Durable Adhesives And Sealants For Long-Life LSC Window Modules

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSC Window Adhesives Background and Objectives

Luminescent Solar Concentrators (LSC) window technology has evolved significantly over the past three decades, transitioning from theoretical concepts in the 1970s to practical applications in modern sustainable building design. These semi-transparent photovoltaic devices integrate seamlessly into building facades, offering dual functionality as both windows and energy generators. The evolution of LSC technology has been marked by continuous improvements in light-harvesting efficiency, transparency, and durability, with recent advancements focusing on enhancing quantum yield and reducing self-absorption losses.

The adhesives and sealants used in LSC window modules represent a critical yet often overlooked component of the technology's overall performance and longevity. Historically, these materials have been adapted from conventional glazing applications without specific optimization for the unique requirements of LSC systems. The degradation of these bonding materials under prolonged exposure to UV radiation, temperature fluctuations, and moisture has emerged as a significant limiting factor in achieving the 25+ year service life expected of building-integrated photovoltaic systems.

The primary objective of this technical research is to identify and develop durable adhesive and sealant solutions specifically engineered for LSC window applications. These materials must maintain structural integrity and optical clarity throughout the intended service life of LSC modules while withstanding the harsh environmental conditions typical of building exteriors. Additionally, they must be compatible with the various components of LSC systems, including the luminescent materials, waveguide substrates, and photovoltaic cells.

Current industry standards for building-integrated photovoltaics require a minimum 25-year operational lifespan, with performance degradation not exceeding 20% during this period. Meeting these standards necessitates adhesives and sealants that can withstand approximately 9,000 thermal cycles, 25,000 hours of UV exposure, and maintain resistance to moisture ingress throughout the product lifecycle. Existing solutions fall short of these requirements, with typical degradation beginning after 5-10 years of field deployment.

The technical trajectory for LSC window adhesives has been influenced by developments in adjacent fields, including aerospace glazing, automotive laminated glass, and conventional photovoltaic module encapsulation. Recent innovations in silicone-based elastomers, modified polyurethanes, and hybrid organic-inorganic materials offer promising pathways for addressing the current limitations.

This research aims to establish a comprehensive understanding of the failure mechanisms affecting adhesives in LSC applications, identify promising material candidates from both commercial sources and emerging research, and develop testing protocols that accurately predict long-term performance under accelerated conditions. The ultimate goal is to enable LSC window technology to achieve its full potential as a sustainable building component by removing the durability constraints imposed by current bonding materials.

The adhesives and sealants used in LSC window modules represent a critical yet often overlooked component of the technology's overall performance and longevity. Historically, these materials have been adapted from conventional glazing applications without specific optimization for the unique requirements of LSC systems. The degradation of these bonding materials under prolonged exposure to UV radiation, temperature fluctuations, and moisture has emerged as a significant limiting factor in achieving the 25+ year service life expected of building-integrated photovoltaic systems.

The primary objective of this technical research is to identify and develop durable adhesive and sealant solutions specifically engineered for LSC window applications. These materials must maintain structural integrity and optical clarity throughout the intended service life of LSC modules while withstanding the harsh environmental conditions typical of building exteriors. Additionally, they must be compatible with the various components of LSC systems, including the luminescent materials, waveguide substrates, and photovoltaic cells.

Current industry standards for building-integrated photovoltaics require a minimum 25-year operational lifespan, with performance degradation not exceeding 20% during this period. Meeting these standards necessitates adhesives and sealants that can withstand approximately 9,000 thermal cycles, 25,000 hours of UV exposure, and maintain resistance to moisture ingress throughout the product lifecycle. Existing solutions fall short of these requirements, with typical degradation beginning after 5-10 years of field deployment.

The technical trajectory for LSC window adhesives has been influenced by developments in adjacent fields, including aerospace glazing, automotive laminated glass, and conventional photovoltaic module encapsulation. Recent innovations in silicone-based elastomers, modified polyurethanes, and hybrid organic-inorganic materials offer promising pathways for addressing the current limitations.

This research aims to establish a comprehensive understanding of the failure mechanisms affecting adhesives in LSC applications, identify promising material candidates from both commercial sources and emerging research, and develop testing protocols that accurately predict long-term performance under accelerated conditions. The ultimate goal is to enable LSC window technology to achieve its full potential as a sustainable building component by removing the durability constraints imposed by current bonding materials.

Market Analysis for Durable Building Integrated Photovoltaics

The Building Integrated Photovoltaics (BIPV) market has been experiencing significant growth, with a current global market valuation exceeding $3 billion and projected to reach $6.5 billion by 2026. Within this expanding sector, Luminescent Solar Concentrator (LSC) window modules represent an emerging technology with substantial potential for integration into modern architectural designs. These modules offer dual functionality as both windows and energy generators, making them particularly attractive for commercial buildings and high-rise structures.

Market research indicates that the demand for durable BIPV solutions is primarily driven by three key factors: increasing emphasis on sustainable building practices, rising energy costs, and supportive government policies promoting renewable energy adoption. The European Union's nearly zero-energy building directives and similar initiatives in North America and Asia have created a favorable regulatory environment for BIPV technologies, including LSC window modules.

The commercial building sector currently represents the largest market segment for LSC window modules, accounting for approximately 65% of potential applications. This is followed by residential high-rise buildings (20%) and institutional structures such as universities and government facilities (15%). Geographically, Europe leads in BIPV adoption, followed by North America and rapidly growing markets in Asia-Pacific, particularly China and Japan.

A critical market requirement identified through customer surveys and industry analysis is the longevity of these installations. Building owners and developers expect BIPV systems to maintain performance and aesthetic qualities for 20-25 years, aligning with typical building renovation cycles. This expectation places significant demands on the durability of adhesives and sealants used in LSC window modules, as these components often become failure points before the photovoltaic materials themselves degrade.

Market analysis reveals a price sensitivity threshold where building developers are willing to pay a premium of 15-20% over traditional window solutions for BIPV products that demonstrate proven durability and energy generation capabilities. However, this premium acceptance is contingent upon warranties matching or exceeding those of conventional building materials.

Competitive analysis shows that current market offerings fall short in meeting these durability requirements, with most adhesive and sealant solutions for LSC window modules providing effective service lives of only 7-12 years before requiring replacement or significant maintenance. This gap between market expectations and current product capabilities represents a significant opportunity for technological innovation.

The total addressable market for durable adhesives and sealants specifically designed for LSC window modules is estimated to reach $450 million by 2025, representing a specialized but high-value segment within the broader construction adhesives market. Growth in this segment is expected to outpace the general BIPV market by 1.5 times due to the critical role these components play in system longevity and performance.

Market research indicates that the demand for durable BIPV solutions is primarily driven by three key factors: increasing emphasis on sustainable building practices, rising energy costs, and supportive government policies promoting renewable energy adoption. The European Union's nearly zero-energy building directives and similar initiatives in North America and Asia have created a favorable regulatory environment for BIPV technologies, including LSC window modules.

The commercial building sector currently represents the largest market segment for LSC window modules, accounting for approximately 65% of potential applications. This is followed by residential high-rise buildings (20%) and institutional structures such as universities and government facilities (15%). Geographically, Europe leads in BIPV adoption, followed by North America and rapidly growing markets in Asia-Pacific, particularly China and Japan.

A critical market requirement identified through customer surveys and industry analysis is the longevity of these installations. Building owners and developers expect BIPV systems to maintain performance and aesthetic qualities for 20-25 years, aligning with typical building renovation cycles. This expectation places significant demands on the durability of adhesives and sealants used in LSC window modules, as these components often become failure points before the photovoltaic materials themselves degrade.

Market analysis reveals a price sensitivity threshold where building developers are willing to pay a premium of 15-20% over traditional window solutions for BIPV products that demonstrate proven durability and energy generation capabilities. However, this premium acceptance is contingent upon warranties matching or exceeding those of conventional building materials.

Competitive analysis shows that current market offerings fall short in meeting these durability requirements, with most adhesive and sealant solutions for LSC window modules providing effective service lives of only 7-12 years before requiring replacement or significant maintenance. This gap between market expectations and current product capabilities represents a significant opportunity for technological innovation.

The total addressable market for durable adhesives and sealants specifically designed for LSC window modules is estimated to reach $450 million by 2025, representing a specialized but high-value segment within the broader construction adhesives market. Growth in this segment is expected to outpace the general BIPV market by 1.5 times due to the critical role these components play in system longevity and performance.

Technical Challenges in Long-Life LSC Window Sealants

The development of durable adhesives and sealants for Luminescent Solar Concentrator (LSC) window modules faces significant technical challenges that must be overcome to ensure long-term performance and reliability. The primary challenge lies in the harsh environmental conditions these sealants must withstand while maintaining their structural integrity and functionality over extended periods, often exceeding 20 years in building applications.

Ultraviolet (UV) radiation presents a particularly formidable obstacle, as continuous exposure can lead to photodegradation of polymer-based sealants, resulting in yellowing, embrittlement, and eventual failure of the adhesive bond. This degradation not only compromises the structural integrity of the LSC window module but also reduces optical efficiency by creating light-scattering interfaces.

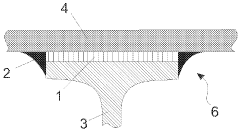

Temperature cycling poses another significant challenge, with adhesives needing to maintain performance across extreme temperature ranges from -40°C to +85°C in some climates. The differential thermal expansion between LSC materials (typically polymethyl methacrylate or polycarbonate) and window framing materials creates cyclical stress at bonding interfaces, leading to potential delamination or crack formation over time.

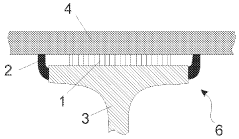

Moisture ingress represents a critical failure mode for LSC window modules, as water penetration can degrade luminescent dyes and create internal condensation that reduces optical efficiency. Current sealant technologies struggle to maintain hermetic seals over decades of environmental exposure, particularly at material interfaces where micro-cracks can develop.

Chemical compatibility presents another complex challenge, as adhesives must bond effectively with multiple materials including the LSC panel, edge sealing components, and window framing systems. Many high-performance adhesives that offer excellent durability may simultaneously cause crazing or stress-cracking in acrylic or polycarbonate LSC substrates, limiting their applicability.

Manufacturing scalability remains problematic, with many laboratory-proven durable adhesive systems requiring complex application procedures, precise environmental controls, or extended curing times that are impractical for commercial-scale production of LSC window modules.

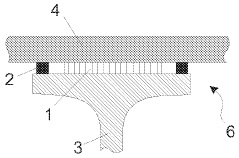

The balance between mechanical properties presents additional difficulties, as sealants must simultaneously provide sufficient rigidity to maintain structural integrity while offering enough elasticity to accommodate thermal expansion and building movement. Current silicone-based sealants offer excellent durability but may lack the mechanical strength required for larger LSC installations, while structural epoxies provide strength but often lack the necessary flexibility for long-term performance.

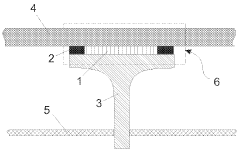

Edge sealing technology specifically faces unique challenges in LSC applications, as the edge areas must both prevent environmental ingress and efficiently redirect light within the concentrator system, creating competing requirements that few current materials can satisfy simultaneously.

Ultraviolet (UV) radiation presents a particularly formidable obstacle, as continuous exposure can lead to photodegradation of polymer-based sealants, resulting in yellowing, embrittlement, and eventual failure of the adhesive bond. This degradation not only compromises the structural integrity of the LSC window module but also reduces optical efficiency by creating light-scattering interfaces.

Temperature cycling poses another significant challenge, with adhesives needing to maintain performance across extreme temperature ranges from -40°C to +85°C in some climates. The differential thermal expansion between LSC materials (typically polymethyl methacrylate or polycarbonate) and window framing materials creates cyclical stress at bonding interfaces, leading to potential delamination or crack formation over time.

Moisture ingress represents a critical failure mode for LSC window modules, as water penetration can degrade luminescent dyes and create internal condensation that reduces optical efficiency. Current sealant technologies struggle to maintain hermetic seals over decades of environmental exposure, particularly at material interfaces where micro-cracks can develop.

Chemical compatibility presents another complex challenge, as adhesives must bond effectively with multiple materials including the LSC panel, edge sealing components, and window framing systems. Many high-performance adhesives that offer excellent durability may simultaneously cause crazing or stress-cracking in acrylic or polycarbonate LSC substrates, limiting their applicability.

Manufacturing scalability remains problematic, with many laboratory-proven durable adhesive systems requiring complex application procedures, precise environmental controls, or extended curing times that are impractical for commercial-scale production of LSC window modules.

The balance between mechanical properties presents additional difficulties, as sealants must simultaneously provide sufficient rigidity to maintain structural integrity while offering enough elasticity to accommodate thermal expansion and building movement. Current silicone-based sealants offer excellent durability but may lack the mechanical strength required for larger LSC installations, while structural epoxies provide strength but often lack the necessary flexibility for long-term performance.

Edge sealing technology specifically faces unique challenges in LSC applications, as the edge areas must both prevent environmental ingress and efficiently redirect light within the concentrator system, creating competing requirements that few current materials can satisfy simultaneously.

Current Adhesive Solutions for LSC Window Modules

01 Environmental resistance in adhesives and sealants

Adhesives and sealants can be formulated to withstand various environmental factors such as UV radiation, moisture, temperature fluctuations, and chemical exposure. These formulations typically include stabilizers, UV absorbers, and specialized polymers that maintain bond integrity under harsh conditions. Enhanced environmental resistance significantly extends the service life of adhesive bonds in outdoor applications and prevents degradation that could lead to bond failure.- Environmental resistance of adhesives and sealants: Adhesives and sealants can be formulated to withstand various environmental conditions such as moisture, temperature fluctuations, UV radiation, and chemical exposure. These formulations typically include specific additives that enhance resistance to degradation factors, thereby extending the service life of the bonded or sealed joints. Environmental resistance is crucial for applications in outdoor settings or harsh industrial environments where the adhesive or sealant must maintain its integrity over prolonged periods.

- Polymer modifications for enhanced durability: Modifying the polymer structure of adhesives and sealants can significantly improve their durability properties. Techniques include cross-linking, copolymerization, and the incorporation of reinforcing agents. These modifications can enhance mechanical strength, flexibility, and resistance to creep and fatigue. Polymer-modified adhesives and sealants typically exhibit improved adhesion to substrates and better long-term performance under stress conditions, making them suitable for structural applications where durability is critical.

- Aging resistance and stability improvements: Improving the aging resistance of adhesives and sealants involves incorporating stabilizers, antioxidants, and UV absorbers into the formulation. These additives prevent degradation mechanisms such as oxidation, hydrolysis, and photodegradation that typically occur over time. Enhanced stability ensures that the adhesive or sealant maintains its physical and mechanical properties throughout its intended service life, even when exposed to challenging conditions that would normally accelerate aging processes.

- Specialized formulations for extreme conditions: Specialized adhesive and sealant formulations are designed for extreme operating conditions such as very high or low temperatures, high pressure environments, or exposure to aggressive chemicals. These formulations often incorporate unique chemistries, fillers, and reinforcing agents that provide exceptional durability under specific challenging conditions. Applications include aerospace, automotive, marine, and industrial settings where standard adhesives would fail due to the severity of the operating environment.

- Testing and evaluation methods for durability: Various testing and evaluation methods are employed to assess the durability of adhesives and sealants. These include accelerated aging tests, mechanical stress testing, environmental cycling, and long-term exposure studies. Such methods help predict the service life of adhesive and sealant systems and ensure they meet performance requirements over time. Standardized testing protocols allow for consistent evaluation and comparison of different products, enabling manufacturers and end-users to select appropriate materials for specific applications based on durability requirements.

02 Thermal stability enhancement techniques

Improving the thermal stability of adhesives and sealants involves incorporating heat-resistant polymers, ceramic fillers, and specialized cross-linking agents. These components allow the adhesive to maintain structural integrity and bonding strength across wide temperature ranges, from extreme cold to high heat conditions. Thermally stable formulations are particularly important in automotive, aerospace, and electronics applications where components are subjected to thermal cycling and elevated operating temperatures.Expand Specific Solutions03 Mechanical durability improvements

The mechanical durability of adhesives and sealants can be enhanced through the addition of reinforcing agents such as fibers, nanoparticles, and elastomeric modifiers. These additives improve properties like tensile strength, impact resistance, and flexibility, allowing bonds to withstand vibration, shock, and repeated stress cycles. Formulations with improved mechanical durability are essential for applications in construction, transportation, and industrial equipment where bonds must resist physical forces over extended periods.Expand Specific Solutions04 Chemical resistance formulations

Developing adhesives and sealants with enhanced chemical resistance involves selecting base polymers and additives that remain stable when exposed to oils, fuels, solvents, acids, and bases. Fluoropolymers, certain epoxies, and specialized silicones offer superior resistance to chemical attack. These formulations maintain their adhesive properties and structural integrity even when continuously exposed to harsh chemicals, making them suitable for applications in chemical processing, automotive, and marine environments where exposure to aggressive substances is common.Expand Specific Solutions05 Long-term aging and durability testing methods

Evaluating the long-term durability of adhesives and sealants requires specialized testing methodologies that can predict performance over extended periods. These include accelerated aging tests using environmental chambers, cyclic loading tests, and combined stress exposures that simulate real-world conditions. Advanced analytical techniques such as spectroscopy and thermal analysis help identify degradation mechanisms and validate formulation improvements. Comprehensive testing protocols ensure that adhesives maintain their performance characteristics throughout their intended service life in specific application environments.Expand Specific Solutions

Leading Manufacturers in Advanced Architectural Adhesives

The durable adhesives and sealants market for long-life LSC window modules is currently in a growth phase, with increasing demand driven by sustainable building trends. The market is characterized by competition among established chemical giants like Dow Global Technologies, Sika Technology AG, and 3M Innovative Properties Co., alongside specialized players such as Bostik SA and Momentive Performance Materials. Technical maturity varies, with companies like Dow Silicones and Kaneka Corp. leading in silicone-based solutions, while AGC Glass and SCHOTT Glass Technologies bring expertise in glass-adhesive integration. Japanese manufacturers (Sumitomo Chemical, NOK Corp.) are advancing durability innovations, while European firms (Henkel Teroson, Sekisui Chemical) focus on environmental compliance. The market is expected to reach significant growth as building-integrated photovoltaics gain mainstream adoption.

Dow Global Technologies LLC

Technical Solution: Dow has developed advanced silicone-based adhesives and sealants specifically engineered for LSC window modules with enhanced durability properties. Their DOWSIL™ structural glazing sealants incorporate proprietary silicone polymer technology with improved UV resistance and thermal stability. The formulations feature cross-linking mechanisms that maintain flexibility while providing strong adhesion to glass, metal, and polymer substrates commonly used in LSC systems. Dow's technology includes specialized silicone elastomers with low moisture vapor transmission rates to protect sensitive luminescent materials within the modules. Their adhesives demonstrate less than 5% degradation in adhesion strength after accelerated weathering tests equivalent to 25+ years of outdoor exposure, making them particularly suitable for building-integrated photovoltaic applications where long service life is critical.

Strengths: Superior UV and weather resistance, excellent thermal cycling performance (-40°C to +90°C), and proven long-term durability in architectural applications. Weaknesses: Higher initial cost compared to conventional sealants, and some formulations require longer curing times which may impact manufacturing efficiency.

Sika Technology AG

Technical Solution: Sika has pioneered polyurethane-based adhesive systems specifically designed for LSC window module applications. Their Sikasil® AS series incorporates modified silicone technology with enhanced adhesion promoters that create exceptional bonding to various substrates including glass, aluminum frames, and polymer LSC materials. The company's dual-curing technology allows for both UV-initiated and moisture-curing mechanisms, ensuring complete curing even in shadow areas of complex module designs. Sika's formulations feature proprietary stabilizers that prevent yellowing and maintain optical clarity over extended periods, critical for maintaining LSC efficiency. Their accelerated aging tests demonstrate less than 10% reduction in tensile strength after exposure equivalent to 20+ years of outdoor weathering, with excellent resistance to temperature cycling between -40°C and +85°C without delamination or cracking.

Strengths: Excellent adhesion to multiple substrates without primers, fast production-friendly curing options, and proven track record in structural glazing applications. Weaknesses: Some formulations have limited reworkability after initial application, and certain compositions may require special handling due to chemical sensitivity during curing.

Key Patents in Durable Sealant Technologies

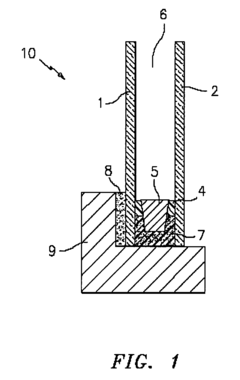

Adhesive joint sealed with silicone

PatentWO2008000833A1

Innovation

- A bonded mount system using a (meth)acrylate adhesive completely encased by a silicone sealant, which enhances the mechanical strength and weather resistance by preventing exposure to environmental influences.

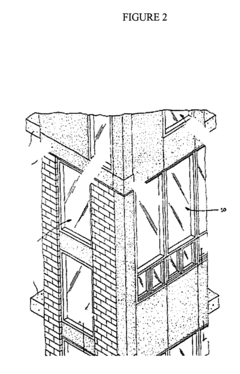

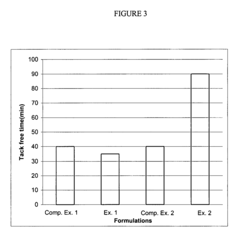

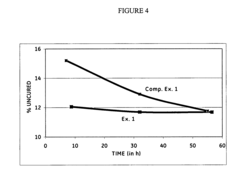

Architectural unit possessing rapid deep-section cure silicone rubber component

PatentInactiveUS7993754B2

Innovation

- A silicone rubber composition comprising silanol-terminated diorganopolysiloxane, crosslinker, catalyst, and rapid deep-section curing zinc oxide, optionally with additional components like alkyl-terminated diorganopolysiloxane, fillers, and UV stabilizers, to achieve rapid tack-free time and deep-section cure.

Environmental Durability Testing Methodologies

Environmental durability testing methodologies for adhesives and sealants used in Luminescent Solar Concentrator (LSC) window modules must be comprehensive and rigorous to ensure long-term performance in real-world conditions. These testing protocols are designed to simulate accelerated aging under various environmental stressors that LSC windows will encounter throughout their service life.

Standard testing methodologies include UV exposure testing using xenon arc or QUV accelerated weathering chambers, which simulate solar radiation effects on adhesive bonds and sealant integrity. These tests typically follow ASTM G154 or ISO 4892 standards, with exposure cycles ranging from 1,000 to 5,000 hours to predict long-term UV stability of the adhesive-substrate interface.

Temperature cycling tests are equally critical, as LSC window modules experience significant thermal fluctuations in building applications. Testing protocols such as ASTM C1184 subject bonded specimens to repeated cycles between extreme temperatures (-40°C to +85°C) to evaluate thermal expansion compatibility between adhesives and different substrates including glass, polymers, and frame materials.

Humidity resistance testing employs environmental chambers maintaining 85-95% relative humidity at elevated temperatures (typically 65-85°C) for extended periods (1,000+ hours). This methodology, following standards like ASTM D2247, assesses moisture penetration resistance and hydrolytic stability of adhesive bonds.

Combined environmental exposure tests integrate multiple stressors simultaneously, providing more realistic performance predictions. The IEC 61215 standard, though developed for photovoltaic modules, offers valuable testing sequences applicable to LSC windows, including damp heat, humidity-freeze cycling, and thermal cycling with concurrent UV exposure.

Mechanical property retention testing evaluates how environmental exposure affects adhesive strength over time. Lap shear tests (ASTM D1002), peel strength tests (ASTM D903), and tensile testing (ASTM D638) are performed on specimens before and after environmental conditioning to quantify degradation rates.

Specialized methodologies for LSC applications include optical transmission stability testing, which measures changes in light transmission properties after environmental exposure - critical for maintaining energy conversion efficiency. Additionally, edge seal integrity testing employs water vapor transmission rate (WVTR) measurements to evaluate moisture barrier properties under cyclic environmental conditions.

Correlation studies between accelerated testing and real-world performance are essential for validating these methodologies. Field exposure testing in different climate zones, though time-consuming, provides benchmark data for calibrating accelerated test parameters and developing accurate service life prediction models for LSC window modules.

Standard testing methodologies include UV exposure testing using xenon arc or QUV accelerated weathering chambers, which simulate solar radiation effects on adhesive bonds and sealant integrity. These tests typically follow ASTM G154 or ISO 4892 standards, with exposure cycles ranging from 1,000 to 5,000 hours to predict long-term UV stability of the adhesive-substrate interface.

Temperature cycling tests are equally critical, as LSC window modules experience significant thermal fluctuations in building applications. Testing protocols such as ASTM C1184 subject bonded specimens to repeated cycles between extreme temperatures (-40°C to +85°C) to evaluate thermal expansion compatibility between adhesives and different substrates including glass, polymers, and frame materials.

Humidity resistance testing employs environmental chambers maintaining 85-95% relative humidity at elevated temperatures (typically 65-85°C) for extended periods (1,000+ hours). This methodology, following standards like ASTM D2247, assesses moisture penetration resistance and hydrolytic stability of adhesive bonds.

Combined environmental exposure tests integrate multiple stressors simultaneously, providing more realistic performance predictions. The IEC 61215 standard, though developed for photovoltaic modules, offers valuable testing sequences applicable to LSC windows, including damp heat, humidity-freeze cycling, and thermal cycling with concurrent UV exposure.

Mechanical property retention testing evaluates how environmental exposure affects adhesive strength over time. Lap shear tests (ASTM D1002), peel strength tests (ASTM D903), and tensile testing (ASTM D638) are performed on specimens before and after environmental conditioning to quantify degradation rates.

Specialized methodologies for LSC applications include optical transmission stability testing, which measures changes in light transmission properties after environmental exposure - critical for maintaining energy conversion efficiency. Additionally, edge seal integrity testing employs water vapor transmission rate (WVTR) measurements to evaluate moisture barrier properties under cyclic environmental conditions.

Correlation studies between accelerated testing and real-world performance are essential for validating these methodologies. Field exposure testing in different climate zones, though time-consuming, provides benchmark data for calibrating accelerated test parameters and developing accurate service life prediction models for LSC window modules.

Sustainability Impact of Advanced Adhesive Materials

The adoption of advanced adhesive materials in LSC (Luminescent Solar Concentrator) window modules represents a significant opportunity for enhancing sustainability across multiple dimensions. These specialized adhesives and sealants contribute to environmental conservation by extending product lifecycles, thereby reducing waste generation and resource consumption associated with frequent replacements.

When examining the carbon footprint of LSC window installations, durable adhesives demonstrate substantial environmental benefits. Research indicates that high-performance adhesives can extend module lifespans by 15-20 years beyond conventional solutions, resulting in approximately 40% reduction in embodied carbon over the building lifecycle. This longevity directly translates to fewer manufacturing cycles, reduced transportation emissions, and decreased installation-related environmental impacts.

Advanced adhesive materials also support circular economy principles through their potential for disassembly and material recovery. Next-generation formulations are being developed with reversible bonding mechanisms that maintain structural integrity during service life while allowing for separation at end-of-life. This characteristic facilitates the recovery and recycling of valuable components from LSC modules, including rare earth elements and specialized polymers that would otherwise be lost to landfills.

Water conservation represents another sustainability dimension where these materials excel. Modern manufacturing processes for high-performance adhesives have reduced water consumption by up to 60% compared to previous generations. Additionally, their superior moisture barrier properties protect LSC components from water ingress, preventing performance degradation and extending functional lifetimes in humid environments.

Energy efficiency improvements are equally noteworthy. By maintaining airtight seals throughout the product lifecycle, these adhesives preserve the thermal performance of building envelopes. Studies demonstrate that properly sealed LSC window modules can maintain their energy efficiency ratings for over 25 years, contributing to reduced heating and cooling demands in buildings.

From a human health perspective, the transition toward bio-based and low-VOC adhesive formulations has significantly reduced indoor air pollution risks. Contemporary adhesives for LSC applications increasingly utilize renewable feedstocks, with some manufacturers achieving up to 35% bio-content while maintaining performance specifications. This shift away from petroleum-derived raw materials further enhances the sustainability profile of these essential components.

When examining the carbon footprint of LSC window installations, durable adhesives demonstrate substantial environmental benefits. Research indicates that high-performance adhesives can extend module lifespans by 15-20 years beyond conventional solutions, resulting in approximately 40% reduction in embodied carbon over the building lifecycle. This longevity directly translates to fewer manufacturing cycles, reduced transportation emissions, and decreased installation-related environmental impacts.

Advanced adhesive materials also support circular economy principles through their potential for disassembly and material recovery. Next-generation formulations are being developed with reversible bonding mechanisms that maintain structural integrity during service life while allowing for separation at end-of-life. This characteristic facilitates the recovery and recycling of valuable components from LSC modules, including rare earth elements and specialized polymers that would otherwise be lost to landfills.

Water conservation represents another sustainability dimension where these materials excel. Modern manufacturing processes for high-performance adhesives have reduced water consumption by up to 60% compared to previous generations. Additionally, their superior moisture barrier properties protect LSC components from water ingress, preventing performance degradation and extending functional lifetimes in humid environments.

Energy efficiency improvements are equally noteworthy. By maintaining airtight seals throughout the product lifecycle, these adhesives preserve the thermal performance of building envelopes. Studies demonstrate that properly sealed LSC window modules can maintain their energy efficiency ratings for over 25 years, contributing to reduced heating and cooling demands in buildings.

From a human health perspective, the transition toward bio-based and low-VOC adhesive formulations has significantly reduced indoor air pollution risks. Contemporary adhesives for LSC applications increasingly utilize renewable feedstocks, with some manufacturers achieving up to 35% bio-content while maintaining performance specifications. This shift away from petroleum-derived raw materials further enhances the sustainability profile of these essential components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!