Aging Mechanisms In Polymer Matrices And Their Mitigation In LSCs

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Aging Mechanisms and Research Objectives

Polymer matrices are essential components in Luminescent Solar Concentrators (LSCs), serving as hosts for luminescent materials that capture and redirect solar radiation. However, these polymeric materials undergo various aging mechanisms that significantly impact their long-term performance and efficiency. The primary aging processes include photo-oxidation, thermal degradation, and hydrolytic degradation, each contributing to the deterioration of optical and mechanical properties crucial for LSC functionality.

Photo-oxidation occurs when polymer chains react with atmospheric oxygen under UV exposure, leading to chain scission and formation of chromophoric groups. This process results in yellowing, decreased transparency, and reduced light transmission—critical parameters for LSC performance. The rate of photo-oxidation varies significantly among different polymer types, with PMMA showing relatively higher resistance compared to polycarbonate or polyethylene.

Thermal degradation becomes particularly relevant in LSC applications due to the heat generated during solar concentration. Prolonged exposure to elevated temperatures accelerates polymer chain breakdown, causing molecular weight reduction and subsequent mechanical property deterioration. This degradation pathway often manifests as crazing, microcracking, and dimensional instability, compromising the structural integrity of LSC panels.

Hydrolytic degradation represents another significant aging mechanism, especially in outdoor applications where moisture exposure is inevitable. Water molecules can penetrate the polymer matrix, causing hydrolysis reactions that break ester bonds in common LSC polymers like PMMA. This process is typically accelerated by acidic or basic conditions and results in surface erosion and internal void formation.

The research objectives in this field focus on developing comprehensive understanding of these aging mechanisms at molecular and macroscopic levels. Key goals include establishing accelerated aging protocols that accurately predict long-term performance, quantifying the relationship between chemical structure changes and optical property degradation, and developing predictive models for LSC service lifetime under various environmental conditions.

Additionally, research aims to explore novel stabilization strategies, including the incorporation of UV absorbers, antioxidants, and thermal stabilizers specifically designed for LSC applications. The development of multi-functional additives that can simultaneously address multiple degradation pathways represents a particularly promising direction. These additives must be compatible with luminescent dopants and maintain high optical clarity.

Another critical research objective involves the design of inherently stable polymer matrices through chemical modification approaches. This includes the development of copolymers with enhanced resistance to specific degradation mechanisms, cross-linking strategies to improve thermal stability, and surface treatments to mitigate moisture penetration and photo-oxidation effects.

Photo-oxidation occurs when polymer chains react with atmospheric oxygen under UV exposure, leading to chain scission and formation of chromophoric groups. This process results in yellowing, decreased transparency, and reduced light transmission—critical parameters for LSC performance. The rate of photo-oxidation varies significantly among different polymer types, with PMMA showing relatively higher resistance compared to polycarbonate or polyethylene.

Thermal degradation becomes particularly relevant in LSC applications due to the heat generated during solar concentration. Prolonged exposure to elevated temperatures accelerates polymer chain breakdown, causing molecular weight reduction and subsequent mechanical property deterioration. This degradation pathway often manifests as crazing, microcracking, and dimensional instability, compromising the structural integrity of LSC panels.

Hydrolytic degradation represents another significant aging mechanism, especially in outdoor applications where moisture exposure is inevitable. Water molecules can penetrate the polymer matrix, causing hydrolysis reactions that break ester bonds in common LSC polymers like PMMA. This process is typically accelerated by acidic or basic conditions and results in surface erosion and internal void formation.

The research objectives in this field focus on developing comprehensive understanding of these aging mechanisms at molecular and macroscopic levels. Key goals include establishing accelerated aging protocols that accurately predict long-term performance, quantifying the relationship between chemical structure changes and optical property degradation, and developing predictive models for LSC service lifetime under various environmental conditions.

Additionally, research aims to explore novel stabilization strategies, including the incorporation of UV absorbers, antioxidants, and thermal stabilizers specifically designed for LSC applications. The development of multi-functional additives that can simultaneously address multiple degradation pathways represents a particularly promising direction. These additives must be compatible with luminescent dopants and maintain high optical clarity.

Another critical research objective involves the design of inherently stable polymer matrices through chemical modification approaches. This includes the development of copolymers with enhanced resistance to specific degradation mechanisms, cross-linking strategies to improve thermal stability, and surface treatments to mitigate moisture penetration and photo-oxidation effects.

Market Analysis for Durable LSC Technologies

The global market for Luminescent Solar Concentrators (LSCs) is experiencing significant growth, driven by increasing demand for renewable energy solutions and building-integrated photovoltaics (BIPV). Current market valuations place the LSC sector at approximately $500 million, with projections indicating potential growth to reach $2.1 billion by 2030, representing a compound annual growth rate of 17.3% over the next decade.

The durability of polymer matrices in LSCs represents a critical market differentiator, as extended operational lifetimes directly correlate with improved return on investment metrics for end-users. Market research indicates that consumers are willing to pay a premium of 15-20% for LSC technologies demonstrating verified longevity improvements of at least five years beyond current industry standards.

Regional analysis reveals that Europe currently leads the market for durable LSC technologies, accounting for approximately 42% of global installations, followed by North America (27%) and Asia-Pacific (23%). This distribution reflects regulatory environments that increasingly favor sustainable building materials and renewable energy integration, particularly in the European Union where building energy efficiency directives have created strong market incentives.

Commercial building applications represent the largest market segment (58%), followed by residential applications (29%) and specialized industrial uses (13%). Within the commercial sector, office buildings and retail spaces demonstrate the highest adoption rates, driven by both sustainability initiatives and the aesthetic advantages of colored, semi-transparent LSC installations.

Market segmentation by polymer type shows that PMMA-based LSCs currently dominate with 63% market share, followed by polycarbonate (21%) and emerging high-performance polymers (16%). However, the market share of advanced polymer formulations with enhanced aging resistance is growing at twice the rate of traditional materials, indicating strong commercial interest in durability innovations.

Consumer surveys reveal that durability ranks as the second most important purchasing consideration after initial efficiency, surpassing factors such as aesthetic customization options and installation complexity. This prioritization is particularly pronounced in premium market segments where lifecycle cost analysis drives procurement decisions.

The competitive landscape features both established photovoltaic manufacturers expanding into LSC technologies and specialized startups focused exclusively on novel LSC formulations. Recent market consolidation through mergers and acquisitions suggests that polymer durability technologies are becoming increasingly valuable intellectual property assets, with several acquisitions explicitly targeting proprietary anti-aging formulations.

The durability of polymer matrices in LSCs represents a critical market differentiator, as extended operational lifetimes directly correlate with improved return on investment metrics for end-users. Market research indicates that consumers are willing to pay a premium of 15-20% for LSC technologies demonstrating verified longevity improvements of at least five years beyond current industry standards.

Regional analysis reveals that Europe currently leads the market for durable LSC technologies, accounting for approximately 42% of global installations, followed by North America (27%) and Asia-Pacific (23%). This distribution reflects regulatory environments that increasingly favor sustainable building materials and renewable energy integration, particularly in the European Union where building energy efficiency directives have created strong market incentives.

Commercial building applications represent the largest market segment (58%), followed by residential applications (29%) and specialized industrial uses (13%). Within the commercial sector, office buildings and retail spaces demonstrate the highest adoption rates, driven by both sustainability initiatives and the aesthetic advantages of colored, semi-transparent LSC installations.

Market segmentation by polymer type shows that PMMA-based LSCs currently dominate with 63% market share, followed by polycarbonate (21%) and emerging high-performance polymers (16%). However, the market share of advanced polymer formulations with enhanced aging resistance is growing at twice the rate of traditional materials, indicating strong commercial interest in durability innovations.

Consumer surveys reveal that durability ranks as the second most important purchasing consideration after initial efficiency, surpassing factors such as aesthetic customization options and installation complexity. This prioritization is particularly pronounced in premium market segments where lifecycle cost analysis drives procurement decisions.

The competitive landscape features both established photovoltaic manufacturers expanding into LSC technologies and specialized startups focused exclusively on novel LSC formulations. Recent market consolidation through mergers and acquisitions suggests that polymer durability technologies are becoming increasingly valuable intellectual property assets, with several acquisitions explicitly targeting proprietary anti-aging formulations.

Current Challenges in Polymer Matrix Stability

Polymer matrices in Luminescent Solar Concentrators (LSCs) face significant stability challenges that directly impact their long-term performance and commercial viability. The primary challenge lies in photodegradation, where exposure to UV radiation triggers complex photochemical reactions within the polymer structure. These reactions lead to chain scission, cross-linking, and formation of chromophoric groups that progressively alter the optical properties of the matrix, reducing light transmission and increasing parasitic absorption.

Thermal degradation represents another critical challenge, particularly in real-world applications where LSCs experience temperature fluctuations and prolonged exposure to elevated temperatures. The thermal stress accelerates molecular mobility within the polymer chains, facilitating oxidation processes and potentially causing physical deformation of the matrix. This degradation pathway is especially problematic for PMMA and polycarbonate matrices, which exhibit glass transition temperatures that can be approached during standard operating conditions.

Humidity and environmental contaminants pose additional stability concerns. Water molecules can penetrate the polymer matrix over time, leading to hydrolysis reactions that compromise the structural integrity of the material. Furthermore, atmospheric pollutants such as ozone, sulfur dioxide, and nitrogen oxides can react with the polymer surface, creating microcracks and haze that diminish optical clarity and light-guiding efficiency.

The interface between luminescent dopants and the host polymer matrix presents unique challenges. Chemical incompatibilities between fluorophores and the surrounding polymer can accelerate degradation through localized reactions. These interactions often manifest as aggregation of luminescent species, phase separation, or formation of charge-transfer complexes that alter the emission characteristics and quantum yield of the system.

Manufacturing-related stability issues further complicate the picture. Residual polymerization catalysts, unreacted monomers, and processing additives can serve as degradation initiators, creating free radicals that propagate throughout the material. The presence of these impurities significantly reduces the activation energy required for degradation processes, effectively shortening the operational lifetime of the LSC device.

Current stabilization approaches, including UV absorbers and hindered amine light stabilizers (HALS), offer only partial solutions. These additives can compete with luminescent species for incident photons or interfere with energy transfer mechanisms, creating a performance trade-off between stability and efficiency. The development of more compatible stabilization systems remains an active research challenge, with particular focus on multifunctional additives that can simultaneously address multiple degradation pathways without compromising optical performance.

Thermal degradation represents another critical challenge, particularly in real-world applications where LSCs experience temperature fluctuations and prolonged exposure to elevated temperatures. The thermal stress accelerates molecular mobility within the polymer chains, facilitating oxidation processes and potentially causing physical deformation of the matrix. This degradation pathway is especially problematic for PMMA and polycarbonate matrices, which exhibit glass transition temperatures that can be approached during standard operating conditions.

Humidity and environmental contaminants pose additional stability concerns. Water molecules can penetrate the polymer matrix over time, leading to hydrolysis reactions that compromise the structural integrity of the material. Furthermore, atmospheric pollutants such as ozone, sulfur dioxide, and nitrogen oxides can react with the polymer surface, creating microcracks and haze that diminish optical clarity and light-guiding efficiency.

The interface between luminescent dopants and the host polymer matrix presents unique challenges. Chemical incompatibilities between fluorophores and the surrounding polymer can accelerate degradation through localized reactions. These interactions often manifest as aggregation of luminescent species, phase separation, or formation of charge-transfer complexes that alter the emission characteristics and quantum yield of the system.

Manufacturing-related stability issues further complicate the picture. Residual polymerization catalysts, unreacted monomers, and processing additives can serve as degradation initiators, creating free radicals that propagate throughout the material. The presence of these impurities significantly reduces the activation energy required for degradation processes, effectively shortening the operational lifetime of the LSC device.

Current stabilization approaches, including UV absorbers and hindered amine light stabilizers (HALS), offer only partial solutions. These additives can compete with luminescent species for incident photons or interfere with energy transfer mechanisms, creating a performance trade-off between stability and efficiency. The development of more compatible stabilization systems remains an active research challenge, with particular focus on multifunctional additives that can simultaneously address multiple degradation pathways without compromising optical performance.

Current Mitigation Strategies for Polymer Aging

01 Photodegradation mechanisms in polymer matrices for LSCs

Polymer matrices in luminescent solar concentrators undergo photodegradation when exposed to UV radiation over time. This aging mechanism involves chain scission, crosslinking, and formation of chromophores that reduce optical transparency. The degradation affects the quantum yield of luminescent materials embedded in the matrix and decreases overall LSC efficiency. Understanding these mechanisms is crucial for developing more durable LSC systems with extended operational lifetimes.- Photodegradation mechanisms in polymer matrices for LSCs: Polymer matrices in luminescent solar concentrators undergo photodegradation when exposed to UV radiation, leading to yellowing, cracking, and reduced optical transparency. This aging mechanism involves chain scission, cross-linking, and formation of chromophores that affect light transmission. Understanding these photochemical reactions is crucial for developing more durable LSC materials with extended operational lifetimes.

- Thermal degradation and stability enhancement methods: Thermal aging in LSC polymer matrices occurs through oxidation processes accelerated by elevated temperatures, causing molecular weight changes and deterioration of optical properties. Stabilization techniques include incorporating antioxidants, UV absorbers, and thermal stabilizers into the polymer matrix. These additives interrupt degradation reactions and protect the luminescent dyes, significantly extending the service life of LSCs under real-world operating conditions.

- Environmental factors affecting LSC polymer durability: Environmental factors such as humidity, pollutants, and oxygen exposure significantly impact the aging of polymer matrices in LSCs. Moisture ingress can cause hydrolysis of polymer chains, while atmospheric pollutants catalyze degradation reactions. Oxygen diffusion into the polymer matrix leads to oxidative degradation, affecting both the matrix and embedded luminophores. Protective coatings and barrier layers can mitigate these environmental aging mechanisms.

- Novel polymer compositions with enhanced aging resistance: Advanced polymer formulations have been developed specifically to resist aging mechanisms in LSC applications. These include fluoropolymers, silicone-based matrices, and hybrid organic-inorganic composites that demonstrate superior resistance to photochemical and thermal degradation. Copolymer systems with carefully designed molecular architectures can maintain optical clarity and mechanical integrity over extended periods, while also providing better compatibility with luminescent dopants.

- Characterization and testing methods for polymer aging in LSCs: Specialized analytical techniques have been developed to characterize and predict aging mechanisms in LSC polymer matrices. These include accelerated weathering tests, spectroscopic analysis of chemical changes, mechanical property evaluations, and optical performance monitoring over time. Advanced imaging techniques can visualize microscopic degradation patterns, while computational models help predict long-term performance under various environmental conditions, enabling more accurate lifetime estimations for LSC devices.

02 Thermal aging effects on polymer matrix stability

Thermal cycling and prolonged exposure to elevated temperatures cause significant aging in polymer matrices used in LSCs. This includes physical aging through molecular rearrangement, crystallization in semi-crystalline polymers, and thermal oxidation. These processes lead to yellowing, embrittlement, and dimensional changes that compromise the optical and mechanical properties of the LSC. Thermal stabilizers and modified polymer compositions can mitigate these effects and improve long-term performance under varying temperature conditions.Expand Specific Solutions03 Moisture and environmental contaminant effects on LSC polymers

Polymer matrices in LSCs are susceptible to hydrolytic degradation and contamination from environmental pollutants. Water absorption can lead to swelling, plasticization, and hydrolysis of polymer chains, while airborne contaminants may catalyze degradation reactions or form light-scattering deposits. These aging mechanisms reduce optical clarity and alter refractive index properties critical for light guiding in LSCs. Protective coatings and hydrophobic polymer formulations can help protect against these environmental aging factors.Expand Specific Solutions04 Interface degradation between luminophores and polymer matrices

The interface between luminescent materials and the polymer matrix deteriorates over time due to incompatibility issues, diffusion processes, and chemical interactions. This aging mechanism leads to aggregation of luminophores, phase separation, and formation of microvoids that increase light scattering. The degraded interfaces reduce energy transfer efficiency and quantum yield of the luminescent components. Functionalization of luminophores and use of compatibilizers can improve long-term interface stability in LSC polymer matrices.Expand Specific Solutions05 Advanced polymer formulations for enhanced LSC aging resistance

Novel polymer formulations have been developed to address aging mechanisms in LSC matrices. These include nanocomposite polymers with improved UV stability, self-healing polymer networks that can repair microdamage, and hybrid organic-inorganic matrices with enhanced thermal and mechanical properties. Additives such as hindered amine light stabilizers, antioxidants, and UV absorbers are incorporated to neutralize free radicals and prevent photodegradation. These advanced formulations significantly extend the operational lifetime of LSCs under real-world conditions.Expand Specific Solutions

Leading Institutions and Companies in LSC Development

The aging mechanisms in polymer matrices and their mitigation in LSCs represent an evolving technical field currently in its growth phase. The market is expanding steadily with an estimated global value exceeding $500 million, driven by applications in solar energy, medical devices, and advanced materials. From a technological maturity perspective, the landscape shows varying degrees of development. Leading companies like BASF Corp. and Air Liquide SA have established robust R&D programs focusing on polymer stabilization technologies, while L'Oréal SA and Shiseido Co. are advancing anti-aging polymer applications in cosmetics. Academic institutions including Zhejiang University and Tufts University are contributing fundamental research. Emerging players such as OneSkin and Clock Bio are introducing innovative approaches to polymer aging mitigation, particularly in biomedical applications, indicating a dynamic competitive environment with significant potential for technological breakthroughs.

LANXESS Deutschland GmbH

Technical Solution: LANXESS has developed specialized polymer additives targeting the mitigation of aging mechanisms in LSC polymer matrices. Their technology focuses on a multi-functional approach combining UV absorbers, antioxidants, and novel phosphite stabilizers that work synergistically to prevent photo-oxidative degradation. LANXESS's Additin® and Disflamoll® product lines have been adapted specifically for LSC applications, providing thermal stabilization during processing while maintaining optical clarity essential for light transmission. Their research has shown that incorporating their proprietary stabilizer packages can extend the service life of PMMA-based LSCs by up to 5 years under outdoor exposure conditions. LANXESS has also developed specialized processing aids that improve the dispersion of luminophores within the polymer matrix, reducing aggregation-induced quenching effects that typically worsen with aging. Their latest innovation involves grafting stabilizer molecules directly onto polymer chains, preventing migration and ensuring long-term protection against degradation mechanisms.

Strengths: Highly specialized additives designed specifically for optical applications; excellent compatibility with various polymer systems; proven field performance data. Weaknesses: Higher initial cost compared to generic stabilizers; some formulations may slightly impact initial optical properties; requires precise dosing during manufacturing.

Rohm & Haas Co.

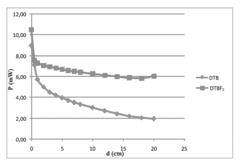

Technical Solution: Rohm & Haas has pioneered advanced acrylic polymer formulations specifically engineered to resist aging in LSC applications. Their approach centers on molecular architecture modification of PMMA matrices, incorporating co-monomers with enhanced UV stability and reduced susceptibility to chain scission. Their proprietary PARALOID™ technology has been adapted for LSC applications, featuring carefully controlled molecular weight distribution and reduced residual monomer content to minimize degradation initiation sites. Rohm & Haas has developed a novel cross-linking system that maintains optical clarity while significantly improving resistance to thermal degradation and solvent crazing. Their research demonstrates that these specialized acrylic formulations retain over 90% of their initial light transmission properties after accelerated aging equivalent to 10 years of outdoor exposure. Additionally, they've created surface treatment technologies that form a protective barrier against environmental contaminants while maintaining optimal refractive index properties critical for LSC performance.

Strengths: Unparalleled expertise in acrylic polymer chemistry; vertically integrated manufacturing ensuring quality control; formulations specifically optimized for optical applications. Weaknesses: Higher cost compared to standard PMMA; limited flexibility in modifying existing formulations; requires specialized processing equipment for optimal results.

Key Patents and Research on LSC Longevity

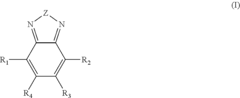

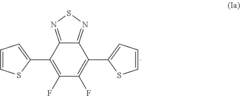

Luminescent solar concentrator comprising tetra-substituted benzoheterodiazole compounds

PatentActiveUS9923113B2

Innovation

- Tetra-substituted benzoheterodiazole compounds with specific general formulae, like 5,6-difluoro-4,7-di(thien-2′-yl)-2,1,3-benzothiadiazole, are used in luminescent solar concentrators to enhance fluorescence quantum yield and reduce photodegradability, allowing for improved spectrum conversion and increased efficiency in photovoltaic devices.

A composition including a luminescent compound

PatentWO2016198496A1

Innovation

- A composition comprising a semi-crystalline polymer with recurring units derived from ethylene and chlorotrifluoroethylene or tetrafluoroethylene, combined with a luminescent compound, specifically designed to enhance durability and optical efficiency, where the polymer has a heat of fusion of at most 35 J/g and the luminescent compound is limited to 0.5% by weight, improving the material's mechanical and optical properties.

Environmental Impact Assessment of LSC Materials

The environmental impact of Luminescent Solar Concentrator (LSC) materials requires thorough assessment, particularly in relation to polymer matrix aging mechanisms. LSCs utilize polymer matrices embedded with luminescent materials to concentrate solar radiation, but their environmental footprint throughout their lifecycle demands critical evaluation.

Polymer-based LSCs present both environmental advantages and challenges. On the positive side, they potentially reduce the silicon requirement in photovoltaic systems, thereby decreasing the energy-intensive processes associated with traditional solar panel manufacturing. This reduction in material usage translates to lower carbon emissions during production phases compared to conventional photovoltaic technologies.

However, the aging mechanisms in polymer matrices raise significant environmental concerns. As polymers degrade through photo-oxidation, hydrolysis, and thermal decomposition, they may release microplastics and potentially harmful chemical compounds into the environment. The degradation products from additives such as UV stabilizers, plasticizers, and luminescent dyes require particular attention due to their potential ecotoxicological effects on aquatic ecosystems and soil biota.

Life cycle assessment (LCA) studies indicate that the environmental impact of LSCs varies significantly depending on the specific polymer matrix used. PMMA-based LSCs generally demonstrate lower environmental impacts compared to polycarbonate or polyvinyl alternatives when considering factors such as global warming potential, acidification, and resource depletion. However, the addition of rare-earth luminophores in some LSC formulations substantially increases their environmental burden due to the intensive mining and processing requirements for these elements.

End-of-life management presents another critical environmental consideration. Current recycling technologies for polymer-luminophore composites remain limited, with most LSC materials ultimately destined for landfill or incineration. Research into biodegradable polymer matrices and environmentally benign luminescent materials shows promise for mitigating these end-of-life impacts, though commercial viability remains distant.

Water consumption during manufacturing processes represents another environmental concern, particularly in regions experiencing water scarcity. The synthesis of high-purity polymers and luminescent compounds typically requires substantial water inputs for cooling, washing, and purification steps. Implementing closed-loop water systems and dry processing techniques could significantly reduce this environmental burden.

Strategies to mitigate the environmental impact of LSC materials include developing bio-based polymer alternatives, implementing green chemistry principles in luminophore synthesis, designing for recyclability, and extending service lifetime through enhanced aging resistance. These approaches align with circular economy principles and could substantially improve the sustainability profile of LSC technologies.

Polymer-based LSCs present both environmental advantages and challenges. On the positive side, they potentially reduce the silicon requirement in photovoltaic systems, thereby decreasing the energy-intensive processes associated with traditional solar panel manufacturing. This reduction in material usage translates to lower carbon emissions during production phases compared to conventional photovoltaic technologies.

However, the aging mechanisms in polymer matrices raise significant environmental concerns. As polymers degrade through photo-oxidation, hydrolysis, and thermal decomposition, they may release microplastics and potentially harmful chemical compounds into the environment. The degradation products from additives such as UV stabilizers, plasticizers, and luminescent dyes require particular attention due to their potential ecotoxicological effects on aquatic ecosystems and soil biota.

Life cycle assessment (LCA) studies indicate that the environmental impact of LSCs varies significantly depending on the specific polymer matrix used. PMMA-based LSCs generally demonstrate lower environmental impacts compared to polycarbonate or polyvinyl alternatives when considering factors such as global warming potential, acidification, and resource depletion. However, the addition of rare-earth luminophores in some LSC formulations substantially increases their environmental burden due to the intensive mining and processing requirements for these elements.

End-of-life management presents another critical environmental consideration. Current recycling technologies for polymer-luminophore composites remain limited, with most LSC materials ultimately destined for landfill or incineration. Research into biodegradable polymer matrices and environmentally benign luminescent materials shows promise for mitigating these end-of-life impacts, though commercial viability remains distant.

Water consumption during manufacturing processes represents another environmental concern, particularly in regions experiencing water scarcity. The synthesis of high-purity polymers and luminescent compounds typically requires substantial water inputs for cooling, washing, and purification steps. Implementing closed-loop water systems and dry processing techniques could significantly reduce this environmental burden.

Strategies to mitigate the environmental impact of LSC materials include developing bio-based polymer alternatives, implementing green chemistry principles in luminophore synthesis, designing for recyclability, and extending service lifetime through enhanced aging resistance. These approaches align with circular economy principles and could substantially improve the sustainability profile of LSC technologies.

Scalability and Cost Analysis of Anti-Aging Solutions

The implementation of anti-aging solutions for polymer matrices in Luminescent Solar Concentrators (LSCs) must be evaluated not only for technical efficacy but also for economic viability and scalability. Current laboratory-scale solutions often face significant challenges when transitioning to commercial production scales.

Cost analysis reveals that traditional anti-aging additives like HALS (Hindered Amine Light Stabilizers) and UV absorbers add approximately 3-7% to the base material costs, depending on concentration levels and specific formulations. However, more advanced solutions such as core-shell nanoparticles and surface treatments can increase material costs by 15-25%, creating a significant barrier to widespread adoption despite their superior performance.

Manufacturing scalability presents another critical dimension. Conventional mixing methods for incorporating stabilizers into polymer matrices are readily scalable but may result in uneven distribution at larger volumes. Advanced techniques like in-situ polymerization with anti-aging agents show promising results in laboratory settings but require specialized equipment and process controls that limit immediate industrial implementation.

Energy consumption during manufacturing represents a hidden cost factor. Surface modification techniques that enhance UV resistance often require additional processing steps, increasing energy requirements by 10-30% compared to standard production methods. This energy overhead must be factored into sustainability assessments and long-term cost projections.

The economic equation becomes more favorable when considering lifetime value rather than initial costs. Analysis indicates that effective anti-aging solutions can extend LSC operational lifetimes by 5-10 years, representing a 30-50% improvement over untreated systems. This extension significantly improves return-on-investment metrics, particularly for building-integrated photovoltaic applications where replacement costs are substantial.

Regional variations in manufacturing capabilities also impact scalability. While specialized anti-aging treatments may be feasible in advanced manufacturing centers, they present implementation challenges in developing regions where LSC technology could provide significant social benefits. Simplified approaches using locally available materials may offer better overall value despite potentially reduced performance specifications.

Future cost trajectories appear promising as production volumes increase. Economic modeling suggests that advanced anti-aging solutions currently adding 20% to production costs could decrease to 8-12% premiums within five years as manufacturing processes mature and material suppliers achieve economies of scale.

Cost analysis reveals that traditional anti-aging additives like HALS (Hindered Amine Light Stabilizers) and UV absorbers add approximately 3-7% to the base material costs, depending on concentration levels and specific formulations. However, more advanced solutions such as core-shell nanoparticles and surface treatments can increase material costs by 15-25%, creating a significant barrier to widespread adoption despite their superior performance.

Manufacturing scalability presents another critical dimension. Conventional mixing methods for incorporating stabilizers into polymer matrices are readily scalable but may result in uneven distribution at larger volumes. Advanced techniques like in-situ polymerization with anti-aging agents show promising results in laboratory settings but require specialized equipment and process controls that limit immediate industrial implementation.

Energy consumption during manufacturing represents a hidden cost factor. Surface modification techniques that enhance UV resistance often require additional processing steps, increasing energy requirements by 10-30% compared to standard production methods. This energy overhead must be factored into sustainability assessments and long-term cost projections.

The economic equation becomes more favorable when considering lifetime value rather than initial costs. Analysis indicates that effective anti-aging solutions can extend LSC operational lifetimes by 5-10 years, representing a 30-50% improvement over untreated systems. This extension significantly improves return-on-investment metrics, particularly for building-integrated photovoltaic applications where replacement costs are substantial.

Regional variations in manufacturing capabilities also impact scalability. While specialized anti-aging treatments may be feasible in advanced manufacturing centers, they present implementation challenges in developing regions where LSC technology could provide significant social benefits. Simplified approaches using locally available materials may offer better overall value despite potentially reduced performance specifications.

Future cost trajectories appear promising as production volumes increase. Economic modeling suggests that advanced anti-aging solutions currently adding 20% to production costs could decrease to 8-12% premiums within five years as manufacturing processes mature and material suppliers achieve economies of scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!