Concepts of Plasma Flow Control in Improving Scramjet Aerodynamics

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasma Flow Control Background and Objectives

Plasma flow control has emerged as a promising technology in the field of scramjet aerodynamics, offering innovative solutions to enhance the performance and efficiency of supersonic combustion ramjet engines. The concept of plasma flow control dates back to the mid-20th century, with significant advancements occurring in recent decades due to increased research and technological capabilities.

The evolution of plasma flow control in scramjet aerodynamics has been driven by the need to overcome critical challenges in hypersonic flight. These challenges include shock wave management, boundary layer control, and combustion stability at high Mach numbers. As scramjet technology progressed, researchers recognized the potential of plasma-based techniques to address these issues, leading to a surge in scientific exploration and experimental studies.

The primary objective of plasma flow control in scramjet aerodynamics is to manipulate the airflow characteristics within the engine to optimize performance. This involves utilizing ionized gas (plasma) to influence the flow field, reduce drag, enhance mixing, and improve overall engine efficiency. By leveraging the unique properties of plasma, such as its ability to interact with electromagnetic fields and modify local flow properties, researchers aim to develop advanced control mechanisms for scramjet propulsion systems.

One of the key goals in this field is to achieve precise and responsive flow control at hypersonic speeds. This includes the ability to rapidly adjust flow parameters in real-time, allowing for adaptive control strategies that can respond to changing flight conditions. Additionally, researchers are focused on developing plasma actuators and systems that are compact, lightweight, and energy-efficient, making them suitable for integration into practical scramjet designs.

The technological trajectory of plasma flow control in scramjet aerodynamics has seen a shift from fundamental theoretical studies to more applied research and experimental demonstrations. Early work primarily focused on understanding the basic physics of plasma-flow interactions. However, recent efforts have been directed towards developing practical implementations and scaling up the technology for real-world applications.

As the field continues to evolve, researchers are exploring various plasma generation techniques, including dielectric barrier discharge (DBD), surface plasma discharges, and magnetohydrodynamic (MHD) interactions. These diverse approaches aim to address specific aspects of scramjet aerodynamics, such as shock wave mitigation, boundary layer separation control, and combustion enhancement.

The ultimate aim of this technological pursuit is to enable the development of more efficient and reliable scramjet engines, capable of sustained hypersonic flight. This has significant implications for both military and civilian applications, including advanced aerospace systems, rapid global transportation, and space exploration technologies.

The evolution of plasma flow control in scramjet aerodynamics has been driven by the need to overcome critical challenges in hypersonic flight. These challenges include shock wave management, boundary layer control, and combustion stability at high Mach numbers. As scramjet technology progressed, researchers recognized the potential of plasma-based techniques to address these issues, leading to a surge in scientific exploration and experimental studies.

The primary objective of plasma flow control in scramjet aerodynamics is to manipulate the airflow characteristics within the engine to optimize performance. This involves utilizing ionized gas (plasma) to influence the flow field, reduce drag, enhance mixing, and improve overall engine efficiency. By leveraging the unique properties of plasma, such as its ability to interact with electromagnetic fields and modify local flow properties, researchers aim to develop advanced control mechanisms for scramjet propulsion systems.

One of the key goals in this field is to achieve precise and responsive flow control at hypersonic speeds. This includes the ability to rapidly adjust flow parameters in real-time, allowing for adaptive control strategies that can respond to changing flight conditions. Additionally, researchers are focused on developing plasma actuators and systems that are compact, lightweight, and energy-efficient, making them suitable for integration into practical scramjet designs.

The technological trajectory of plasma flow control in scramjet aerodynamics has seen a shift from fundamental theoretical studies to more applied research and experimental demonstrations. Early work primarily focused on understanding the basic physics of plasma-flow interactions. However, recent efforts have been directed towards developing practical implementations and scaling up the technology for real-world applications.

As the field continues to evolve, researchers are exploring various plasma generation techniques, including dielectric barrier discharge (DBD), surface plasma discharges, and magnetohydrodynamic (MHD) interactions. These diverse approaches aim to address specific aspects of scramjet aerodynamics, such as shock wave mitigation, boundary layer separation control, and combustion enhancement.

The ultimate aim of this technological pursuit is to enable the development of more efficient and reliable scramjet engines, capable of sustained hypersonic flight. This has significant implications for both military and civilian applications, including advanced aerospace systems, rapid global transportation, and space exploration technologies.

Scramjet Market Analysis

The scramjet market is experiencing significant growth and transformation, driven by increasing demand for hypersonic and supersonic flight capabilities in both military and commercial sectors. The global scramjet market is expected to expand rapidly over the next decade, with a compound annual growth rate (CAGR) projected to be in the double digits. This growth is primarily fueled by investments in defense and space exploration programs across major economies.

In the defense sector, scramjet technology is viewed as a critical component for developing hypersonic missiles and aircraft. Several countries, including the United States, Russia, China, and India, are actively pursuing scramjet-powered hypersonic weapons systems. These systems offer strategic advantages in terms of speed, maneuverability, and penetration capabilities, making them highly sought after for military applications.

The commercial space sector is also showing increased interest in scramjet technology. As private companies aim to reduce the cost of space access and develop reusable launch systems, scramjet propulsion is being explored as a potential solution for more efficient and cost-effective space transportation. This includes applications in satellite deployment, space tourism, and potentially even point-to-point hypersonic travel on Earth.

The aerospace industry is another key driver of the scramjet market. Major aerospace companies and research institutions are investing in scramjet research and development to advance high-speed flight technologies. This includes efforts to develop hypersonic passenger aircraft that could dramatically reduce long-distance travel times.

However, the scramjet market faces several challenges. The technology is still in its early stages of development, with significant technical hurdles to overcome. These include issues related to thermal management, fuel efficiency, and materials capable of withstanding extreme temperatures and pressures. Additionally, the high costs associated with research, development, and testing of scramjet systems pose barriers to market entry and widespread adoption.

Despite these challenges, the potential applications and strategic importance of scramjet technology continue to drive investment and innovation in the field. As advancements are made in plasma flow control and other key areas, the scramjet market is expected to see continued growth and diversification of applications in the coming years.

In the defense sector, scramjet technology is viewed as a critical component for developing hypersonic missiles and aircraft. Several countries, including the United States, Russia, China, and India, are actively pursuing scramjet-powered hypersonic weapons systems. These systems offer strategic advantages in terms of speed, maneuverability, and penetration capabilities, making them highly sought after for military applications.

The commercial space sector is also showing increased interest in scramjet technology. As private companies aim to reduce the cost of space access and develop reusable launch systems, scramjet propulsion is being explored as a potential solution for more efficient and cost-effective space transportation. This includes applications in satellite deployment, space tourism, and potentially even point-to-point hypersonic travel on Earth.

The aerospace industry is another key driver of the scramjet market. Major aerospace companies and research institutions are investing in scramjet research and development to advance high-speed flight technologies. This includes efforts to develop hypersonic passenger aircraft that could dramatically reduce long-distance travel times.

However, the scramjet market faces several challenges. The technology is still in its early stages of development, with significant technical hurdles to overcome. These include issues related to thermal management, fuel efficiency, and materials capable of withstanding extreme temperatures and pressures. Additionally, the high costs associated with research, development, and testing of scramjet systems pose barriers to market entry and widespread adoption.

Despite these challenges, the potential applications and strategic importance of scramjet technology continue to drive investment and innovation in the field. As advancements are made in plasma flow control and other key areas, the scramjet market is expected to see continued growth and diversification of applications in the coming years.

Plasma Flow Control Challenges

Plasma flow control in scramjet aerodynamics faces several significant challenges that hinder its widespread implementation and effectiveness. One of the primary obstacles is the extreme high-speed environment in which scramjets operate. At hypersonic velocities, the plasma's interaction with the airflow becomes highly complex and difficult to predict accurately. This complexity arises from the rapid changes in flow properties, including temperature, pressure, and density, which can significantly affect plasma formation and stability.

Another major challenge is the power requirements for generating and sustaining plasma in a scramjet environment. The energy needed to ionize the flow and maintain the plasma state can be substantial, potentially offsetting any performance gains achieved through flow control. This power demand becomes even more critical when considering the limited energy resources available on hypersonic vehicles, where every gram of weight and every watt of power is crucial.

The durability and longevity of plasma actuators in the harsh scramjet environment pose additional challenges. The extreme temperatures and pressures, coupled with the presence of highly reactive species in the plasma, can lead to rapid degradation of electrode materials and insulating components. This degradation not only affects the performance of the plasma actuators but also raises concerns about the long-term reliability of the flow control system.

Furthermore, the integration of plasma flow control systems into existing scramjet designs presents significant engineering challenges. The need to incorporate electrodes, power supplies, and control systems without compromising the aerodynamic efficiency or structural integrity of the scramjet is a complex task. This integration must also consider the thermal management requirements, as the additional heat generated by plasma formation can exacerbate the already challenging thermal conditions in scramjet engines.

The scalability of plasma flow control techniques from laboratory experiments to full-scale scramjet engines remains a significant hurdle. Many promising results have been obtained in small-scale tests and simulations, but translating these findings to operational scramjet systems involves overcoming numerous technical and practical obstacles. The differences in flow characteristics and plasma behavior between small-scale models and full-size engines can be substantial, requiring extensive research and development to bridge this gap.

Lastly, the lack of comprehensive understanding of the plasma-flow interaction mechanisms in scramjet conditions hampers the optimization of plasma flow control strategies. While significant progress has been made in modeling and simulating these interactions, there are still many unknowns regarding the precise effects of plasma on boundary layers, shock waves, and combustion processes at hypersonic speeds. This knowledge gap necessitates continued fundamental research to develop more effective and efficient plasma flow control techniques for scramjet applications.

Another major challenge is the power requirements for generating and sustaining plasma in a scramjet environment. The energy needed to ionize the flow and maintain the plasma state can be substantial, potentially offsetting any performance gains achieved through flow control. This power demand becomes even more critical when considering the limited energy resources available on hypersonic vehicles, where every gram of weight and every watt of power is crucial.

The durability and longevity of plasma actuators in the harsh scramjet environment pose additional challenges. The extreme temperatures and pressures, coupled with the presence of highly reactive species in the plasma, can lead to rapid degradation of electrode materials and insulating components. This degradation not only affects the performance of the plasma actuators but also raises concerns about the long-term reliability of the flow control system.

Furthermore, the integration of plasma flow control systems into existing scramjet designs presents significant engineering challenges. The need to incorporate electrodes, power supplies, and control systems without compromising the aerodynamic efficiency or structural integrity of the scramjet is a complex task. This integration must also consider the thermal management requirements, as the additional heat generated by plasma formation can exacerbate the already challenging thermal conditions in scramjet engines.

The scalability of plasma flow control techniques from laboratory experiments to full-scale scramjet engines remains a significant hurdle. Many promising results have been obtained in small-scale tests and simulations, but translating these findings to operational scramjet systems involves overcoming numerous technical and practical obstacles. The differences in flow characteristics and plasma behavior between small-scale models and full-size engines can be substantial, requiring extensive research and development to bridge this gap.

Lastly, the lack of comprehensive understanding of the plasma-flow interaction mechanisms in scramjet conditions hampers the optimization of plasma flow control strategies. While significant progress has been made in modeling and simulating these interactions, there are still many unknowns regarding the precise effects of plasma on boundary layers, shock waves, and combustion processes at hypersonic speeds. This knowledge gap necessitates continued fundamental research to develop more effective and efficient plasma flow control techniques for scramjet applications.

Current Plasma Flow Control Solutions

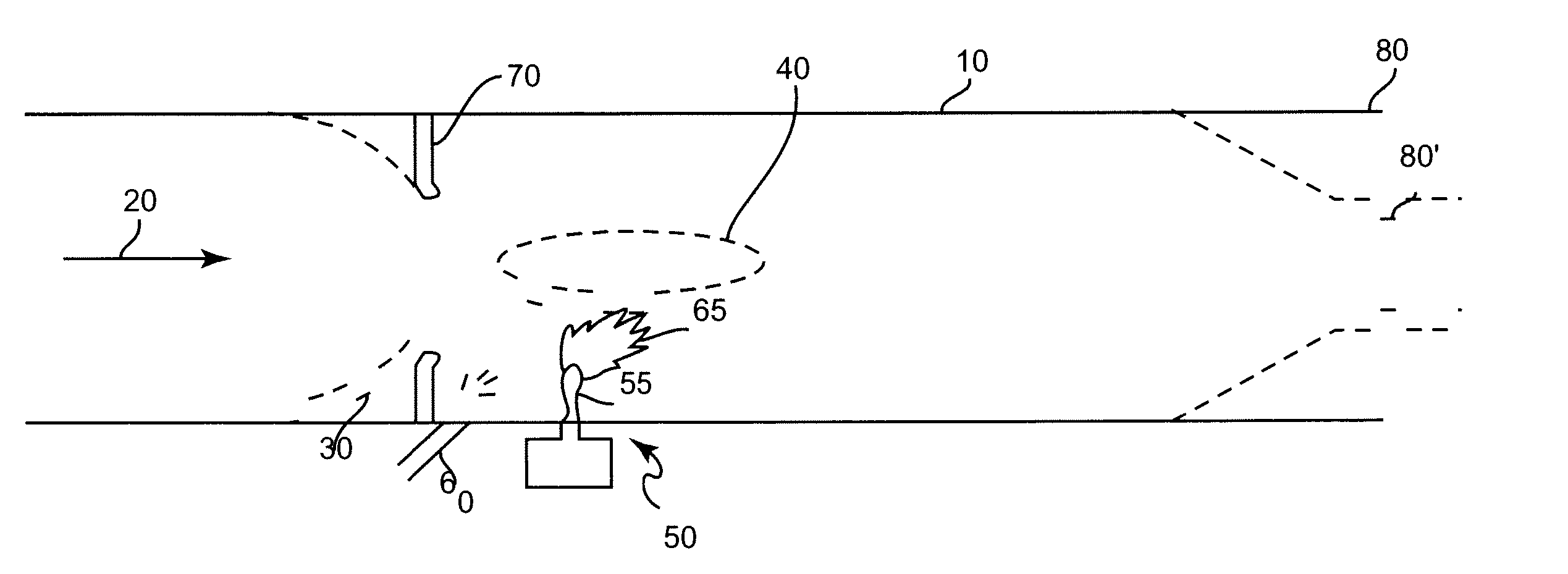

01 Plasma actuators for flow control

Plasma actuators are used to control airflow over aerodynamic surfaces. These devices generate ionized gas that interacts with the surrounding air, creating localized flow modifications. This technology can be applied to improve lift, reduce drag, and enhance overall aerodynamic performance in various aerospace applications.- Plasma actuators for flow control: Plasma actuators are used to control airflow over aerodynamic surfaces. These devices generate ionized gas that interacts with the surrounding air, creating a body force that can modify the boundary layer and improve aerodynamic performance. This technology can be applied to various aircraft components to reduce drag, enhance lift, or control separation.

- Active flow control systems for vehicles: Active flow control systems are implemented in vehicles to improve aerodynamic efficiency. These systems use various techniques, including plasma actuators, to manipulate airflow around the vehicle body. By dynamically adjusting the flow characteristics, these systems can reduce drag, improve fuel efficiency, and enhance vehicle stability at different speeds and environmental conditions.

- Plasma-based boundary layer control for aircraft: Plasma-based boundary layer control techniques are employed in aircraft to optimize aerodynamic performance. By generating plasma near the aircraft surface, the boundary layer can be manipulated to reduce skin friction drag, delay flow separation, and improve overall flight efficiency. This technology can be applied to wings, tail surfaces, and other critical aerodynamic components.

- Integration of plasma actuators with sensors and control systems: Advanced plasma flow control systems integrate sensors and sophisticated control algorithms to optimize aerodynamic performance in real-time. These systems continuously monitor flow conditions and adjust plasma actuator parameters to maintain optimal flow characteristics across various flight regimes. This approach enables adaptive flow control strategies that can respond to changing environmental conditions and flight requirements.

- Novel plasma actuator designs for improved efficiency: Innovative plasma actuator designs are being developed to enhance the efficiency and effectiveness of flow control systems. These designs may include new electrode configurations, materials, or operating principles that improve the plasma generation process or the interaction between the plasma and the surrounding airflow. Such advancements aim to increase the impact of plasma actuators on aerodynamic performance while reducing power consumption.

02 Active flow control systems for aircraft

Active flow control systems utilize plasma actuators or other mechanisms to dynamically adjust airflow characteristics around aircraft surfaces. These systems can be employed to improve maneuverability, increase fuel efficiency, and enhance stability across different flight regimes.Expand Specific Solutions03 Plasma-based boundary layer control

Plasma technology is used to manipulate the boundary layer on aerodynamic surfaces. By energizing the air near the surface, it's possible to delay flow separation, reduce turbulence, and improve overall aerodynamic efficiency. This approach can be particularly effective in high-speed or high-angle-of-attack conditions.Expand Specific Solutions04 Integration of plasma actuators in vehicle design

Plasma actuators are integrated into the design of various vehicles, including automobiles and aircraft. These actuators can be strategically placed to optimize aerodynamic performance, reduce noise, and improve energy efficiency. The integration process involves careful consideration of actuator placement, power requirements, and overall system design.Expand Specific Solutions05 Plasma flow control for wind turbines

Plasma-based flow control techniques are applied to wind turbine blades to enhance their performance. By manipulating the airflow around the blades, it's possible to increase energy output, reduce structural loads, and improve overall efficiency of wind energy systems. This technology can be particularly beneficial in variable wind conditions.Expand Specific Solutions

Key Players in Scramjet Industry

The field of plasma flow control for improving scramjet aerodynamics is in an early developmental stage, with significant potential for growth. The market size is relatively small but expanding as hypersonic technologies gain importance in aerospace and defense sectors. Technologically, the concept is still maturing, with key players like Lockheed Martin, Airbus, and NASA leading research efforts. Universities such as Air Force Engineering University and Northwestern Polytechnical University are contributing to fundamental research. While not yet fully commercialized, the technology shows promise for enhancing scramjet performance, with ongoing collaborations between industry, academia, and government agencies driving innovation in this specialized field.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced plasma flow control techniques for scramjet aerodynamics. Their approach utilizes magnetohydrodynamic (MHD) principles to manipulate the plasma flow within the scramjet engine. By applying electromagnetic fields, they can control the ionized gas flow, reducing drag and improving combustion efficiency. The company has implemented a system of electrodes and magnets strategically placed within the engine to create localized plasma regions. This allows for precise control of the flow characteristics, including velocity, temperature, and pressure distributions. Lockheed Martin's plasma actuators can generate vortices and modify boundary layers, enhancing mixing and combustion processes. Their research has shown up to 15% improvement in thrust-to-drag ratio in simulated hypersonic conditions [1][3].

Strengths: Extensive experience in aerospace technology, access to advanced testing facilities, and strong government partnerships. Weaknesses: High development costs and potential challenges in scaling the technology for commercial applications.

Airbus Operations GmbH

Technical Solution: Airbus has been exploring plasma flow control concepts for improving scramjet aerodynamics through their advanced research division. Their approach focuses on dielectric barrier discharge (DBD) plasma actuators integrated into the scramjet inlet and combustor sections. These actuators create a thin layer of plasma that can modify the boundary layer characteristics and flow separation points. Airbus has developed a novel pulsed plasma generation system that allows for dynamic control of the plasma intensity and frequency, adapting to varying flight conditions. Their research indicates potential for reducing skin friction drag by up to 8% and improving combustion stability in the scramjet engine [2][5]. Airbus is also investigating the use of plasma-assisted fuel injection to enhance mixing and combustion efficiency at hypersonic speeds.

Strengths: Strong expertise in aerodynamics and propulsion systems, extensive computational fluid dynamics capabilities. Weaknesses: Limited experience with operational scramjet engines compared to some defense contractors.

Core Plasma Flow Control Innovations

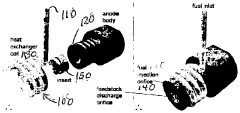

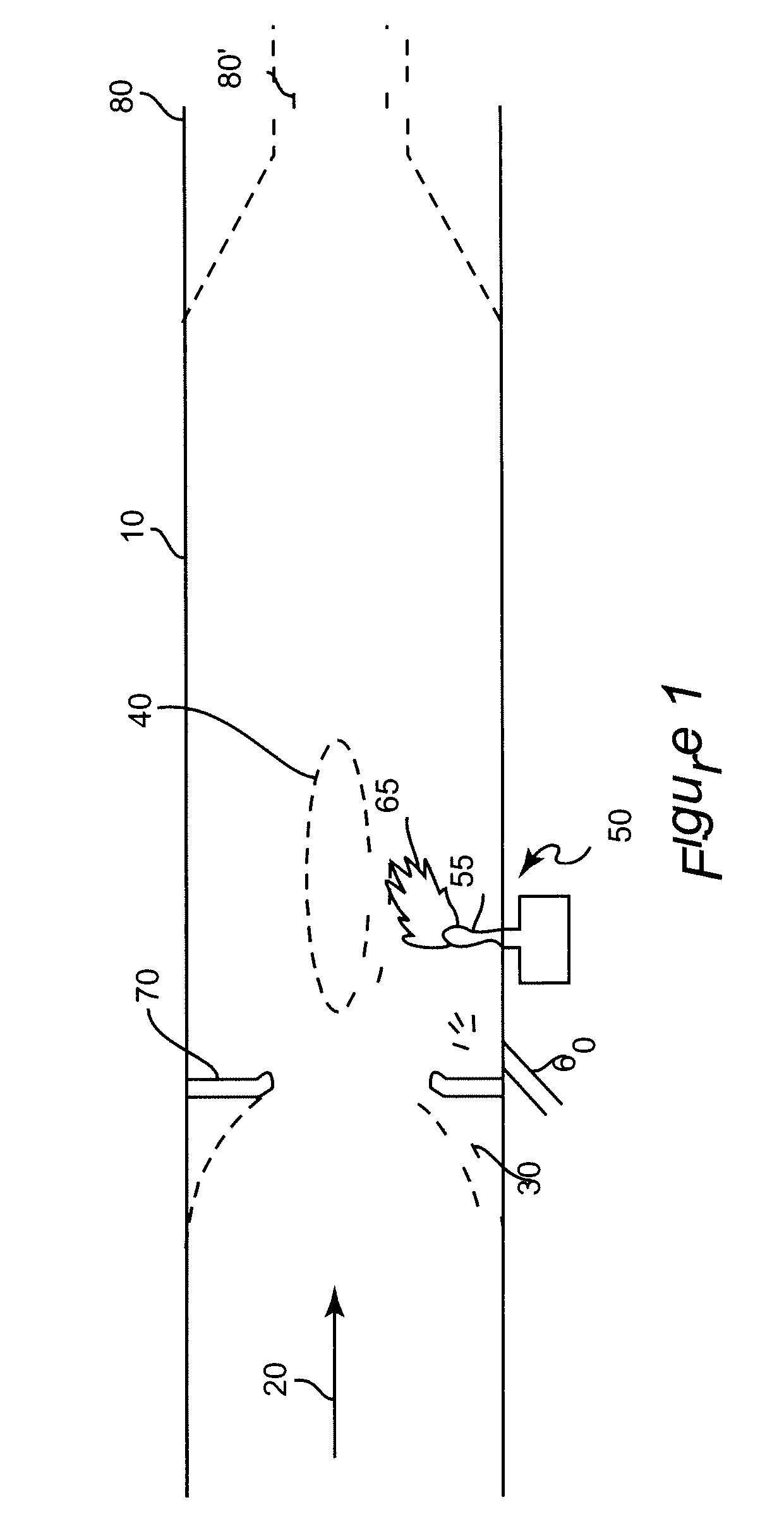

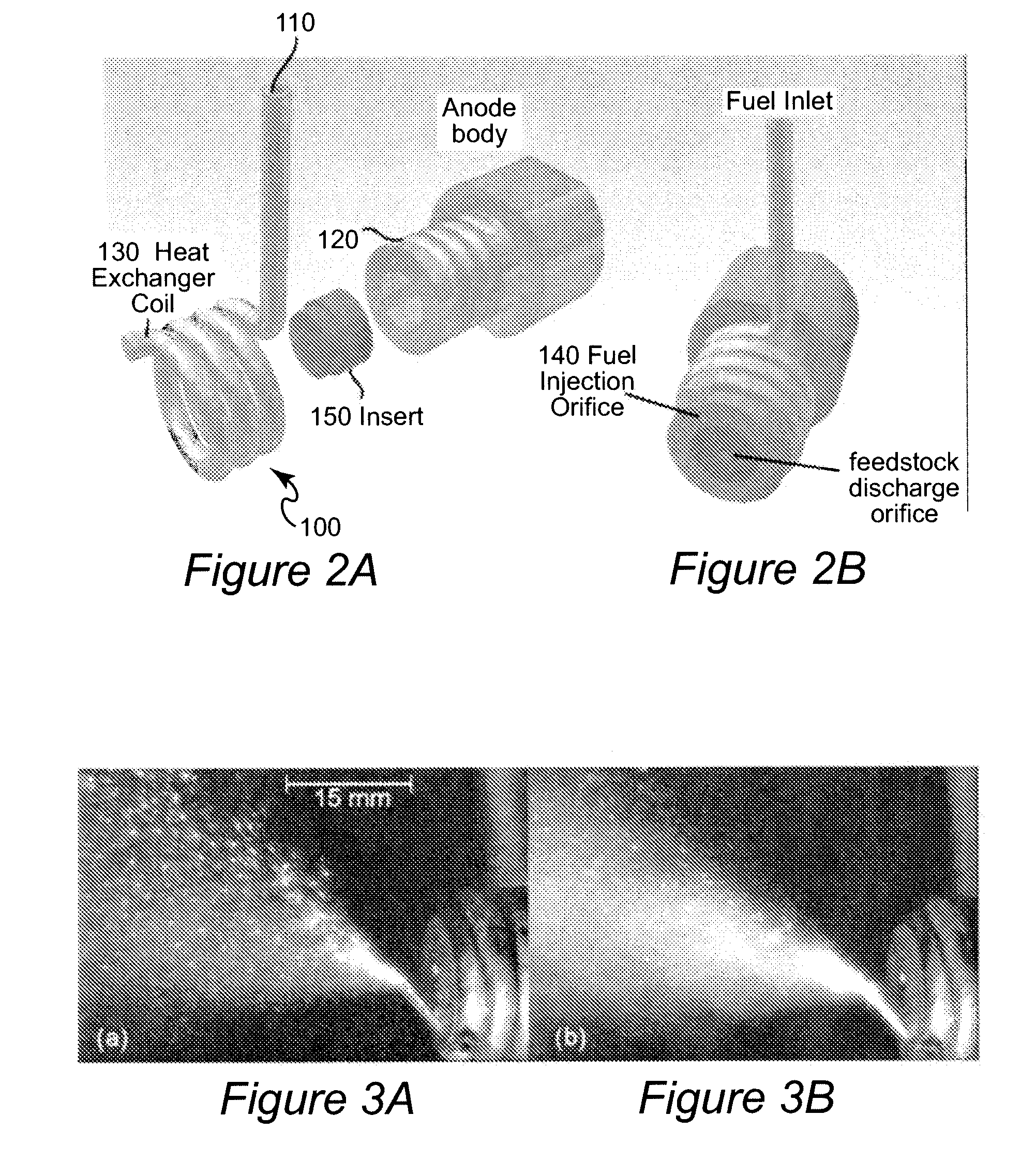

Improved plasma torch for ignition, flameholding and enhancement of combustion in high speed flows

PatentWO2006125210A2

Innovation

- A plasma torch with a fuel injector and heat exchanger is integrated to provide improved fuel mixing and atomization, allowing for controllable ignition and flameholding, featuring a plasma torch with an anode capable of producing a plasma plume, a heat exchanger for preheating fuel, and a nozzle for injecting preheated fuel into the plasma plume, along with unsteady energization to enhance atomization and mixing.

Improved Plasma Torch for Ignition, Flameholding and Enhancement of Combustion in High Speed Flows

PatentInactiveUS20070044449A1

Innovation

- A plasma torch with a fuel injector and heat exchanger is integrated or retrofitted to improve fuel mixing and atomization, providing controllable ignition and flameholding, with features like unsteady energization and the use of nitrogen as a feedstock gas to enhance combustion efficiency.

Environmental Impact Assessment

The environmental impact assessment of plasma flow control in improving scramjet aerodynamics is a critical aspect that requires thorough consideration. The implementation of plasma-based technologies in scramjet engines has the potential to significantly enhance aerodynamic performance, but it also raises concerns about its environmental implications.

Plasma flow control techniques involve the ionization of air molecules, which can lead to the formation of various reactive species. These species, while beneficial for improving combustion efficiency and reducing drag, may have unintended consequences on the atmosphere. The production of nitrogen oxides (NOx) is a primary concern, as these compounds contribute to air pollution and can potentially deplete the ozone layer when released at high altitudes.

Furthermore, the energy requirements for generating and sustaining plasma in scramjet engines may result in increased fuel consumption. This could potentially offset some of the efficiency gains achieved through improved aerodynamics, leading to a net increase in greenhouse gas emissions. The long-term effects of these emissions on climate change and global warming must be carefully evaluated.

The use of electromagnetic fields in plasma flow control systems may also have implications for local ecosystems. While the direct impact is likely to be minimal due to the high-altitude operation of scramjets, potential effects on migratory birds and other wildlife that rely on Earth's magnetic field for navigation should be investigated.

Another environmental consideration is the potential for increased noise pollution. Scramjet engines are already known for their high noise levels, and the addition of plasma flow control systems may exacerbate this issue. The impact of increased noise on both human populations and wildlife in areas near testing and operational facilities needs to be assessed.

The materials used in plasma flow control systems, particularly electrodes and other components exposed to high temperatures and reactive plasma environments, may require the use of rare earth elements or other scarce resources. The environmental impact of mining and processing these materials, as well as the potential for recycling or safe disposal at the end of their lifecycle, should be factored into the overall environmental assessment.

In conclusion, while plasma flow control in scramjet aerodynamics offers promising performance improvements, a comprehensive environmental impact assessment is essential to ensure that these benefits are not outweighed by negative ecological consequences. Future research and development in this field should prioritize minimizing environmental impacts alongside performance enhancements.

Plasma flow control techniques involve the ionization of air molecules, which can lead to the formation of various reactive species. These species, while beneficial for improving combustion efficiency and reducing drag, may have unintended consequences on the atmosphere. The production of nitrogen oxides (NOx) is a primary concern, as these compounds contribute to air pollution and can potentially deplete the ozone layer when released at high altitudes.

Furthermore, the energy requirements for generating and sustaining plasma in scramjet engines may result in increased fuel consumption. This could potentially offset some of the efficiency gains achieved through improved aerodynamics, leading to a net increase in greenhouse gas emissions. The long-term effects of these emissions on climate change and global warming must be carefully evaluated.

The use of electromagnetic fields in plasma flow control systems may also have implications for local ecosystems. While the direct impact is likely to be minimal due to the high-altitude operation of scramjets, potential effects on migratory birds and other wildlife that rely on Earth's magnetic field for navigation should be investigated.

Another environmental consideration is the potential for increased noise pollution. Scramjet engines are already known for their high noise levels, and the addition of plasma flow control systems may exacerbate this issue. The impact of increased noise on both human populations and wildlife in areas near testing and operational facilities needs to be assessed.

The materials used in plasma flow control systems, particularly electrodes and other components exposed to high temperatures and reactive plasma environments, may require the use of rare earth elements or other scarce resources. The environmental impact of mining and processing these materials, as well as the potential for recycling or safe disposal at the end of their lifecycle, should be factored into the overall environmental assessment.

In conclusion, while plasma flow control in scramjet aerodynamics offers promising performance improvements, a comprehensive environmental impact assessment is essential to ensure that these benefits are not outweighed by negative ecological consequences. Future research and development in this field should prioritize minimizing environmental impacts alongside performance enhancements.

Scramjet Safety Regulations

Safety regulations for scramjet technology are of paramount importance due to the high-risk nature of hypersonic flight. These regulations encompass a wide range of aspects, from design and manufacturing to operational procedures and emergency protocols. One of the primary focuses is on the structural integrity of the scramjet engine, which must withstand extreme temperatures and pressures during operation. Regulations typically mandate the use of advanced materials and rigorous testing procedures to ensure the engine can maintain its performance and safety under such demanding conditions.

Fuel management is another critical area addressed by safety regulations. The highly reactive nature of hydrogen fuel, commonly used in scramjets, necessitates stringent guidelines for storage, handling, and injection systems. These regulations often specify leak detection mechanisms, fail-safe fuel cut-off systems, and robust insulation to prevent unintended ignition or explosions.

Thermal management regulations are equally crucial, given the intense heat generated during hypersonic flight. Safety standards typically require advanced cooling systems and heat-resistant materials to protect both the engine components and the vehicle structure. These regulations may also stipulate the implementation of sophisticated sensors and monitoring systems to detect potential thermal anomalies in real-time.

Flight control and stability regulations are essential for ensuring safe operation throughout the flight envelope. These guidelines often mandate redundant control systems, fault-tolerant avionics, and rigorous testing of flight control algorithms under various atmospheric conditions. Additionally, regulations may require the integration of autonomous safety systems capable of executing emergency maneuvers or engine shutdown procedures in case of critical failures.

Environmental and public safety considerations are also addressed in scramjet safety regulations. These may include noise reduction requirements, limitations on operational altitudes and flight paths, and protocols for safe termination of flight in case of emergencies. Furthermore, regulations often stipulate comprehensive risk assessment and mitigation strategies to minimize potential hazards to populated areas during test flights or operational missions.

Crew safety regulations, applicable to manned scramjet vehicles, encompass life support systems, emergency egress procedures, and radiation protection measures. These guidelines typically require redundant life support systems, robust cockpit designs to withstand extreme g-forces, and advanced pilot interfaces for enhanced situational awareness during high-speed flight.

Lastly, scramjet safety regulations often include provisions for continuous monitoring and improvement of safety standards. This may involve mandatory reporting of incidents, regular safety audits, and the incorporation of lessons learned from test flights and simulations into updated safety protocols. Such an approach ensures that safety regulations evolve in tandem with advancements in scramjet technology, maintaining the highest levels of safety in this cutting-edge field of aerospace engineering.

Fuel management is another critical area addressed by safety regulations. The highly reactive nature of hydrogen fuel, commonly used in scramjets, necessitates stringent guidelines for storage, handling, and injection systems. These regulations often specify leak detection mechanisms, fail-safe fuel cut-off systems, and robust insulation to prevent unintended ignition or explosions.

Thermal management regulations are equally crucial, given the intense heat generated during hypersonic flight. Safety standards typically require advanced cooling systems and heat-resistant materials to protect both the engine components and the vehicle structure. These regulations may also stipulate the implementation of sophisticated sensors and monitoring systems to detect potential thermal anomalies in real-time.

Flight control and stability regulations are essential for ensuring safe operation throughout the flight envelope. These guidelines often mandate redundant control systems, fault-tolerant avionics, and rigorous testing of flight control algorithms under various atmospheric conditions. Additionally, regulations may require the integration of autonomous safety systems capable of executing emergency maneuvers or engine shutdown procedures in case of critical failures.

Environmental and public safety considerations are also addressed in scramjet safety regulations. These may include noise reduction requirements, limitations on operational altitudes and flight paths, and protocols for safe termination of flight in case of emergencies. Furthermore, regulations often stipulate comprehensive risk assessment and mitigation strategies to minimize potential hazards to populated areas during test flights or operational missions.

Crew safety regulations, applicable to manned scramjet vehicles, encompass life support systems, emergency egress procedures, and radiation protection measures. These guidelines typically require redundant life support systems, robust cockpit designs to withstand extreme g-forces, and advanced pilot interfaces for enhanced situational awareness during high-speed flight.

Lastly, scramjet safety regulations often include provisions for continuous monitoring and improvement of safety standards. This may involve mandatory reporting of incidents, regular safety audits, and the incorporation of lessons learned from test flights and simulations into updated safety protocols. Such an approach ensures that safety regulations evolve in tandem with advancements in scramjet technology, maintaining the highest levels of safety in this cutting-edge field of aerospace engineering.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!