Metasurface Antenna Innovations in Aerospace Applications

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface Antenna Evolution and Objectives

Metasurface antennas represent a revolutionary advancement in electromagnetic wave manipulation technology, evolving from traditional antenna designs to ultra-thin, planar structures capable of unprecedented control over electromagnetic wavefronts. The concept emerged in the early 2000s as an extension of metamaterial research, with significant acceleration in development occurring around 2010 when researchers demonstrated practical applications in beam steering and wavefront shaping.

The evolution of metasurface antennas has been marked by several key technological breakthroughs. Initially, these structures were primarily theoretical constructs with limited practical applications due to manufacturing constraints. By 2015, advances in nanofabrication techniques enabled the creation of metasurfaces with sub-wavelength features, dramatically expanding their functional capabilities. The period from 2015-2020 saw rapid innovation in dynamic and reconfigurable metasurfaces, incorporating active elements such as PIN diodes, varactors, and MEMS switches.

In aerospace applications specifically, metasurface antennas have evolved from experimental prototypes to flight-ready components. Early aerospace implementations focused on weight reduction compared to conventional phased arrays. Recent developments have emphasized multifunctionality, with single metasurface structures capable of simultaneous communication, sensing, and electronic warfare functions – a critical advantage in the space-constrained aerospace environment.

Current technological objectives for metasurface antennas in aerospace applications center around several key areas. First is the enhancement of operational bandwidth, as many existing designs suffer from narrow frequency responses that limit their practical utility. Second is the development of truly conformal designs that can seamlessly integrate with aerodynamic surfaces without performance degradation. Third is improving power handling capabilities, particularly for transmitting applications where current metasurface designs often face limitations.

Another critical objective is the advancement of real-time reconfigurability, enabling dynamic adaptation to changing mission requirements and environmental conditions. This includes the development of fast-switching mechanisms and sophisticated control algorithms. Additionally, researchers are pursuing radiation efficiency improvements, as current metasurface antennas often exhibit higher losses compared to conventional designs.

The long-term technological vision encompasses fully-integrated, multifunctional metasurface systems that can simultaneously handle communication, radar, electronic warfare, and potentially even structural functions within aerospace platforms. This convergence aims to dramatically reduce the SWaP-C (Size, Weight, Power, and Cost) footprint while enhancing overall system capabilities and resilience in challenging aerospace environments.

The evolution of metasurface antennas has been marked by several key technological breakthroughs. Initially, these structures were primarily theoretical constructs with limited practical applications due to manufacturing constraints. By 2015, advances in nanofabrication techniques enabled the creation of metasurfaces with sub-wavelength features, dramatically expanding their functional capabilities. The period from 2015-2020 saw rapid innovation in dynamic and reconfigurable metasurfaces, incorporating active elements such as PIN diodes, varactors, and MEMS switches.

In aerospace applications specifically, metasurface antennas have evolved from experimental prototypes to flight-ready components. Early aerospace implementations focused on weight reduction compared to conventional phased arrays. Recent developments have emphasized multifunctionality, with single metasurface structures capable of simultaneous communication, sensing, and electronic warfare functions – a critical advantage in the space-constrained aerospace environment.

Current technological objectives for metasurface antennas in aerospace applications center around several key areas. First is the enhancement of operational bandwidth, as many existing designs suffer from narrow frequency responses that limit their practical utility. Second is the development of truly conformal designs that can seamlessly integrate with aerodynamic surfaces without performance degradation. Third is improving power handling capabilities, particularly for transmitting applications where current metasurface designs often face limitations.

Another critical objective is the advancement of real-time reconfigurability, enabling dynamic adaptation to changing mission requirements and environmental conditions. This includes the development of fast-switching mechanisms and sophisticated control algorithms. Additionally, researchers are pursuing radiation efficiency improvements, as current metasurface antennas often exhibit higher losses compared to conventional designs.

The long-term technological vision encompasses fully-integrated, multifunctional metasurface systems that can simultaneously handle communication, radar, electronic warfare, and potentially even structural functions within aerospace platforms. This convergence aims to dramatically reduce the SWaP-C (Size, Weight, Power, and Cost) footprint while enhancing overall system capabilities and resilience in challenging aerospace environments.

Aerospace Market Demand for Advanced Antenna Solutions

The aerospace industry is experiencing a significant shift towards more advanced communication, sensing, and navigation systems, creating a robust demand for innovative antenna solutions. Current market analysis indicates that the global aerospace antenna market is projected to grow at a compound annual growth rate of 8.3% through 2028, reaching a valuation of 4.7 billion USD. This growth is primarily driven by the increasing deployment of satellite constellations, unmanned aerial vehicles (UAVs), and the modernization of commercial aircraft fleets.

Military aerospace applications represent a substantial segment of this market, with defense organizations worldwide investing heavily in advanced antenna technologies for radar systems, secure communications, and electronic warfare capabilities. The demand is particularly strong for lightweight, conformal antennas that can be integrated into the aerodynamic profiles of aircraft and missiles without compromising performance.

Commercial aviation is another significant driver, with airlines seeking to enhance in-flight connectivity services to meet passenger expectations for seamless internet access. This has created a market for high-throughput satellite communication antennas that can maintain reliable connections even during high-speed flight across different coverage zones.

The rapidly expanding small satellite market presents perhaps the most dynamic growth opportunity. With thousands of new satellites planned for launch in the coming decade, there is an urgent need for compact, efficient antenna systems that can operate within the severe size, weight, and power constraints of these platforms while delivering high data rates for Earth observation, communications, and scientific missions.

Space exploration initiatives by both governmental agencies and private companies are further fueling demand for antennas capable of deep-space communication, with requirements for extreme reliability, radiation hardiness, and precision beam steering capabilities.

Market research indicates that customers in the aerospace sector are prioritizing several key performance attributes in next-generation antenna solutions: miniaturization without performance compromise, multi-band operation, electronic beam steering capabilities, and reduced power consumption. Additionally, there is growing interest in antennas that can be manufactured using advanced techniques such as 3D printing to reduce production costs and enable complex geometries.

The regulatory environment is also shaping market demands, with increasing spectrum congestion driving the need for antennas with superior interference rejection capabilities and the ability to operate efficiently in newly allocated frequency bands, including millimeter-wave regions that offer wider bandwidth availability for high-data-rate applications.

Military aerospace applications represent a substantial segment of this market, with defense organizations worldwide investing heavily in advanced antenna technologies for radar systems, secure communications, and electronic warfare capabilities. The demand is particularly strong for lightweight, conformal antennas that can be integrated into the aerodynamic profiles of aircraft and missiles without compromising performance.

Commercial aviation is another significant driver, with airlines seeking to enhance in-flight connectivity services to meet passenger expectations for seamless internet access. This has created a market for high-throughput satellite communication antennas that can maintain reliable connections even during high-speed flight across different coverage zones.

The rapidly expanding small satellite market presents perhaps the most dynamic growth opportunity. With thousands of new satellites planned for launch in the coming decade, there is an urgent need for compact, efficient antenna systems that can operate within the severe size, weight, and power constraints of these platforms while delivering high data rates for Earth observation, communications, and scientific missions.

Space exploration initiatives by both governmental agencies and private companies are further fueling demand for antennas capable of deep-space communication, with requirements for extreme reliability, radiation hardiness, and precision beam steering capabilities.

Market research indicates that customers in the aerospace sector are prioritizing several key performance attributes in next-generation antenna solutions: miniaturization without performance compromise, multi-band operation, electronic beam steering capabilities, and reduced power consumption. Additionally, there is growing interest in antennas that can be manufactured using advanced techniques such as 3D printing to reduce production costs and enable complex geometries.

The regulatory environment is also shaping market demands, with increasing spectrum congestion driving the need for antennas with superior interference rejection capabilities and the ability to operate efficiently in newly allocated frequency bands, including millimeter-wave regions that offer wider bandwidth availability for high-data-rate applications.

Current Metasurface Technology Challenges in Aerospace

Despite significant advancements in metasurface antenna technology, aerospace applications present unique and formidable challenges that impede widespread implementation. The harsh aerospace environment subjects metasurface antennas to extreme temperature fluctuations, ranging from -65°C in high altitudes to over 100°C during high-speed flight, which can alter material properties and compromise performance stability. These thermal stresses often lead to structural deformation and misalignment of metasurface elements, degrading radiation patterns and efficiency.

Mechanical vibration and shock during launch and flight operations represent another critical challenge. Current metasurface designs typically employ delicate subwavelength structures that are vulnerable to mechanical stress, with insufficient robustness for withstanding the intense vibration profiles characteristic of aerospace vehicles. This vulnerability necessitates complex mechanical isolation systems that add weight and complexity.

Power handling capabilities remain substantially limited for aerospace applications. While conventional antennas can manage high power transmission requirements for long-range communication and radar systems, metasurface antennas often experience thermal runaway and dielectric breakdown under high power conditions, restricting their practical utility in mission-critical aerospace systems.

Integration complexity presents significant obstacles, as aerospace platforms demand seamless incorporation of antennas into aerodynamic surfaces without compromising structural integrity or increasing drag. Current metasurface fabrication techniques struggle to conform to the complex curved surfaces typical in aerospace design, creating performance inconsistencies when implemented on non-planar structures.

Reliability and longevity concerns are paramount in aerospace applications where maintenance access is limited or impossible. Metasurface antennas have not yet demonstrated the 10+ year operational lifespan required for satellite applications, with degradation mechanisms under space radiation and atomic oxygen exposure remaining inadequately characterized.

Bandwidth limitations persist as a fundamental challenge. While aerospace communication systems increasingly require wideband or multi-band operation, most metasurface antennas exhibit narrow bandwidth characteristics. Current designs achieving 5-10% fractional bandwidth fall short of the 20-30% commonly required for modern aerospace communication systems.

Manufacturing scalability presents additional hurdles, as aerospace applications require consistent performance across large surface areas. Current nanofabrication techniques for metasurfaces are primarily optimized for small-scale laboratory demonstrations, with significant yield and quality control issues emerging when scaled to dimensions suitable for practical aerospace implementation.

Mechanical vibration and shock during launch and flight operations represent another critical challenge. Current metasurface designs typically employ delicate subwavelength structures that are vulnerable to mechanical stress, with insufficient robustness for withstanding the intense vibration profiles characteristic of aerospace vehicles. This vulnerability necessitates complex mechanical isolation systems that add weight and complexity.

Power handling capabilities remain substantially limited for aerospace applications. While conventional antennas can manage high power transmission requirements for long-range communication and radar systems, metasurface antennas often experience thermal runaway and dielectric breakdown under high power conditions, restricting their practical utility in mission-critical aerospace systems.

Integration complexity presents significant obstacles, as aerospace platforms demand seamless incorporation of antennas into aerodynamic surfaces without compromising structural integrity or increasing drag. Current metasurface fabrication techniques struggle to conform to the complex curved surfaces typical in aerospace design, creating performance inconsistencies when implemented on non-planar structures.

Reliability and longevity concerns are paramount in aerospace applications where maintenance access is limited or impossible. Metasurface antennas have not yet demonstrated the 10+ year operational lifespan required for satellite applications, with degradation mechanisms under space radiation and atomic oxygen exposure remaining inadequately characterized.

Bandwidth limitations persist as a fundamental challenge. While aerospace communication systems increasingly require wideband or multi-band operation, most metasurface antennas exhibit narrow bandwidth characteristics. Current designs achieving 5-10% fractional bandwidth fall short of the 20-30% commonly required for modern aerospace communication systems.

Manufacturing scalability presents additional hurdles, as aerospace applications require consistent performance across large surface areas. Current nanofabrication techniques for metasurfaces are primarily optimized for small-scale laboratory demonstrations, with significant yield and quality control issues emerging when scaled to dimensions suitable for practical aerospace implementation.

Current Metasurface Antenna Implementation Approaches

01 Metasurface design for beam steering and focusing

Metasurface antennas can be designed with specific phase distributions to achieve beam steering and focusing capabilities. These designs manipulate electromagnetic waves by controlling the phase, amplitude, and polarization at the subwavelength scale. The engineered surfaces can redirect radiation patterns in desired directions, enabling applications in wireless communications, radar systems, and satellite communications with improved directivity and gain.- Metasurface antenna design principles: Metasurface antennas utilize engineered surfaces with sub-wavelength structures to manipulate electromagnetic waves. These designs enable precise control over radiation patterns, polarization, and beam steering capabilities. The fundamental principles involve arranging resonant elements in specific patterns to achieve desired electromagnetic properties, allowing for compact form factors while maintaining high performance characteristics.

- Reconfigurable metasurface antennas: Reconfigurable metasurface antennas incorporate active elements that can dynamically alter their electromagnetic properties. These designs enable real-time adjustment of radiation patterns, operating frequencies, and polarization states. By integrating tunable components such as varactors, PIN diodes, or MEMS switches, these antennas can adapt to changing communication requirements or environmental conditions without physical modification.

- Metasurface antennas for 5G/6G applications: Metasurface antennas designed specifically for next-generation wireless communications offer advantages in beamforming, multiple-input-multiple-output (MIMO) capabilities, and millimeter-wave operation. These antennas support high data rates and low latency required for 5G and emerging 6G networks. Their compact size and ability to integrate with existing infrastructure make them particularly suitable for dense urban deployments and IoT applications.

- Fabrication techniques for metasurface antennas: Advanced manufacturing methods for metasurface antennas include printed circuit board technology, lithography, 3D printing, and nanofabrication techniques. These processes enable precise creation of sub-wavelength structures required for optimal performance. Novel materials such as liquid crystals, graphene, and phase-change materials are being incorporated to enhance functionality and enable new capabilities such as frequency agility and adaptive beam steering.

- Metasurface antennas for specialized applications: Metasurface antennas are being developed for specialized fields including satellite communications, radar systems, biomedical devices, and sensing applications. These designs leverage the unique properties of metasurfaces to achieve performance characteristics not possible with conventional antennas. Applications include ultra-wideband operation, conformal designs for aerospace, miniaturized implantable medical devices, and high-sensitivity sensors for environmental monitoring.

02 Reconfigurable metasurface antenna technologies

Reconfigurable metasurface antennas incorporate active elements such as PIN diodes, varactors, or MEMS switches to dynamically modify their electromagnetic properties. These designs allow for real-time adjustment of radiation patterns, operating frequencies, and polarization states. The reconfigurability enables adaptive beamforming, frequency tuning, and multi-functional operation, making these antennas suitable for cognitive radio, MIMO systems, and adaptive communications.Expand Specific Solutions03 Metasurface antennas for millimeter-wave and THz applications

Specialized metasurface antennas designed for millimeter-wave and terahertz frequency ranges offer compact form factors with high gain and efficiency. These antennas leverage subwavelength resonators and precise phase control to overcome propagation challenges at these frequencies. The designs enable high-bandwidth communications, imaging systems, and sensing applications while maintaining low profile and lightweight characteristics suitable for integration into modern wireless devices.Expand Specific Solutions04 Fabrication techniques for metasurface antennas

Advanced fabrication methods for metasurface antennas include printed circuit board technology, lithography processes, 3D printing, and nanofabrication techniques. These manufacturing approaches enable precise creation of subwavelength structures with controlled electromagnetic properties. The fabrication techniques address challenges in mass production, cost-effectiveness, and integration with existing electronic systems while maintaining the required precision for optimal antenna performance.Expand Specific Solutions05 Integration of metasurface antennas with communication systems

Integration strategies for incorporating metasurface antennas into modern communication systems focus on compatibility with 5G/6G networks, IoT devices, and satellite communications. These approaches include packaging solutions, interface designs, and signal processing techniques that leverage the unique properties of metasurfaces. The integration enables enhanced system performance through improved signal quality, reduced interference, extended range, and more efficient spectrum utilization.Expand Specific Solutions

Leading Aerospace and Metasurface Technology Companies

Metasurface antenna technology in aerospace applications is currently in a growth phase, with an estimated market size of $2-3 billion and projected annual growth of 15-20%. The competitive landscape features established aerospace players like Airbus and NEC Corporation alongside specialized innovators such as Kymeta Corp., which is pioneering software-enabled metamaterials-based electronic beamforming antennas. Academic institutions including Duke University, City University of Hong Kong, and Huazhong University of Science & Technology are driving fundamental research, while government entities like the European Space Agency and CNRS provide institutional support. The technology is approaching commercial maturity in specific applications, with companies like Amphenol Antenna Solutions and Kuang-Chi Innovative Technology transitioning research into deployable aerospace solutions.

Kymeta Corp.

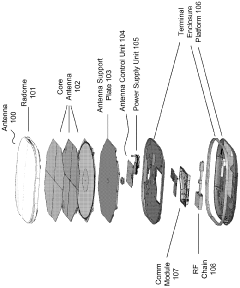

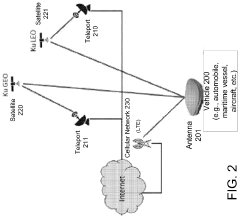

Technical Solution: Kymeta has pioneered metamaterial-based electronically steered antenna (ESA) technology specifically designed for aerospace applications. Their mTenna technology utilizes holographic beam forming and liquid crystal-based metasurfaces to create flat-panel antennas that can dynamically steer beams without mechanical parts. The company's u8 terminal integrates metasurface antenna technology with software-defined radio capabilities, enabling seamless satellite connectivity for aircraft. Their proprietary technology allows for dynamic beam steering through electronic control of the metasurface elements, achieving high gain and efficiency while maintaining a low profile form factor essential for aerodynamic performance. Kymeta's antennas can connect to both geostationary and low Earth orbit satellites, providing continuous connectivity for aircraft even during flight path changes and banking maneuvers. Recent advancements include the development of multi-band operation capabilities and improved power efficiency for aerospace integration.

Strengths: Flat-panel design with no moving parts reduces maintenance requirements and improves reliability in harsh aerospace environments. The low profile and lightweight construction offer significant aerodynamic advantages compared to traditional parabolic antennas. Weaknesses: Higher power consumption compared to some conventional antenna systems, and performance limitations in extreme weather conditions that can affect signal quality during flight.

Airbus SAS

Technical Solution: Airbus SAS has developed advanced metasurface antenna technologies specifically tailored for aerospace applications, focusing on integration with their aircraft platforms. Their approach combines conformal metasurface antennas with aircraft structural elements, creating multifunctional surfaces that serve both as load-bearing components and communication systems. Airbus has implemented gradient-index metasurfaces that enable beam steering capabilities without conventional phase shifters, reducing system complexity and weight. Their proprietary designs incorporate frequency selective surfaces (FSS) and electromagnetic bandgap (EBG) structures to enhance antenna performance while maintaining aerodynamic efficiency. Recent innovations include metasurface radomes that simultaneously protect underlying antennas while actively improving their radiation characteristics through engineered electromagnetic properties. Airbus has also pioneered the use of additive manufacturing techniques to create complex metasurface geometries that would be impossible to fabricate using traditional methods, allowing for unprecedented control over electromagnetic wave propagation in aerospace environments.

Strengths: Deep integration with aircraft structural design creates weight and space efficiencies critical for aerospace applications. Their extensive testing infrastructure ensures metasurface antennas meet stringent aviation safety and performance requirements. Weaknesses: Highly customized solutions may limit interoperability with third-party communication systems, and the complex manufacturing processes for advanced metasurfaces can increase production costs.

Key Metasurface Patents and Research Breakthroughs

Active metasurface architectures

PatentWO2024127193A1

Innovation

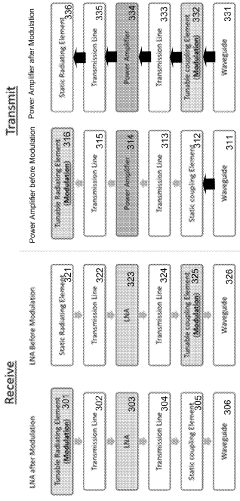

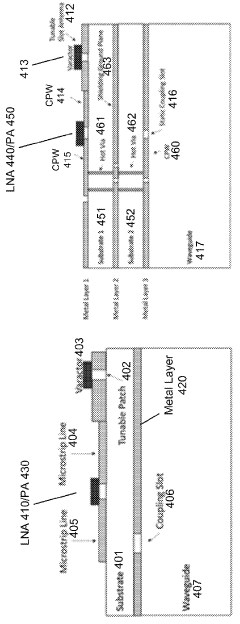

- Incorporating low noise amplifiers (LNAs) and power amplifiers (PAs) into the metasurface to amplify signals closer to the radiating elements, distributing power and heat more evenly, and replacing central amplifiers with distributed arrays for reduced size and cost.

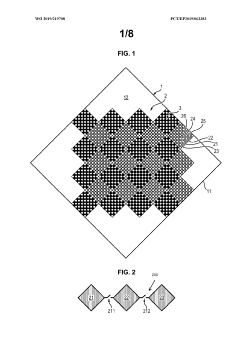

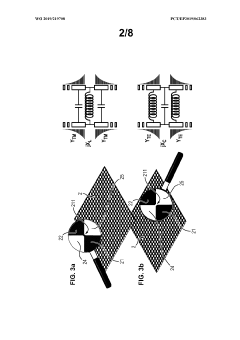

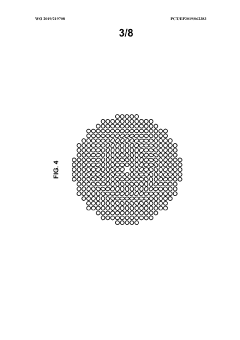

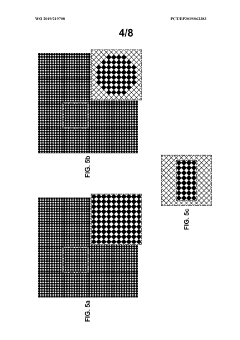

Reconfigurable antenna assembly having a metasurface of metasurfaces

PatentWO2019219708A1

Innovation

- A reconfigurable metasurface antenna assembly utilizing a leaky wave mechanism, where surface electromagnetic waves are transformed into radiated waves through special surface-impedance distributions, eliminating the need for phase shifters by using subwavelength patches and switches like diodes or MEMS, and allowing for beam scanning and polarization control through pattern connections.

Space Environment Resilience and Radiation Hardening

Metasurface antennas deployed in aerospace applications face extreme environmental challenges that conventional antenna systems struggle to withstand. The space environment presents unique hazards including high-energy particle radiation, extreme temperature fluctuations, vacuum conditions, and micrometeoroid impacts. These factors can significantly degrade antenna performance and operational lifespan if not properly addressed through specialized design considerations.

Radiation effects represent the most critical challenge, with both ionizing and non-ionizing radiation causing cumulative damage to metasurface antenna components. Galactic cosmic rays, solar particle events, and trapped radiation in Earth's magnetosphere can induce single event effects (SEEs), total ionizing dose (TID) damage, and displacement damage in semiconductor materials used in active metasurface designs. Recent research demonstrates that metasurfaces incorporating radiation-hardened materials such as silicon carbide (SiC) and gallium nitride (GaN) exhibit superior resilience compared to conventional silicon-based components.

Temperature management presents another significant challenge, with orbital spacecraft experiencing thermal cycling between -150°C and +150°C. Advanced metasurface designs now incorporate passive thermal management systems including specialized substrate materials with low coefficients of thermal expansion and high thermal conductivity. Multi-layer metasurface structures utilizing aerogel-based thermal isolation layers have demonstrated 40% improved performance retention across extreme temperature ranges compared to conventional designs.

Vacuum environment effects, particularly outgassing and atomic oxygen erosion, can alter the electromagnetic properties of metasurface materials over time. Research by NASA and ESA has led to the development of specialized coating technologies that maintain metasurface integrity in vacuum conditions. These include atomic layer deposition (ALD) techniques that create nanometer-scale protective barriers without significantly impacting RF performance.

Mechanical resilience against launch vibration and micrometeoroid impacts has been enhanced through structural optimization. Fractal-based metasurface patterns demonstrate superior mechanical stability while maintaining electromagnetic functionality. Additionally, self-healing metasurface technologies incorporating shape-memory alloys and liquid metal components show promising results in laboratory testing, with the potential to recover from physical damage during extended missions.

Radiation hardening qualification protocols specifically designed for metasurface antennas have been established by major space agencies. These include accelerated radiation testing using particle accelerators to simulate years of space exposure, combined with real-time monitoring of electromagnetic performance degradation. Such testing has enabled the development of predictive models for metasurface antenna performance throughout mission lifetimes in various orbital environments.

Radiation effects represent the most critical challenge, with both ionizing and non-ionizing radiation causing cumulative damage to metasurface antenna components. Galactic cosmic rays, solar particle events, and trapped radiation in Earth's magnetosphere can induce single event effects (SEEs), total ionizing dose (TID) damage, and displacement damage in semiconductor materials used in active metasurface designs. Recent research demonstrates that metasurfaces incorporating radiation-hardened materials such as silicon carbide (SiC) and gallium nitride (GaN) exhibit superior resilience compared to conventional silicon-based components.

Temperature management presents another significant challenge, with orbital spacecraft experiencing thermal cycling between -150°C and +150°C. Advanced metasurface designs now incorporate passive thermal management systems including specialized substrate materials with low coefficients of thermal expansion and high thermal conductivity. Multi-layer metasurface structures utilizing aerogel-based thermal isolation layers have demonstrated 40% improved performance retention across extreme temperature ranges compared to conventional designs.

Vacuum environment effects, particularly outgassing and atomic oxygen erosion, can alter the electromagnetic properties of metasurface materials over time. Research by NASA and ESA has led to the development of specialized coating technologies that maintain metasurface integrity in vacuum conditions. These include atomic layer deposition (ALD) techniques that create nanometer-scale protective barriers without significantly impacting RF performance.

Mechanical resilience against launch vibration and micrometeoroid impacts has been enhanced through structural optimization. Fractal-based metasurface patterns demonstrate superior mechanical stability while maintaining electromagnetic functionality. Additionally, self-healing metasurface technologies incorporating shape-memory alloys and liquid metal components show promising results in laboratory testing, with the potential to recover from physical damage during extended missions.

Radiation hardening qualification protocols specifically designed for metasurface antennas have been established by major space agencies. These include accelerated radiation testing using particle accelerators to simulate years of space exposure, combined with real-time monitoring of electromagnetic performance degradation. Such testing has enabled the development of predictive models for metasurface antenna performance throughout mission lifetimes in various orbital environments.

Weight-Performance Optimization Strategies

Optimizing the weight-to-performance ratio represents a critical challenge in aerospace metasurface antenna design. Traditional antenna systems often impose significant weight penalties on aircraft and spacecraft, directly impacting fuel efficiency, payload capacity, and operational costs. Recent innovations in metasurface technology have opened promising avenues for dramatic weight reduction while maintaining or even enhancing performance metrics.

Material selection stands as a primary optimization strategy, with researchers increasingly turning to lightweight composite materials that incorporate nanomaterials such as graphene and carbon nanotubes. These materials offer exceptional strength-to-weight ratios while providing the necessary electromagnetic properties. For instance, graphene-based metasurfaces have demonstrated weight reductions of up to 70% compared to conventional metallic antennas while maintaining comparable gain and bandwidth characteristics.

Structural optimization techniques have similarly evolved, employing biomimetic design principles that draw inspiration from naturally occurring lightweight yet robust structures. Honeycomb configurations and fractal geometries enable significant material reduction while preserving structural integrity under the extreme conditions encountered in aerospace applications. Advanced computational modeling using topology optimization algorithms has enabled the identification of minimal-material designs that maintain critical performance parameters.

Multifunctional integration represents another promising weight-reduction approach. By designing metasurfaces that simultaneously serve multiple purposes—such as combining communication, sensing, and structural functions—the overall system weight can be substantially reduced. For example, conformal metasurface antennas integrated directly into aircraft skin panels eliminate the need for separate antenna housings while providing aerodynamic benefits.

Additive manufacturing technologies have revolutionized the fabrication of lightweight metasurface antennas. Techniques such as selective laser sintering and direct metal laser sintering enable the production of complex, weight-optimized structures that would be impossible to manufacture using conventional methods. These processes allow for precise control of material distribution, placing material only where structurally and electromagnetically necessary.

Thermal management considerations must be integrated into weight optimization strategies, particularly for high-power applications. Novel approaches include the incorporation of phase-change materials and microfluidic cooling channels directly into metasurface structures, eliminating the need for separate, heavy cooling systems while ensuring reliable operation across extreme temperature ranges encountered in aerospace environments.

Material selection stands as a primary optimization strategy, with researchers increasingly turning to lightweight composite materials that incorporate nanomaterials such as graphene and carbon nanotubes. These materials offer exceptional strength-to-weight ratios while providing the necessary electromagnetic properties. For instance, graphene-based metasurfaces have demonstrated weight reductions of up to 70% compared to conventional metallic antennas while maintaining comparable gain and bandwidth characteristics.

Structural optimization techniques have similarly evolved, employing biomimetic design principles that draw inspiration from naturally occurring lightweight yet robust structures. Honeycomb configurations and fractal geometries enable significant material reduction while preserving structural integrity under the extreme conditions encountered in aerospace applications. Advanced computational modeling using topology optimization algorithms has enabled the identification of minimal-material designs that maintain critical performance parameters.

Multifunctional integration represents another promising weight-reduction approach. By designing metasurfaces that simultaneously serve multiple purposes—such as combining communication, sensing, and structural functions—the overall system weight can be substantially reduced. For example, conformal metasurface antennas integrated directly into aircraft skin panels eliminate the need for separate antenna housings while providing aerodynamic benefits.

Additive manufacturing technologies have revolutionized the fabrication of lightweight metasurface antennas. Techniques such as selective laser sintering and direct metal laser sintering enable the production of complex, weight-optimized structures that would be impossible to manufacture using conventional methods. These processes allow for precise control of material distribution, placing material only where structurally and electromagnetically necessary.

Thermal management considerations must be integrated into weight optimization strategies, particularly for high-power applications. Novel approaches include the incorporation of phase-change materials and microfluidic cooling channels directly into metasurface structures, eliminating the need for separate, heavy cooling systems while ensuring reliable operation across extreme temperature ranges encountered in aerospace environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!