Metasurface Antennas: Potential for Integration in Wearable Devices

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface Antenna Technology Evolution and Objectives

Metasurface antennas represent a revolutionary advancement in antenna technology, evolving from traditional antenna designs to ultra-thin, planar structures capable of manipulating electromagnetic waves with unprecedented precision. The evolution began in the early 2000s with the theoretical exploration of metamaterials, which demonstrated the ability to achieve properties not found in natural materials. By 2010, researchers had successfully developed the first practical metasurface prototypes, marking a significant milestone in antenna miniaturization.

The technological progression accelerated between 2015-2020, when metasurfaces transitioned from laboratory curiosities to viable components for communication systems. This period saw the development of reconfigurable metasurfaces capable of beam steering and frequency tuning without mechanical parts, representing a paradigm shift in antenna functionality. The integration of active elements further enhanced their adaptability, allowing dynamic control over radiation patterns.

Recent advancements have focused on flexible and conformal metasurface antennas, directly addressing the requirements of wearable technology. These developments have reduced thickness to sub-millimeter dimensions while maintaining performance comparable to conventional antennas many times their size. The incorporation of novel materials such as graphene and liquid crystals has expanded the operational frequency range from microwave to terahertz bands.

The primary objective of metasurface antenna research for wearable applications centers on achieving seamless integration with textiles and flexible substrates while maintaining robust performance under deformation. This includes developing manufacturing techniques compatible with mass production of textile-integrated antennas and ensuring durability through multiple washing cycles and daily wear conditions.

Another critical goal involves optimizing power efficiency and radiation patterns specifically for on-body communications, accounting for the complex electromagnetic environment created by human tissue proximity. Researchers aim to develop metasurfaces that can adaptively reconfigure their properties to maintain optimal performance regardless of body position or movement.

Looking forward, the field is targeting the development of self-powered metasurface antennas that can harvest ambient energy, thereby eliminating the need for separate power sources in wearable devices. Additionally, researchers are exploring multifunctional metasurfaces that simultaneously serve as antennas, sensors, and energy harvesters, maximizing functionality while minimizing form factor.

The convergence of metasurface technology with emerging fields such as Internet of Things (IoT) and 5G/6G communications represents a promising direction, potentially enabling unprecedented connectivity for wearable health monitoring, augmented reality, and personal communication systems with minimal impact on device aesthetics and comfort.

The technological progression accelerated between 2015-2020, when metasurfaces transitioned from laboratory curiosities to viable components for communication systems. This period saw the development of reconfigurable metasurfaces capable of beam steering and frequency tuning without mechanical parts, representing a paradigm shift in antenna functionality. The integration of active elements further enhanced their adaptability, allowing dynamic control over radiation patterns.

Recent advancements have focused on flexible and conformal metasurface antennas, directly addressing the requirements of wearable technology. These developments have reduced thickness to sub-millimeter dimensions while maintaining performance comparable to conventional antennas many times their size. The incorporation of novel materials such as graphene and liquid crystals has expanded the operational frequency range from microwave to terahertz bands.

The primary objective of metasurface antenna research for wearable applications centers on achieving seamless integration with textiles and flexible substrates while maintaining robust performance under deformation. This includes developing manufacturing techniques compatible with mass production of textile-integrated antennas and ensuring durability through multiple washing cycles and daily wear conditions.

Another critical goal involves optimizing power efficiency and radiation patterns specifically for on-body communications, accounting for the complex electromagnetic environment created by human tissue proximity. Researchers aim to develop metasurfaces that can adaptively reconfigure their properties to maintain optimal performance regardless of body position or movement.

Looking forward, the field is targeting the development of self-powered metasurface antennas that can harvest ambient energy, thereby eliminating the need for separate power sources in wearable devices. Additionally, researchers are exploring multifunctional metasurfaces that simultaneously serve as antennas, sensors, and energy harvesters, maximizing functionality while minimizing form factor.

The convergence of metasurface technology with emerging fields such as Internet of Things (IoT) and 5G/6G communications represents a promising direction, potentially enabling unprecedented connectivity for wearable health monitoring, augmented reality, and personal communication systems with minimal impact on device aesthetics and comfort.

Market Demand for Wearable Device Antenna Solutions

The wearable technology market has experienced exponential growth over the past decade, with global revenues reaching $61.3 billion in 2022 and projected to surpass $155.4 billion by 2029. This remarkable expansion is driven by increasing consumer demand for health monitoring devices, smart accessories, and augmented reality wearables. Within this ecosystem, antenna solutions represent a critical component that enables wireless connectivity, yet they face significant design constraints in wearable applications.

Current market research indicates that consumers prioritize device comfort, aesthetics, and unobtrusive form factors when purchasing wearable technology. Traditional antenna designs often compromise these qualities due to their rigid structure, substantial footprint, and electromagnetic interference issues. A 2023 industry survey revealed that 78% of wearable device manufacturers identify antenna integration as a major design challenge, particularly as devices become smaller and more feature-rich.

The healthcare segment demonstrates particularly strong demand for advanced antenna solutions, with medical wearables requiring reliable connectivity for continuous patient monitoring. This sector alone is expected to grow at a CAGR of 19.7% through 2028, creating substantial market opportunities for innovative antenna technologies. Similarly, the fitness and sports wearables segment values antenna solutions that maintain performance during physical activity while withstanding environmental factors like sweat and motion.

Consumer electronics giants have begun investing heavily in compact antenna technologies, with major players allocating an average of 15% of their R&D budgets to connectivity solutions for wearable products. This investment trend underscores the strategic importance of antenna technology in maintaining competitive advantage in the wearables market.

Market analysis reveals growing demand for antenna solutions that can conform to non-planar surfaces, operate efficiently near biological tissues, and maintain performance despite the proximity of other electronic components. These requirements align perfectly with the potential capabilities of metasurface antennas, which offer conformal designs, reduced electromagnetic absorption by body tissues, and enhanced directional performance in compact form factors.

Enterprise and industrial wearables represent another expanding market segment, with applications in logistics, manufacturing, and field service operations. These use cases demand robust connectivity in challenging environments, creating additional pressure for antenna solutions that deliver consistent performance while maintaining worker comfort during extended use periods.

The convergence of 5G networks and IoT ecosystems is further accelerating demand for advanced antenna solutions in wearable devices. As these networks proliferate, consumers expect seamless connectivity across multiple devices, creating market pull for antenna technologies that can support multiple frequency bands while maintaining energy efficiency to preserve battery life.

Current market research indicates that consumers prioritize device comfort, aesthetics, and unobtrusive form factors when purchasing wearable technology. Traditional antenna designs often compromise these qualities due to their rigid structure, substantial footprint, and electromagnetic interference issues. A 2023 industry survey revealed that 78% of wearable device manufacturers identify antenna integration as a major design challenge, particularly as devices become smaller and more feature-rich.

The healthcare segment demonstrates particularly strong demand for advanced antenna solutions, with medical wearables requiring reliable connectivity for continuous patient monitoring. This sector alone is expected to grow at a CAGR of 19.7% through 2028, creating substantial market opportunities for innovative antenna technologies. Similarly, the fitness and sports wearables segment values antenna solutions that maintain performance during physical activity while withstanding environmental factors like sweat and motion.

Consumer electronics giants have begun investing heavily in compact antenna technologies, with major players allocating an average of 15% of their R&D budgets to connectivity solutions for wearable products. This investment trend underscores the strategic importance of antenna technology in maintaining competitive advantage in the wearables market.

Market analysis reveals growing demand for antenna solutions that can conform to non-planar surfaces, operate efficiently near biological tissues, and maintain performance despite the proximity of other electronic components. These requirements align perfectly with the potential capabilities of metasurface antennas, which offer conformal designs, reduced electromagnetic absorption by body tissues, and enhanced directional performance in compact form factors.

Enterprise and industrial wearables represent another expanding market segment, with applications in logistics, manufacturing, and field service operations. These use cases demand robust connectivity in challenging environments, creating additional pressure for antenna solutions that deliver consistent performance while maintaining worker comfort during extended use periods.

The convergence of 5G networks and IoT ecosystems is further accelerating demand for advanced antenna solutions in wearable devices. As these networks proliferate, consumers expect seamless connectivity across multiple devices, creating market pull for antenna technologies that can support multiple frequency bands while maintaining energy efficiency to preserve battery life.

Current Challenges in Metasurface Antenna Integration

Despite the promising potential of metasurface antennas in wearable technology, several significant challenges currently impede their widespread integration. The miniaturization of these antennas while maintaining performance presents a fundamental obstacle. While metasurfaces can theoretically reduce antenna size, achieving this without compromising gain, bandwidth, and efficiency remains difficult, particularly in the sub-6 GHz bands commonly used for consumer communications.

Flexibility requirements pose another critical challenge. Wearable devices demand antennas that can withstand repeated bending, stretching, and compression without performance degradation. Current metasurface designs often utilize rigid substrates that crack under mechanical stress, leading to resonance shifts and efficiency losses. Although flexible substrates exist, they frequently exhibit higher losses and reduced electromagnetic performance compared to their rigid counterparts.

Biocompatibility and safety concerns represent significant hurdles for body-worn applications. Metasurface antennas must comply with specific absorption rate (SAR) regulations while maintaining performance in close proximity to biological tissues. The complex electromagnetic interactions between metasurfaces and human tissue can alter radiation patterns and reduce efficiency, necessitating sophisticated design approaches.

Manufacturing scalability presents substantial difficulties. Current fabrication methods for high-performance metasurfaces often rely on expensive and time-consuming techniques like electron beam lithography or focused ion beam milling. These processes are incompatible with the high-volume, low-cost production requirements of consumer wearable devices. Alternative methods such as inkjet printing offer better scalability but typically yield lower performance.

Power consumption optimization remains problematic, particularly for active metasurface designs. Wearable devices have strict power budgets, yet tunable or reconfigurable metasurfaces often require additional biasing networks and control circuitry that increase power demands. Developing energy-efficient metasurface antennas without sacrificing functionality represents a significant engineering challenge.

Integration with other electronic components presents complex design considerations. Metasurface antennas must coexist with batteries, processors, sensors, and displays in extremely confined spaces. The electromagnetic coupling between these components can degrade antenna performance, while the metasurface itself may interfere with other device functions. Comprehensive electromagnetic compatibility analysis becomes essential but adds design complexity.

Environmental durability poses additional challenges, as wearable devices encounter sweat, moisture, temperature variations, and physical impacts. Metasurface antennas must maintain performance across these conditions, requiring protective encapsulation that doesn't compromise electromagnetic properties. Current encapsulation methods often introduce additional losses or detuning effects that must be compensated for in the design phase.

Flexibility requirements pose another critical challenge. Wearable devices demand antennas that can withstand repeated bending, stretching, and compression without performance degradation. Current metasurface designs often utilize rigid substrates that crack under mechanical stress, leading to resonance shifts and efficiency losses. Although flexible substrates exist, they frequently exhibit higher losses and reduced electromagnetic performance compared to their rigid counterparts.

Biocompatibility and safety concerns represent significant hurdles for body-worn applications. Metasurface antennas must comply with specific absorption rate (SAR) regulations while maintaining performance in close proximity to biological tissues. The complex electromagnetic interactions between metasurfaces and human tissue can alter radiation patterns and reduce efficiency, necessitating sophisticated design approaches.

Manufacturing scalability presents substantial difficulties. Current fabrication methods for high-performance metasurfaces often rely on expensive and time-consuming techniques like electron beam lithography or focused ion beam milling. These processes are incompatible with the high-volume, low-cost production requirements of consumer wearable devices. Alternative methods such as inkjet printing offer better scalability but typically yield lower performance.

Power consumption optimization remains problematic, particularly for active metasurface designs. Wearable devices have strict power budgets, yet tunable or reconfigurable metasurfaces often require additional biasing networks and control circuitry that increase power demands. Developing energy-efficient metasurface antennas without sacrificing functionality represents a significant engineering challenge.

Integration with other electronic components presents complex design considerations. Metasurface antennas must coexist with batteries, processors, sensors, and displays in extremely confined spaces. The electromagnetic coupling between these components can degrade antenna performance, while the metasurface itself may interfere with other device functions. Comprehensive electromagnetic compatibility analysis becomes essential but adds design complexity.

Environmental durability poses additional challenges, as wearable devices encounter sweat, moisture, temperature variations, and physical impacts. Metasurface antennas must maintain performance across these conditions, requiring protective encapsulation that doesn't compromise electromagnetic properties. Current encapsulation methods often introduce additional losses or detuning effects that must be compensated for in the design phase.

Existing Metasurface Integration Approaches for Wearables

01 Metasurface antenna design principles

Metasurface antennas utilize engineered surfaces with sub-wavelength structures to manipulate electromagnetic waves. These designs typically involve periodic arrangements of resonant elements that control phase, amplitude, and polarization of incident waves. The fundamental principles include impedance matching, phase gradient control, and resonant element optimization to achieve desired radiation patterns, bandwidth, and efficiency characteristics.- Design and structure of metasurface antennas: Metasurface antennas utilize engineered surfaces with sub-wavelength structures to manipulate electromagnetic waves. These designs typically incorporate periodic or quasi-periodic arrays of resonant elements that can control phase, amplitude, and polarization of incident waves. The structural design enables enhanced directivity, bandwidth, and radiation efficiency compared to conventional antennas, while maintaining a low profile and reduced physical footprint.

- Frequency manipulation and multi-band operation: Metasurface antennas can be engineered to operate across multiple frequency bands simultaneously or to dynamically tune their operating frequency. By incorporating specific resonant elements and geometries, these antennas can achieve frequency selective surfaces, wideband operation, or reconfigurable frequency responses. This capability makes them particularly valuable for applications requiring operation across diverse frequency ranges or adaptive spectrum utilization.

- Beam steering and radiation pattern control: Advanced metasurface antennas incorporate mechanisms for dynamic beam steering and radiation pattern control without mechanical movement. By integrating active components such as varactors, PIN diodes, or MEMS switches, these antennas can electronically reconfigure their radiation characteristics. This enables capabilities such as beam scanning, null placement, and adaptive pattern formation, which are critical for applications in radar systems, satellite communications, and 5G/6G wireless networks.

- Integration with communication systems: Metasurface antennas are being integrated into modern communication systems to enhance performance and enable new capabilities. These implementations include integration with MIMO systems, IoT devices, satellite communications, and next-generation wireless networks. The compact form factor and superior electromagnetic properties of metasurface antennas make them ideal for space-constrained applications while providing improved signal quality, coverage, and data throughput.

- Fabrication techniques and materials: Advanced fabrication methods and novel materials are being developed specifically for metasurface antennas. These include techniques such as photolithography, 3D printing, and nanoimprinting, along with materials like liquid crystals, phase-change materials, and 2D materials (graphene, MXenes). These innovations enable the creation of complex metasurface geometries with precise sub-wavelength features while allowing for flexible, conformal, or transparent antenna implementations that can be integrated into various surfaces and devices.

02 Beam steering and focusing capabilities

Metasurface antennas can dynamically control beam direction and focus without mechanical movement. By incorporating tunable elements or reconfigurable materials, these antennas can electronically steer radiation patterns in desired directions. Advanced designs enable multi-beam operation, adaptive focusing, and real-time beam reconfiguration for applications in radar systems, satellite communications, and wireless networks.Expand Specific Solutions03 Frequency-selective metasurface antennas

Frequency-selective metasurface antennas incorporate structures that respond differently to various frequency bands. These designs can achieve multi-band operation, frequency filtering, or wideband performance through carefully engineered resonant elements. By manipulating the geometry, spacing, and material properties of the metasurface elements, these antennas can operate efficiently across multiple frequency ranges while maintaining compact form factors.Expand Specific Solutions04 Fabrication and manufacturing techniques

Advanced fabrication methods for metasurface antennas include printed circuit board technology, lithography, additive manufacturing, and nanofabrication techniques. These processes enable precise creation of sub-wavelength structures required for effective metasurface operation. Manufacturing considerations include material selection, structural precision, scalability, and cost-effectiveness for various applications ranging from consumer electronics to aerospace systems.Expand Specific Solutions05 Integration with communication systems

Metasurface antennas can be integrated with various communication systems to enhance performance. These antennas offer advantages including reduced size, improved gain, and enhanced directivity compared to conventional antennas. Integration approaches include embedding metasurfaces in mobile devices, incorporating them into base station equipment, and deploying them in satellite communication systems. The compact nature and versatile performance characteristics make metasurface antennas particularly valuable for next-generation wireless networks.Expand Specific Solutions

Leading Companies in Metasurface Antenna Research

Metasurface antennas represent an emerging technology in the wearable device integration market, currently in the early growth phase with increasing adoption across consumer electronics and telecommunications sectors. The global market is expanding rapidly, projected to reach significant scale as applications in smart wearables proliferate. Technologically, the field shows varying maturity levels: established players like Kymeta Corp. lead in commercial deployment for satellite communications, while tech giants Samsung, Google, and Huawei are advancing integration capabilities for consumer applications. Research institutions (CNRS, Sorbonne, South China University of Technology) are driving fundamental innovations, with companies like Oura Health and Snap exploring specialized implementations. The ecosystem demonstrates a balanced mix of academic research, corporate R&D, and emerging startups like Ultimetas, indicating healthy innovation potential despite remaining miniaturization and manufacturing challenges.

Kymeta Corp.

Technical Solution: Kymeta has developed innovative metasurface antenna technology specifically designed for mobile connectivity applications. Their mTenna platform utilizes electronically steerable metamaterial-based antennas that can maintain satellite connections while in motion. For wearable integration, Kymeta has miniaturized their technology to create low-profile, lightweight antennas that can be embedded into flexible substrates. Their proprietary Holographic Beam Forming technology enables dynamic beam steering without mechanical parts, making it ideal for wearable applications where traditional phased arrays would be impractical. The company has demonstrated prototypes with thickness under 2mm that can be conformed to curved surfaces while maintaining high gain and efficiency across multiple frequency bands[1]. Kymeta's approach uses liquid crystal-based tunable elements within the metasurface structure to achieve electronic reconfigurability with lower power consumption compared to conventional phased arrays.

Strengths: Superior beam-steering capabilities without mechanical components; ultra-thin form factor suitable for wearable integration; lower power consumption than conventional phased arrays. Weaknesses: Higher manufacturing costs compared to conventional antennas; requires specialized control electronics that add complexity; performance may degrade when conformally mounted on highly curved surfaces.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced metasurface antenna technology specifically targeting wearable device integration. Their approach utilizes multi-functional metasurfaces that combine antenna functionality with electromagnetic interference (EMI) shielding capabilities. Samsung's design incorporates patterned metallic structures on flexible polymer substrates that can be directly integrated into the housing of wearable devices like smartwatches and fitness trackers. The company has demonstrated metasurface antennas operating in the 2.4GHz and 5GHz bands with a thickness of less than 0.5mm while achieving gains comparable to conventional antennas that are significantly larger[2]. Their proprietary fabrication technique allows for mass production using standard PCB manufacturing processes, reducing costs while maintaining performance. Samsung has also developed adaptive impedance matching circuits that work in conjunction with their metasurface antennas to compensate for detuning effects when worn on the body, addressing a key challenge for wearable antenna performance[3]. Recent prototypes have shown the ability to maintain stable performance even when bent or flexed, making them suitable for integration into fabric-based wearables.

Strengths: Extremely thin profile (sub-0.5mm) ideal for space-constrained wearables; dual functionality providing both antenna performance and EMI shielding; established manufacturing processes for mass production. Weaknesses: Performance still degrades somewhat in close proximity to human tissue; limited bandwidth compared to some competing technologies; requires additional adaptive circuitry to maintain performance in dynamic wearable environments.

Key Patents and Breakthroughs in Metasurface Antennas

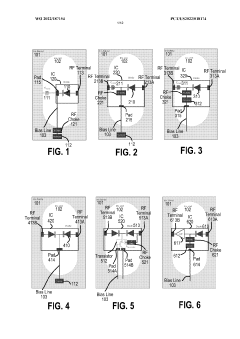

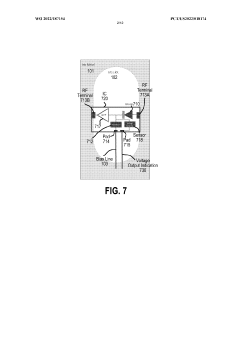

Metasurface antenna with integrated varactor circuits

PatentWO2022187154A1

Innovation

- Integration of varactor diodes on IC chips within metasurface antennas, coupled with transistors to provide tuning voltage, allows for independent control of antenna elements, eliminating the need for external transistors and enabling active metasurface antennas without centralized down-converters or power amplifiers.

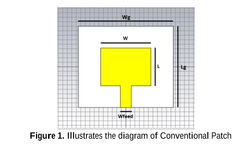

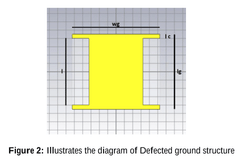

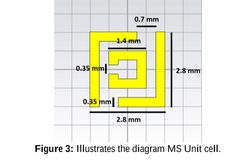

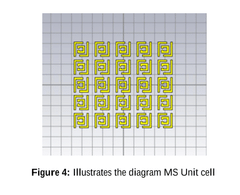

Design of metasurface (MS) based microstrip patch antenna at 5 ghz band suitable for wi-fi and wimax applications

PatentPendingIN202241076118A

Innovation

- Integration of metasurface (MS) technology with microstrip patch antennas to enhance performance characteristics for Wi-Fi and WiMAX applications in the 5 GHz band.

- Utilization of artificially fabricated metamaterials with negative permeability and permittivity properties to provide improved surface impedance and beam shaping capabilities.

- Development of frequency reconfigurable antennas based on metasurface technology operating in the 4.5-5.5 GHz band with potential for gain optimization.

Materials Science Advancements for Flexible Metasurfaces

Recent advancements in materials science have revolutionized the development of flexible metasurfaces, creating unprecedented opportunities for integration into wearable antenna systems. Traditional rigid metasurfaces, while effective in conventional applications, present significant limitations when incorporated into wearable devices that require conformability to human body contours and resilience during movement.

The emergence of novel flexible substrate materials represents a critical breakthrough in this domain. Polymers such as polyimide (PI), polyethylene terephthalate (PET), and polydimethylsiloxane (PDMS) have demonstrated exceptional mechanical flexibility while maintaining stable electromagnetic properties across varying deformation states. These materials exhibit low loss tangent values and consistent dielectric constants, essential characteristics for reliable antenna performance in dynamic environments.

Conductive nanomaterials have similarly transformed the fabrication landscape for flexible metasurface antennas. Silver nanowires (AgNWs), graphene, and liquid metal alloys like eutectic gallium-indium (EGaIn) enable the creation of stretchable conductive patterns that maintain functionality under mechanical stress. Recent research has achieved conductivity retention exceeding 90% at strain levels of 30%, representing significant progress toward truly conformable antenna systems.

Fabrication techniques have evolved in parallel with material innovations. Additive manufacturing methods, particularly direct ink writing and aerosol jet printing, now allow precise deposition of conductive materials onto flexible substrates with feature resolution approaching 10 micrometers. These techniques facilitate complex metasurface geometries previously unattainable through conventional fabrication routes.

Encapsulation technologies have similarly advanced to protect flexible metasurfaces from environmental factors while preserving their mechanical properties. Thin-film barrier materials incorporating alternating organic and inorganic layers achieve water vapor transmission rates below 10^-6 g/m²/day, ensuring long-term reliability in wearable applications exposed to perspiration and environmental moisture.

Composite material systems represent another frontier, with researchers developing heterogeneous structures that combine the electromagnetic performance of traditional metasurfaces with the mechanical compliance required for wearable integration. Metamaterial-embedded elastomers and fabric-integrated conductive meshes demonstrate this approach, achieving deformation-invariant electromagnetic responses through careful material selection and structural design.

The integration of self-healing materials constitutes an emerging research direction with significant potential for wearable metasurface antennas. Polymers incorporating dynamic covalent bonds or microcapsules with healing agents can autonomously repair mechanical damage, potentially extending device lifetime in the challenging mechanical environment of wearable applications.

The emergence of novel flexible substrate materials represents a critical breakthrough in this domain. Polymers such as polyimide (PI), polyethylene terephthalate (PET), and polydimethylsiloxane (PDMS) have demonstrated exceptional mechanical flexibility while maintaining stable electromagnetic properties across varying deformation states. These materials exhibit low loss tangent values and consistent dielectric constants, essential characteristics for reliable antenna performance in dynamic environments.

Conductive nanomaterials have similarly transformed the fabrication landscape for flexible metasurface antennas. Silver nanowires (AgNWs), graphene, and liquid metal alloys like eutectic gallium-indium (EGaIn) enable the creation of stretchable conductive patterns that maintain functionality under mechanical stress. Recent research has achieved conductivity retention exceeding 90% at strain levels of 30%, representing significant progress toward truly conformable antenna systems.

Fabrication techniques have evolved in parallel with material innovations. Additive manufacturing methods, particularly direct ink writing and aerosol jet printing, now allow precise deposition of conductive materials onto flexible substrates with feature resolution approaching 10 micrometers. These techniques facilitate complex metasurface geometries previously unattainable through conventional fabrication routes.

Encapsulation technologies have similarly advanced to protect flexible metasurfaces from environmental factors while preserving their mechanical properties. Thin-film barrier materials incorporating alternating organic and inorganic layers achieve water vapor transmission rates below 10^-6 g/m²/day, ensuring long-term reliability in wearable applications exposed to perspiration and environmental moisture.

Composite material systems represent another frontier, with researchers developing heterogeneous structures that combine the electromagnetic performance of traditional metasurfaces with the mechanical compliance required for wearable integration. Metamaterial-embedded elastomers and fabric-integrated conductive meshes demonstrate this approach, achieving deformation-invariant electromagnetic responses through careful material selection and structural design.

The integration of self-healing materials constitutes an emerging research direction with significant potential for wearable metasurface antennas. Polymers incorporating dynamic covalent bonds or microcapsules with healing agents can autonomously repair mechanical damage, potentially extending device lifetime in the challenging mechanical environment of wearable applications.

Biocompatibility and Safety Considerations

The integration of metasurface antennas into wearable devices necessitates rigorous assessment of biocompatibility and safety considerations. These factors are paramount when designing technology that maintains prolonged contact with human skin and operates in close proximity to biological tissues.

Materials used in metasurface antenna fabrication must meet stringent biocompatibility standards. Traditional antenna materials like copper and other metals may cause skin irritation or allergic reactions when in direct contact with the epidermis. Recent research has focused on developing biocompatible alternatives such as conductive polymers, silver nanowires embedded in flexible substrates, and graphene-based composites that minimize adverse biological responses while maintaining electromagnetic performance.

Electromagnetic radiation safety represents another critical consideration. While metasurface antennas typically operate at power levels below international safety thresholds, their proximity to the human body requires careful evaluation of Specific Absorption Rate (SAR) values. Studies indicate that properly designed metasurface antennas can actually reduce SAR compared to conventional antennas by directing electromagnetic energy away from the body and improving radiation efficiency.

Long-term exposure effects must also be thoroughly investigated. Current scientific consensus suggests minimal risk from non-ionizing radiation at the power levels used in wearable communications, but continuous research monitors potential cellular-level impacts. Metasurface designs that incorporate frequency-selective surfaces can potentially mitigate any concerns by filtering specific wavelengths.

Thermal management presents additional challenges, as excessive heat generation may cause discomfort or, in extreme cases, thermal damage to skin tissue. Advanced metasurface designs incorporate passive cooling mechanisms and thermally conductive materials to dissipate heat efficiently. Some researchers are exploring phase-change materials that can absorb excess thermal energy during peak operation periods.

Regulatory compliance frameworks vary globally, with standards established by organizations such as the FDA, FCC, and IEC governing wearable electronic devices. These regulations typically specify maximum permissible exposure limits, biocompatibility testing protocols, and performance standards. Manufacturers must navigate these complex regulatory landscapes to ensure their metasurface-enabled wearable devices receive necessary approvals.

Emerging research is investigating biologically inspired metasurface designs that not only ensure safety but potentially offer beneficial interactions with biological systems. These include surfaces with antimicrobial properties to prevent bacterial colonization during extended wear periods and materials that adapt their properties based on physiological conditions of the wearer.

Materials used in metasurface antenna fabrication must meet stringent biocompatibility standards. Traditional antenna materials like copper and other metals may cause skin irritation or allergic reactions when in direct contact with the epidermis. Recent research has focused on developing biocompatible alternatives such as conductive polymers, silver nanowires embedded in flexible substrates, and graphene-based composites that minimize adverse biological responses while maintaining electromagnetic performance.

Electromagnetic radiation safety represents another critical consideration. While metasurface antennas typically operate at power levels below international safety thresholds, their proximity to the human body requires careful evaluation of Specific Absorption Rate (SAR) values. Studies indicate that properly designed metasurface antennas can actually reduce SAR compared to conventional antennas by directing electromagnetic energy away from the body and improving radiation efficiency.

Long-term exposure effects must also be thoroughly investigated. Current scientific consensus suggests minimal risk from non-ionizing radiation at the power levels used in wearable communications, but continuous research monitors potential cellular-level impacts. Metasurface designs that incorporate frequency-selective surfaces can potentially mitigate any concerns by filtering specific wavelengths.

Thermal management presents additional challenges, as excessive heat generation may cause discomfort or, in extreme cases, thermal damage to skin tissue. Advanced metasurface designs incorporate passive cooling mechanisms and thermally conductive materials to dissipate heat efficiently. Some researchers are exploring phase-change materials that can absorb excess thermal energy during peak operation periods.

Regulatory compliance frameworks vary globally, with standards established by organizations such as the FDA, FCC, and IEC governing wearable electronic devices. These regulations typically specify maximum permissible exposure limits, biocompatibility testing protocols, and performance standards. Manufacturers must navigate these complex regulatory landscapes to ensure their metasurface-enabled wearable devices receive necessary approvals.

Emerging research is investigating biologically inspired metasurface designs that not only ensure safety but potentially offer beneficial interactions with biological systems. These include surfaces with antimicrobial properties to prevent bacterial colonization during extended wear periods and materials that adapt their properties based on physiological conditions of the wearer.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!