uses software-defined antennas based on metamaterial principles. Their approach employs reconfigurable metasurfaces with electronically controlled meta-atoms that can dynamically change their electromagnetic properties. Pivotal's technology specifically addresses the power consumption challenge by using low-cost, low-loss materials and innovative circuit designs that require minimal power for beam steering. Their Echo and Pivot products utilize this technology for 5G mmWave signal boosting, enabling efficient penetration through physical barriers like windows and walls. The company's manufacturing approach integrates their metasurface technology with conventional PCB fabrication techniques, allowing for cost-effective mass production while maintaining precise control over the electromagnetic properties of each meta-element.

Strengths: Lower power consumption compared to traditional phased arrays; simplified architecture reduces manufacturing complexity; software-defined operation enables adaptive performance. Weaknesses: Limited power handling capability for high-power transmission applications; challenges in achieving wide instantaneous bandwidth; performance degradation in extreme environmental conditions.

Critical Patents and Research Breakthroughs in Metasurface Technology

Antenna array with partially reflective depolarizing metasurface

PatentPendingUS20250096483A1

Innovation

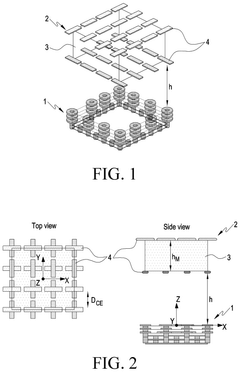

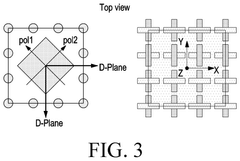

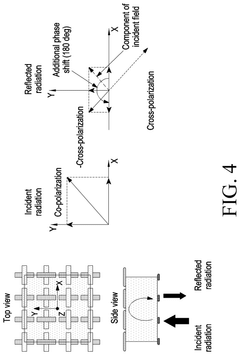

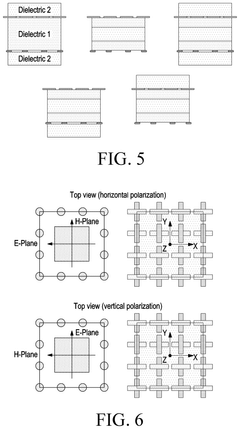

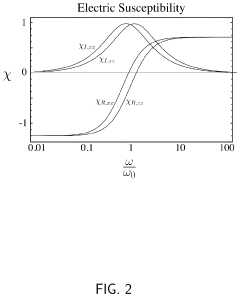

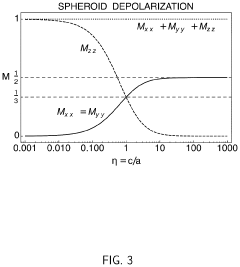

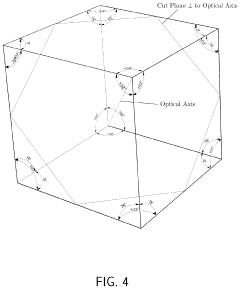

- The proposed solution involves a steerable antenna array with a partially reflective depolarizing metasurface. This metasurface is a dielectric layer with conductive elements on both sides, orthogonally arranged to reflect part of the antenna array's radiation, reducing coupling between elements and enhancing gain at wide scan angles.

Optometaphoresis: programmable metaphotonics by particle migration and light-bending in nanoparticle colloids controlled by near-field micro-structured current-voltage-energized phased-array antenna-electrodes inducing dielectrophoresis

PatentPendingUS20240118579A1

Innovation

- The development of optometaphoresis, which utilizes near-field micro-structured phased-array antenna-electrodes to control nanoparticles in a colloid, allowing for dynamic manipulation of refractive index and light steering through dielectrophoresis, enabling software-programmable, compact, and reconfigurable optical devices.

Manufacturing Scalability and Cost Considerations

The manufacturing scalability and cost considerations represent significant technical barriers for the widespread adoption of metasurface antennas. Current fabrication methods for metasurface antennas predominantly rely on sophisticated nanofabrication techniques such as electron-beam lithography, focused ion beam milling, and nanoimprint lithography. These processes, while capable of achieving the necessary nanoscale precision, are inherently slow, expensive, and limited to small production volumes, typically constrained to laboratory settings.

The intricate subwavelength structures that constitute metasurfaces require nanometer-level precision in fabrication. This precision requirement creates substantial challenges when attempting to scale production to commercial levels. The unit cost of metasurface antennas remains prohibitively high due to the specialized equipment, clean room facilities, and highly skilled technicians required for their production. For instance, the fabrication of a single metasurface antenna prototype can cost thousands of dollars and take several days to complete.

Material selection further complicates the manufacturing equation. Many high-performance metasurface designs incorporate exotic materials or precise multilayer structures that are difficult to process using conventional manufacturing techniques. The integration of active components, such as varactors or PIN diodes for tunable metasurfaces, adds another layer of complexity to the manufacturing process, requiring precise alignment and reliable electrical connections at the microscale.

Yield rates present another significant challenge. The complex nature of metasurface structures means that minor fabrication defects can significantly impact performance. Current manufacturing processes typically exhibit low yield rates, further driving up the effective cost per functional unit. This issue becomes particularly pronounced when attempting to fabricate large-area metasurfaces needed for certain applications like satellite communications or radar systems.

Industry standardization is also lacking in metasurface manufacturing. Unlike conventional antenna production, which benefits from decades of established manufacturing protocols and quality control standards, metasurface production remains largely experimental. This absence of standardization impedes the development of dedicated, cost-effective manufacturing equipment and processes specifically optimized for metasurface antennas.

Recent research has begun exploring alternative fabrication approaches, including roll-to-roll nanoimprinting, self-assembly techniques, and additive manufacturing methods. These approaches show promise for reducing costs and increasing production volumes, but significant technical hurdles remain before they can match the precision and reliability of traditional nanofabrication methods while achieving the economies of scale necessary for commercial viability.

The intricate subwavelength structures that constitute metasurfaces require nanometer-level precision in fabrication. This precision requirement creates substantial challenges when attempting to scale production to commercial levels. The unit cost of metasurface antennas remains prohibitively high due to the specialized equipment, clean room facilities, and highly skilled technicians required for their production. For instance, the fabrication of a single metasurface antenna prototype can cost thousands of dollars and take several days to complete.

Material selection further complicates the manufacturing equation. Many high-performance metasurface designs incorporate exotic materials or precise multilayer structures that are difficult to process using conventional manufacturing techniques. The integration of active components, such as varactors or PIN diodes for tunable metasurfaces, adds another layer of complexity to the manufacturing process, requiring precise alignment and reliable electrical connections at the microscale.

Yield rates present another significant challenge. The complex nature of metasurface structures means that minor fabrication defects can significantly impact performance. Current manufacturing processes typically exhibit low yield rates, further driving up the effective cost per functional unit. This issue becomes particularly pronounced when attempting to fabricate large-area metasurfaces needed for certain applications like satellite communications or radar systems.

Industry standardization is also lacking in metasurface manufacturing. Unlike conventional antenna production, which benefits from decades of established manufacturing protocols and quality control standards, metasurface production remains largely experimental. This absence of standardization impedes the development of dedicated, cost-effective manufacturing equipment and processes specifically optimized for metasurface antennas.

Recent research has begun exploring alternative fabrication approaches, including roll-to-roll nanoimprinting, self-assembly techniques, and additive manufacturing methods. These approaches show promise for reducing costs and increasing production volumes, but significant technical hurdles remain before they can match the precision and reliability of traditional nanofabrication methods while achieving the economies of scale necessary for commercial viability.

Materials Science Advancements for Enhanced Metasurface Performance

The advancement of materials science represents a critical frontier in overcoming the technical barriers facing metasurface antennas. Current metasurface implementations are significantly constrained by the limited range of available materials that can effectively manipulate electromagnetic waves at desired frequencies. Traditional materials often exhibit high losses, narrow bandwidth operation, and insufficient phase control capabilities, restricting the performance envelope of metasurface antennas.

Recent research has focused on developing novel metamaterials with engineered electromagnetic properties that can provide full 360-degree phase control while maintaining high efficiency. Particularly promising are developments in low-loss dielectric resonators, which offer superior performance compared to their metallic counterparts, especially at higher frequencies. These materials demonstrate reduced ohmic losses and enhanced power handling capabilities, addressing key limitations in current designs.

Tunable materials represent another significant advancement pathway. Materials that can dynamically alter their electromagnetic properties in response to external stimuli (electrical, optical, thermal, or mechanical) are essential for creating reconfigurable metasurfaces. Liquid crystals, phase-change materials, and graphene-based composites have shown considerable promise in this domain, though challenges remain in achieving rapid switching speeds and maintaining performance consistency over multiple reconfiguration cycles.

Nanofabrication techniques have evolved to enable the creation of increasingly complex metasurface structures with feature sizes below 100 nm. These advancements allow for more precise control over electromagnetic wave manipulation but require further refinement to achieve cost-effective mass production. The integration of novel two-dimensional materials such as transition metal dichalcogenides (TMDs) and hexagonal boron nitride (hBN) offers new possibilities for ultra-thin, highly efficient metasurfaces.

Multilayer and heterogeneous material systems represent a frontier approach to overcome bandwidth limitations. By carefully engineering stacked layers of different materials with complementary electromagnetic responses, researchers have demonstrated broadband operation that was previously unattainable with single-layer designs. These composite structures can maintain phase control across significantly wider frequency ranges.

Temperature stability remains a critical challenge, particularly for applications in harsh environments. Research into thermally robust materials that maintain their electromagnetic properties across wide temperature ranges is essential for practical deployment. Similarly, materials that can withstand environmental factors such as humidity, UV exposure, and mechanical stress will be crucial for real-world implementation of metasurface antenna technology in various sectors including telecommunications, aerospace, and defense.

Recent research has focused on developing novel metamaterials with engineered electromagnetic properties that can provide full 360-degree phase control while maintaining high efficiency. Particularly promising are developments in low-loss dielectric resonators, which offer superior performance compared to their metallic counterparts, especially at higher frequencies. These materials demonstrate reduced ohmic losses and enhanced power handling capabilities, addressing key limitations in current designs.

Tunable materials represent another significant advancement pathway. Materials that can dynamically alter their electromagnetic properties in response to external stimuli (electrical, optical, thermal, or mechanical) are essential for creating reconfigurable metasurfaces. Liquid crystals, phase-change materials, and graphene-based composites have shown considerable promise in this domain, though challenges remain in achieving rapid switching speeds and maintaining performance consistency over multiple reconfiguration cycles.

Nanofabrication techniques have evolved to enable the creation of increasingly complex metasurface structures with feature sizes below 100 nm. These advancements allow for more precise control over electromagnetic wave manipulation but require further refinement to achieve cost-effective mass production. The integration of novel two-dimensional materials such as transition metal dichalcogenides (TMDs) and hexagonal boron nitride (hBN) offers new possibilities for ultra-thin, highly efficient metasurfaces.

Multilayer and heterogeneous material systems represent a frontier approach to overcome bandwidth limitations. By carefully engineering stacked layers of different materials with complementary electromagnetic responses, researchers have demonstrated broadband operation that was previously unattainable with single-layer designs. These composite structures can maintain phase control across significantly wider frequency ranges.

Temperature stability remains a critical challenge, particularly for applications in harsh environments. Research into thermally robust materials that maintain their electromagnetic properties across wide temperature ranges is essential for practical deployment. Similarly, materials that can withstand environmental factors such as humidity, UV exposure, and mechanical stress will be crucial for real-world implementation of metasurface antenna technology in various sectors including telecommunications, aerospace, and defense.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!